Key Drilling Technologies in Extended-Reach Well M with Ultra-High HD/VD Ratio in the South China Sea

-

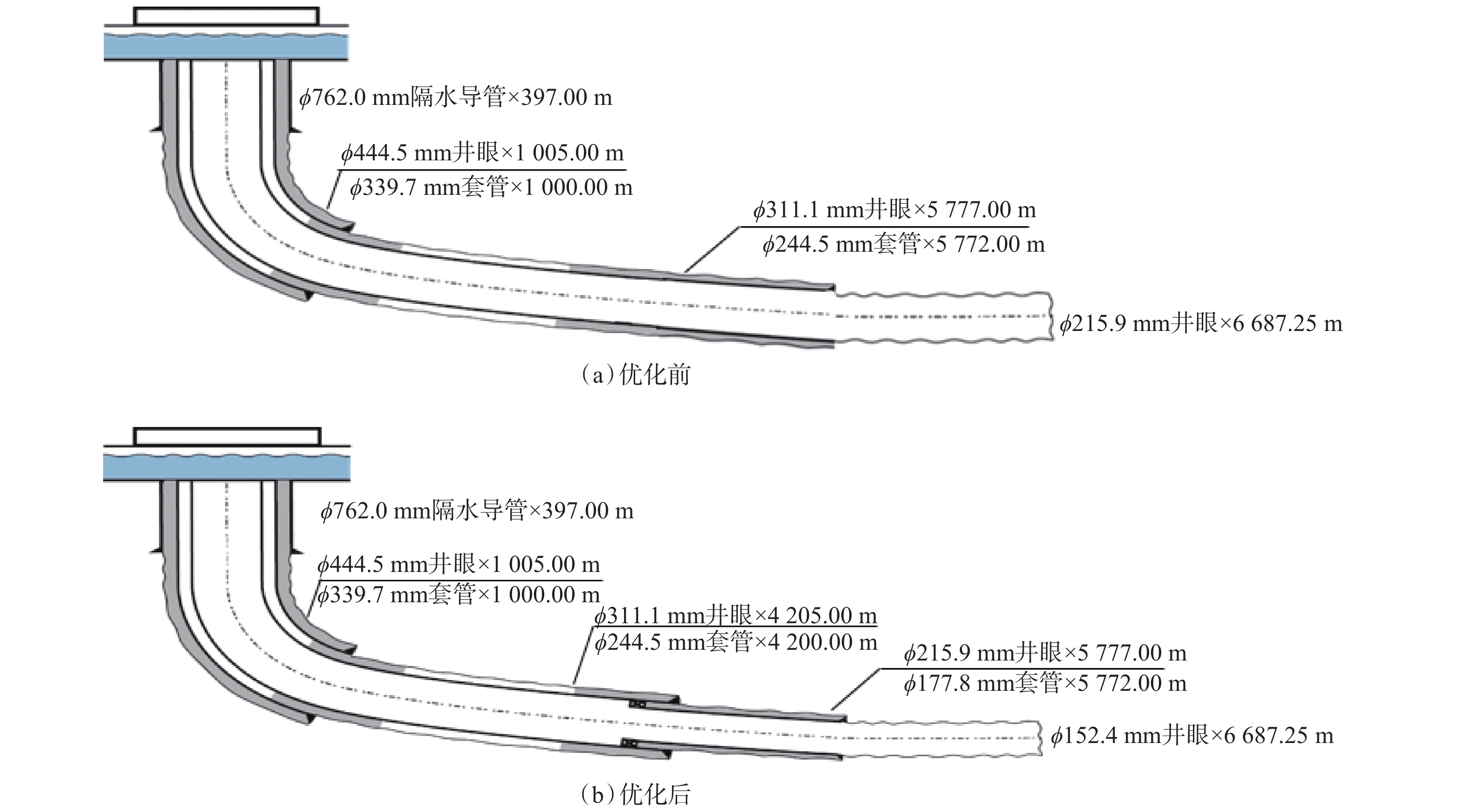

摘要: 为开发南海东部某油田边际油藏,设计了一口水垂比高达4.90的大位移井M井,钻井过程中面临储层埋深浅、稳斜裸眼井段长、安全密度窗口窄、井眼清洁困难和套管下入摩阻大等技术难点。通过研究与应用井眼轨迹控制、井身结构优化、井筒当量循环密度ECD控制工艺和安全高效下套管工艺等技术,顺利完成了该井的钻井作业。应用结果表明,五开井身结构显著提高了井壁稳定性;使用连续循环阀系统及岩屑床破坏器,井底ECD变化率降低至小于1.9%;应用漂浮下套管及全掏空旋转下尾管工艺,顺利下入ϕ244.5 mm套管×4 200.00 m及ϕ177.8 mm尾管×5 772.00 m。超大水垂比大位移井钻井关键技术在M井应用后,创下了中海石油海上油田最大水垂比大位移井钻井作业纪录,为后续类似大位移井的开发积累了经验。Abstract: In order to develop marginal oil reservoirs in an oil field in the eastern South China Sea, an extended reach Well M with a HD/VD (horizontal displacement to vertical depth) ratio of up to 4.90 was designed. During the drilling process, technical problems were encountered, such as shallow reservoir buried depth, long tangent open-hole section, narrow safe density window, difficult borehole cleaning, and strong casing-running friction resistance, etc. The drilling operation was completed owing to research and application of technologies including borehole trajectory control and casing program optimization, ECD (equivalent circulating density) control of drilling fluids in the wellbore, and safe and efficient casing-running technology. The application results showed that the borehole wall stability was greatly enhanced by the five-section casing program. The ECD change rate of the bottomhole was reduced to less than 1.9% by the continuous circulating valve system and cuttings bed destroyers. The ϕ244.5 mm casing was run to the designed depth of 4 200.00 m via the floating casing-running technology, and the ϕ177.8 mm liner was run to the depth of 5 772.00 m by the hollowed-out rotating liner-running technology. The application of the key drilling technologies of extended-reach wells with ultra-high HD/VD ratio in Well M sets a new record for China National Offshore Oil Corporation in the drilling of such wells, and provides valuable experience for the subsequent development of similar extended-reach wells.

-

-

表 1 M井与邻井中心距及分离系数

Table 1 Center-to-center distances and separation coefficients of Well M to adjacent wells

邻井 井深/m 垂深/m 与M井最小中心距/m 与M井最小分离系数 对应M井井深/m 对应M井垂深/m B 5 491.30 1 209.36 143.00 0.484 5 395.00 1 187.54 C 5 285.25 1 223.60 80.00 0.453 5 205.35 1 168.20 表 2 下入ϕ177.8 mm尾管遇阻点及大钩悬重/扭矩

Table 2 Blocking point depths and hook load/torque of ϕ177.8 mm liner running

井深/m 大钩悬重/kN 旋转扭矩/(kN·m) 4 650.53 694.8 10.8~14.8 4 794.20 697.7 10.5~15.0 4 970.65 699.7 12.1~15.0 5 149.02 760.5 11.3~15.3 5 500.89 864.3 12.1~17.6 5 700.48 944.7 12.5~17.3 -

[1] 魏宏安,张武辇,唐海雄. 超大水垂比大位移井钻井技术[J]. 石油钻采工艺,2005,27(1):1–5. doi: 10.3969/j.issn.1000-7393.2005.01.001 WEI Hongan, ZHANG Wunian, TANG Haixiong. Drilling technology of extendedreach well with ultra-high horizontal displacement to vertical depth ratio[J]. Oil Drilling & Production Technology, 2005, 27(1): 1–5. doi: 10.3969/j.issn.1000-7393.2005.01.001

[2] 王波,王旭,邢志谦,等. 冀东油田人工端岛大位移井钻井完井技术[J]. 石油钻探技术,2018,46(4):42–46. WANG Bo, WANG Xu, XING Zhiqian, et al. Drilling and completion technologies of extended-reach wells in the artificial island of the Jidong Oilfield[J]. Petroleum Drilling Techniques, 2018, 46(4): 42–46.

[3] 高德利,黄文君,李鑫. 大位移井钻井延伸极限研究与工程设计方法[J]. 石油钻探技术,2019,47(3):1–8. doi: 10.11911/syztjs.2019069 GAO Deli, HUANG Wenjun, Li Xin. Research on extension limits and engineering design methods for extended reach drilling[J]. Petroleum Drilling Techniques, 2019, 47(3): 1–8. doi: 10.11911/syztjs.2019069

[4] 刁斌斌,高德利. 邻井定向分离系数计算方法[J]. 石油钻探技术,2012,40(1):22–27. doi: 10.3969/j.issn.1001-0890.2012.01.005 DIAO Binbin, GAO Deli. Calculation method of adjacent well oriented separation factors[J]. Petroleum Drilling Techniques, 2012, 40(1): 22–27. doi: 10.3969/j.issn.1001-0890.2012.01.005

[5] 赵宝祥,陈江华,李炎军,等. 涠洲油田大位移井井眼清洁技术及应用[J]. 石油钻采工艺,2020,42(2):156–161. ZHAO Baoxiang, CHEN Jianghua, LI Yanjun, et al. Hole cleaning technology suitable for extended reach wells and its application in the Weizhou Oilfield[J]. Oil Drilling & Production Technology, 2020, 42(2): 156–161.

[6] 田志欣,李文金,张武辇,等. 阀式连续循环钻井技术在番禺油田大位移井的应用[J]. 石油钻采工艺,2017,39(4):413–416. TIAN Zhixin, Li Wenjin, ZHANG Wunian, et al. Application of valve-type continuous circulation drilling technology to the extended reach wells in Panyu Oilfield[J]. Oil Drilling & Production Technology, 2017, 39(4): 413–416.

[7] 刘小刚,范白涛,杨进,等. 大斜度井岩屑床清除工具安放位置计算[J]. 石油矿场机械,2016,45(3):46–50. doi: 10.3969/j.issn.1001-3482.2016.03.010 LIU Xiaogang, FAN Baitao, YANG Jin, et al. Calculating spacing for cutting-bed-remover in highly deviated wells[J]. Oil Field Equipment, 2016, 45(3): 46–50. doi: 10.3969/j.issn.1001-3482.2016.03.010

[8] 王先洲,左洪国,夏景刚,等. 南堡13-1706大位移井钻井技术[J]. 石油钻采工艺,2019,41(2):137–142. WANG Xianzhou, ZUO Hongguo, XIA Jinggang, et al. Drilling technologies used in an extended reach well named Nanpu 13-1706[J]. Oil Drilling & Production Technology, 2019, 41(2): 137–142.

[9] 姚俊材,郭志楠,郭海龄,等. 威德福Rip-Tide扩眼器在渤海大位移水平井的应用[J]. 钻采工艺,2017,40(2):24–26. doi: 10.3969/J.ISSN.1006-768X.2017.02.08 YAO Juncai, GUO Zhinan, GUO Hailing, et al. Application of Weatherford Rip-Tide reamer in extended reach well in Bohai oilfield[J]. Drilling & Production Technology, 2017, 40(2): 24–26. doi: 10.3969/J.ISSN.1006-768X.2017.02.08

[10] 黄兴,姬广奇,刘成真,等. 单投球式液压扩眼器安放位置优选[J]. 石化技术,2020,27(3):257–258. doi: 10.3969/j.issn.1006-0235.2020.03.159 HUANG Xing, JI Guangqi, LIU Chengzhen, et al. Optimal placement of single-ball hydraulic reamer[J]. Petrochemical Industry Technology, 2020, 27(3): 257–258. doi: 10.3969/j.issn.1006-0235.2020.03.159

[11] 林四元,张杰,韩成,等. 东方气田浅部储层大位移水平井钻井关键技术[J]. 石油钻探技术,2019,47(5):17–21. LIN Siyuan, ZHANG Jie, HAN Cheng, et al. Key technology for horizontal well of extended reach drilling in the shallow reservoirs of the Dongfang Gas Fields[J]. Petroleum Drilling Techniques, 2019, 47(5): 17–21.

[12] 崔国杰,谢荣斌,祝国伟,等. 渤海油田大位移井提速提效创新技术与实践[J]. 中国海上油气,2019,31(5):133–138. CUI Guojie, XIE Rongbin, ZHU Guowei, et al. Innovative technologies and practices of speed-up and efficiency improvement for extended reach wells in Bohai Oilfield[J]. China Offshore Oil and Gas, 2019, 31(5): 133–138.

[13] 阮臣良,王小勇,张瑞,等. 大斜度井旋转尾管下入关键技术[J]. 石油钻探技术,2016,44(4):52–57. RUAN Chenliang, WANG Xiaoyong, ZHANG Rui, et al. Key techniques of rotating liners running in high angle well[J]. Petroleum Drilling Techniques, 2016, 44(4): 52–57.

-

期刊类型引用(19)

1. 马龙,杨森,罗立帆,刘桓竭. 考虑钻柱动力学的PDC钻头破岩动态特性. 机械设计与研究. 2025(01): 76-82 .  百度学术

百度学术

2. 黄明泉. 页岩气三维水平井剖面设计技术. 江汉石油职工大学学报. 2024(01): 45-47 .  百度学术

百度学术

3. 孙钢,姜政华,解赤栋. 隆页5-1HF一级井身结构攻关研究. 石化技术. 2024(03): 42-44 .  百度学术

百度学术

4. 王纪伟,宋丽阳,康玉柱,魏海鹏,陈刚,李东晖. 中美典型常压页岩气开发对比与启示. 特种油气藏. 2024(04): 1-9 .  百度学术

百度学术

5. 毕开原. 我国页岩气钻完井关键技术现状及发展趋势. 石油机械. 2024(11): 12-20+28 .  百度学术

百度学术

6. 施赵南,高斐. 力-化耦合作用下水化坍塌周期研究. 科技创新与应用. 2023(13): 71-74 .  百度学术

百度学术

7. 庄艳君. 安场页岩气井眼轨道优化与地质导向技术. 科技资讯. 2023(10): 131-136 .  百度学术

百度学术

8. 姚红生,王伟,何希鹏,郑永旺,倪振玉. 南川复杂构造带常压页岩气地质工程一体化开发实践. 油气藏评价与开发. 2023(05): 537-547 .  百度学术

百度学术

9. 姚红生,房启龙,袁明进,张壮. 渝东南常压页岩气工程工艺技术进展及下一步攻关方向. 石油实验地质. 2023(06): 1132-1142 .  百度学术

百度学术

10. 王运海,贺庆,朱智超,龙志平,彭兴,曹建山. 渝东南南川地区常压页岩气示范井应用评价及推广效果. 石油实验地质. 2023(06): 1160-1169 .  百度学术

百度学术

11. 蔡勋育,周德华,赵培荣,张华,钱恪然,万成祥. 中国石化深层、常压页岩气勘探开发进展与展望. 石油实验地质. 2023(06): 1039-1049 .  百度学术

百度学术

12. 张露,张玉胜,江波,王希勇,朱化蜀,张继尹. DY3-1HF常压页岩气水平井低成本钻井技术. 西部探矿工程. 2021(07): 89-91 .  百度学术

百度学术

13. 邓媛,何世明,邓祥华,彭远春,何世云,汤明. 力化耦合作用下的层理性页岩气水平井井壁失稳研究. 石油钻探技术. 2020(01): 26-33 .  本站查看

本站查看

14. 夏海帮. 页岩气井双暂堵压裂技术研究与现场试验. 石油钻探技术. 2020(03): 90-96 .  本站查看

本站查看

15. 耿朝辉. 我国页岩气钻井新技术及新工艺的研究与应用. 中国石油和化工标准与质量. 2019(07): 185-186 .  百度学术

百度学术

16. 孔令豪,何世明,汤明,袁兰峰,张光福. 考虑钻柱屈曲的环空压降计算. 断块油气田. 2019(03): 375-379 .  百度学术

百度学术

17. 赵景芳,刘雪婧,耿铁. BIO–OIL环保基液的研制与现场试验. 石油钻探技术. 2019(03): 75-81 .  本站查看

本站查看

18. 朱亮,楼一珊,沈建中,贺庆,秦杜. 南川页岩气田岩石抗钻特性参数分布规律研究及应用. 油气藏评价与开发. 2019(05): 84-88 .  百度学术

百度学术

19. 蔡世荣,任克雄. 宜昌地区页岩气勘探开发前景及开发模式探析. 国土资源情报. 2019(09): 46-51 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: