Inspiration and Practice of Drilling and Completion in 10 000-Meter Ultra-Deep Wells in the Gulf of Mexico

-

摘要:

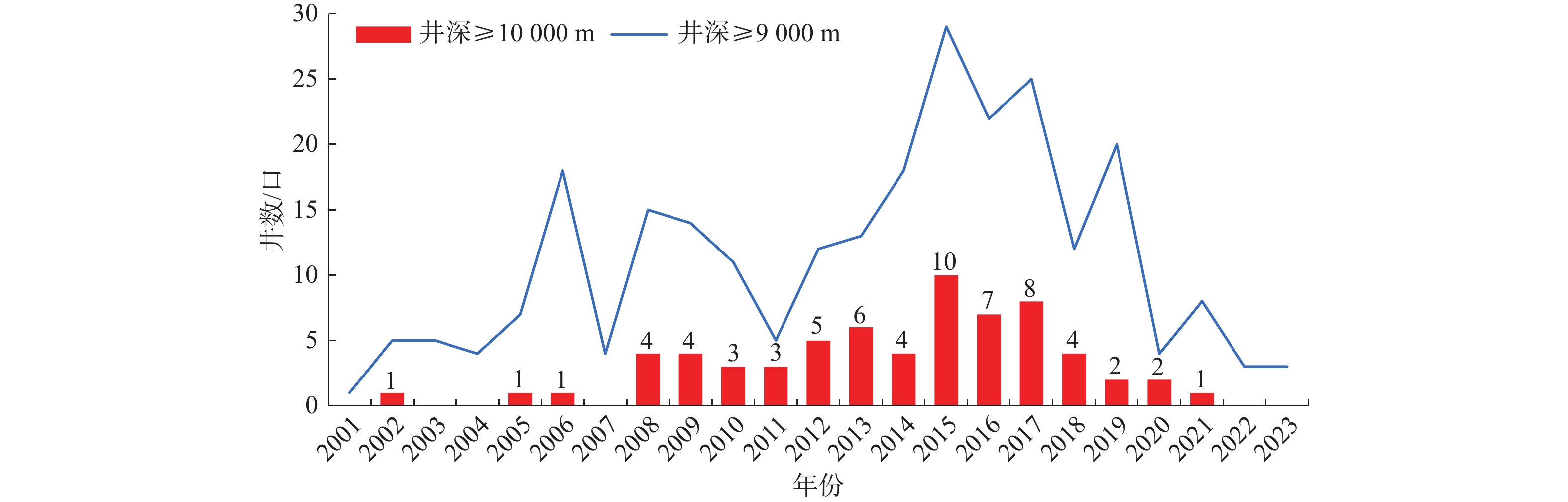

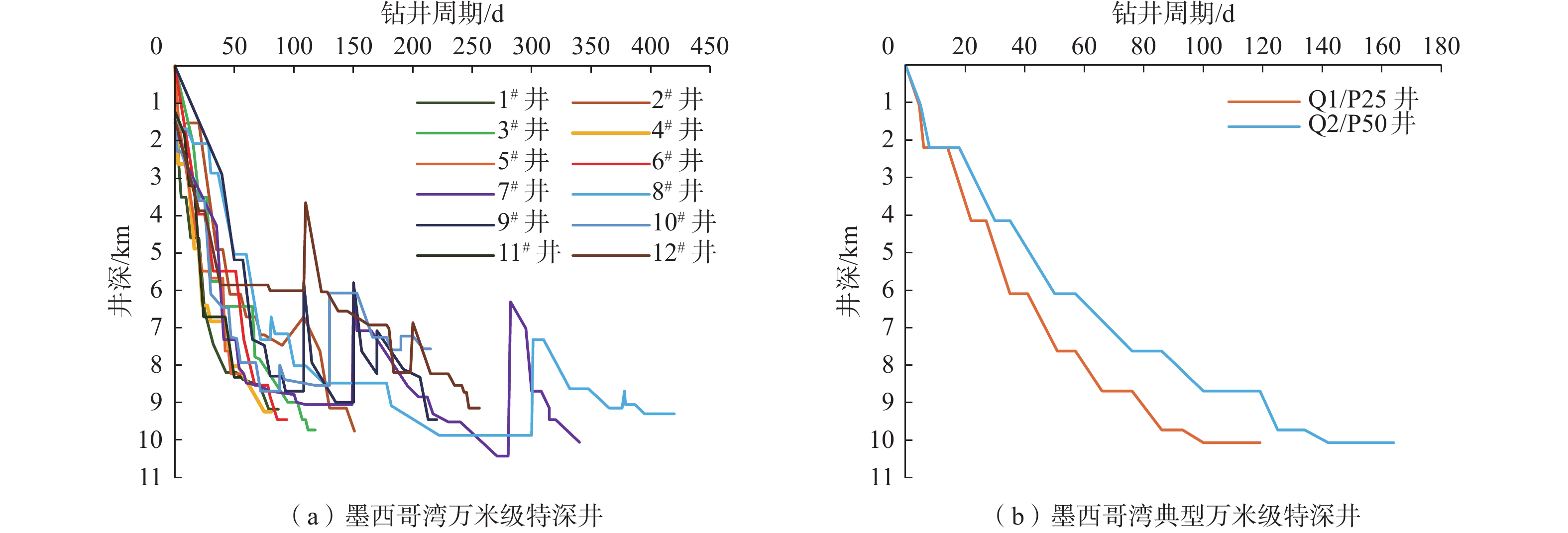

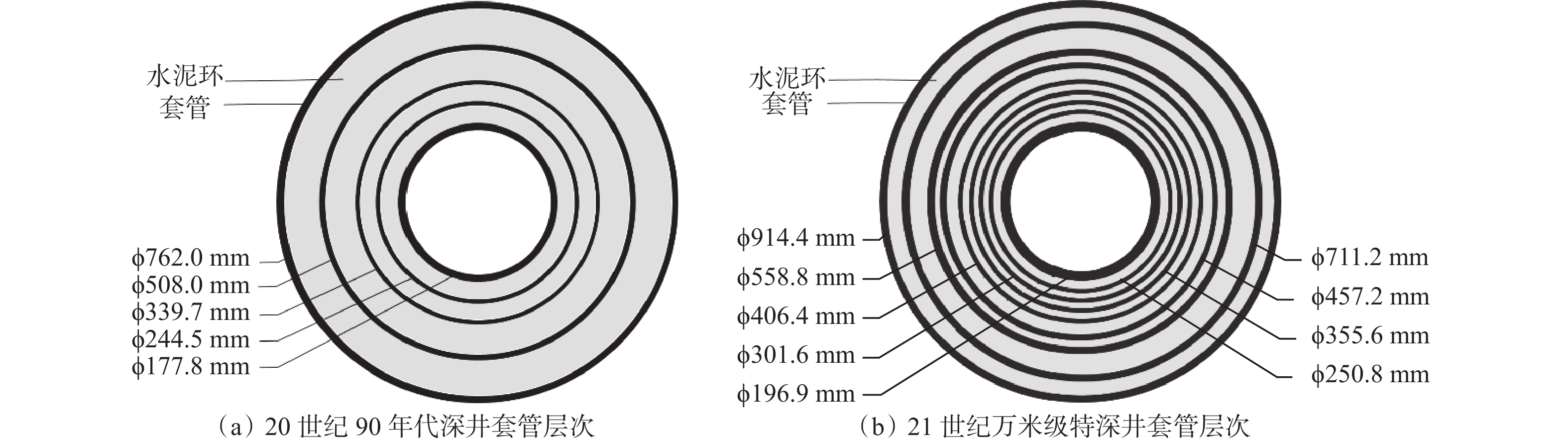

目前,我国陆上钻井能力已达9 000 m水平,且随着深地塔科1井钻深突破万米,成为全球第二个实现陆上万米钻探的国家,初步具备万米深地油气资源勘探开发能力。但是,目前我国仅完钻5口井深超过9 000 m的特深井,万米深地钻完井技术仍处于起步与探索阶段。美国墨西哥湾是世界上超深特深井数量最多的地区,并在钻井−完井−开发一体化设计理念、井身结构优化与拓展、关键装备与工具仪器、强化钻井参数提速和井下事故复杂防控等方面已形成先进理念与成熟做法。为此,系统总结分析了美国墨西哥湾万米级特深井钻井周期、钻完井成本、原油产量、钻完井方案、成熟应用装备、工艺技术等,认为我国在地质条件、地层可钻性等方面存在差异,万米级特深井的数量、钻井周期及机械钻速与美国墨西哥湾相比仍存在一定差距。结合我国万米深地油气资源钻探面临的工程难题与挑战,提出了万米深地钻探工程技术及装备发展方向及建议,为实现我国万米深地油气资源勘探开发,推动钻完井关键技术装备迭代升级提供参考借鉴。

Abstract:Currently, China’s onshore drilling capability has reached the level of 9000 m in depth. In addition, the drilling depth of Well Take-1 has successfully exceeded 10000 m, making China the second country in the world to achieve onshore drilling depths of over 10 000 m, indicating the ability to explore and develop oil and gas resources at 10000 m in depth. However, at present, only five ultra-deep wells over 9000 m have been drilled in China, and the drilling and completion technology for wells over 9 000 m is still in the initial exploratory stage. The Gulf of Mexico in the United States has the largest number of ultra-deep wells in the world, and advanced concepts and mature practices have been formed in multiple areas including the design concept of drilling-completion-development integration, casing program optimization and expansion, key equipment and tools, drilling parameters strengthening for speeding up, and prevention and control of complex downhole situations. To this end, the drilling cycle, drilling and completion cost, crude oil production, drilling and completion scheme, mature application equipment, and technology of ultra-deep wells in the Gulf of Mexico were systematically summarized. It is concluded that due to differences in geological conditions and formation drillability, there are gaps in the number, drilling cycle, and rate of penetration of 10000-meter ultra-deep wells in China compared with those in the Gulf of Mexico. In accordance with the engineering problems and challenges faced in drilling China’s oil and gas resources over 10000 m in depth, development directions and suggestions of 10000-meter drilling engineering technology and equipment are introduced, so as to provide a reference for achieving the exploration and development of China’s oil and gas resources over 10000 m in depth and promoting the iterative upgrading of key drilling and completion technology and equipment.

-

我国油气对外依存度持续上升,常规油气田进入开发后期,页岩油气等非常规油气资源的重要性日益显著[1-2]。2022年,中国石油的页岩油产量突破300×104 t,页岩油作为油气资源的后起之秀,其规模化开发正加速推进[3]。作为实现页岩油藏规模效益开发的关键技术,水平井和体积压裂技术受页岩复杂孔隙结构和固液相互作用影响[4-5],目前在页岩油渗流机理、压裂液返排规律及产能预测等方面仍面临诸多问题与挑战。

页岩油藏压裂过程中,高压泵注的压裂液使主裂缝和次生裂缝延伸,形成复杂人工裂缝网络;同时,压裂液会通过渗吸作用进入并滞留在基质中,返排过程中少量排出,影响页岩油后续产能[6-8]。实践表明,不同页岩油藏储层的压裂液返排率与产能差异较大,其返排特征主要受页岩储层中油水两相渗流特性影响,由页岩孔隙结构特征控制。页岩油储层孔隙结构通常具有纳米级孔隙发育、孔径分布范围广的特点,前人基于页岩孔隙内流体流动规律、孔径分布等提出了多种两相相对渗透率计算方法。Wang Jinxun等人[9]将多孔介质概念化为不同尺寸管道串并联的毛细管模型,考虑孔隙尺寸分布及孔隙形状,推导了储层相渗的经典计算方法。Li Ran等人[10]综合考虑单孔内两相流动特征和孔隙分形结构,建立了页岩两相相渗计算方法,并分析了孔隙尺寸和结构对相渗特征的影响。Su Yuliang等人[11]考虑页岩有机和无机孔隙内油水赋存特征,建立了页岩油水两相相渗计算方法。数值模拟是常用的油藏产能评价手段,但体积压裂后的页岩油藏多尺度孔隙和裂缝储渗空间发育[12-13],传统双重介质模型、局部网格加密等模拟方法具有计算量大、难以处理复杂结构裂缝等局限,同时,页岩油流动受多种机理影响[14-17],数值模拟难度大。

嵌入式离散裂缝模型是将复杂裂缝几何形态直接嵌入正交背景网格中,简化了裂缝的几何剖分过程,极大地降低了计算量和复杂度[18]。国内外学者综合页岩油渗流机理和嵌入式离散裂缝模型,开展了页岩油井产能模拟分析[19-20],但目前尚未实现微观页岩油水相渗计算与宏观页岩油井产能的耦合。因此,笔者结合页岩油藏相渗计算方法、嵌入式离散裂缝模型和油水两相渗流数学模型,提出了考虑页岩孔隙结构作用下油水两相渗流特性的页岩油井产能数值模拟方法,分析了体积压裂后页岩油藏压裂液空间分布特征和油井产能,实现了页岩微观油水两相渗流特性与宏观油井产能的一体化评价。

1. 数学模型及求解

1.1 页岩油藏相渗计算方法

基于毛细管相渗计算模型,结合实际页岩孔隙形状和孔径分布,建立页岩油藏油水两相相渗计算方程。考虑页岩储层中复杂的孔隙形状,采用三角形毛细管模型表征页岩油藏储层。根据三角形毛细管中油水分布状态,单个毛细管中的油水两相流动规律可表示为:

Qo=πr4eff8μoLΔp (1) Qw=(14G−π)r4dζμwLΔp (2) 式中:Qo和Qw分别为毛细管中油相和水相的流量,m3/s;μo和μw分别为油相和水相黏度,Pa·s;L为毛细管长度,m;Δp为施加在毛细管上的压差,Pa;ζ为水与孔隙壁面相互作用的无因次阻力系数(用于表征孔隙表面性质对流体流动的影响);reff为毛细管有效油相半径,m;G为三角形毛细管的形状因子;rd为油水稳定状态下的界面曲率半径,m。

reff=21√GP2−(14G−π)r2dπ+1rin (3) rd=P0.5G+√πG (4) 式中:P为三角形毛细管截面周长,m;rin为毛细管内切圆半径,m。

结合单个毛细管中油水流动规律和页岩孔径分布,可得页岩储层油水相对渗透率计算公式:

Kro,m=5πm∑k=1fkr4eff,k6n∑k=1fkr2in,kAk (5) Krw,m=20m∑k=1fk(14G−π)r4d,k3βn∑k=1fkr2in,kAk+n∑k=m+1fkr2in,kAkn∑k=1fkr2in,kAk (6) Sw,m=m∑k=1fk(14G−π)r2d,k+14Gn∑k=m+1fkr2in,kn∑k=1fkAk (7) 式中:n为不同尺寸孔隙总数,其中,1~m为中心含水的孔隙尺寸数量,m+1~n为边缘含水的孔隙尺寸数量;Ak为第k个尺寸的毛细管截面积,m2;f k为第k个尺寸的毛细管所占比例。

因此,已知页岩储层的孔径分布后,便可根据式(5)—式(7)计算出页岩油水相对渗透率

1.2 页岩油藏油水两相渗流数学模型

考虑页岩油藏中的油水两相渗流过程,其基质和裂缝中油水两相流体质量守恒关系可统一表达为连续性方程。

\frac{\partial }{{\partial t}}\left( {\phi {\rho _\beta }{S_\beta }} \right) = - \nabla \cdot \left( {{\rho _\beta }{{\boldsymbol{v}}_\beta }} \right) + {q_\beta } (8) 式中:β为o或w,代表油相或水相;ϕ为孔隙度;ρβ为β相流体的密度,kg/m3;Sβ为β相流体饱和度;qβ为β相流体的源汇项,kg/(m3·s);vβ为β相流体的渗流速度,m/s。

考虑页岩中流体流动的最小启动压力梯度效应,用非线性渗流模型描述基质中油水两相流动[21]。裂缝中通常不存在启动压力梯度效应,因此采用常规达西定律描述裂缝内的油水两相流动过程:

{{\boldsymbol{v}}_\beta } = - \frac{{K{K_{{\text{r}}\beta }}}}{{{\mu _\beta }}}\nabla {\psi _\beta }\left( {1 - \frac{{\text{1}}}{{a + b\left| {\nabla {\psi _\beta }} \right|}}} \right) (9) \psi_\beta=p_\beta-\rho_\beta \mathrm{g} h (10) 式中:K为绝对渗透率,m2;Krβ为β相流体的相对渗透率;b为拟启动压力梯度的倒数,(Pa/m)−1;a为非线性渗流凹形曲线段的影响因子;ψβ 为β相流体的流动势,Pa;pβ为β相流体压力,Pa;h为深度,m。

1.3 页岩油藏渗流模型求解方法

为了高效求解页岩油藏油水两相流体流动,基于嵌入式离散裂缝模型对体积压裂后页岩油藏中复杂裂缝进行几何离散和网格剖分(见图1)。对于给定的体积压裂页岩油藏模型,采用结构化网格对基质区域进行剖分,将水力压裂缝和天然裂缝网络嵌入至剖分后的结构化网格中,利用结构化网格边界切割裂缝网络,形成离散裂缝网格单元,综合形成页岩油藏数值模拟的网格单元系统。

基于网格单元系统,采用有限体积法对油水两相渗流模型进行数值离散,并推导得到离散方程的残差形式:

\begin{split} R_{\beta ,i}^{t + 1} = &\sum\limits_{j \in {\eta _i}} {\left[ {\left( {{\rho _\beta }{\lambda _\beta }} \right)_{ij + \frac{1}{2}}^{t + 1}T_{ij}^{t + 1}\left( {\psi _{\beta j}^{t + 1} - \psi _{\beta i}^{t + 1}} \right)\left( {1 - \gamma _{ij}^{t + 1}} \right)} \right]} + \\ &\left( {V{q_\beta }} \right)_i^{t + 1} - \frac{{\left( {V\phi {\rho _\beta }{S_\beta }} \right)_i^{t + 1} - \left( {V\phi {\rho _\beta }{S_\beta }} \right)_i^t}}{{\Delta t}} \end{split} (11) 式中:

ij+\dfrac{1}{2} 表示单元i和j界面上的加权平均;Rβ,i为单元i中β相连续性方程的残差,kg/s;ηi为单元i的邻近单元集合;t+1为当前时间步;t为上一时间步;Δt为当前时间步长,s;V为单元体积,m3;λ为流度,定义为λ= Kr /μ,(Pa·s)−1;Tij为单元i和j间的传导率,可分为基质和裂缝不同介质单元组合间的传导率[22-23];γij为启动压力梯度引起的附加阻力系数。{\gamma _{ij}} = \frac{1}{{a + \dfrac{{b\left| {\psi _{\beta j}^{t + 1} - \psi _{\beta i}^{t + 1}} \right|}}{{{d_{ij}}}}}} (12) 式中:dij为单元i和j间的距离,m。

采用牛顿-拉夫森方法求解离散的残差方程。

\sum\limits_c {\frac{{\partial R_{\beta ,i}^{t + 1}\left( {{\boldsymbol{x}}_k^{t + 1}} \right)}}{{\partial {x_c}}}} \delta {x_{c,k + 1}} = - R_{\beta ,i}^{t + 1}\left( {{\boldsymbol{x}}_k^{t + 1}} \right) (13) {\boldsymbol{x}}_{k + 1}^{t + 1} = {\boldsymbol{x}}_k^{t + 1} + {\mathbf{\delta }}{{\boldsymbol{x}}_{k + 1}} (14) 式中:k为迭代层次;c为主变量向量元素;x为主变量向量,选取油相压力和含水饱和度为主变量。

在每个时间步中,采用上述求解格式进行迭代计算,并更新主变量至残差向量的范数小于设定的允许误差,进入下一个时间步进行计算。

2. 页岩油藏压裂液分布及产能模拟分析

2.1 页岩油藏油水相对渗透率计算

选取单峰型孔径分布和双峰型孔径分布2种典型孔径分布页岩(见图2),在孔隙形状参数相同的基础上,采用页岩油藏相渗计算方法计算油水相对渗透率,结果见图3。由图3可知,相比于单峰型孔径分布,双峰型孔径分布的孔隙尺寸更大,油相的流动能力更强。因此,双峰型孔径分布的页岩储层油相相对渗透率更大,水相相对渗透率更小。

2.2 页岩油藏压裂液分布特征分析

为分析压裂过程中压裂液的分布特征,基于胜利油田某页岩油井地质及压裂设计资料,结合嵌入式离散裂缝模型,建立体积压裂页岩油藏模型(见图4)。该页岩油藏基质孔隙度7.0%,渗透率0.5 μD;水力裂缝开度为4 mm,渗透率为5 D;天然裂缝开度为0.3 mm,渗透率0.1 D;初始油藏压力40 MPa,初始含水饱和度为0.05,油相和水相的黏度分别为0.40和0.25 mPa∙s,压裂液注入量为1.0×104 m3,压裂后闷井时间为30 d,油水相对渗透率曲线采用图3中单峰型孔径分布的计算结果。注入压裂液后的页岩油藏基质、裂缝中的压力和含水饱和度分布模拟结果如图5所示,压裂结束闷井30 d后的基质、裂缝中的压力和含水饱和度分布则如图6所示。

从图5和图6可以看出,压裂液主要进入压裂缝及其周边天然裂缝和基质中,引起近水力裂缝周边区域压力升高,该区域裂缝内含水饱和度显著上升,近水力裂缝基质内含水饱和度有所提升。进入闷井阶段后,裂缝和基质中的压力逐渐向周围区域耗散,近水力裂缝高压区域内的压力逐渐降低。同时,裂缝内的压裂液在毛细管力作用下渗吸进入基质,裂缝内含水饱和度降低,对基质中的原油产生一定的渗吸置换作用。

2.3 页岩油藏压后产能分析

在压裂液注入和闷井的模拟结果基础上,开展页岩油藏压后产能数值模拟,对页岩油藏衰竭开发动用范围和产油量进行评价。衰竭开发1 000 d后的储层基质和裂缝中的压力和含油饱和度分布如图7所示。经体积压裂后的页岩油藏裂缝网络发育,衰竭开发过程中油藏动用程度高,天然裂缝发育范围内基本可以动用开发。此外,衰竭开发后裂缝内含水量低,但基质内的含水饱和度分布与生产前差异不大,其原因在于压裂液在毛管力作用下滞留在基质中,生产压差难以克服毛管阻力,这也解释了实际页岩储层压裂后压裂液返排率低的现象。页岩油藏生产1 000 d的日产油量和累计产油量曲线如图8所示。体积压裂页岩油藏衰竭开发产量递减速度快,经1 000 d开发后油井累计产油量可达61 145 m3。此外,开发过程中累计产水量为3 335 m3,忽略地层水产出,计算得出压裂液反排率为33%,与现场实际基本符合。由此可见,受页岩油水两相渗流特性及毛管力作用影响,页岩储层压裂后压裂液返排率较低,但体积压裂后的页岩油藏动用程度较好。

3. 结 论

1)考虑页岩孔隙结构作用下油水两相渗流特性,压裂页岩油藏产能数值模拟方法可实现页岩油藏油水相对渗透率、压裂液分布和返排以及油井产能的全流程评价。

2)基于页岩储层孔径分布以及孔隙结构参数,采用毛细管模型可得到页岩油藏油水相对渗透率,不同页岩孔径分布下油水相对渗透率存在较大差异。

3)压裂液主要分布于压裂缝及其周边的天然裂缝和基质中,闷井阶段进入周边基质,基质毛管阻力作用导致压裂液返排率较低,但体积压裂后的页岩油藏动用范围和程度较好。

-

表 1 越洋钻探公司深水钻井平台/钻井船关键装备性能参数

Table 1 Key equipment performance parameters of TransOcean Deepwater Drilling Platform/Ship

装备

类型设备名称 性能参数 动力

装备柴油

发电机4~6台,总功率20 000~48 000 kW,配合直流发电机驱动,主动力 1~2台,总功率500~2 500 kW,配合直流发电机驱动,应急动力 钻机

装备钻机大钩 主载荷9 060~12 700 kN ,辅助载荷

0~12 000 kN绞车 1~2台,载荷10 000~12 500 kN 顶驱 NOV TD-100或TD125型,1~2台,最大钩载10 000~12 500 kN,最大转速250~280 r/min,最大连续输出扭矩88~137 kN·m,冲管承压上限51.6 MPa 钻井泵 NOV 2200HP Triplex型,4~5 台,承压上限51.6 MPa 高压管汇 承压上限51.6 MPa 固控设备 2~6台300目振动筛,除砂除泥一体机,中高速离心机等 防喷

装备闸板

防喷器NOV或Cameron公司五至七闸板防喷器1台,压力等级105 MPa 环形

防喷器NOV或Cameron公司环形防喷器2台,压力等级70 MPa 表 2 典型万米级特深井钻井应用的关键钻具

Table 2 Key drilling tools used in typical 10 000-meter ultra-deep wells

开次 井眼直径/

mm垂深/m 关键钻具 最大

井斜/(°)最大狗腿度/

((°)·(30m)−1)导管 762.0 0~2 224 螺杆 0.35 0.09 一开 660.4 2 224~2 771 旋导 1.22 0.82 二开 460.4×533.4 2 771~3 536 旋导+随钻扩眼工具 0.09 0.10 三开 419.1×482.6 3 536~5 212 旋导+随钻扩眼工具 0.17 0.17 四开 368.3×400.1 5 212~7 162 旋导+随钻扩眼工具 0.37 0.53 五开 311.1×342.9 7 162~7 681 旋导+随钻扩眼工具 0.31 0.40 六开 269.9 7 681~8 716 旋导 0.06 0.06 表 3 典型万米级特深井不同井段应用的钻杆

Table 3 Drill pipes used in typical 10 000-meter ultra-deep wells at different sections

开次 井眼直径/mm 井深/m 钻杆钢级 钻杆直径/mm 导管 一开 660.4 2743 S135 168.3 二开 457.2×558.8 2743~3962 S135 三开 419.1×508.0 3962~5790 S135 四开 368.3×419.1 5790~7620 S135 五开 311.1×342.9 7620~8230 S135 168.3+149.2 六开 269.9×311.1 8230~8841 S135 七开 215.9×250.8 8 841~10360 S135 168.3+149.2+139.7 表 4 多口典型万米级特深井不同尺寸井眼下的钻井参数

Table 4 Drilling parameters used in wellbore with different sizes of typical 10 000-meter ultra-deep wells

开次 地层 井眼直径/mm 钻具组合 井深/m 钻压/kN 转速/

(r·min−1)扭矩/

(kN·m)排量/

(L·s−1)立压/

MPa钻速/

(m·h−1)一开 泥线—盐上 660.4 PDC钻头+旋导 2316~3383 40~70 150 13~23 82 28~30 25~33 一开 泥线—盐上 660.4 复合钻头+旋导 2073~2438 40~70 150 6~13 74~88 18~21 76~127 一开 盐膏层 660.4 复合钻头+旋导 2438~3048 260~280 150 40~47 75~88 21~25 38~40 二开 盐膏层 419.1×558.8 PDC钻头+旋导+随钻扩眼工具 3718~5669 170~250 180 47~68 75 34~40 76~96 二开 盐膏层 419.1 复合钻头+旋导 3048~6035 300~350 160 40~54 56 21~28 45~50 三开 盐膏层 469.9×533.4 PDC钻头+随钻扩眼工具 5943~6401 140~250 150~160 54~67 30~38 四开 盐下 250.8×269.9 复合钻头+随钻扩眼工具 7620~8839 130~250 130~180 20~50 30~33 30~35 12~20 四开 盐下 250.8×269.9 复合钻头+随钻扩眼工具 7620~9144 130~250 110~140 25~44 36 27~35 12~54 -

[1] 王兆明,温志新,贺正军,等. 全球近10年油气勘探新进展特点与启示[J]. 中国石油勘探,2022,27(2):27–37. WANG Zhaoming, WEN Zhixin, HE Zhengjun, et al. Characteristics and enlightenment of new progress in global oil and gas exploration in recent ten years[J]. China Petroleum Exploration, 2022, 27(2): 27–37.

[2] 赵文智,窦立荣. 中国陆上剩余油气资源潜力及其分布和勘探对策[J]. 石油勘探与开发,2001,28(1):1–5. ZHAO Wenzhi, DOU Lirong. Potential, distribution and exploration strategy of petroleum resources remained onshore China[J]. Petroleum Exploration and Development, 2001, 28(1): 1–5.

[3] 苏义脑,路保平,刘岩生,等. 中国陆上深井超深井钻完井技术现状及攻关建议[J]. 石油钻采工艺,2020,42(5):527–542. SU Yinao, LU Baoping, LIU Yansheng, et al. Status and research suggestions on the drilling and completion technologies for onshore deep and ultra deep wells in China[J]. Oil Drilling & Production Technology, 2020, 42(5): 527–542.

[4] 汪海阁,黄洪春,毕文欣,等. 深井超深井油气钻井技术进展与展望[J]. 天然气工业,2021,41(8):163–177. doi: 10.3787/j.issn.1000-0976.2021.08.015 WANG Haige, HUANG Hongchun, BI Wenxin, et al. Deep and ultra-deep oil/gas well drilling technologies: progress and prospect[J]. Natural Gas Industry, 2021, 41(8): 163–177. doi: 10.3787/j.issn.1000-0976.2021.08.015

[5] 汪海阁,黄洪春,纪国栋,等. 中国石油深井、超深井和水平井钻完井技术进展与挑战[J]. 中国石油勘探,2023,28(3):1–11. WANG Haige, HUANG Hongchun, JI Guodong, et al. Progress and challenges of drilling and completion technologies for deep, ultra-deep and horizontal wells of CNPC[J]. China Petroleum Exploration, 2023, 28(3): 1–11.

[6] WEATHERL M H. GOM deepwater field development challenges at Green Canyon 468 Pony[R]. SPE 137220, 2010.

[7] 赵阳,卢景美,刘学考,等. 墨西哥湾深水油气勘探研究特点与发展趋势[J]. 海洋地质前沿,2014,30(6):27–32. ZHAO Yang, LU Jingmei, LIU Xuekao, et al. Oil and gas exploration in deep water area of Gulf of Mexico[J]. Marine Geology Frontiers, 2014, 30(6): 27–32.

[8] TAYLOR S, HINER M. Permanent borehole seismic in ultra deep offshore appraisal wells[R]. OTC 22580, 2011.

[9] CUNHA J C, MOREIRA O, AZEVEDO G H, et al. Challenges on drilling and completion operations of deep wells in ultra-deepwater zones in the Gulf of Mexico[R]. SPE 125111, 2009.

[10] 张兴文. 墨西哥湾盆地深部油气藏地质特征、形成条件及成藏模式[D]. 北京:中国石油大学(北京),2021. ZHANG Xingwen. Geological characteristics, formation conditions and accumulation models of deep and ultra-deep oil and gas in the Gulf of Mexico Basin[D]. Beijing: China University of Petroleum(Beijing), 2021.

[11] 张兴文,庞雄奇,李才俊,等. 深层—超深层高孔高渗碎屑岩油气藏地质特征、形成条件及成藏模式:以墨西哥湾盆地为例[J]. 石油学报,2021,42(4):466–480. ZHANG Xingwen, PANG Xiongqi, LI Caijun, et al. Geological characteristics, formation conditions and accumulation model of deep and ultra-deep, high-porosity and high-permeability clastic reservoirs: a case study of Gulf of Mexico Basin[J]. Acta Petrolei Sinica, 2021, 42(4): 466–480.

[12] CHAVEZ M A, GARCIA G A, POGOSON O, et al. Lower tertiary: a fully comprehensive well completion design methodology to overcome reservoir challenges[R]. SPE 165062, 2013.

[13] 卢景美,张金川,严杰,等. 墨西哥湾北部深水区Wilcox沉积特征及沉积模式研究[J]. 沉积学报,2014,32(6):1132–1139. LU Jingmei, ZHANG Jinchuan, YAN Jie, et al. Study on depositional characteristics and model of Wilcox in the deep waters of northern Gulf of Mexico[J]. Acta Sedimentologica Sinica, 2014, 32(6): 1132–1139.

[14] 何保生,张钦岳,冷雪霜. 墨西哥超深水盐下钻井技术及实践[J]. 中国海上油气,2021,33(6):101–109. HE Baosheng, ZHANG Qinyue, LENG Xueshuang. Ultra deepwater pre-salt drilling technologies and their practices in Mexico[J]. China Offshore Oil and Gas, 2021, 33(6): 101–109.

[15] 张星星,黄小龙,严德,等. 墨西哥湾深水岩膏地层钻井实践[J]. 石油钻采工艺,2015,37(1):99–102. ZHANG Xingxing, HUANG Xiaolong, YAN De, et al. Drilling practices of deepwater salt rock stratum in Gulf of Mexico[J]. Oil Drilling & Production Technology, 2015, 37(1): 99–102.

[16] MALDONADO B, ARRAZOLA A, MORTON B. Ultradeep HP/HT completions: classification, design methodologies, and technical challenges[R]. OTC 17927, 2006.

[17] MATHUR R, SEILER N, SRINIVASAN A, et al. Opportunities and challenges of deepwater subsalt drilling[R]. SPE 127687, 2010.

[18] KUNNING J, WU Yafei, THOMSON I J, et al. Non-retrievable rotating liner drilling system successfully deployed to overcome challenging highly stressed rubble zone in a GOM ultra-deepwater sub-salt application[R]. SPE 124854, 2009.

[19] ALI T H, MATHUR R, SHARMA N. Build-to-suit technologies for wellbore construction in deepwater and ultradeepwater Gulf of Mexico[R]. SPE 136840, 2010.

[20] CHAMAT E, ISRAEL R. Efficient and reliable vertical drilling of top holes with RSS in deepwater GOM[R]. SPE 151395, 2012.

[21] PRASAD U, ROY CHOWDHURY A, ANDERSON M. Drilling mechanics analysis of record hybrid drill bit runs in Gulf of Mexico salt formation and its correlation with rock-mechanical properties of salt[R]. SPE 195860, 2019.

[22] UBARU C, THOMSON I, RADFORD S. Drilling and under-reaming in the GOM deepwater ultradeep lower tertiary: history of a record run in the world’s deepest oil or gas well[R]. SPE 145259, 2011.

[23] BARKER J W. Wellbore design with reduced clearance between casing strings[R]. SPE 37615, 1997.

[24] ROSENBERG S M, GALA D M. Liner drilling technology as a tool to reduce NPT-Gulf of Mexico experiences[R]. SPE 146158, 2011.

[25] YI Xianjie, CORBIN K, DAVIS J, et al. Solving deepwater GoM pore pressure puzzle: multiple activation reamer eliminates trip prior to running coring bottomhole assembly[R]. SPE 167916, 2014.

[26] FILIPPOV A, MACK R, COOK L, et al. Expandable tubular solutions[R]. SPE 56500, 1999.

[27] BULLOCK M, RUZIC N, PEREZ M, et al. High performance solid expandables for deepwater[R]. SPE 170257, 2014.

[28] TOUBOUL N, WOMBLE L, KOTRLA J, et al. New technologies combine to reduce drilling costs in ultradeepwater applications[R]. SPE 90830, 2004.

[29] NYLUND J, FLAMING S, MITRUSHI K. Power of design: solid expandable installation sets multiple new records in deepshelf HP/HT well[R]. SPE 128366, 2010.

[30] CRUZ E J, BAKER R V, YORK P, et al. Mitigating sub-salt rubble zones using high collapse, cost effective solid expandable Monobore systems[R]. OTC 19008, 2007.

[31] SIDDIQUI A A, KARIMI M. Including enabling technologies in the wellbore construction basis of design: smart strategy to benefit from casing while drilling, open-hole expandable liners, and liner drilling[R]. OTC 24089, 2013.

[32] WHITSON C D, MCFADYEN M K. Lessons learned in the planning and drilling of deep, subsalt wells in the deepwater Gulf of Mexico[R]. SPE 71363, 2001.

[33] MOYER M C, LEWIS S B, COTTON M T, et al. Challenges associated with drilling a deepwater, subsalt exploration well in the Gulf of Mexico: Hadrian prospect[R]. SPE 154928, 2012.

[34] SHAUGHNESSY J, DAUGHERTY W, GRAFF R, et al. More ultra-deepwater drilling problems[R]. SPE 105792, 2007.

[35] WILLIAMS C, MASON J S, SPAAR J. Operational efficiency on eight-well sidetrack program saves $7.3 million vs historical offsets in MP 299/144 GOM[R]. SPE 67826, 2001.

[36] SOARES C, ARMENTA M, PANCHAL N. Enhancing reamer drilling performance in deepwater Gulf of Mexico wells[J]. SPE Drilling & Completion, 2020, 35(3): 329–356.

[37] ROY CHOWDHURY A, SERRANO R, RODRIGUE W. Pilot bit and reamer matching: real-time downhole data differentiates hybrid drill bit’s suitability with concentric reamer in deepwater, Gulf of Mexico application[R]. SPE 194060, 2019.

[38] EDWARDS H, VAN NOORT R, CLAIRMONT B, et al. Modeling system improves salt drilling technique with concentric reamer/RSS, deepwater GoM[R]. SPE 158920, 2012.

[39] JELLISON M, CHANDLER R B, LANGDON S, et al. Deepwater and critical drilling with new connection technology: case histories and lessons learned[R]. SPE 133857, 2010.

[40] ROHLEDER S A, SANDERS W W, WILLIAMSON R N, et al. Challenges of drilling an ultra-deep well in deepwater: Spa Prospect[R]. SPE 79810, 2003.

[41] D'AMBROSIO P, PROCHASKA E, BOUSKA R, et al. Cost effective ultra-large diameter PDC bit drilling in deepwater Gulf of Mexico[R]. SPE 163448, 2013.

[42] RAMIREZ S, AGUILAR R, GONZALEZ L F, et al. Evolution of rotary steerable BHA designs in Mexico offshore: solution to stop multiple drillstring failures in high-vibration environment[R]. SPE 138963, 2010.

[43] DYKSTRA M W, ARMENTA M A, AIN F A M, et al. Converting power to performance: Gulf of Mexico examples of an optimization workflow for bit selection, drilling system design and operation[R]. OTC 29065, 2018.

[44] CHOWDHURY A R, CALLAIS R, ROTHE M, et al. Mitigating salt and sub-salt drilling challenges using hybrid bit technology in deepwater, Gulf of Mexico[R]. SPE 180342, 2016.

[45] HAVARD K, DURAIRAJAN B, STITH S, et al. Collaborative bit and reamer design solution for performance drilling in salt and high durability in challenging subsalt interval in one run, deepwater Gulf of Mexico[R]. OTC 29783, 2019.

[46] 韩天旺. 双梯度钻井条件下深水井身结构设计优化研究[D]. 北京:中国石油大学(北京),2020. HAN Tianwang. Optimal design of deepwater well structure with dual gradient drilling technology[D]. Beijing: China University of Petroleum (Beijing), 2020.

[47] HARIHARAN P R, JUDGE R A. The economic analysis of a two-rig approach to drill in deepwater Gulf of Mexico using dual gradient pumping technology[R]. SPE 84272, 2003.

[48] SCHUBERT J J, JUVKAM-WOLD H C, CHOE J. Well-control procedures for dual gradient drilling as compared to conventional riser drilling[J]. SPE Drilling & Completion, 2006, 21(4): 287–295.

[49] ZIEGLER R, SABRI M S, IDRIS M R, et al. First successful commercial application of dual gradient drilling in ultra-deepwater GOM[R]. SPE 166272, 2013.

[50] DOWELL J D. Deploying the world’s first commercial dual gradient drilling system[R]. SPE 137319, 2010.

[51] STAVE R. Implementation of dual gradient drilling[R]. OTC 25222, 2014.

[52] ZIEGLER R. Dual gradient drilling is ready for primetime: the benefits of a retrofit system for better well control, enhanced water depth capability and flat time reduction[R]. OTC 25267, 2014.

[53] CHUSTZ M J, MAY J, WALLACE C, et al. Managed-pressure drilling with dynamic annular pressure-control system proves successful in redevelopment program on auger TLP in deepwater Gulf of Mexico[R]. SPE 108348, 2007.

[54] RAMIREZ S, AGUILAR R, HERRERA R, et al. First MPD automated system application in offshore Gulf of Mexico well confirms method, huge benefits[R]. SPE 138907, 2010.

[55] SAMUEL N, SANTOS H, VALLURI S. First deepwater MPD operation in the Gulf of Mexico: challenges and lessons learned[R]. SPE 180324, 2016.

[56] HERNANDEZ J, ARNONE M, VALECILLOS J, et al. Using managed pressure drilling and early kick/loss detection system to execute a challenging deepwater completions job in the Gulf of Mexico[R]. SPE 194554, 2019.

[57] TEOH M, MOGHAZY S, SMELKER K, et al. Managed pressure cementing MPC within a narrow pressure window, deepwater Gulf of Mexico application[R]. SPE 194536, 2019.

[58] VACZI K, MORALES D, CHIMA C. Implementation of MPD systems in the deepwater Gulf of Mexico to drill highly depleted reservoir sections[R]. SPE 208771, 2022.

[59] TUCKWELL N, NABIYEV A, PARKER M, et al. MPD during the global pandemic in the Gulf of Mexico: how virtual meetings, planning, and communication facilitated a safe and successful implementation of CBHP MPD[R]. SPE 206392, 2021.

[60] TUCKWELL N, ARNONE M. Real-time downhole pressure environment determination during managed pressure drilling, tripping, and cementing operations to improve well construction safety standards in deepwater Gulf of Mexico[R]. SPE 210541, 2022.

[61] ARMENTA M, DYKSTRA M, MUESEL J, et al. Delivering best in class ROP performance by pushing the operational envelope with novel advanced bit designs[R]. SPE 191730, 2018.

[62] RAHMANI R, OMIDVAR N, HANLEY C. Novel drill bit technology combined with system matcher increases torque efficiency and reduces stick-slip and vibrations[R]. SPE 189671, 2018.

[63] ROY CHOWDHURY A, SERRANO R, MARTIN B, et al. Self-adaptive depth of cut control technology: a path-breaking approach to address torsional dysfunction and securing drilling performance gain in challenging deepwater Gulf of Mexico well[R]. SPE 191510, 2018.

[64] RODRIGUE W, CALLAIS R, ROY CHOWDHURY A. Self-adjusting PDC bits reduce drilling dysfunction, increase drilling efficiency in Gulf of Mexico wells[R]. SPE 194128, 2019.

[65] CHOWDHURY A R, CALLAIS R, RODRIGUE W, et al. Meeting the large-diameter drilling challenges and securing sustainable performance gains using hybrid bit technology in deepwater Gulf of Mexico[R]. SPE 187052, 2017.

[66] MCCARTHY J, KABBARA A, BURNETT T, et al. Careful planning and application of an asymmetric vibration damping tool dramatically improves underreaming while drilling performance in deepwater drilling[R]. SPE 156164, 2012.

[67] GAINES M, MORRISON R D, HERRINGTON D. Step change drilling technology modifies drill string dynamics and results in reduced drilling vibrations[R]. SPE 166445, 2013.

[68] AMORIM D, HANLEY C, LEITE D J. BHA selection and parameter definition using vibration prediction software leads to significant drilling performance improvements[R]. SPE 152231, 2012.

[69] COMPTON M, VERANO F, NELSON G, et al. Managing downhole vibrations for hole-enlargement-while-drilling in deepwater environment: a proven approach utilizing drillstring dynamics model[R]. SPE 139234, 2010.

[70] ALGU D R, DENHAM W, NELSON G, et al. Maximizing hole enlargement while drilling (HEWD) performance with state-of-the-art BHA dynamic analysis program and operation road map[R]. SPE 115607, 2008.

[71] PLUTT L A J, PERE A L, PARDO N O, et al. Achieving improved performance through drilling optimization and vibration management at a GoM development project[R]. SPE 119299, 2009.

[72] PEREIRA R, CARDOZO J, BOGAERTS M, et al. Use of surfactant in cement slurry to mitigate incompatibility with synthetic-based drilling fluids[R]. OTC 27902, 2017.

[73] DIEFFENBAUGHER J, DUPRE R, AUTHEMENT G, et al. Drilling fluids planning and execution for a world record water depth well[R]. SPE 92587, 2005.

[74] JAIMES J P, CROY S, BOUGUETTA M, et al. Drilling fluids design and field deployment for the first HTHP deepwater production project in the US Gulf of Mexico[R]. SPE 208668, 2022.

[75] MCBEE J, EVANS B, UMBHER K. Lessons learned on Gulf of Mexico gas wells drilled with OBM and completed with heavy brine[R]. SPE 109589, 2007.

[76] VAN OORT E, LEE J, FRIEDHEIM J, et al. New flat-rheology synthetic-based mud for improved deepwater drilling[R]. SPE 90987, 2004.

[77] CLAPPER D K, SZABO J J, SPENCE S, et al. One sack rapid mix and pump solution to severe lost circulation[R]. SPE 139817, 2011.

[78] DARUGAR Q A, SZABO J J, CLAPPER D K, et al. Single-sack fibrous pill treatment for high fluid loss zones[R]. SPE 149120, 2011.

[79] VAN OORT E, FRIEDHEIM J, PIERCE T, et al. Avoiding losses in depleted and weak zones by constantly strengthening wellbores[J]. SPE Drilling & Completion, 2011, 26(4): 519–530.

[80] OAKLEY D, CONN L. Drilling fluid design enlarges the hydraulic operating windows of managed pressure drilling operations[R]. SPE 139623, 2011.

[81] KAMGANG S, PIERRE A, NEUPANE R, et al. Cement evaluation case studies; application of multiphysics measurements to address different challenges in deepwater Gulf of Mexico environment[R]. OTC 31601, 2022.

[82] O’LEARY J, FLORES J C, RUBINSTEIN P, et al. Cementing deepwater, low-temperature Gulf of Mexico formations prone to shallow flows[R]. SPE 87161, 2004.

[83] DIARRA R, BOGAERTS M, ANDREWS H, et al. Low-temperature dispersant improves cement slurry properties in deepwater operations[R]. OTC 27534, 2017.

[84] FULLER G A, BOLADO D, HARDY F, et al. A Gulf of Mexico case history: benefits of foamed cementing to combat a SWF[R]. SPE 128160, 2010.

[85] FAUL R, REDDY B R, GRIFFITH J, et al. Next-generation cementing systems to control shallow water flow[R]. OTC 11977, 2000.

[86] ASLAKSON J, DOHERTY D, SMALLEY E. Preventing annular flow after cementing, one pulse at a time: offshore Gulf of Mexico cement pulsation field results[R]. SPE 94230, 2005.

[87] VALLEJO V, OLIVARES A, SALINAS D, et al. Ultra deepwater salt zone cementing in Gulf of Mexico wells[R]. OTC 27960, 2017.

[88] ZHANG Jincai, STANDIFIRD W, LENAMOND C. Casing ultradeep, ultralong salt sections in deep water: a case study for failure diagnosis and risk mitigation in record-depth well[R]. SPE 114273, 2008.

[89] HUNTER B, TAHMOURPOUR F, FAUL R. Cementing casing strings across salt zones: an overview of global best practices[J]. SPE Drilling & Completion, 2010, 25(4): 426–437.

[90] BOGAERTS M, CARDOZO J, FLAMANT N, et al. Novel 3D fluid displacement simulations improve cement job design and planning in the Gulf of Mexico[R]. SPE 196077, 2019.

[91] DOOPLY M, SIANIPAR S, RODRIGUEZ F, et al. Overcoming tight annulus cementing design challenges: Gulf of Mexico case study[R]. SPE 189687, 2018.

[92] CONTRERAS J, BOGAERTS M, GRIFFIN D, et al. Real-time monitoring and diagnoses on deepwater cement barrier placement: case studies from the Gulf of Mexico and Atlantic Canada[R]. OTC 27797, 2017.

[93] DUSSEAULT M B, MAURY V, SANFILIPPO F, et al. Drilling through salt: constitutive behavior and drilling strategies[R]. ARMA-04-608, 2004.

[94] SALEH S, WILLIAMS K E, RIZVI A. Rubble zone below salt: identification and best drilling practices[R]. SPE 166115, 2013.

[95] VICEER S, ALBERTIN M L, VINSON G, et al. Improving drilling efficiency using a look-ahead VSP to predict pressure, exiting salt: five Gulf of Mexico examples[R]. OTC 18262, 2006.

[96] HAN Gang, HUNTER K C, OSMOND J, et al. Drilling through bitumen in Gulf of Mexico: the shallower vs the deeper[R]. OTC 19307, 2008.

[97] HAN Gang, HUNTER K, RESSLER J, et al. Deepwater bitumen drilling: what happened downhole?[R]. SPE 111600, 2008.

[98] HAN Gang, OSMOND J, ZAMBONINI J. A $100MM “rock”: Bitumen in the deepwater Gulf of Mexico[R]. ARMA-09-010, 2009.

[99] RICH D, ROGERS B, DYSON W, et al. GoM deepwater completions: the devil is in the details[R]. OTC 20399, 2010.

[100] MILLHEIM K, WILLIAMS T E, YEMINGTON C R. Evaluation of well testing systems for three deepwater Gulf of Mexico (GOM) reservoir types[R]. SPE 145682, 2011.

[101] SANFORD J R, CORDEDDU C, EDWARDS W J, et al. Subsea slimhole completions in deepwater Gulf of Mexico: case histories[R]. SPE 110359, 2007.

[102] TECHENTIEN B, GRIGSBY T, FROSELL T. Current state of the one-trip multizone sand control completion system and the conundrum faced in the Gulf of Mexico lower tertiary[R]. OTC 27183, 2016.

[103] DUSTERHOFT R, STROBEL M, SZATNY M. An automated software workflow to optimize Gulf of Mexico Lower Tertiary Wilcox sand reservoirs[R]. SPE 151754, 2012.

[104] BURGER R, GRIGSBY T, ROSS C, et al. Single-trip multiple-zone completion technology has come of age and meets the challenging completion needs of the Gulf of Mexico’s deepwater lower tertiary play[R]. SPE 128323, 2010.

[105] TECHENTIEN B, INGRAM S, GROSSMANN A. The future state of completions for the lower tertiary in the Gulf of Mexico[R]. OTC 27203, 2016.

[106] OGIER K S, HADDAD Z, MOREIRA O, et al. The world’s deepest frac-pack completions using a single-trip multi-zone system: a Gulf of Mexico case study in the Lower Tertiary Formation[R]. SPE 147313, 2011.

[107] 刘岩生,张佳伟,黄洪春. 中国深层—超深层钻完井关键技术及发展方向[J]. 石油学报,2024,45(1):312–324. LIU Yansheng, ZHANG Jiawei, HUANG Hongchun. Key technologies and development direction for deep and ultra-deep drilling and completion in China[J]. Acta Petrolei Sinica, 2024, 45(1): 312–324.

[108] 陈宗琦,刘湘华,白彬珍,等. 顺北油气田特深井钻井完井技术进展与发展思考[J]. 石油钻探技术,2022,50(4):1–10. CHEN Zongqi, LIU Xianghua, BAI Binzhen, et al. Technical progress and development consideration of drilling and completion engineering for ultra-deep wells in the Shunbei Oil & Gas Field[J]. Petroleum Drilling Techniques, 2022, 50(4): 1–10.

[109] HAHN D, ATKINS M, RUSSELL J, et al. Gulf of Mexico shelf deep ultra HPHT completions-current technology gaps[R]. SPE 97560, 2005.

[110] SANDERS W, BAUMANN C E, WILLIAMS H A R, et al. Efficient perforation of high-pressure deepwater wells[R]. OTC 21758, 2011.

[111] BAUMANN C, BARNARD K, WILLIAMS H. Gunshock risk evaluation when perforating high pressure wells[R]. SPE 159119, 2012.

[112] BRINSDEN M, GAVRIC Z, LE C, et al. Perforating the largest high-pressure wells in the Gulf of Mexico[R]. OTC 26644, 2016.

-

期刊类型引用(2)

1. 郝世俊,褚志伟,李泉新,方俊,陈龙,刘建林. 煤矿井下近钻头随钻测量技术研究现状和发展趋势. 煤田地质与勘探. 2023(09): 10-19 .  百度学术

百度学术

2. 郑奕挺,宋红喜. 近钻头伽马响应特征及实验分析. 科学技术与工程. 2022(10): 3932-3940 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: