Research and Application of Environmental Protection Technologies for Drilling Fluid Treatment in Shengli Oilfield

-

摘要:

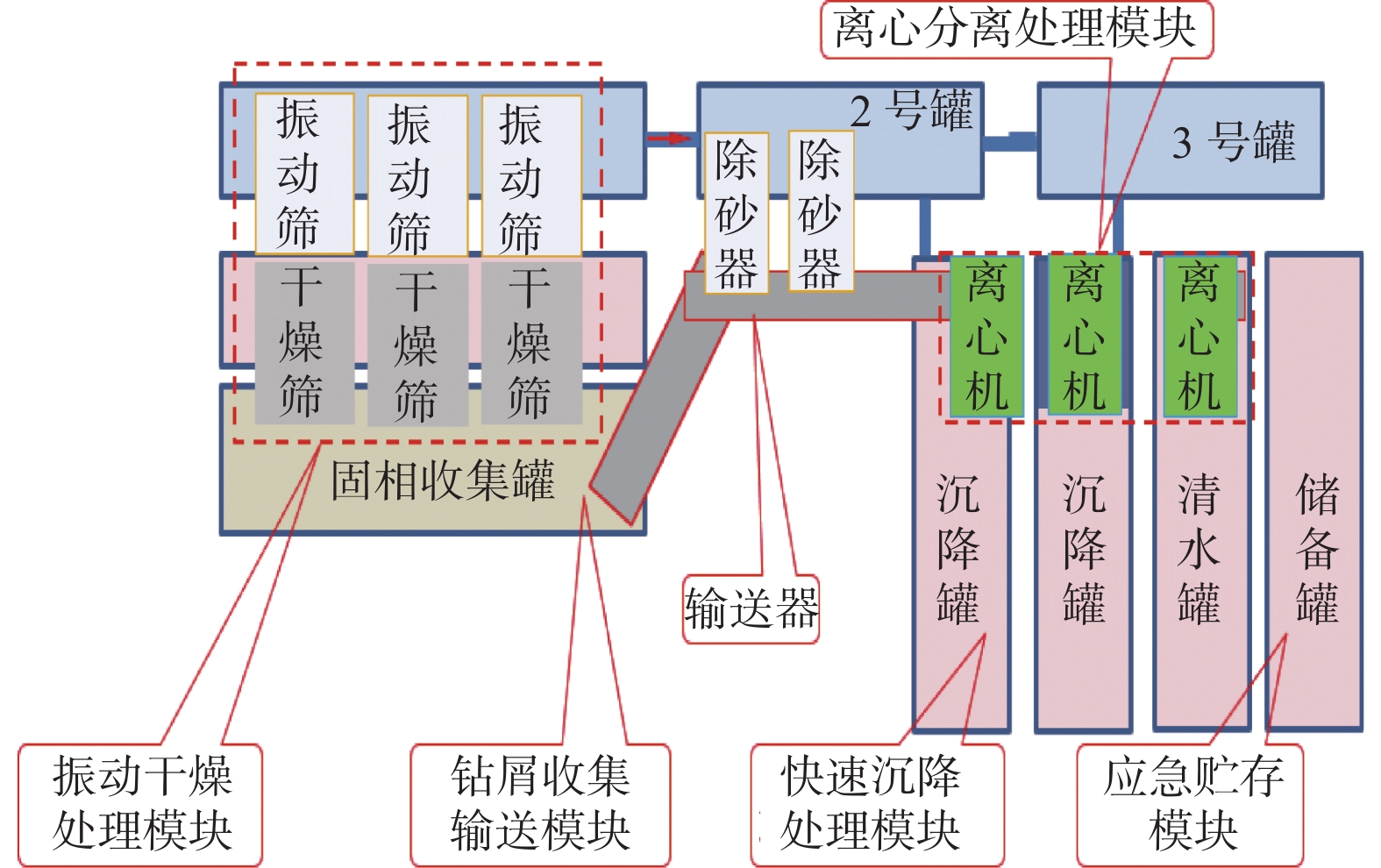

在胜利油田钻井过程中,废弃物总量大、污染物含量高,废弃物污染控制集中于末端治理,资源化利用程度低、成本高,无法实现钻井过程中的污染控制,严重影响油田生态环境。针对该油田钻井过程中的环保关键技术难题,以“减量化、无害化、资源化”为目标,进行了理论研究、装备研发、技术攻关和集成应用,形成了钻井污染物源头控制、全井段钻井废弃物随钻过程减量化和钻井废弃物末端无害化处理与资源化利用等3项核心技术,创新了覆盖“源头控制、过程减量、末端治理”的钻井液环保处理技术。“十三五”期间,该钻井液环保处理技术在胜利油区及新疆、四川等地的中国石化工区实现规模化应用,建成了胜利油田滨105、盐222、桩146等绿色低碳钻井示范工程,为保障胜利油田绿色低碳开发提供了技术支撑,也为我国陆上油气田绿色低碳开发提供了有益借鉴。

Abstract:In the drilling process of Shengli Oilfield, a large amount of drilling waste was generated, with excessive pollutants. However, the pollution control of drilling wastes in Shengli Oilfield focuses on the end treatment, with low waste resource utilization and high cost, which makes it impossible to realize the pollution control in the drilling process and seriously threatens the ecological environment of the oilfield. In order to solve the key technical problems of environmental protection in the drilling process of Shengli Oilfield, theoretical research, equipment development, technical breakthroughs, and integrated application were carried out with the goal of “pollution reduction, harmlessness, and resource utilization”. Three core technologies were formed, including control of drilling pollution source, reduction of drilling waste while drilling in the whole well section, and harm-free treatment and resource utilization of drilling waste at the end. In addition, the environmental protection technology for drilling fluid treatment covering “source control, process reduction, and end treatment” was innovated. During the “Thirteenth Five-Year Plan” period, the environmental protection technology for drilling fluid treatment was widely applied in Shengli, Sichuan, and Xinjiang Oilfields, and a series of green and low-carbon drilling demonstration projects were established in B-105, Y-222, Z-146 blocks of Shengli Oilfield, which provides technical support for the green and low-carbon development of Shengli Oilfield and a useful reference for the green and low-carbon development of onshore oilfields in China.

-

-

表 1 SLRF钻井液流变滤失性能评价结果

Table 1 Rheological and filtration property evaluation of SLRF drilling fluids

配方 实验条件 密度/

(kg·L−1)表观黏度/

(mPa·s)塑性黏度/

(mPa·s)动切力/Pa 静切力/Pa API滤失量/

mL高温高压

滤失量/mLpH值 初切 终切 SLRF 常温 1.04 35.0 22.0 13.0 8 10 3.0 9.0 SLRF 120 ℃/16 h 1.04 30.5 20.5 10.0 7 9 2.8 6.8 9.0 SLRF+10%黏土 120 ℃/16 h 1.05 40.5 25.0 15.5 9 12 3.2 7.0 8.5 表 2 SLHB钻井液流变性和滤失性评价结果

Table 2 Rheological and filtration property evaluation of SLHB drilling fluids

实验条件 密度/(kg·L−1) 表观黏度/(mPa·s) 塑性黏度/(mPa·s) 动切力/Pa 静切力/Pa API滤失量/mL 高温高压滤失量/mL pH值 初切 终切 常温 1.50 51.5 36.0 15.5 5.0 9.5 2.8 9.0 180 ℃/16 h 1.50 38.5 28.0 10.5 4.0 6.5 2.8 7.8 9.0 表 3 SLHB钻井液环保性能评价结果

Table 3 Environmental protection performance evaluation of SLHB drilling fluids

钻井液体系 EC50/(mg·L−1) 生物降解性,% 总镉含量/(mg·kg−1) 总铅含量/(mg·kg−1) 总铬含量/(mg·kg−1) SLHB体系 >50 000 9.7 0.57 24.3 13.6 聚磺体系 <10 000 1.7 20.10 127.9 104.8 评价标准 ≥30 000 ≥5.0 <15.00 <1 000.0 <1 000.0 -

[1] 何立成. 胜利油田沙河街组页岩油水平井固井技术[J]. 石油钻探技术,2022,50(2):45–50. HE Licheng. A cementing technology for horizontal shale oil wells in Shahejie Formation of Shengli Oilfield[J]. Petroleum Drilling Techniques, 2022, 50(2): 45–50.

[2] 刘文士,张烈辉,朱进,等. 四川盆地南部地区页岩气开发及其减污降碳再认识[J]. 天然气工业,2023,43(4):165–176. LIU Wenshi, ZHANG Liehui, ZHU Jin, et al. Recognition on shale gas development and its pollution and carbon reduction in the southern Sichuan Basin[J]. Natural Gas Industry, 2023, 43(4): 165–176.

[3] 王景. 临兴–神府井区废弃钻井液处理技术[J]. 石油钻探技术,2022,50(1):60–64. WANG Jing. Treatment technology of waste drilling fluids in the Linxing-Shenfu well area[J]. Petroleum Drilling Techniques, 2022, 50(1): 60–64.

[4] CUI Zhisong, LUAN Xiao, LI Shujun, et al. Genotoxicity detection of oil-containing drill cuttings by Comet assay based on a demersal marine fish Mugilogobius chulae[J]. Ecotoxicology and Environmental Safety, 2021, 208: 111655. doi: 10.1016/j.ecoenv.2020.111655

[5] 韩来聚,李公让. 胜利油田钻井环保技术进展及发展方向[J]. 石油钻探技术,2019,47(3):89–94. HAN Laiju, LI Gongrang. Progress, development trends, and outlook for drilling environmental protection technologies in the Shengli Oilfield[J]. Petroleum Drilling Techniques, 2019, 47(3): 89–94.

[6] 周启成,梁应红,单海霞,等. 抗高温高密度生物质钻井液体系研究及应用[J]. 石油钻探技术,2022,50(6):78–84. ZHOU Qicheng, LIANG Yinghong, SHAN Haixia, et al. Research and application of a high-temperature resistant and high-density biomass drilling fluid system[J]. Petroleum Drilling Techniques, 2022, 50(6): 78–84.

[7] 刘均一,郭保雨,王勇,等. 环保型水基钻井液在胜利油田的研究与应用[J]. 钻井液与完井液,2020,37(1):64–70. LIU Junyi, GUO Baoyu, WANG Yong, et al. Study and application of environmentally friendly water base drilling fluid in Shengli Oilfield[J]. Drilling Fluid & Completion Fluid, 2020, 37(1): 64–70.

[8] 于雷,张敬辉,李公让,等. 低活度强抑制封堵钻井液研究与应用[J]. 石油钻探技术,2018,46(1):44–48. YU Lei, ZHANG Jinghui, LI Gongrang, et al. Research and application of plugging drilling fluid with low-activity and high inhibition properties[J]. Petroleum Drilling Techniques, 2018, 46(1): 44–48.

[9] LIU Junyi, GUO Baoyu, LI Gongrang, et al. Synthesis and performance of environmental-friendly starch-based filtrate reducers for water-based drilling fluids[J]. Fresenius Environmental Bulletin, 2019, 28(7): 5618–5623.

[10] 孙露露,耿晓光,宋涛,等. 响应面优化深层废弃水基钻井液无害化处理工艺[J]. 钻井液与完井液,2022,39(3):327–333. SUN Lulu, GENG Xiaoguang, SONG Tao, et al. Response surface optimization of biosafety disposal of waste water based drilling fluids for deep drilling[J]. Drilling Fluid & Completion Fluid, 2022, 39(3): 327–333.

[11] 周佰刚,马孟磊,杨暕暕,等. 废弃水基钻井液不落地高效处理技术研究[J]. 钻采工艺,2021,44(3):108–111. ZHOU Baigang, MA Menglei, YANG Jianjian, et al. Study on high efficiency treatment technology of waste water-based drilling fluid without landing[J]. Drilling & Production Technology, 2021, 44(3): 108–111.

[12] 蒋卓,曹砚锋,王荐,等. 环保型易脱稳钻井液技术[J]. 钻井液与完井液,2020,37(2):180–184. JIANG Zhuo, CAO Yanfeng, WANG Jian, et al. Study on environmentally friendly easy-to-destabilize drilling fluid technology[J]. Drilling Fluid & Completion Fluid, 2020, 37(2): 180–184.

[13] 李新亮,蒋官澄,彭双磊,等. 长链烷烃季铵盐DODMAC对钻井液中劣质固相的絮凝作用[J]. 油田化学,2017,34(3):397–401. LI Xinliang, JIANG Guancheng, PENG Shuanglei, et al. Flocculation performance of long chain alkyl quarternary ammonium salt DODMAC for inferior solid phase in the drilling fluid[J]. Oilfield Chemistry, 2017, 34(3): 397–401.

[14] 江丽,刘春艳,王红娟,等. 国内外页岩气开发环境管理现状及对比[J]. 天然气工业,2021,41(12):146–155. JIANG Li, LIU Chunyan, WANG Hongjuan, et al. Domestic and foreign environmental management of shale gas development: status and comparison[J]. Natural Gas Industry, 2021, 41(12): 146–155.

[15] 田文欣,俞浩杰. 页岩储层高性能环保型水基钻井液体系及其环境影响评价[J]. 断块油气田,2023,30(1):38–43. TIAN Wenxin, YU Haojie. High performance and environment-friendly water-based drilling fluid for shale reservoir and its environmental impact assessment[J]. Fault-Block Oil & Gas Field, 2023, 30(1): 38–43.

[16] HUANG Weian, LEI Ming, LI Gongrang, et al. Surface coating on solidified water-based drilling waste materials and its mechanism for resource reuse[J]. Journal of Chemical Technology and Biotechnology, 2020, 95(8): 2149–2158. doi: 10.1002/jctb.6400

-

期刊类型引用(5)

1. 江锚,吴建树,彭成勇,马伟云,白玉湖,杨帆. 致密气不同类型甜点对水平井压裂产能影响规律. 科学技术与工程. 2025(11): 4515-4525 .  百度学术

百度学术

2. 尹帅,赵军辉,刘平,沈志成. 裂缝性储层天然缝与水力缝开启条件及扩展规律研究. 石油钻探技术. 2024(03): 98-105 .  本站查看

本站查看

3. 刘善勇,尹彪,楼一珊,张艳. 粗糙裂缝内支撑剂运移与展布规律数值模拟. 石油钻探技术. 2024(04): 104-109 .  本站查看

本站查看

4. 刘顺,刘建斌,陈鑫,周志祥,黄凯,杜恒毅,张亚龙,王宗振. 耐温自降解暂憋剂性能影响因素实验. 特种油气藏. 2024(06): 145-150 .  百度学术

百度学术

5. 石明星,李沁,邱思杨,雷雲,敬伟. 压裂时天然裂缝对储层温度分布的影响. 钻井液与完井液. 2023(04): 540-550 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: