Research and Field Test of Ultra-Short Radius Horizontal Drilling Technology Combining Coiled Tubing and Flexible BHA

-

摘要:

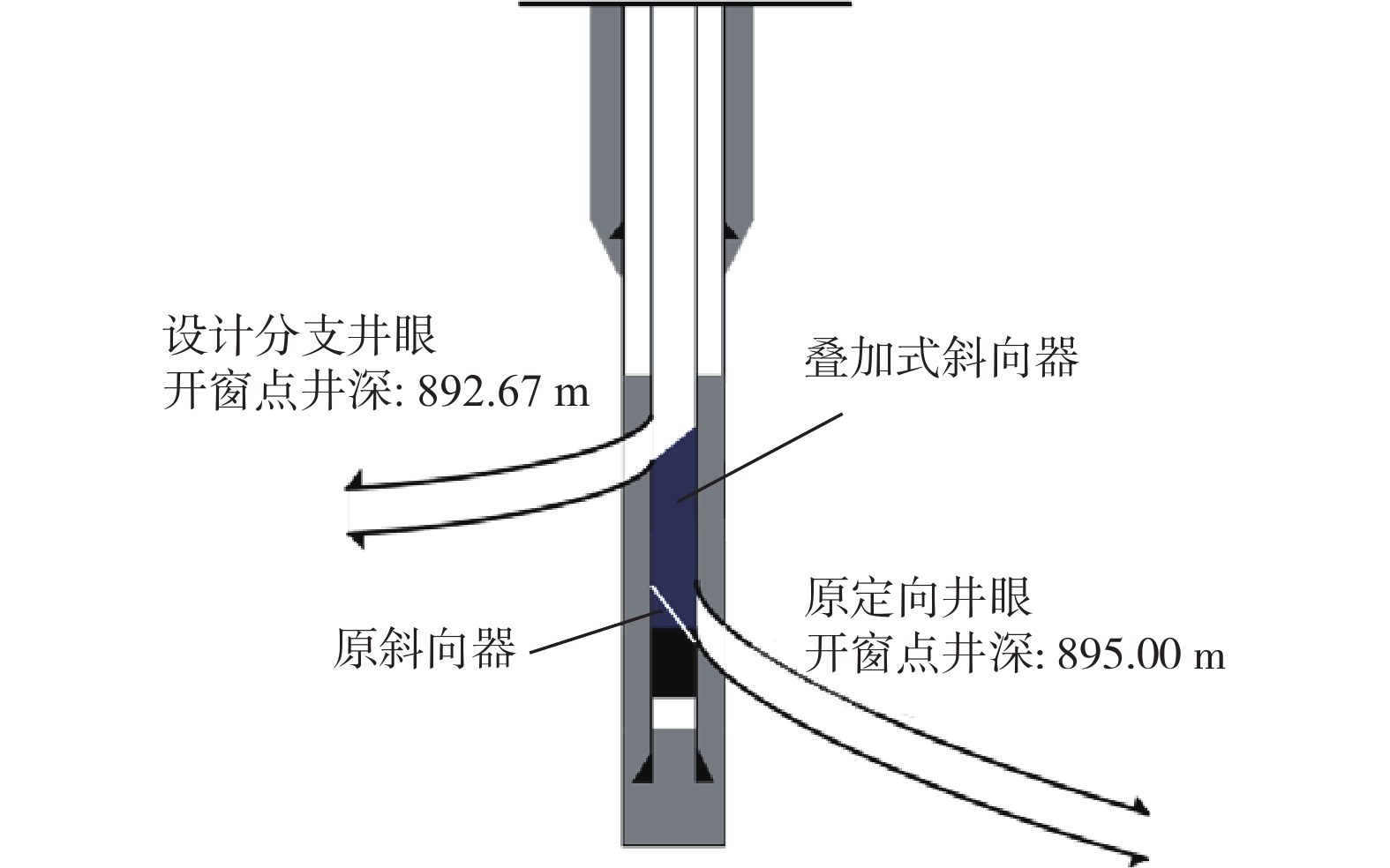

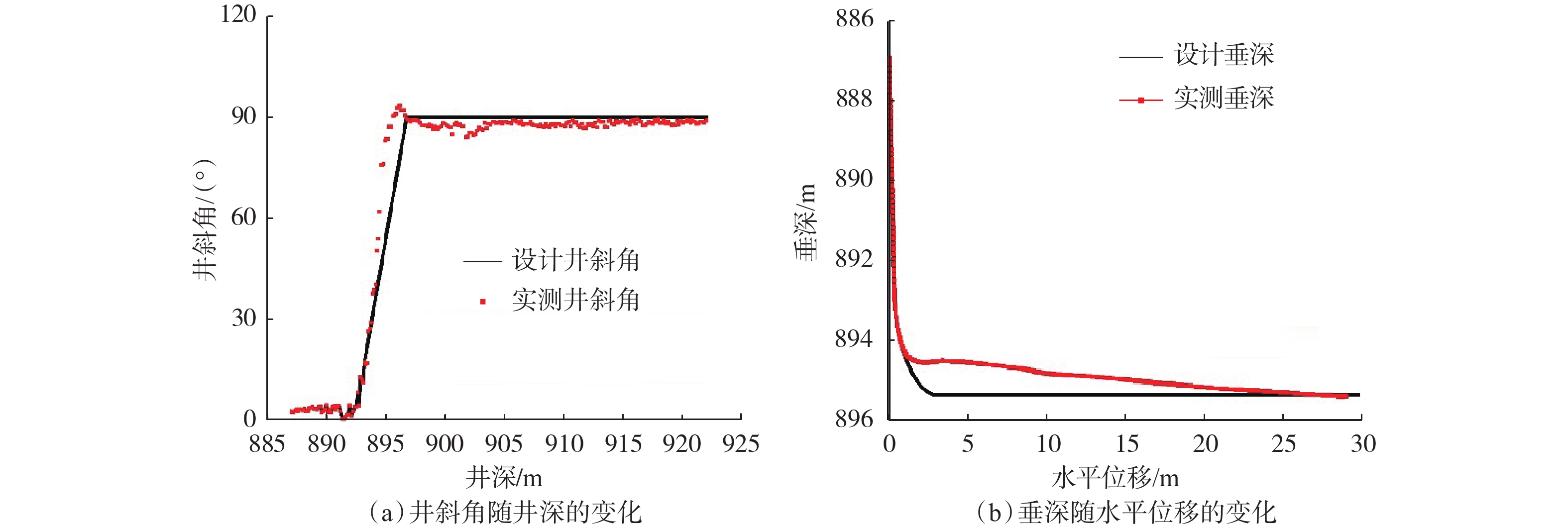

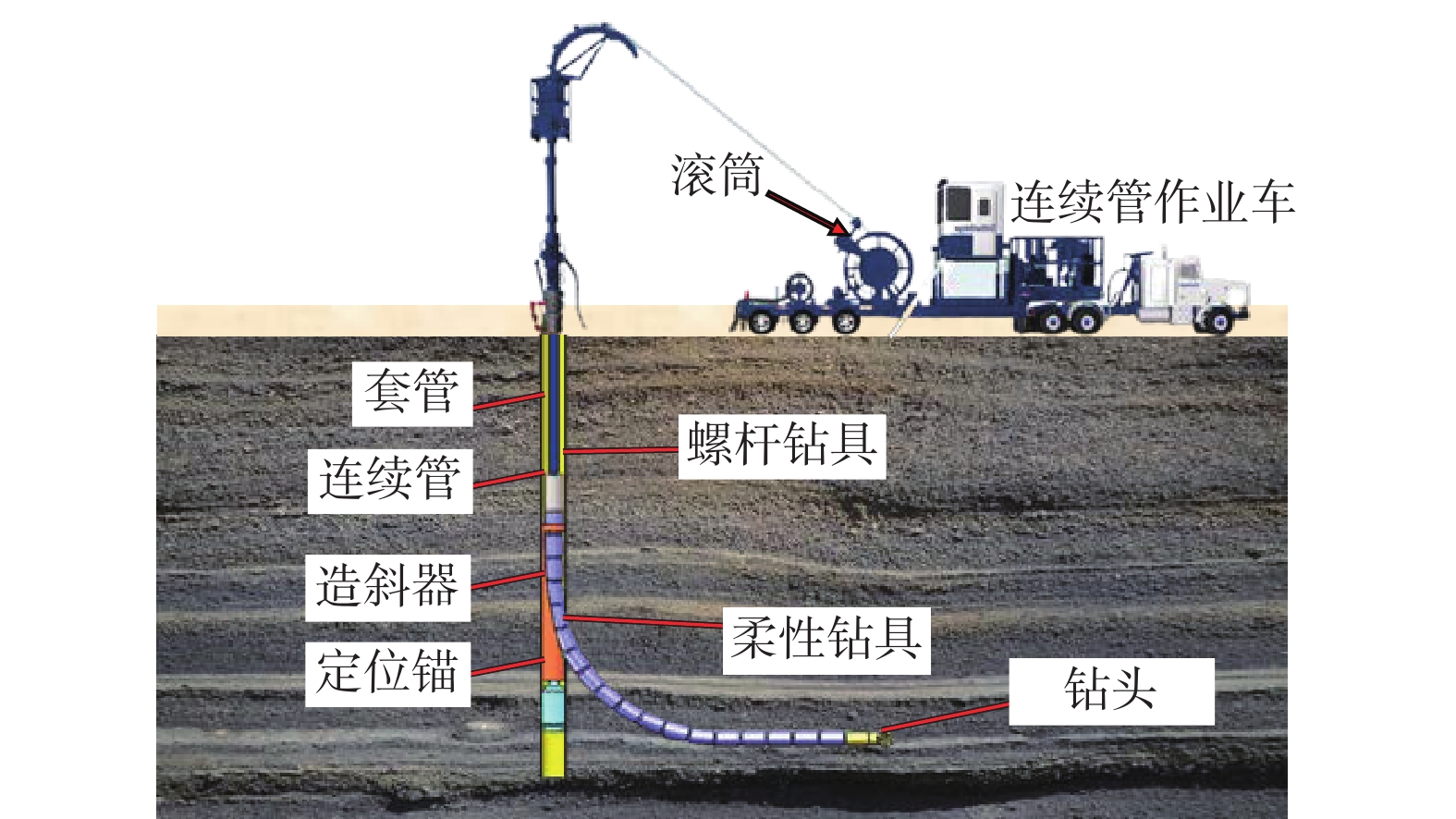

超短半径水平井在油气田老井改造、剩余油挖潜方面作用很大,但常用的柔性钻具超短半径水平井钻井技术存在起下钻周期长、作业成本高的问题。考虑连续管钻井具有钻井效率高、成本低和安全可靠等优点,提出了将连续管与柔性钻具相结合的钻井新思路,并研制了高速和低速大扭矩螺杆、改进了柔性钻具结构、研制了叠加式斜向器和造斜PDC钻头等关键工具,优化了配套施工工艺,初步形成了“连续管+柔性钻具”超短半径水平井钻井技术。该技术在江汉油田陵72-5CZ井开展了首次现场试验,成功完成了长30.21 m的超短半径水平分支井眼,平均机械钻速0.8 m/h,实钻井眼轨迹与设计井眼轨道吻合良好,水平段平均稳斜角为88.17°。现场试验结果验证了“连续管+柔性钻具”超短半径水平井钻井技术的可行性,为剩余油挖潜和低渗油田高效开发提供了一项新技术。

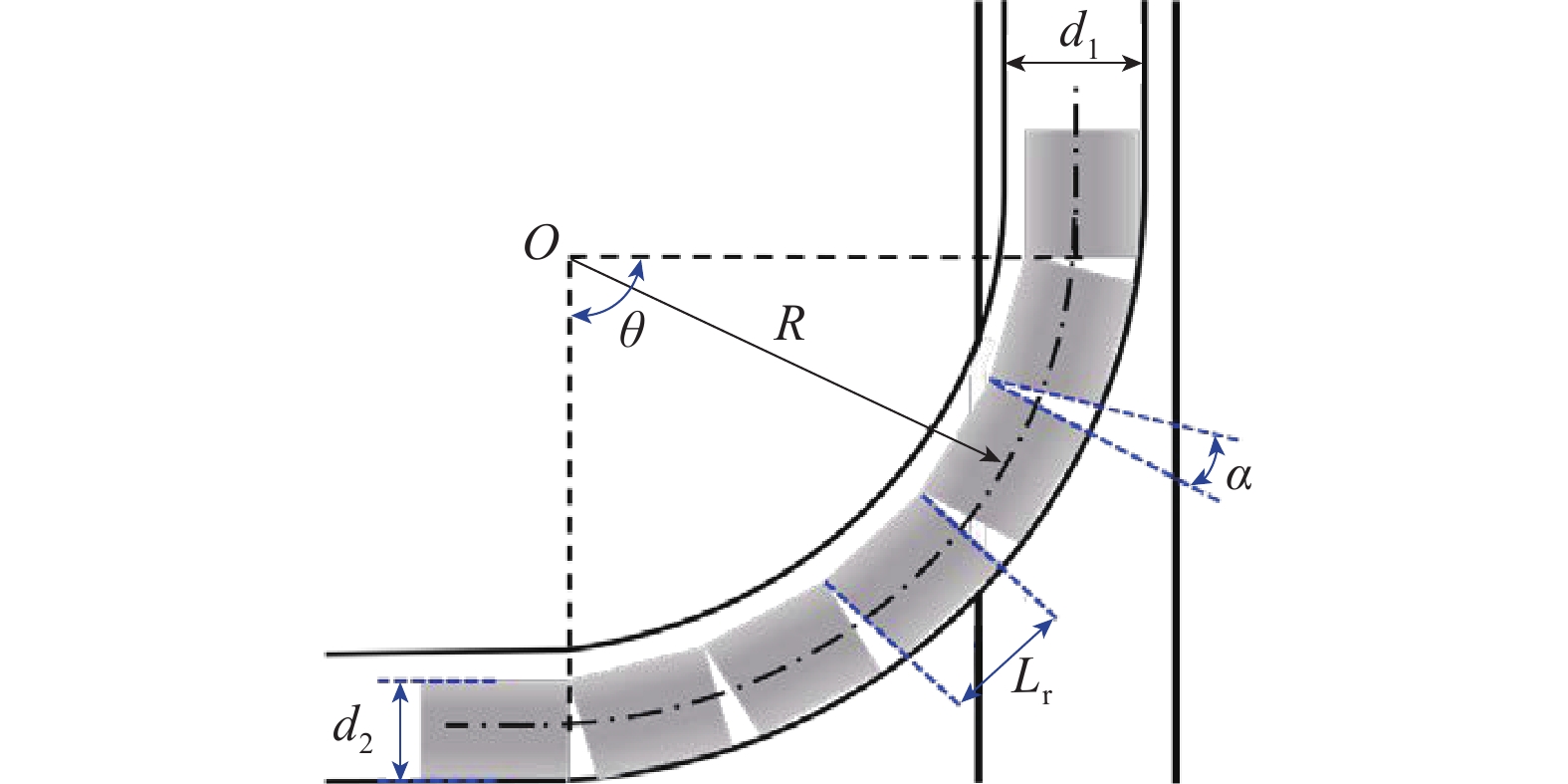

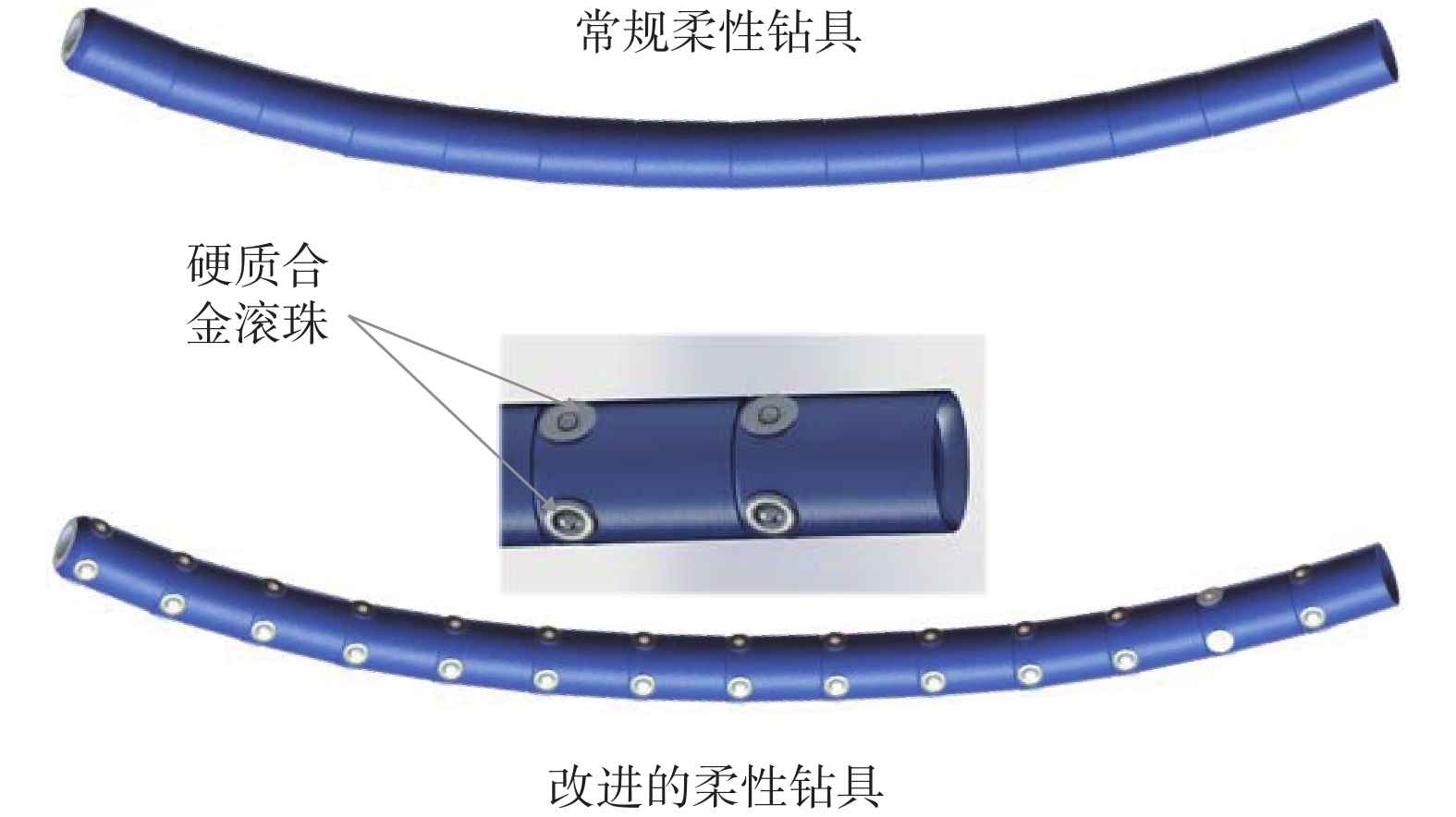

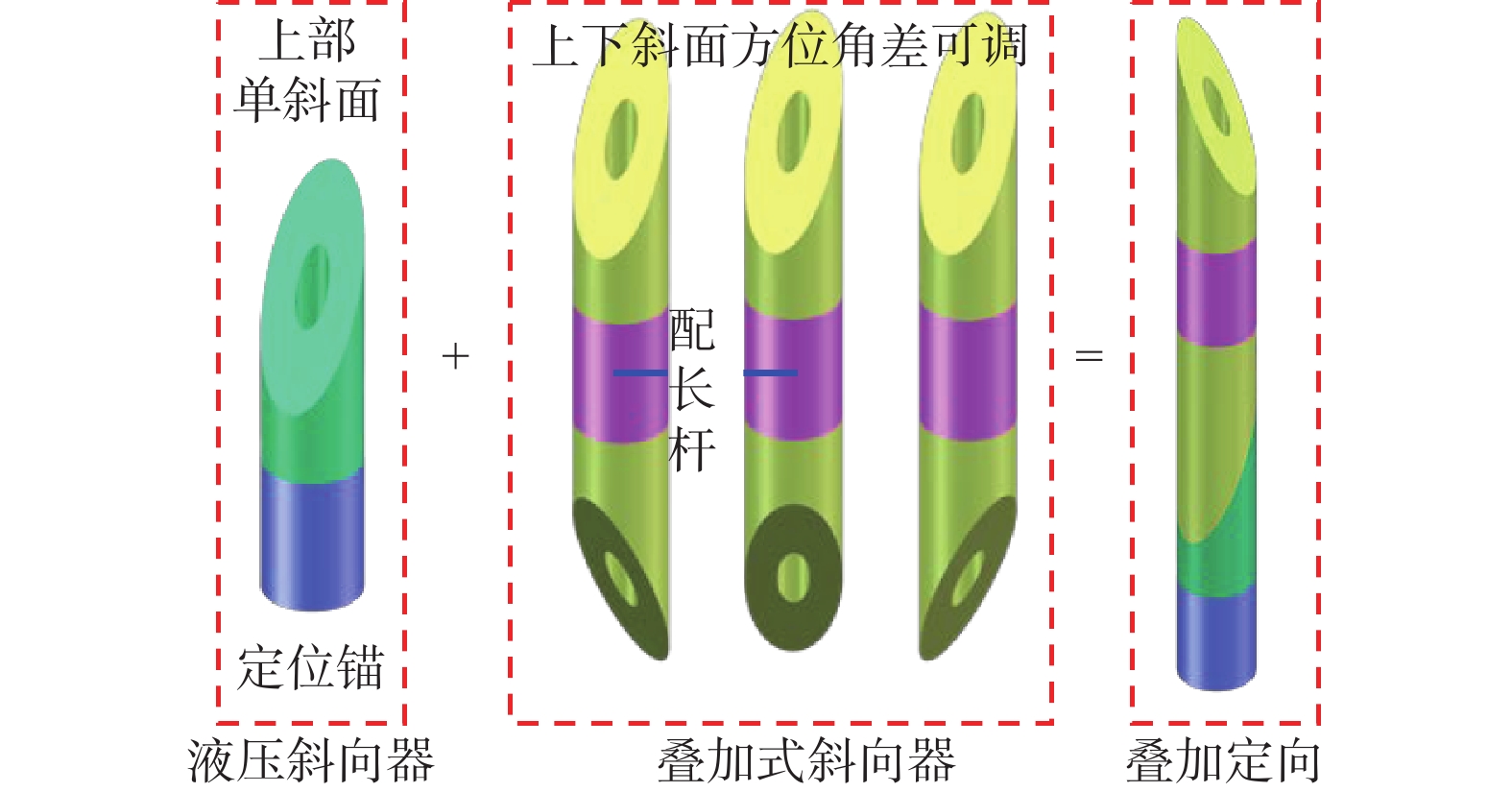

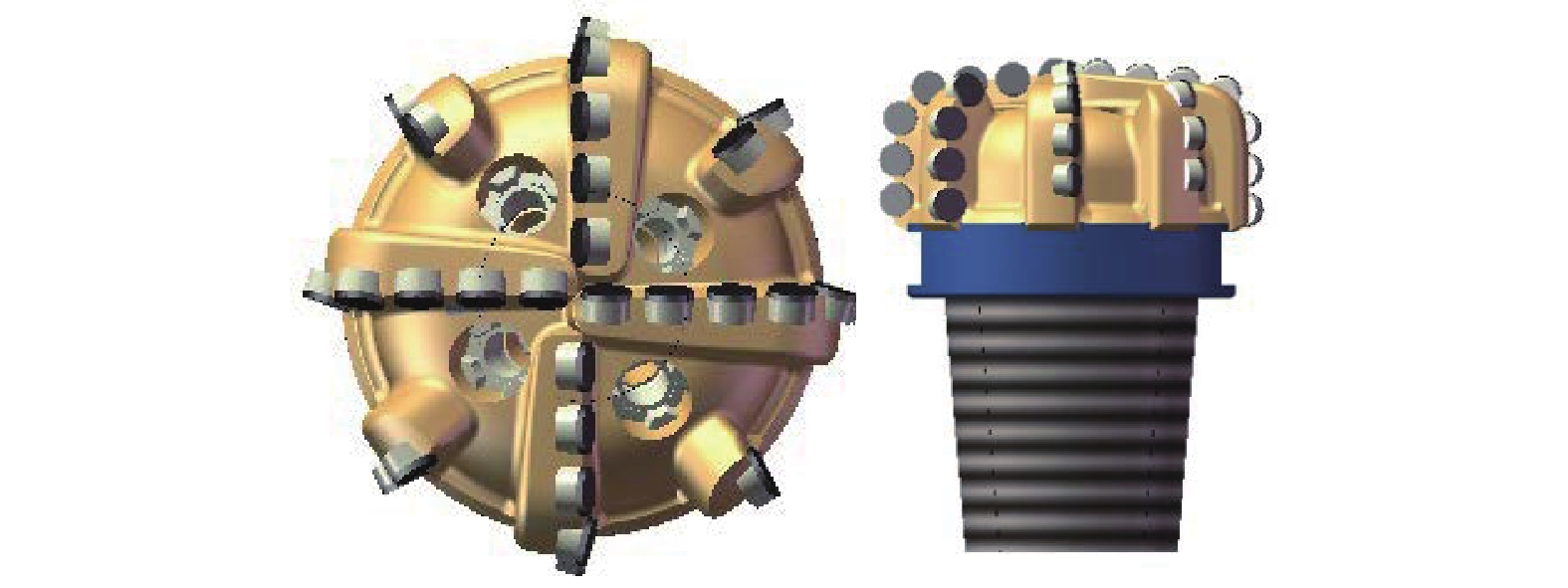

Abstract:Ultra-short radius horizontal wells play an important role in the stimulation of old oil and gas wells and the potential tapping of remaining oil. The commonly used ultra-short radius horizontal drilling technology with flexible bottom hole assembly (BHA), however, faces the problems of long tripping periods and high operation costs. In contrast, coiled tubing drilling tools feature high drilling efficiency with low costs and are safe and reliable. Hence, this study combined the advantages of coiled tubing and flexible BHA and developed key tools for ultra-short radius horizontal drilling, including large-torque positive displacement motors (PDM) at high and low rotary speed, optimized flexible BHA, stacking whipstock and build-up PDC bit, etc. Moreover, supporting operation processes were optimized. As a result, the ultra-short radius horizontal drilling technology combining coiled tubing and flexible BHA was preliminarily developed. The technology was first applied in a field test in Well Ling 72-5CZ of Jianghan Oilfield, and an ultra-short radius horizontal lateral well of 30.21 m was drilled, with an average rate of penetration of 0.8 m/h. The trajectory was in good agreement with the designed one, and the horizontal section has an average inclination angle of 88.17°. The field test results verify that the ultra-short radius horizontal drilling technology combining coiled tubing and flexible BHA is feasible, and it can provide a new technology for the potential tapping of remaining oil and efficient development of low-permeability oil fields.

-

-

表 1 高转速和低转速大扭矩螺杆钻具的主要性能参数

Table 1 Main parameters of large-torque PDM at high and low rotary speed

型号 直径/mm 转速/(r·min−1) 使用排量/(L·s−1) 工作压降/MPa 最大扭矩/(N·m) 最大压降/MPa 最大功率/kW 井眼直径/mm 9LZ105×7-4.0 105 132~265 8.3~16.6 3.2 3798 5.4 26.5~53.0 121~149 9LZ105×7-3.0 105 46~95 6.6~13.0 3.0 4700 4.2 50.0 121~139 -

[1] DICKINSON W, DICKINSON R W. Horizontal radial drilling system[R]. SPE13949, 1985.

[2] 张义,鲜保安,赵庆波,等. 超短半径径向水平井新技术及其在煤层气开采中的应用[J]. 中国煤层气,2008,5(3):20–24. doi: 10.3969/j.issn.1672-3074.2008.03.005 ZHANG Yi, XIAN Baoan, ZHAO Qingbo, et al. Study on new technologies of ultra-short radius radial horizontal wells and application in coal-bed methane development[J]. China Coalbed Methane, 2008, 5(3): 20–24. doi: 10.3969/j.issn.1672-3074.2008.03.005

[3] 李根生, 黄中伟, 沈忠厚, 等. 水力喷射侧钻径向分支井眼的方法及装置: CN200710176846.0[P]. 2009−05−13. LI Gensheng, HUANG Zhongwei, SHEN Zhonghou, et al. The method and apparatus for drilling radial horizontal holes by high-pressure water jet: CN200710176846.0[P]. 2009−05−13.

[4] 黄中伟,李根生,唐志军,等. 水力喷射侧钻径向微小井眼技术[J]. 石油钻探技术,2013,41(4):37–41. doi: 10.3969/j.issn.1001-0890.2013.04.009 HUANG Zhongwei, LI Gensheng, TANG Zhijun, et al. Technology of hydra-jet sidetracking of horizontal micro-radial laterals[J]. Petroleum Drilling Techniques, 2013, 41(4): 37–41. doi: 10.3969/j.issn.1001-0890.2013.04.009

[5] 李根生,黄中伟,李敬彬. 水力喷射径向水平井钻井关键技术研究[J]. 石油钻探技术,2017,45(2):1–9. doi: 10.11911/syztjs.201702001 LI Gensheng, HUANG Zhongwei, LI Jingbin. Study of the key techniques in radial jet drilling[J]. Petroleum Drilling Techniques, 2017, 45(2): 1–9. doi: 10.11911/syztjs.201702001

[6] CIRIGLIANO R A, BLACUTT J F T. First experience in the application of radial perforation technology in deep wells[R]. SPE107182, 2007.

[7] DICKINSON W, DYKSTRA H, NEES J M, et al. The ultrashort radius radial system applied to thermal recovery of heavy oil[R]. SPE24087, 1992.

[8] 管申,郭浩,程林,等. WZ-X1井超短半径水平井轨迹控制技术研究及应用[J]. 钻采工艺,2020,43(6):21–23. GUAN Shen, GUO Hao, CHENG Lin, et al. Research and application of trajectory control technology for ultra-short radius horizontal drilling in Well WZ-X1[J]. Drilling & Production Technology, 2020, 43(6): 21–23.

[9] 朱健军. 侧钻超短半径水平井J37-26-P14井钻井设计与施工[J]. 石油钻探技术,2011,39(5):106–109. doi: 10.3969/j.issn.1001-0890.2011.05.023 ZHU Jianjun. Drilling design and implementation of sidetracking ultra-short radius horizontal Well J37-26-P14[J]. Petroleum Drilling Techniques, 2011, 39(5): 106–109. doi: 10.3969/j.issn.1001-0890.2011.05.023

[10] 赵峰. 超短半径侧钻分支水平井曙1-23-0370CH井设计与施工[J]. 石油钻采工艺,2009,31(6):37–39. doi: 10.3969/j.issn.1000-7393.2009.06.009 ZHAO Feng. Design and application of super-short radius side-tracking technology in SHU1-23-0370CH multilateral horizontal well[J]. Oil Drilling & Production Technology, 2009, 31(6): 37–39. doi: 10.3969/j.issn.1000-7393.2009.06.009

[11] 王羽曦. 超短半径水平井钻井技术在注入井解堵中的应用[J]. 石油钻探技术,2013,41(5):89–92. doi: 10.3969/j.issn.1001-0890.2013.05.017 WANG Yuxi. Application of ultra-short radius horizontal well drilling technology in plugging removal in injectors[J]. Petroleum Drilling Techniques, 2013, 41(5): 89–92. doi: 10.3969/j.issn.1001-0890.2013.05.017

[12] 刘合, 孙强, 黄守志, 等. 一种油层深部定点定方位保压取心工具: CN201920091328.7[P]. 2020−01−07. LIU He, SUN Qiang, HUANG Shouzhi, et al. A pressure-preservation coring tool at fixed point and azimuth in deep oil reservoir: CN201920091328.7[P]. 2020−01−07.

[13] 宫华,郑瑞强,范存,等. 大庆油田超短半径水平井钻井技术[J]. 石油钻探技术,2011,39(5):19–22. doi: 10.3969/j.issn.1001-0890.2011.05.004 GONG Hua, ZHENG Ruiqiang, FAN Cun, et al. Ultra-short radius horizontal well drilling technology in Daqing Oilfield[J]. Petroleum Drilling Techniques, 2011, 39(5): 19–22. doi: 10.3969/j.issn.1001-0890.2011.05.004

[14] 郭永宾,管申,刘智勤,等. 多分支超短半径钻井技术在我国海上油田的首次应用[J]. 中国海上油气,2020,32(5):137–144. GUO Yongbin, GUAN Shen, LIU Zhiqin, et al. First application of multi-lateral ultra-short radius drilling in China offshore oilfields[J]. China Offshore Oil and Gas, 2020, 32(5): 137–144.

[15] 张绍林,孙强,李涛,等. 基于柔性钻具低成本超短半径老井侧钻技术[J]. 石油机械,2017,45(12):18–22. doi: 10.16082/j.cnki.issn.1001-4578.2017.12.004 ZHANG Shaolin, SUN Qiang, LI Tao, et al. The low cost ultra-short radius sidetracking technology in produced wells based on flexible drill pipe[J]. China Petroleum Machinery, 2017, 45(12): 18–22. doi: 10.16082/j.cnki.issn.1001-4578.2017.12.004

[16] GOURLEY G. Flexible drilling tool may aid in enhanced oil recovery[R]. SPE59536, 2000.

[17] AL-HADY A S, LAPRAD D, AL SADI A. Ultra short radius drilling trials in PDO[R]. SPE81410, 2003.

[18] 杨刚,孟尚志,李斌,等. 深部煤层气T型井钻井技术[J]. 煤炭科学技术,2018,46(6):189–194. doi: 10.13199/j.cnki.cst.2018.06.032 YANG Gang, MENG Shangzhi, LI Bin, et al. Drilling technology of T-shaped well in deep coalbed methane[J]. Coal Science and Technology, 2018, 46(6): 189–194. doi: 10.13199/j.cnki.cst.2018.06.032

[19] 雷群,李益良,李涛,等. 中国石油修井作业技术现状及发展方向[J]. 石油勘探与开发,2020,47(1):155–162. doi: 10.11698/PED.2020.01.15 LEI Qun, LI Yiliang, LI Tao, et al. Technical status and development direction of workover operation of PetroChina[J]. Petroleum Exploration and Development, 2020, 47(1): 155–162. doi: 10.11698/PED.2020.01.15

[20] 王海涛,李相方. 连续油管技术在井下作业中的应用现状及思考[J]. 石油钻采工艺,2008,30(6):120–124. doi: 10.3969/j.issn.1000-7393.2008.06.028 WANG Haitao, LI Xiangfang. Application situation and thinking about coiled tubing techniques in downhole operation[J]. Oil Drilling & Production Technology, 2008, 30(6): 120–124. doi: 10.3969/j.issn.1000-7393.2008.06.028

[21] 陈会年,张国龙,胡清富. 连续油管钻井技术的发展及应用[J]. 石油钻探技术,2000,28(2):19–21. doi: 10.3969/j.issn.1001-0890.2000.02.007 CHEN Huinian, ZHANG Guolong, HU Qingfu. Developments and applications of coiled tubing drilling techniques[J]. Petroleum Drilling Techniques, 2000, 28(2): 19–21. doi: 10.3969/j.issn.1001-0890.2000.02.007

[22] 苏新亮,李根生,沈忠厚,等. 连续油管钻井技术研究与应用进展[J]. 天然气工业,2008,28(8):55–57. doi: 10.3787/j.issn.1000-0976.2008.08.015 SU Xinliang, LI Gensheng, SHEN Zhonghou, et al. Research on coiled tubing drilling technology and its application[J]. Natural Gas Industry, 2008, 28(8): 55–57. doi: 10.3787/j.issn.1000-0976.2008.08.015

[23] 彭在美,窦树柏,董帅,等. 连续油管国内外应用概况及国内的研制方向[J]. 焊管,2008,31(4):7–13. doi: 10.3969/j.issn.1001-3938.2008.04.002 PENG Zaimei, DOU Shubai, DONG Shuai, et al. Coiled tubing application at home and aboard and direction of China coiled tubing research[J]. Welded Pipe and Tube, 2008, 31(4): 7–13. doi: 10.3969/j.issn.1001-3938.2008.04.002

[24] 刘寿军,李根生. 我国连续管技术面临的挑战和发展建议[J]. 石油机械,2013,41(11):1–5. doi: 10.3969/j.issn.1001-4578.2013.11.001 LIU Shoujun, LI Gensheng. Challenges for China’s coiled tubing technology and development suggestions[J]. China Petroleum Machinery, 2013, 41(11): 1–5. doi: 10.3969/j.issn.1001-4578.2013.11.001

[25] 李根生,宋先知,黄中伟,等. 连续管钻井完井技术研究进展及发展趋势[J]. 石油科学通报,2016,1(1):81–90. LI Gensheng, SONG Xianzhi, HUANG Zhongwei, et al. Research progress and prospects of well drilling and completion with coiled tubing[J]. Petroleum Science Bulletin, 2016, 1(1): 81–90.

-

期刊类型引用(18)

1. 刁斌斌,高德利,刘喆,吴华鹏. 井深随钻测量误差校正与井眼位置不确定性计算方法. 石油钻探技术. 2024(02): 181-186 .  本站查看

本站查看

2. 许泽凡,宋红伟,张明菊,胡少兵,陈雪菲,程为彬. 融合DBSCAN多测点算法的磁方位校正. 网络安全与数据治理. 2023(02): 83-88 .  百度学术

百度学术

3. 商森,连世鑫. MWD磁干扰的判断和矫正. 石化技术. 2023(07): 140-142 .  百度学术

百度学术

4. 于瑞丰,刁斌斌,高德利. 考虑磁方位校正的井眼轨迹测量误差计算. 石油钻探技术. 2023(06): 25-31 .  本站查看

本站查看

5. 宋晓健,郑邦贤,谭勇志,黄秉亚,马鸿彦,董晨曦. 基于数据融合的近钻头井眼轨迹参数动态测量方法. 石油钻探技术. 2022(01): 38-44 .  本站查看

本站查看

6. 孟庆威,姜天杰,刘泳敬,杨杰,王越支. 基于有限元分析的方位角误差计算和修正. 石油钻探技术. 2022(03): 66-73 .  本站查看

本站查看

7. 蒲文学,范光第,朱建建,赵国山. 磁性随钻测斜仪所需无磁钻具长度及影响因素研究. 石油钻探技术. 2022(04): 129-134 .  本站查看

本站查看

8. 陈庚绪,李红星,王新刚,白雪龙,王越之. 测量误差对井眼轨迹不确定性的影响分析. 煤炭技术. 2021(04): 54-56 .  百度学术

百度学术

9. 李国梁,姜天杰,卢华涛,侯晓东,余义兵,张菲菲. 磁力随钻测量无磁钻铤长度优化设计. 中国石油和化工标准与质量. 2021(18): 126-129 .  百度学术

百度学术

10. 于瑞丰,刁斌斌,高德利. 基于邻井距离测量误差的救援井磁测距工具优选方法. 石油钻探技术. 2021(06): 118-124 .  本站查看

本站查看

11. 孟卓然. BHA轴向磁干扰对方位测量误差的影响——基于人工磁场模拟方法. 石油学报. 2020(08): 1011-1018 .  百度学术

百度学术

12. 肖通,姜天杰,兰铁坤,王昊. 丛式井井眼防碰技术措施探讨. 石化技术. 2020(08): 31+35 .  百度学术

百度学术

13. 蒋必辞,田小超,张鹏,汲方林,丛琳,王盼. 随钻伽马对方位角测量的影响及校正方法研究. 煤炭科学技术. 2020(12): 175-181 .  百度学术

百度学术

14. 刘建光,底青云,张文秀. 基于多测点分析法的水平井高精度磁方位校正方法. 地球物理学报. 2019(07): 2759-2766 .  百度学术

百度学术

15. 龚大洪,陈元鹏,杨文娟,杨金生,王志玲,张树义,马鸿彦. 一种井眼轨迹不确定性方法的可视化研究与应用. 钻采工艺. 2019(06): 9-12+1 .  百度学术

百度学术

16. 刘庆. 随钻测量仪传感器正交校准方法研究. 自动化仪表. 2018(05): 74-76+80 .  百度学术

百度学术

17. 范光第,蒲文学,赵国山,黄根炉. 磁力随钻测斜仪轴向磁干扰校正方法. 石油钻探技术. 2017(04): 121-126 .  本站查看

本站查看

18. 韩少波,邵婷婷. 基于BP神经网络的油井井斜角误差补偿研究. 内蒙古石油化工. 2015(01): 37-38 .  百度学术

百度学术

其他类型引用(11)

下载:

下载: