Optimization Design and Numerical Analysis of Flow Passage Converters in LWD Tools

-

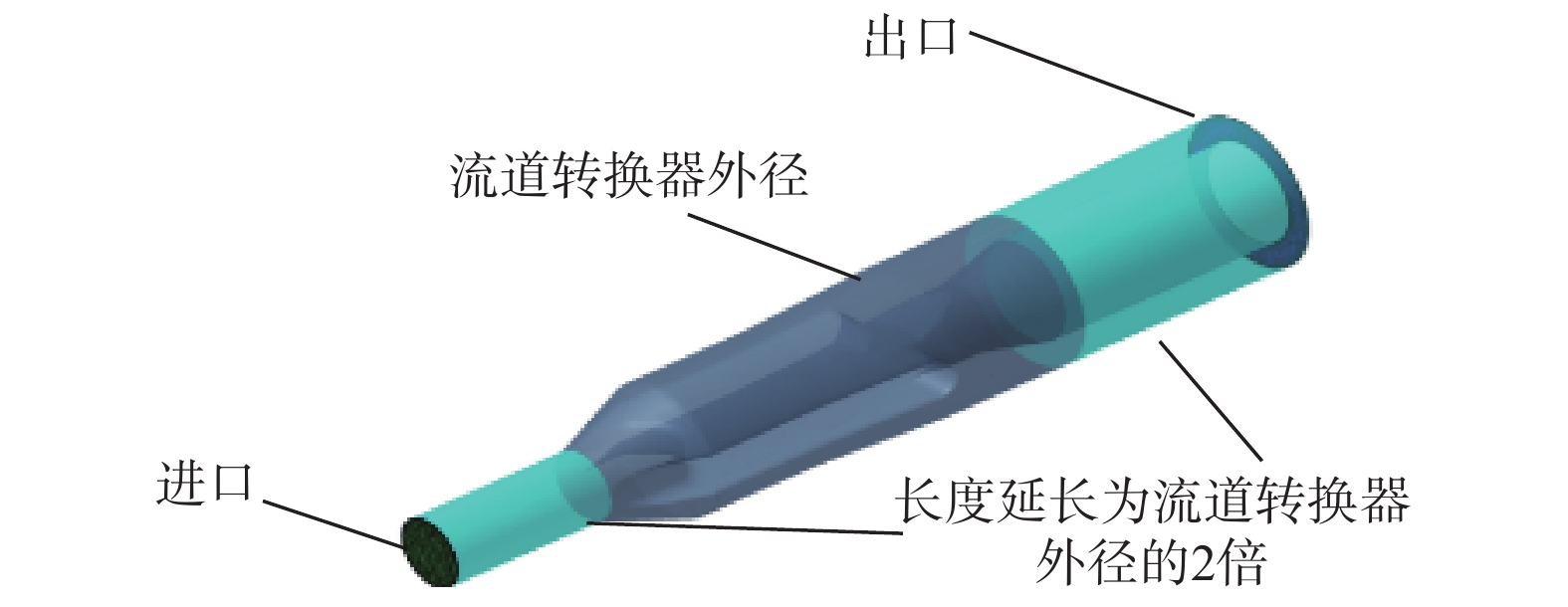

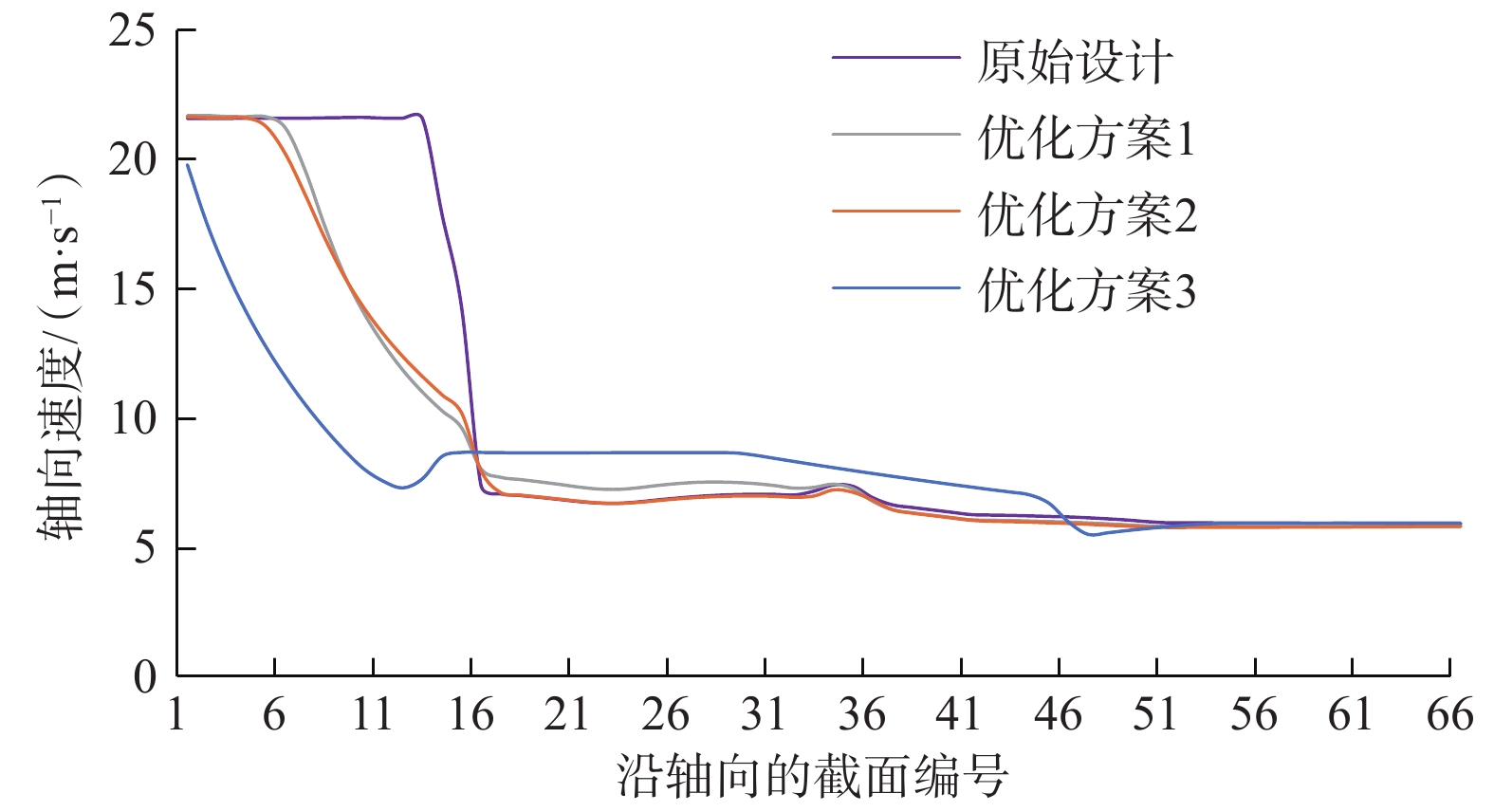

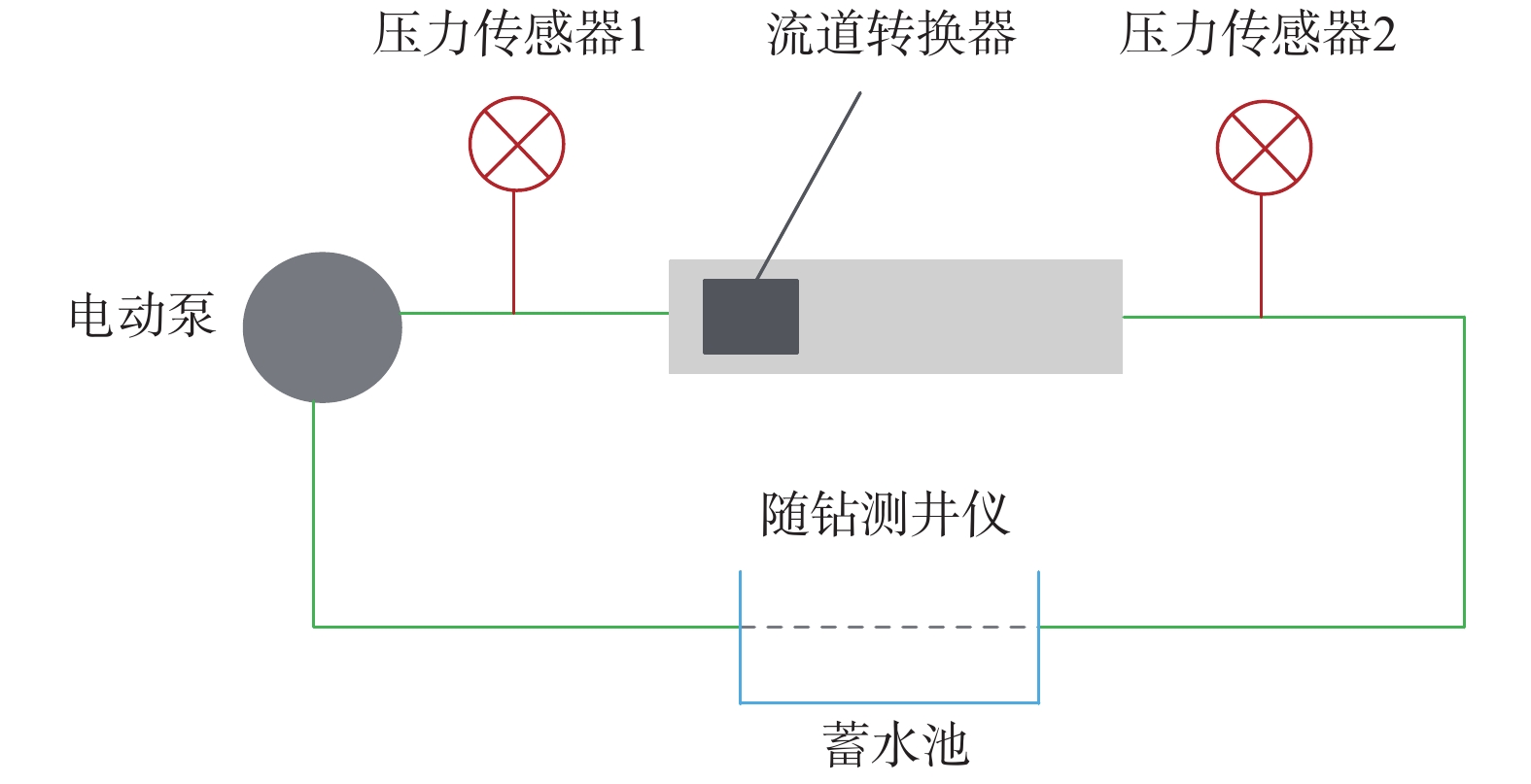

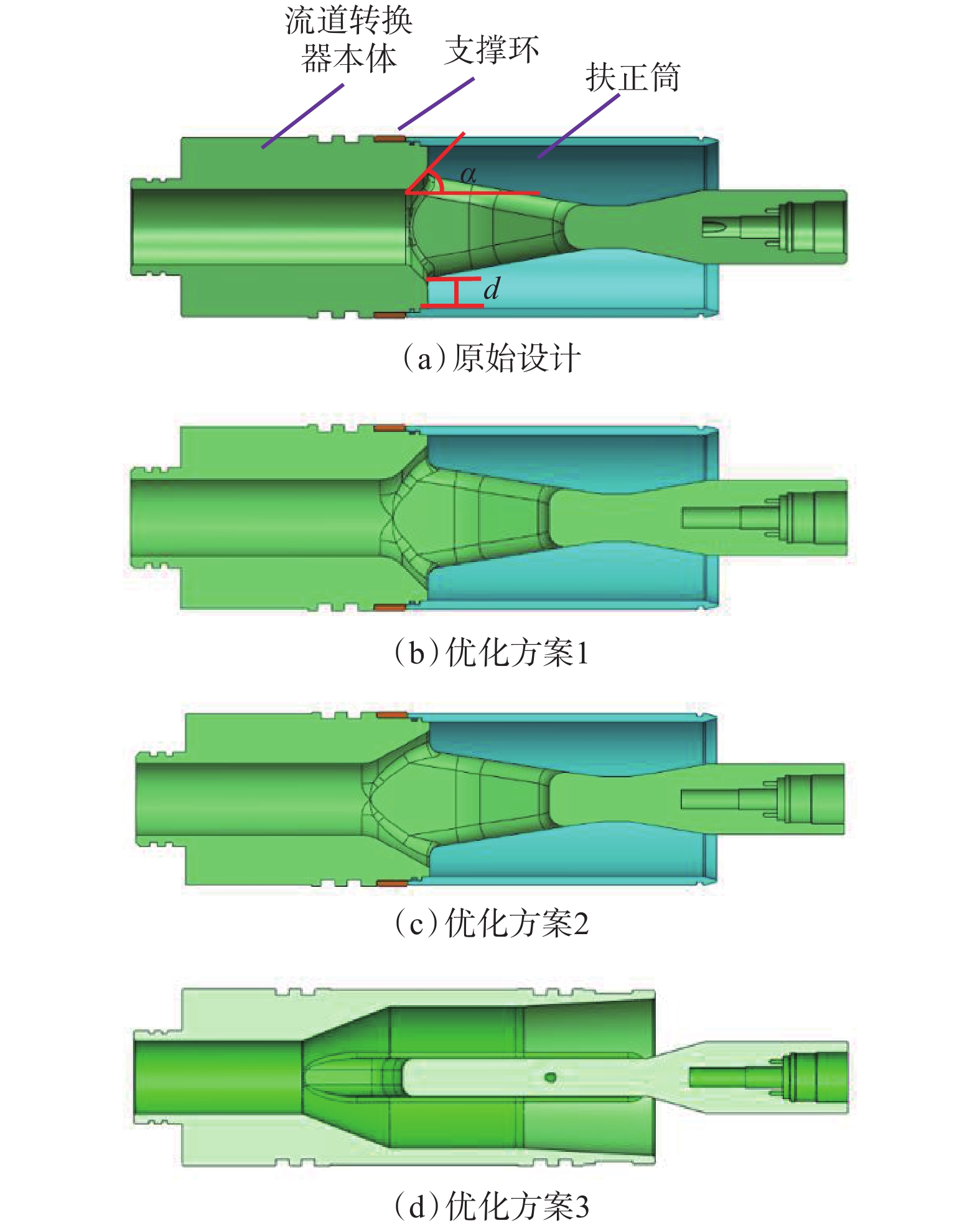

摘要: 随钻测井仪流道转换器流道截面设计不合理,不仅会造成随钻测井仪器内流道局部流场紊乱,致使仪器局部冲刷严重,造成仪器使用寿命缩短;还会导致仪器压力损失偏高,影响仪器的适用性。为此,采用CFD方法,对某型随钻测井仪流道转换器进行优化设计,并对4种设计方案进行了全三维数值模拟和对比,认为影响流道转换器流场性能的主要因素是扩张角和内流道截面积的连续性。最优设计方案的扩张角较小,内流道截面积连续,轴向速度下降更平缓,总压损失最小,流场流速分布更均匀。试验结果表明,流道转换器扩张角、内流道截面积不连续性与流道转换器流场分布均匀性呈负相关,与压力损失呈正相关;总压损失系数理论值与试验值对应的差值不大于0.076%,且变化趋势均与理论分析结果相同。研究结果为流道转换器的优化设计提供了理论依据。Abstract: Improper design of flow passage converter section in LWD ( logging while drilling) tools can cause local flow-field turbulence and result in serious local erosion of the tool, thus reducing its service life. It can also lead to large pressure loss of the tool and affect its applicability. For this reason, CFD (computational fluid dynamics) method was applied for the optimization design of a certain type of flow passage converter in an LWD tool. According to the full 3D numerical simulation and comparison of four design schemes, the main factors affecting the flow-field performance of the flow passage converter were thought to be the expansion angle and the continuity of the cross-sectional area of the internal flow passage. The optimal design has a smaller expansion angle, a more continuous cross-sectional area of the internal flow passage, a gentler decline in axial velocity, a minimum total pressure loss, and a more uniform flow velocity distribution in the flow field. The research results showed that the expansion angle and the discontinuity of the cross-sectional area of the internal flow passage were negatively associated with the uniformity of the flow field distribution in the flow passage converter and positively with the pressure loss. The difference between theoretical and experimental total pressure loss coefficients was not more than 0.076%, and the change trend was the same as the result of theoretical analysis. The research results can effectively serve as a theoretical basis for the optimization design of flow passage converters.

-

Keywords:

- LWD tool /

- flow passage converter /

- optimization design /

- numerical simulation

-

-

表 1 流道转换器设计方案

Table 1 Design schemes for the flow passage converter

设计方案 α/(°) d/mm 结构类型 加工工艺 原始设计 45 16 分体式,流道突变 简单 优化方案1 45 6 分体式,流道突变 较简单 优化方案2 30 6 分体式,流道突变 较简单 优化方案3 20 0 整体式,流道连续 复杂 表 2 流道转换器4种设计方案流动压力损失计算结果

Table 2 Calculated flow pressure loss in four design schemes of the flow passage converter

设计方案 进口压力/kPa 出口压力/kPa 总压损失系数,% 原始设计 10 000 9 853.8 1.462 优化方案1 10 000 9 880.8 1.192 优化方案2 10 000 9 886.0 1.140 优化方案3 10 000 9 959.3 0.407 表 3 流道转换器4种设计方案的流动压力损失试验结果

Table 3 Experimental flow pressure loss in four design schemes for the flow passage converter

设计方案 进口压力/kPa 出口压力/kPa 总压损失系数,% 原始设计 520.0 512.0 1.538 优化方案1 585.0 577.7 1.248 优化方案2 514.0 508.0 1.167 优化方案3 477.0 475.0 0.419 -

[1] 侯亮. 2020国外测井技术进展与趋势[J]. 世界石油工业,2020,27(6):49–54. HOU Liang. Development and trend of foreign well logging technologies in 2020[J]. World Petroleum Industry, 2020, 27(6): 49–54.

[2] 布志虹,任干能,陈乐. 随钻测井技术[J]. 断块油气田,2001,8(4):22–24. doi: 10.3969/j.issn.1005-8907.2001.04.007 BU Zhihong, REN Ganneng, CHEN Le. Logging while drilling technology[J]. Fault-Block Oil & Gas Field, 2001, 8(4): 22–24. doi: 10.3969/j.issn.1005-8907.2001.04.007

[3] 涂春赵,张国强,刘如明,等. 随钻方位电阻率测井仪在渤海油田的应用与探索[J]. 石油管材与仪器,2020,6(6):70–73. TU Chunzhao, ZHANG Guoqiang, LIU Ruming, et al. Application of directional wave propagation resistivity tool in Bohai Oilfield[J]. Petroleum Tubular Goods & Instruments, 2020, 6(6): 70–73.

[4] 林楠,王敬萌,亢武臣,等. 最新随钻声波测井仪的技术性能与应用实例[J]. 石油钻探技术,2006,34(4):73–76. doi: 10.3969/j.issn.1001-0890.2006.04.022 LIN Nan, WANG Jingmeng, KANG Wuchen, et al. Technical performances and applications of the newly developed sonic LWD tools[J]. Petroleum Drilling Techniques, 2006, 34(4): 73–76. doi: 10.3969/j.issn.1001-0890.2006.04.022

[5] 朱祖扬,倪卫宁,张卫,等. 随钻一体化测井仪平台开发[J]. 石油钻探技术,2019,47(1):118–126. doi: 10.11911/syztjs.2019016 ZHU Zuyang, NI Weining, ZHANG Wei, et al. The development of an integrated logging instrument platform while drilling[J]. Petroleum Drilling Techniques, 2019, 47(1): 118–126. doi: 10.11911/syztjs.2019016

[6] 路保平,倪卫宁. 高精度随钻成像测井关键技术[J]. 石油钻探技术,2019,47(3):148–155. doi: 10.11911/syztjs.2019060 LU Baoping, NI Weining. The key technologies of high precision imaging logging while drilling[J]. Petroleum Drilling Techniques, 2019, 47(3): 148–155. doi: 10.11911/syztjs.2019060

[7] 李亨,刘迪仁,倪小威,等. 钻井液侵入情况下随钻电磁波电阻率测井的响应[J]. 断块油气田,2019,26(5):675–680. LI Heng, LIU Diren, NI Xiaowei, et al. Logging responses of electromagnetic wave resistivity while drilling with drilling fluid intrusion[J]. Fault-Block Oil & Gas Field, 2019, 26(5): 675–680.

[8] 李安宗,秦泓江,王珺,等. 随钻可控源中子测井仪器研究[J]. 石油钻采工艺,2011,33(5):105–109. doi: 10.3969/j.issn.1000-7393.2011.05.028 LI Anzong, QIN Hongjiang, WANG Jun, et al. Study on neutron logging while drilling tool controllable neutron source[J]. Oil Drilling & Production Technology, 2011, 33(5): 105–109. doi: 10.3969/j.issn.1000-7393.2011.05.028

[9] 王智明,王红亮,邓晓清,等. 随钻仪器机电接口标准化推进产品产业化[J]. 石油工业技术监督,2017,33(12):19–22. doi: 10.3969/j.issn.1004-1346.2017.12.005 WANG Zhiming, WANG Hongliang, DENG Xiaoqing, et al. Standardization of mechanical and electrical interfaces of LWD instruments to pomote product industrialization[J]. Technical Supervision in Petroleum Industry, 2017, 33(12): 19–22. doi: 10.3969/j.issn.1004-1346.2017.12.005

[10] 李杰,罗瑜林,刘西恩. 随钻用流道转换接头损伤规律研究及改进方法[J]. 石油矿场机械,2018,47(3):14–18. doi: 10.3969/j.issn.1001-3482.2018.03.003 LI Jie, LUO Yulin, LIU Xien. Research on the damage revolution law of flow channels crossover subs while drilling and the development method[J]. Oil Field Equipment, 2018, 47(3): 14–18. doi: 10.3969/j.issn.1001-3482.2018.03.003

[11] 杨顺辉,陶兴华,殷琨,等. 计算流体动力学在冲击器设计和模拟中的应用[J]. 石油钻探技术,2008,36(5):40–42. doi: 10.3969/j.issn.1001-0890.2008.05.010 YANG Shunhui, TAO Xinghua, YIN Kun, et al. Application of CFD on the design and simulation of hydro-efflux hammer[J]. Petroleum Drilling Techniques, 2008, 36(5): 40–42. doi: 10.3969/j.issn.1001-0890.2008.05.010

[12] 王福军. 计算流体动力学分析: CFD软件原理与应用[M]. 北京: 清华大学出版社, 2004: 4–17. WANG Fujun. Principle and application of CFD software for computational fluid dynamics analysis[M]. Beijing: Tsinghua Univer-sity Press, 2004: 4–17.

[13] 药晓江,董景新,尚捷,等. 随钻测井用涡轮发电机叶轮组水力性能分析[J]. 石油机械,2015,43(6):6–10, 75. YAO Xiaojiang, DONG Jingxin, SHANG Jie, et al. Hydraulic performance analysis of turbine impeller assembly for LWD[J]. China Petroleum Machinery, 2015, 43(6): 6–10, 75.

[14] 孔珑. 可压缩流体动力学[M]. 北京: 水利电力出版社, 1991: 3–18. KONG Long. Compressible fluid dynamics[M]. Beijing: Water Conservancy and Electric Power Press, 1991: 3–18.

[15] 张永学,李振林. 流体机械内部流动数值模拟方法综述[J]. 流体机械,2006,34(7):34–38. doi: 10.3969/j.issn.1005-0329.2006.07.009 ZHANG Yongxue, LI Zhenlin. Summary of numerical simulation methods for flow in fluid machinery[J]. Fluid Machinery, 2006, 34(7): 34–38. doi: 10.3969/j.issn.1005-0329.2006.07.009

下载:

下载: