Research and Field Test of Electrically Controlled Sidewall Deep Penetrating Perforating Technology

-

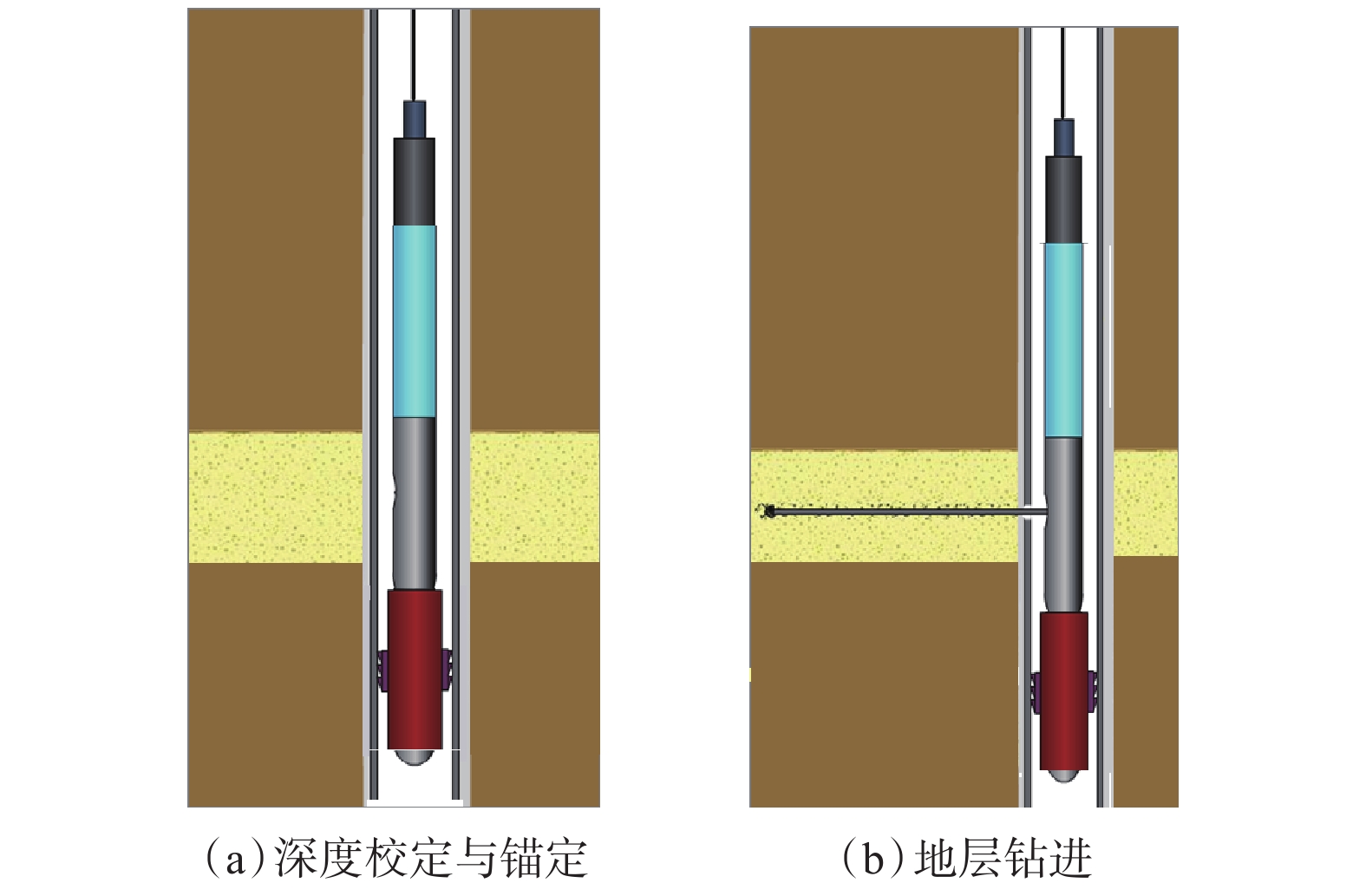

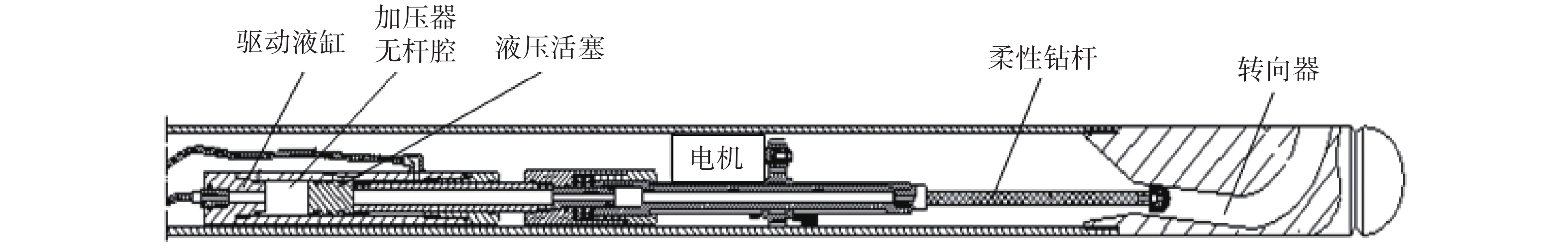

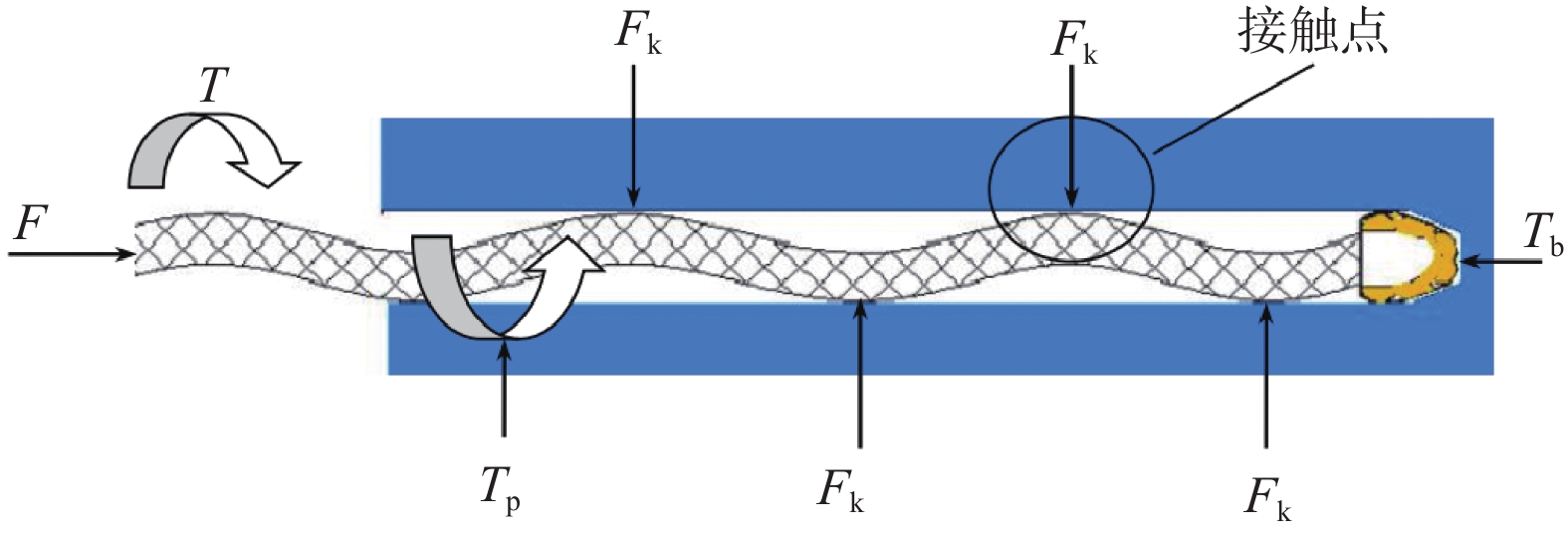

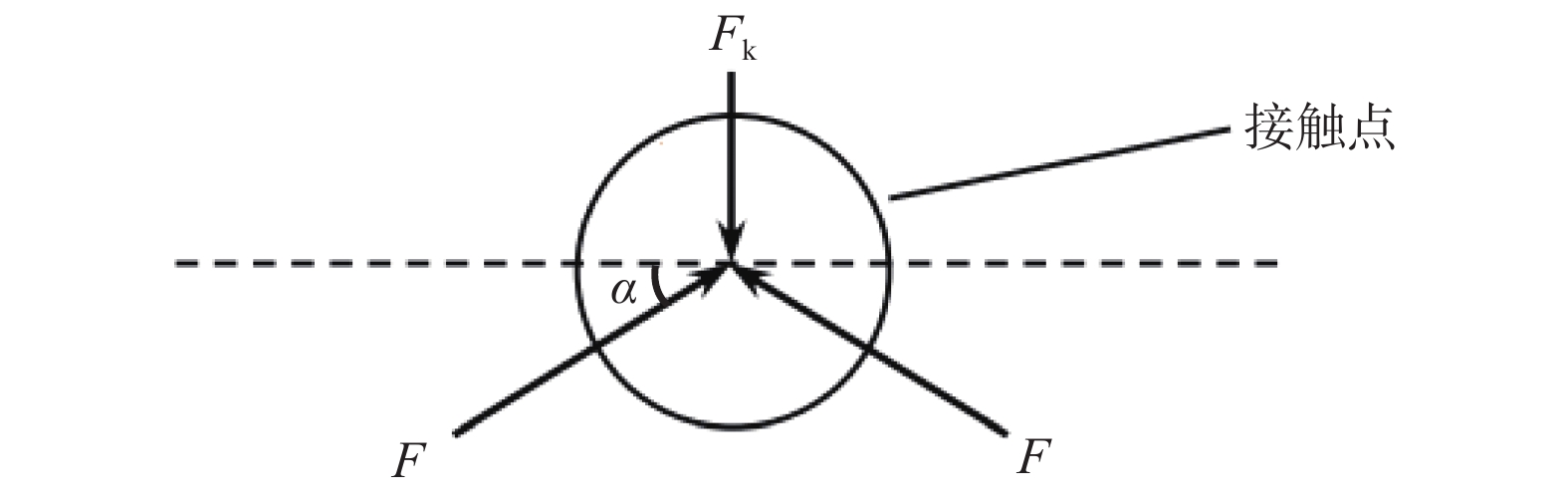

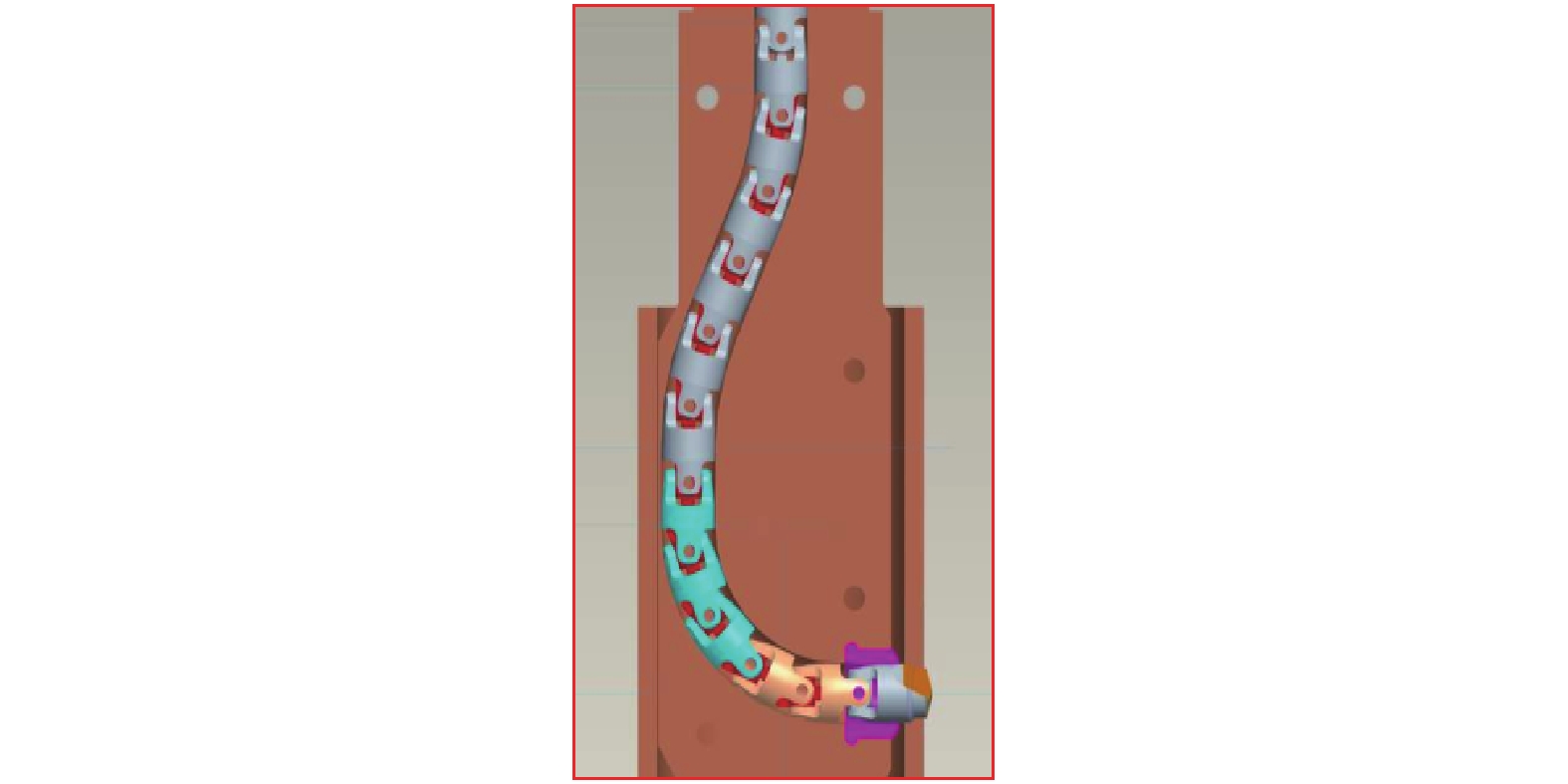

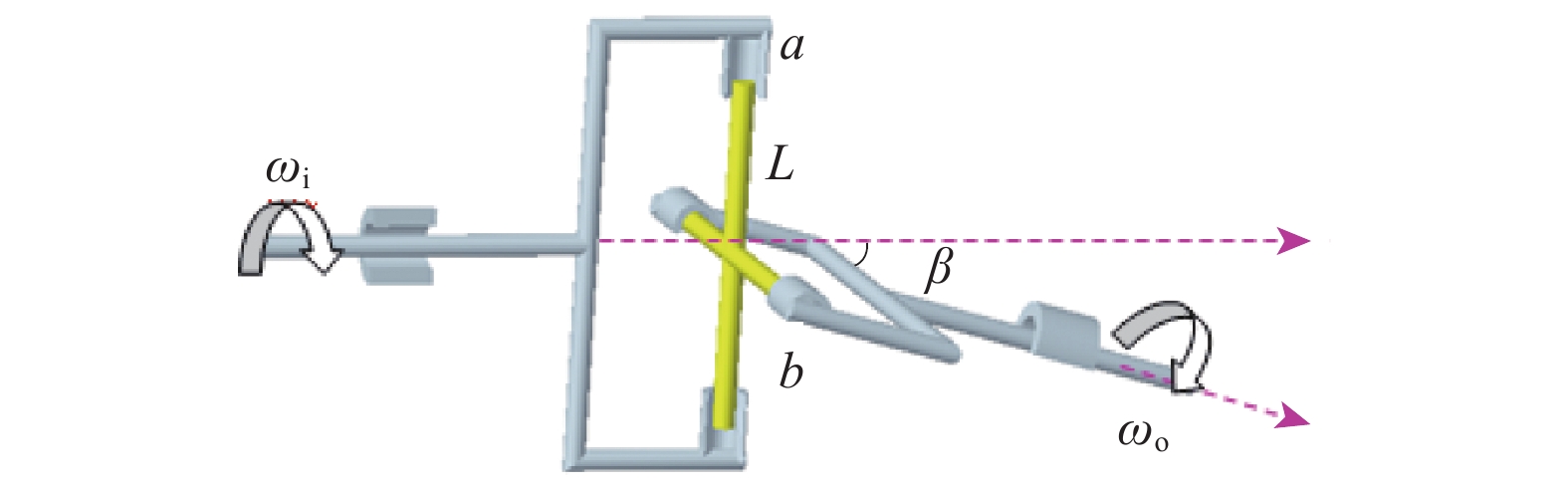

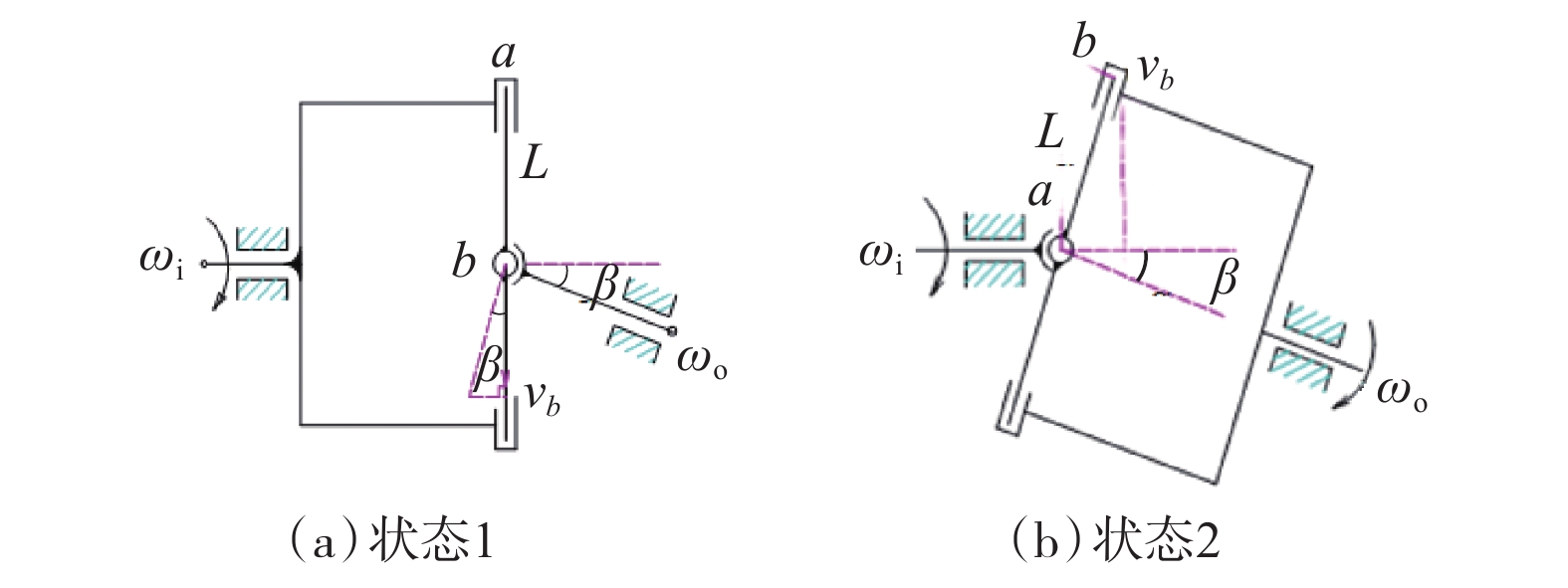

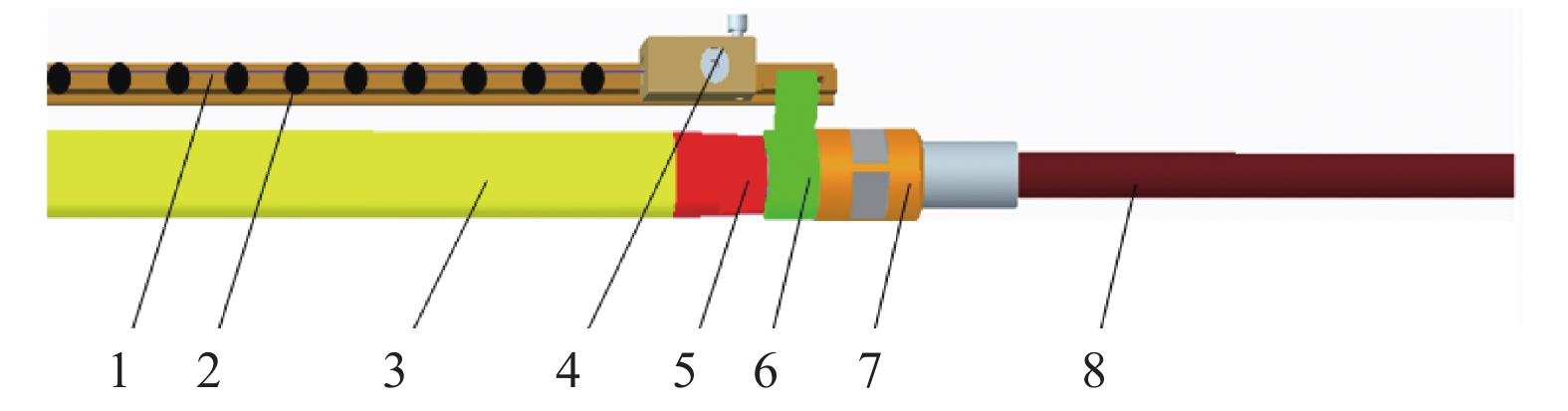

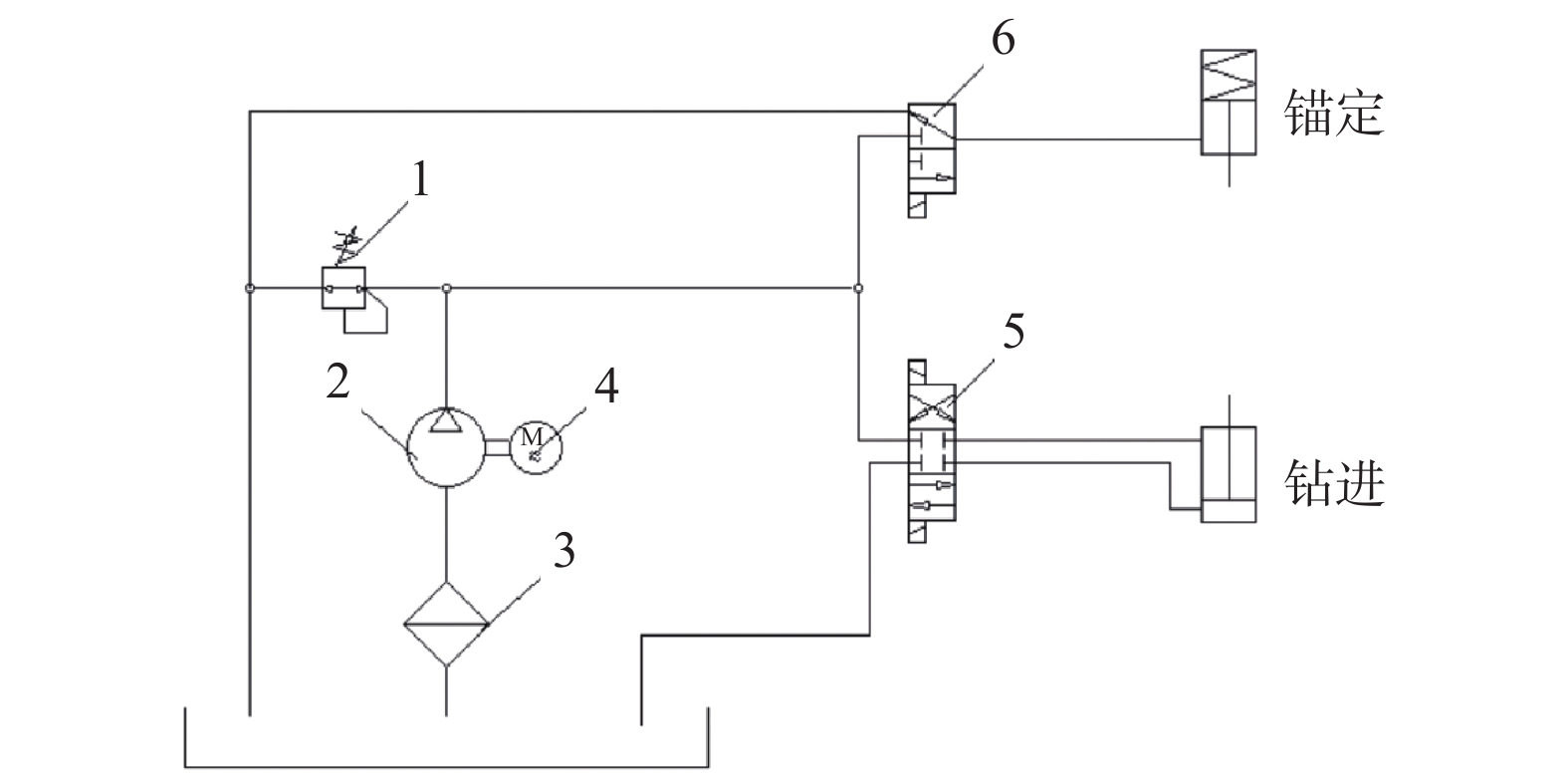

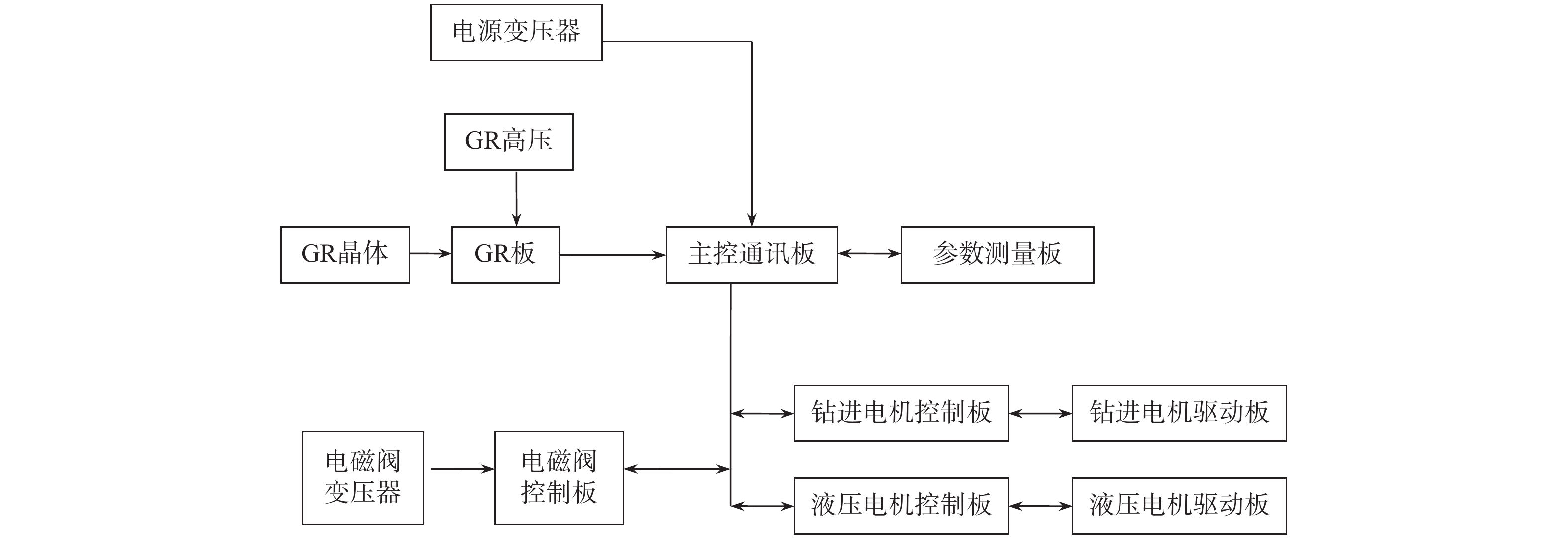

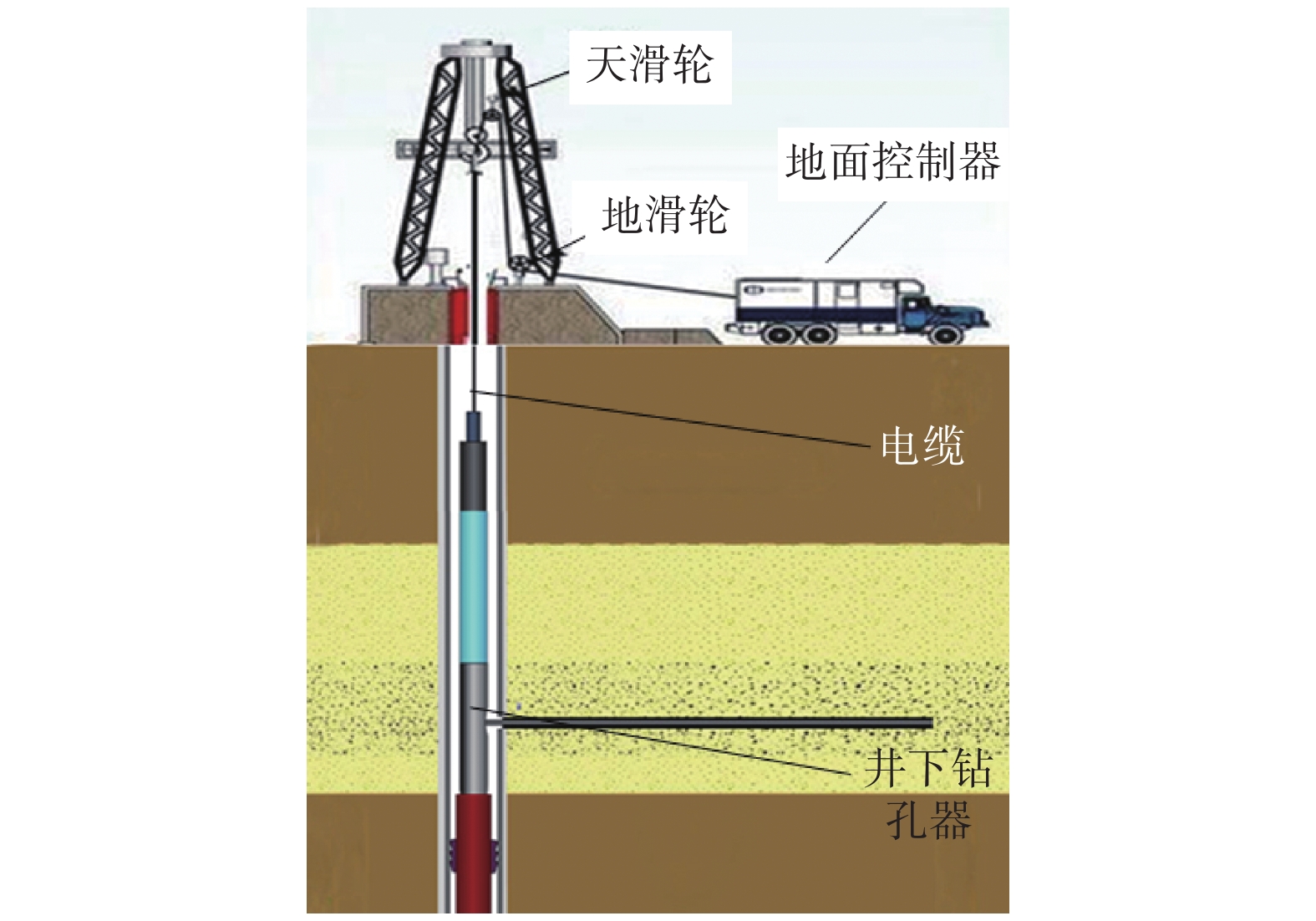

摘要: 现有水力钻孔技术虽然弥补了传统火药射孔穿透距离短、有压实效应等不足,但施工时需要油管或连续管配合,作业周期长、成本高,而且仅依靠地面泵压信号难以直接准确监测施工进程。针对这一问题,进行了井壁深穿透电控钻孔技术研究。优选直流电机代替高压水泵作为施工的能量来源;采用电缆悬吊方式代替油管或连续管传送钻孔工具,通过电缆传输电能和发送控制命令控制钻孔作业;研制实时监测系统,以及时准确地监测地层钻进过程,形成了井壁深穿透电控钻孔系统。地面试验和现场试验证明,该技术可钻入地层2.00 m以上,形成直径20.0~30.0 mm的孔道,其监测系统通过识别和记录井下霍尔传感器在地层钻进时产生的脉冲电信号,可及时准确地计算出实际钻孔长度。研究结果表明,井壁深穿透电控钻孔技术采用电缆传送,高效、快速、成本低,很好地弥补了传统火药射孔的不足,为沟通改造近井地层提供了一种新方法;同时,该技术的监测系统可在施工时对钻进长度等参数实时监测,解决了现有水力钻孔技术无法监测施工进程的问题。Abstract: Traditional explosive perforation is subject to a short penetration distance and a compaction effect. Although the existing hydraulic perforating technology has remedied the deficiencies, it needs to cooperate with oil tubing or coiled tubing, with a long operation period and a high cost. Also, it is difficult to monitor the construction process directly and accurately only with surface pump pressure signals. With regard to this problem, research was performed on electrically controlled sidewall deep penetrating perforating technology (ECSDPPT). DC motors were selected to replace high-pressure water pumps as the energy source. Perforating tools were suspended by electric cables for transmission instead of oil tubing or coiled tubing, and the cables also transmitted electrical energy and delivered commands to control perforating operations. A real-time monitoring system was developed to monitor the drilling process into formations timely and accurately. As a result, an electrically controlled sidewall deep penetrating perforating system was built. Ground and field tests prove that the ECSDPPT enables the drilling into formations by over 2.00 m, forming a borehole with a diameter of 20.0–30.0 mm. The monitoring system can accurately calculate the actual perforating length in time by identifying and recording the electric pulse signals from a downhole Hall sensor during formation drilling. The research results demonstrate that the ECSDPPT relying on cable transmission is fast, efficient and low-cost. It overcomes the shortcomings of conventional explosive perforation, providing a new method for connecting and reforming near wellbore formations. In addition, the monitoring system can record the drilling length and other parameters in real time during construction, effectively solving the failure of the existing hydraulic perforating technology in monitoring the working process.

-

Keywords:

- electric control /

- perforating /

- deep penetrating /

- sidewall /

- near wellbore formation /

- field test

-

-

表 1 无刷直流电机效率测试结果

Table 1 Efficiency tests of brushless DC motors

测试

序号电压/

V电流/

A输入功率/

W转速/

(r·min–1)输出功率/

W电机

效率,%1 600 1.6 976 400 902 92 2 600 2.5 1 510 400 1 390 92 3 600 3.5 2 106 400 1 913 91 表 2 试验井与邻井完井效果对比

Table 2 Comparison between completion results of test wells and adjacent wells

井号 完井方式 施工井段/m 有效层厚度/m 水量/m3 单位厚度产水量/m3 J31 电控钻孔 2 352.00~2 397.00 45.00 30.3 0.673 J20 电控钻孔 2 021.00~2 045.00 24.00 19.1 0.796 J-W1-02 筛管完井 2 092.00~2 374.00 165.00 50.0 0.303 J2-9-12 射孔完井 2 065.00~2 076.00

2 111.00~2 160.0060.00 19.2 0.320 -

[1] 李军,毕胜宇,柳贡慧,等. 低渗透岩芯实弹射孔实验研究[J]. 西南石油大学学报(自然科学版),2011,33(1):102–106. LI Jun, BI Shengyu, LIU Gonghui, et al. Study on perforation test of low permeability core with shaped charge[J]. Journal of Southwest Petroleum University (Science & Technology Edition), 2011, 33(1): 102–106.

[2] 张艺耀,李进,冯硕,等. 自清洁射孔技术在渤海油田的应用[J]. 石油矿场机械,2020,49(4):69–73. doi: 10.3969/j.issn.1001-3482.2020.04.014 ZHANG Yiyao, LI Jin, FENG Shuo, et al. Application of self-cleaning perforation technology in Bohai Oilfield[J]. Oil Field Equipment, 2020, 49(4): 69–73. doi: 10.3969/j.issn.1001-3482.2020.04.014

[3] 范翔宇,王俊瑞,夏宏泉,等. 基于灰色系统理论的钻井液污染储层深度预测[J]. 西南石油大学学报(自然科学版),2013,35(3):98–104. FAN Xiangyu, WANG Junrui, XIA Hongquan, et al. Drilling fluid′s damage depth prediction method based on the grey system theory[J]. Journal of Southwest Petroleum University (Science & Technology Edition), 2013, 35(3): 98–104.

[4] 李东传,唐国海,孙新波,等. 射孔压实带研究[J]. 石油勘探与开发,2000,27(5):112–114. doi: 10.3321/j.issn:1000-0747.2000.05.034 LI Dongchuan, TANG Guohai, SUN Xinbo, et al. A study on perforation crushed-zone[J]. Petroleum Exploration and Development, 2000, 27(5): 112–114. doi: 10.3321/j.issn:1000-0747.2000.05.034

[5] 任建民. 超短半径水平井喷射钻井机理[J]. 石油机械,1994,22(10):50–55. REN Jianmin. Jet drilling mechanism of ultra-short radius horizontal well[J]. China Petroleum Machinery, 1994, 22(10): 50–55.

[6] 张锦宏. 中国石化石油工程技术现状及发展建议[J]. 石油钻探技术,2019,47(3):9–17. ZHANG Jinhong. Current status and outlook for the development of Sinopec,s petroleum engineering technologies[J]. Petroleum Drilling Techniques, 2019, 47(3): 9–17.

[7] 中国石油集团长城钻探工程有限公司. 深穿透电控钻孔装置: CN201810623247.7 [P]. 2018-11-30. CNPC Greatwall Drilling Company. Electrically controlled deep penetrating perforating device: CN201810623247.7 [P]. 2018-11-30.

[8] 宗世伟,徐东后,李伟,等. 无刷直流电机在旋转式井壁取芯仪中的应用[J]. 石油仪器,2013,27(6):5–6, 9. ZONG Shiwei, XU Donghou, LI Wei, et al. Application of brushless DC motor in rotary wall coring apparatus[J]. Petroleum Instruments, 2013, 27(6): 5–6, 9.

[9] 宋伟刚. 机器人学: 运动学、动力学与控制[M]. 北京: 科学出版社, 2007: 50–70. SONG Weigang. Robotics: kinematics, dynamics and control[M]. Beijing: Science Press, 2007: 50–70.

[10] 罗敏,徐亭亭,贾丽,等. 超短半径水平井柔性钻杆非线性力学分析[J]. 机械设计与制造工程,2016,45(7):21–24. doi: 10.3969/j.issn.2095-509X.2016.07.004 LUO Min, XU Tingting, JIA Li, et al. Nonlinear mechanics analysis of flexible drill rod in ultra short radius horizontal well[J]. Machine Design and Manufacturing Engineering, 2016, 45(7): 21–24. doi: 10.3969/j.issn.2095-509X.2016.07.004

[11] 张继峰,刘忠和,朱再思,等. 穿透射孔技术最新发展及应用[J]. 石油机械,2002,30(10):68–70. doi: 10.3969/j.issn.1001-4578.2002.10.024 ZHANG Jifeng, LIU Zhonghe, ZHU Zaisi, et al. The latest development and application of hydraulic deep p enetration technology[J]. China Petroleum Machinery, 2002, 30(10): 68–70. doi: 10.3969/j.issn.1001-4578.2002.10.024

[12] 阮海龙,纪卫军,沈立娜,等. 针对复杂地层金刚石钻头的改进与应用[J]. 探矿工程(岩土钻掘工程),2010,37(1):67–69. RUAN Hailong, JI Weijun, SHEN Lina, et al. Improvement and application of diamond bit for drilling in complex formation[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 2010, 37(1): 67–69.

[13] 张斯其. 霍尔传感器电机测速综合改进技术研究[J]. 微特电机,2018,46(5):31–34. doi: 10.3969/j.issn.1004-7018.2018.05.008 ZHANG Siqi. Research on hall sensor motor speed improvement technology[J]. Small & Special Electrical Machines, 2018, 46(5): 31–34. doi: 10.3969/j.issn.1004-7018.2018.05.008

[14] 郝晓剑. 测控电路设计与应用[M]. 北京: 电子工业出版社, 2017: 136-152. HAO Xiaojian. Design and application of measurement and control circuit[M]. Beijing: Electronic Industry Press, 2017: 136-152.

[15] 刘平全. 径向水平井技术发展及工具特点[J]. 石油矿场机械,2018,47(1):23–27. LIU Pingquan. Design and operation of descaling device used for tubing string[J]. Oil Field Equipment, 2018, 47(1): 23–27.

下载:

下载: