Drainage Gas Recovery Technique with Downhole Intelligent Robots in Low Pressure and Low Production Gas Wells

-

摘要:

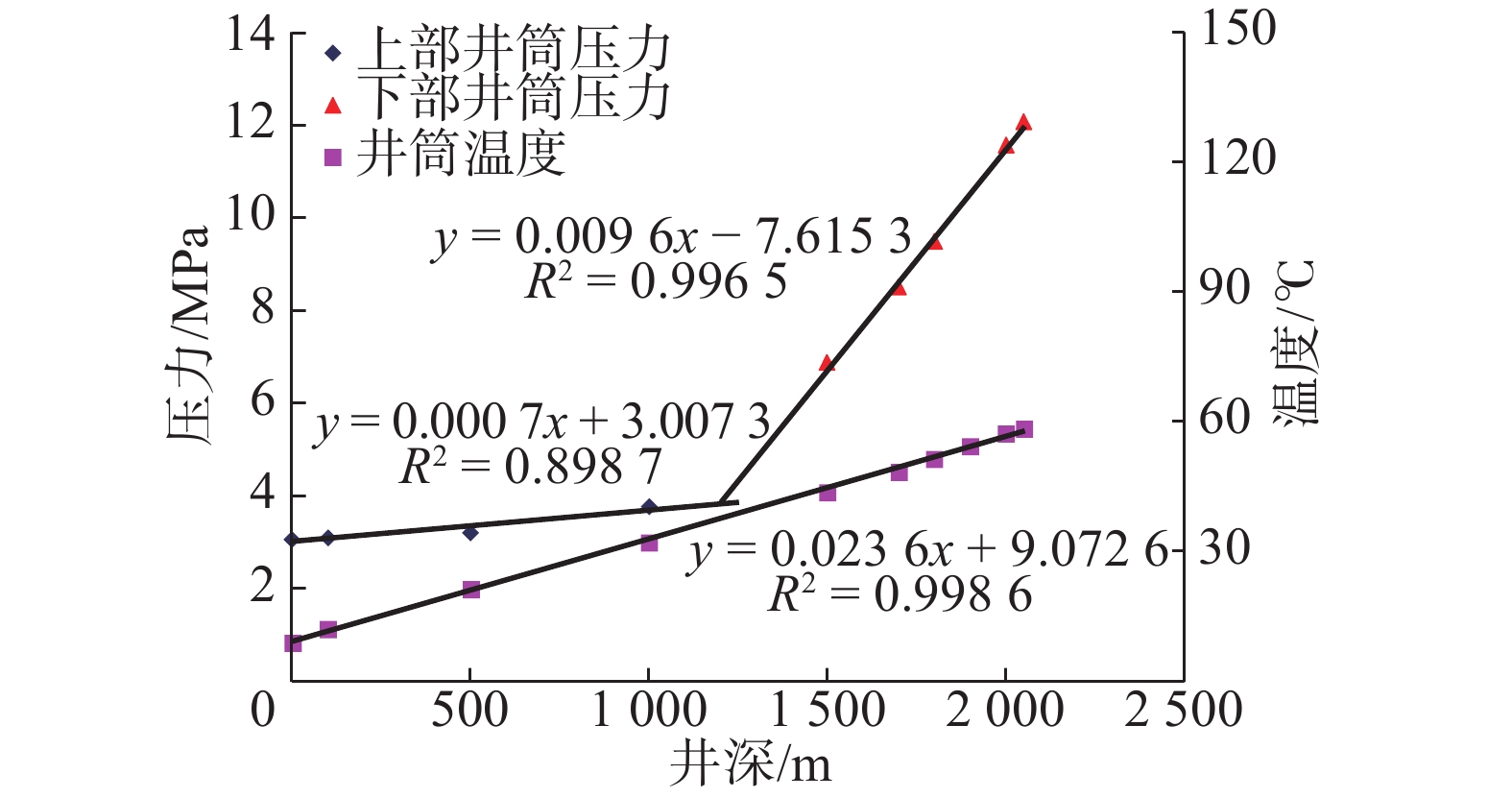

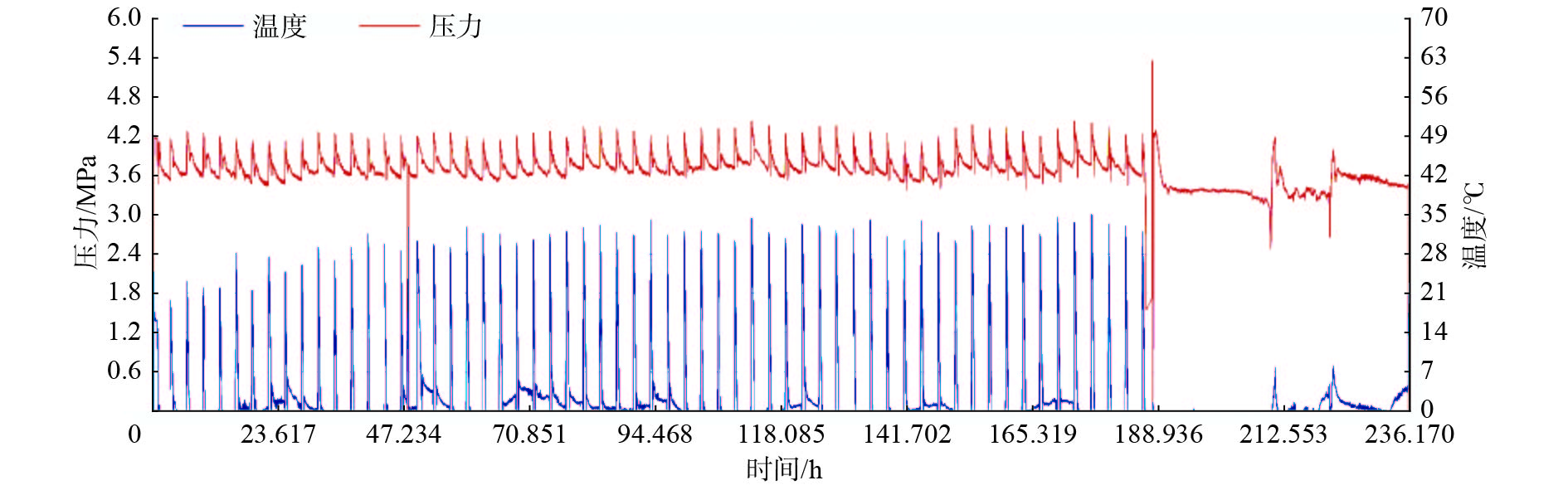

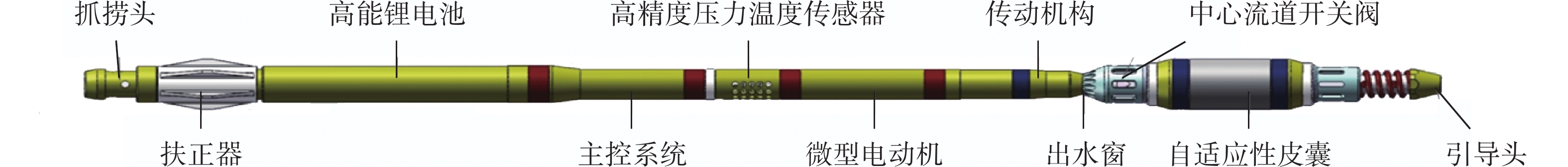

低压低产气井积液减产现象严重,而泡排、柱塞、液氮气举等常规排水采气工艺难以满足其长期稳产和提高采收率的要求,为此,基于柱塞气举工艺原理,研制了一种新型排水采气井下智能机器人,该机器人能实时监测与追踪井筒动液面位置,自动控制装置内部中心流道开关,可以在井眼内自动上行,从而实现气井分段、逐级定量排水。在东胜气田1口井的先导试验表明,井下智能机器人能够在井筒内自由稳定行走,实现自主定量排水和气井不关井连续采气,产气量稳定上升,油套压差持续降低,井筒积液得到有效缓解,达到了低压低产气井长期稳产和提高采收率的目的。研究与试验结果表明,井下智能机器人排水采气技术有效解决了常规排水采气工艺存在的问题,有利于实现低压低产气井的长期稳产和提高低压含水气藏的采收率。

Abstract:The output of low pressure and low production gas wells has been significantly reduced due to the presence of liquid loading, and it is difficult to maintain long-term stable production and to enhance gas recovery through conventional drainage gas recovery technologies, such as foam drainage, plunger gas lifting and liquid nitrogen gas lifting. To solve this problem, a novel downhole intelligent robot for drainage gas recovery was developed based on the principle of plunger gas lifting. The robot automatically segments and quantifies drainage by monitoring and tracking the dynamic liquid level within wellbore in real time, and then automatically controlling the opening and closing of the center channel in the device. It does so byenabling the downhole intelligent robot to go upward along the wellbore automatically. The robot was tried out in the field in one well in Dongsheng Gas Field. The results were positive. The robot is able to move around steadily and freely in the wellbore and achieve independent quantitative drainage and continuous gas recovery without shutting in the gas well. Using robotics, gas production ramped up steadily, the tubing/casing pressure difference dropped in a continuous manner, and liquid loading in the wellbore was mitigated. Thus robotics and automated control systems allowed long-term stable production and EOR of low pressure/low production gas well. The downhole intelligent robot effectively solved the technical problems encountered in conventional drainage gas recovery, and made it possible to have efficient development of low pressure and low production water-bearing gas reservoirs.

-

-

表 1 A井井下智能机器人排水采气效果

Table 1 Effect of drainage gas recovery after application of downhole intelligent robot technology in Well A

项目 油管压力/MPa 套管压力/MPa 油套压差/MPa 产气量/(m3·d–1) 产液量/(m3·d–1) 液气比/(m3·(10–4m–3)) 生产时率,% 助排措施 试验前(30 d) 3.5 6.2 2.7 5 012 0.55 0.96 97.5 泡排+降压带液 试验中(15 d) 3.8 6.0 2.2 7 315 0.95 1.30 100.0 无 -

[1] 陈路原. 大牛地气田盒1气藏水平井开发工程技术与实践[J]. 石油钻探技术, 2015, 43(1): 44–51. CHEN Luyuan. Technology and practice for horizontal well development in the He-1 Gas Reservoir of Daniudi Gas Field[J]. Petroleum Drilling Techniques, 2015, 43(1): 44–51.

[2] 狄敏燕,陈超峰,王东林,等. 气井井筒积液分析及排水工艺研究[J]. 石油钻探技术, 2010, 38(6): 109–112. doi: 10.3969/j.issn.1001-0890.2010.06.024 DI Minyan, CHEN Chaofeng, WANG Donglin, et al. Analysis of well bore fluid accumulation and water drainage technology[J]. Petroleum Drilling Techniques, 2010, 38(6): 109–112. doi: 10.3969/j.issn.1001-0890.2010.06.024

[3] 周舰,王志彬,罗懿,等. 高气液比气井临界携液气流量计算新模型[J]. 断块油气田, 2013, 20(6): 775–778, 796. ZHOU Jian, WANG Zhibin, LUO Yi, et al. New model to calculate critical liquid-carrying gas flow rate in gas well with high gas-liquid ratio[J]. Fault-Block Oil & Gas Field, 2013, 20(6): 775–778, 796.

[4] 周琴. 徐深气田气井临界携液影响因素研究[J]. 特种油气藏, 2019, 26(3): 119–122. doi: 10.3969/j.issn.1006-6535.2019.03.022 ZHOU Qin. Critical unloading sensitivity analysis of the gas well in the Xushen Gasfield[J]. Special Oil & Gas Reservoirs, 2019, 26(3): 119–122. doi: 10.3969/j.issn.1006-6535.2019.03.022

[5] 杨川东.采气工程[M].北京: 石油工业出版社, 2001: 37–50. YANG Chuandong. Gas recovery project[M]. Beijing: Petroleum Industry Press, 2001: 37–50.

[6] 王志彬,李颖川. 气井连续携液机理研究[J]. 石油学报, 2012, 33(4): 681–686. doi: 10.7623/syxb201204021 WANG Zhibin, LI Yingchuan. The mechanism of continuously removing liquids from gas wells[J]. Acta Petrolei Sinica, 2012, 33(4): 681–686. doi: 10.7623/syxb201204021

[7] OYEWOLE P O, GARG D O. Plunger lift application and optimization in the San Juan North Basin: our journey[R]. SPE 106761, 2007.

[8] 冯国强,隋义勇,冯国勇. 柱塞举升优化设计及敏感性分析[J]. 石油钻探技术, 2007, 35(5): 104–107. doi: 10.3969/j.issn.1001-0890.2007.05.030 FENG Guoqiang, SUI Yiyong, FENG Guoyong. Optimum design and sensitivity analysis for plunger lift[J]. Petroleum Drilling Techniques, 2007, 35(5): 104–107. doi: 10.3969/j.issn.1001-0890.2007.05.030

[9] 李长书. 智能柱塞气举采油工艺在塔河油田的应用[J]. 石油钻探技术, 2002, 30(3): 55–57. doi: 10.3969/j.issn.1001-0890.2002.03.022 LI Changshu. Applications of gas lift production with intelligent plug technology in Tahe Oilfield[J]. Petroleum Drilling Techniques, 2002, 30(3): 55–57. doi: 10.3969/j.issn.1001-0890.2002.03.022

[10] 陈科贵,田宝,于静,等. 柱塞气举排水采气工艺在定向井中的优化设计与应用[J]. 断块油气田, 2014, 21(3): 401–404. CHEN Kegui, TIAN Bao, YU Jing, et al. Optimization design and application of plunger gas lift for water drainage and gas recovery in directional well[J]. Fault-Block Oil & Gas Field, 2014, 21(3): 401–404.

[11] 殷庆国,刘方,贺杰新,等. 柱塞气举排水采气工艺技术研究与应用[J]. 石油机械, 2018, 46(9): 69–74. YIN Qingguo, LIU Fang, HE Jiexin, et al. Study and application of plunger gas lift for water drainage and gas recovery technology[J]. China Petroleum Machinery, 2018, 46(9): 69–74.

[12] 杨亚聪,穆谦益,白晓弘,等. 柱塞气举排水采气技术优化研究[J]. 石油化工应用, 2013, 32(10): 11–13. doi: 10.3969/j.issn.1673-5285.2013.10.003 YANG Yacong, MU Qianyi, BAI Xiaohong, et al. Optimization study on plunger gas lift of drainage gas recovery technology[J]. Petrochemical Industry Application, 2013, 32(10): 11–13. doi: 10.3969/j.issn.1673-5285.2013.10.003

[13] 于蓉. 对柱塞气举排水采气工艺的几点认识[J]. 钻采工艺, 1994, 17(2): 82–85. YU Rong. Some understanding of the technology of drainage gas production with plunger gas lift[J]. Drilling & Production Technology, 1994, 17(2): 82–85.

[14] 董耀文,谭明文,周兴付,等. 柱塞气举在川西地区定向井中的应用研究[J]. 天然气工业, 2011, 31(6): 53–55. doi: 10.3787/j.issn.1000-0976.2011.06.010 DONG Yaowen, TAN Mingwen, ZHOU Xingfu, et al. Application of plunger air lift in directional wells in the Western Sichuan Basin[J]. Natural Gas Industry, 2011, 31(6): 53–55. doi: 10.3787/j.issn.1000-0976.2011.06.010

[15] 肖述琴, 樊莲莲, 杨旭东, 等. 不关井连续生产分体式柱塞装置研制与应用[J]. 石油矿场机械, 2013, 12(9): 71–73. doi: 10.3969/j.issn.1001-3482.2013.09.019 XIAO Suqin, FAN Lianlian, YANG Xudong, et al. New device of continuous production split plunger[J]. Oil Field Equipment, 2013, 12(9): 71–73. doi: 10.3969/j.issn.1001-3482.2013.09.019

[16] 周朝,吴晓东,张同义,等. 排液采气涡流工具结构参数优化实验研究[J]. 石油钻探技术, 2018, 46(6): 105–110. ZHOU Chao, WU Xiaodong, ZHANG Tongyi, et al. Experimental research for parameter optimization of the vortex tool for drainage gas recovery[J]. Petroleum Drilling Techniques, 2018, 46(6): 105–110.

-

期刊类型引用(12)

1. 皮光林. 美国页岩油气产业现状及工程技术演进趋势. 当代石油石化. 2023(05): 6-9 .  百度学术

百度学术

2. 张锦宏,周爱照,成海,毕研涛. 中国石化石油工程技术新进展与展望. 石油钻探技术. 2023(04): 149-158 .  本站查看

本站查看

3. 路保平. 中国石化石油工程技术新进展与发展建议. 石油钻探技术. 2021(01): 1-10 .  本站查看

本站查看

4. 杨书博,乔文孝,赵琪琪,倪卫宁,吴金平. 随钻前视声波测井钻头前方声场特征研究. 石油钻探技术. 2021(02): 113-120 .  本站查看

本站查看

5. 刘媛,董易凡,刘博卿,杨圣方. 对外合作企业在降本增效中的技术创新. 石油工业技术监督. 2020(03): 55-57+62 .  百度学术

百度学术

6. 李晓平,石祥超,李皋,李昆成. 新时期石油与天然气工程研究生培养目标定位探讨. 教育教学论坛. 2020(52): 99-101 .  百度学术

百度学术

7. 王国申. 石油钻井自动化关键技术应用. 中国石油和化工标准与质量. 2020(24): 177-179 .  百度学术

百度学术

8. 路保平,倪卫宁. 高精度随钻成像测井关键技术. 石油钻探技术. 2019(03): 148-155 .  本站查看

本站查看

9. 王敏生,光新军,耿黎东. 页岩油高效开发钻井完井关键技术及发展方向. 石油钻探技术. 2019(05): 1-10 .  本站查看

本站查看

10. 刘晓峰,党万恒,梁振琪. 海洋石油完井技术现状及发展趋势. 石化技术. 2019(10): 194+333 .  百度学术

百度学术

11. 光新军,王敏生,叶海超,皮光林. 我国油气工程领域“卡脖子”技术分析及发展对策建议. 石油科技论坛. 2019(05): 32-39 .  百度学术

百度学术

12. 郑奕挺,方方,吴金平,钱德儒,张卫. 近钻头随钻伽马成像快速正弦曲线拟合方法. 石油钻探技术. 2019(06): 116-122 .  本站查看

本站查看

其他类型引用(3)

下载:

下载: