Research Status and Development Trend of Drilling Digital Twin Technology

-

摘要:

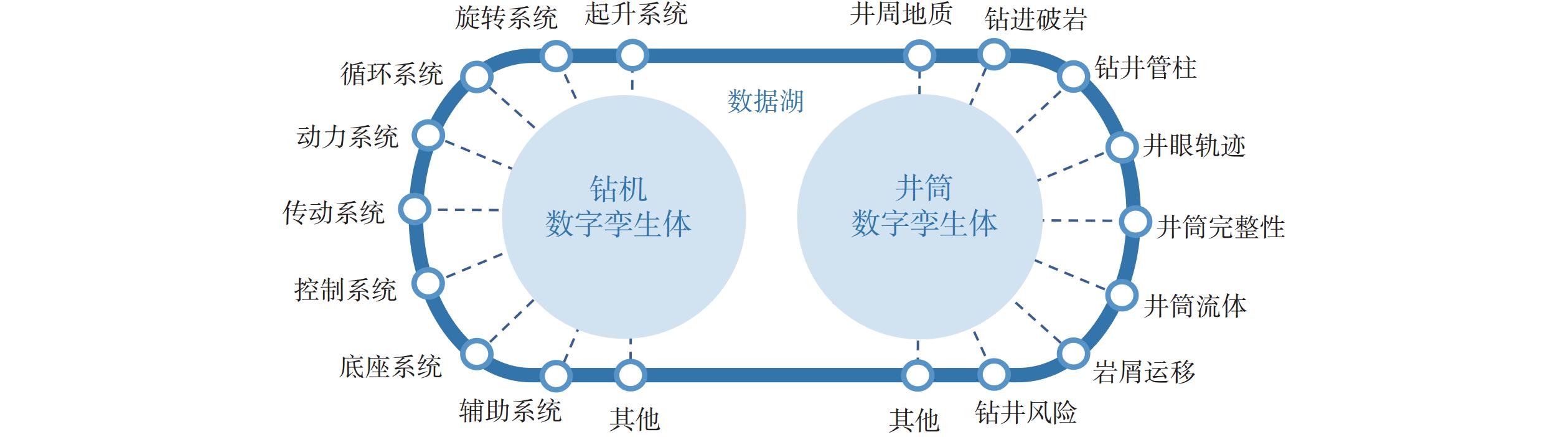

在第四次工业革命技术浪潮的推动下,油气钻井行业正朝着信息化、数字化、智能化方向快速发展,钻井数字孪生技术成为行业前沿与热点。钻井数字孪生技术是将真实钻井工程映射到虚拟空间,建立集成多学科、多物理量、多尺度的钻井过程全生命周期虚拟仿真模型,实现钻前演练、钻中优化、钻后分析等功能,保障安全、高效、低成本钻进,提高复杂油气储层钻井效率。在分析数字孪生技术在钻井工程中的应用现状的基础上,将钻井数字孪生分为钻机数字孪生和井筒数字孪生,并提出钻井数字孪生五维系统架构;同时,分析了钻井数字孪生未来发展趋势,包括钻井数据实时高效传输、地质模型精细表征、多领域一体化建模与仿真、仿真模型动态自适应更新、机理与数据融合建模、安全高效的人机交互及云边协同软件系统架构,并提出我国钻井数字孪生技术发展的相关建议。研究结果可为钻井数字孪生技术体系的构建提供参考,对于推动钻井行业智能化革新具有一定的指导意义。

Abstract:Driven by the technological impetus of the Fourth Industrial Revolution, the oil and gas drilling industry is rapidly advancing towards informatization, digitization, and intelligentization, with drilling digital twin technology emerging as a frontier and hotspot in the field. Drilling digital twin technology aims to map real drilling operations into virtual space and establish integrated, multi-disciplinary, multi-physical, and multi-scale virtual simulation models throughout the entire lifecycle of drilling. This enables functions such as pre-drilling rehearsal, in-drilling optimization, and post-drilling analysis, ensuring safe, efficient, and cost-effective drilling while enhancing the drilling efficiency of complex oil and gas formation. The current application status of digital twin technology in drilling engineering was introduced, and drilling digital twins were categorized into rig digital twins and wellbore digital twins. A five-dimensional system architecture for drilling digital twins was proposed. Furthermore, future development trends in drilling digital twins were analyzed, including real-time and efficient transmission of drilling data, refinement and quantification of geological models, multi-domain integrated modeling and simulation, dynamic adaptive updating of simulation models, the integration of mechanistic and data-driven modeling, safe and efficient human-machine interaction, and cloud-edge collaborative software system architecture. Relevant suggestions for the development of drilling digital twin technology in China were also proposed. The research findings could serve as a reference for establishing a drilling digital twin technology system and provide guidance for promoting intelligent innovation in the drilling industry.

-

新疆风城油田超稠油油藏埋深只有180~250 m,储层岩性以中—细砂岩为主,属辫状河沉积,胶结程度低,油层平均孔隙度30.6%,平均渗透率1 627 mD,含油饱和度71%。平均油层厚度35.7 m,油藏原始地层温度17~25 ℃,原始地层压力系数0.987,地层温度下原油黏度100~600 Pa·s,黏温反应敏感,温度每升高10℃原油黏度降低50%~70%,采用蒸汽吞吐和蒸汽驱取得了很好的开采效果。

但是,由于受构造、储层非均质性、油藏埋藏浅以及蒸汽与稠油流度比差异大、地层出砂等因素的影响,注入高温蒸汽易沿高渗透带或大孔道发生窜流;使热采效率严重下降,甚至出现蒸汽沿油层上部盖层薄弱、存在浅部破损带的地区窜漏出地表,发生地表汽窜[1]。蒸汽地下窜流和地表汽窜不仅严重影响产能水平,也会造成地面污染等问题。风城油田作业区自2008年以来,先后出现30多处地表窜漏点,导致地表窜漏点附近的井组不能正常生产,严重影响对应区块的产能水平。因此,新疆风城油田迫切需要解决蒸汽地下窜流和地表汽窜问题,而最有效的方法是使用高温封堵剂封堵汽窜通道。但稠油热采注入蒸汽温度可达280~300 ℃,对高温封堵剂的耐温性能要求很高。目前,高温封堵剂的种类主要有高温冻胶堵剂、高温泡沫堵剂、树脂类高温堵剂、有机无机复合颗粒堵剂等[2-12],这些高温封堵剂存在耐温能力有限、封堵强度不高的问题。因此,研究开发耐温性能和封堵能力强的新型稠油热采高温封堵剂,对于新疆风城油田稠油热采具有现实意义。

为解决上述问题,笔者采用有机胺作催化剂合成了油溶性酚醛树脂OSR,并通过有机硅偶联剂和环氧树脂改性,研制了新型酚醛环氧树脂类的高温封堵剂HTD。室内性能评价和现场试验都表明,HTD具有很好的抗温和封堵性能,在风城油田高孔高渗浅层超稠油热采中使用,可取得良好的经济效益。

1. 高温封堵剂HTD的研制

1.1 研制思路

调研发现,酚醛树脂类物质抗温能力较为理想[13],如果通过环氧树脂及有机硅偶联剂改性可进一步提高其抗温性能[14-16]。合成酚醛树脂时,一般采用无机酸和无机碱作为催化剂,采用强碱性的氢氧化钠作为催化剂。合成酚醛树脂反应速度较快,合成的酚醛树脂固结温度较低。而多乙烯多胺是一种有机弱碱,还可作为环氧树脂固化剂。因此,研制高温封堵剂的思路是:以弱碱性的有机胺和纯碱为催化剂合成油溶性酚醛树脂,并与环氧树脂、有机硅偶联剂、稀释剂等复配,配制出新型酚醛环氧树脂类高温封堵剂。

1.2 试剂与仪器

试剂:苯酚,化学纯;甲醛,化学纯;碳酸钠,分析纯;四乙烯五胺,化学纯;有机硅偶联剂,工业品;稀释剂,工业品;E44环氧树脂,工业品。

仪器:DZF-6050台式真空干燥箱;DV-Ⅱ+PRO黏度计;高温高压岩心流动试验装置;高温老化罐,400 mL;万能压力试验机。

1.3 研制过程

1)合成油溶性酚醛树脂。将苯酚和醛按质量比1.0∶2.5~3.0加热溶解混匀,加入1.5%有机胺及0.5%碳酸钠作为催化剂,置于有机合成装置中,将温度升至84 ℃,在不断搅拌条件下反应6 h,然后抽真空脱去低沸点物质,至无馏出液为止,所得产物为棕色透明的黏稠液体,即为油溶性酚醛树脂(代号OSR)。

2)配制高温封堵剂。取油溶性酚醛树脂OSR与E44环氧树脂,按质量比7∶3混合均匀,再加入混合了3%树脂的有机硅偶联剂、10%~15%树脂的稀释剂调节黏度,并充分搅匀,得到酚醛环氧树脂类高温封堵剂(代号HTD)。

1.4 基本性能测试

用DV-Ⅱ+PRO黏度计测HTD的黏度,结果为40~60 mPa·s。将HTD挤入模拟地层(用恒温干燥箱模拟油藏高温环境),在80~300 ℃温度下经过6~12 h后,树脂能成胶固化,形成较高强度的固结体,说明HTD能达到很好的高温封堵效果。

2. 高温封堵剂HTD的性能评价

2.1

为进一步了解高温封堵剂HTD的高温固化性能、耐温性能及高温封堵性能,在实验室内按如下基本步骤开展了评价试验:1)筛选一定粒径(20~40目)的石英砂,加入一定量的HTD,将其与石英砂搅拌均匀;2)将上述混合物充填于直径30 mm、高40 mm的玻璃管里并进行压实,置于高温老化罐中,添加水浸没样品,密闭容器,在恒温干燥箱中恒温养护一定时间;3)取出观察分析成胶固化情况,并切割打磨成规则的圆柱体,用万能压力试验机测其抗压强度等,然后使用高温高压岩心流动试验装置评价HTD的封堵性能。

2.1.1 石英砂用量的影响

在实验室内,将20~40目石英砂与高温封堵剂HTD充分混匀,使其在180 ℃下恒温6 h后形成固结体。然后分析了不同石英砂含量对HTD固化性能的影响,结果如图1所示。

由图1可知,石英砂含量对石英砂与HTD所形成固结体的抗压强度有一定影响,石英砂用量由低到高,固结体抗压强度逐步升高。石英砂含量为70%时,固结体的抗压强度最高,可达12.6 MPa;此后抗压强度开始下降,石英砂含量达到80%后固结体的抗压强度开始迅速下降。这是因为,石英砂含量较小时,HTD高温固结后骨架支撑作用小,抗压强度较低,随着石英砂含量增大,骨架的支撑作用增强,固结体抗压强度逐步升高,但石英砂含量较大时,HTD不足以把石英砂全部包裹固结好,因此固结体的抗压强度会降低。

2.1.2 温度的影响

通过试验分析了不同温度下高温封堵剂HTD的固化性能(试验条件:石英砂用量为70%,固化时间为8 h),结果如图2所示。

由图2可知,温度对石英砂与HTD所形成固结体的抗压强度影响较大。温度为80 ℃时,固结体的抗压强度很低,但随着温度升高,固结体抗压强度不断提高,温度达到160 ℃时固结体抗压强度已达11.6 MPa,不过,此后温度再升高,固结体抗压强度的提高幅度变小。试验发现,温度高于180 ℃后,固结体出现了体积膨胀现象,与玻璃管胶结致密、牢固,这说明HTD可与砂岩地层很好地胶结,并具有很高的固结强度(高于12.8 MPa)。因此,HTD适合作为稠油热采的封堵剂。

2.2 耐温性能

稠油热采时注入蒸汽的温度可达260 ℃以上,因此,封堵剂在高温下需要保持长久的稳定性。为此,在260,280和300 ℃温度下进行了高温封堵剂HTD与石英砂的固结体在长时间下的热稳定性能试验(试验条件:石英砂用量为70%;恒温时间为60,120和180 d),结果如图3所示。

由图3可知,在260~300 ℃温度下,HTD与石英砂所形成固结体恒温养护较长时间后,仍具有很高的抗压强度。随着温度升高,抗压强度有一定的下降,但下降幅度很小。如在300 ℃下恒温放置180 d后,抗压强度仍然高于12 MPa。这说明HTD具有良好的耐温性能,抗温能力可达300 ℃以上。

2.3 高温封堵性能

利用高温高压岩心流动试验装置,通过岩心流动试验分析了高温封堵剂HTD对不同渗透率的填砂管岩心的封堵效果。考虑有稠油热采蒸汽窜流通道,地层渗透率有较大幅度升高,因此采用填砂管制作了高渗透率岩心,先将其抽真空,测水相渗透率Kw1,再挤入高温封堵剂HTD,挤入HTD的体积为砂管岩心的1倍孔隙体积;然后关紧岩心两端的进出口,在指定温度下恒温8 h,再测岩心的水相渗透率Kw2,记录承压强度,计算水相封堵率及突破压力梯度,结果见表1。

表 1 高温封堵剂HTD的高温封堵性能试验结果Table 1. Experimental result of high temperature plugging performance of HTD序号 Kw1/

mD温度/

℃Kw2/

mD封堵率,

%突破压力梯度/

(MPa·m–1)1 11540 220 51.03 99.56 38.7 2 17320 240 66.12 99.62 39.3 3 15360 260 52.15 99.66 40.3 4 14760 300 41.06 99.72 40.7 注:砂管岩心长度为30 cm,突破压力梯度为突破压力除以岩心长度。 由表1可知,高温封堵剂HTD对高渗透率岩心的封堵效果很好。将HTD挤入岩心后,在220~300 ℃温度条件下恒温8 h后,高渗透率岩心的封堵率高于99.5%,突破压力梯度大于35 MPa/m。新疆风城油田蒸汽注入压力大多低于15.0 MPa,因此HTD可满足稠油热采封堵和抑制蒸汽窜流的要求。

3. 现场试验

风城油田F-109井区于2010年投产,采用稠油蒸汽吞吐开采方式,在经过4轮吞吐后,蒸汽沿着上覆地层裂缝通道突破至近地表,在覆盖层薄弱区形成地面窜漏。受地面蒸汽窜漏影响,区内14口井不能正常注汽生产,产油量下降。该井区之前采用膨润土–水泥及聚合物冻胶进行了封堵试验,发现封堵承压能力低,有效期短。为此,2018年9月,在风城油田F-109井区地表窜漏区域进行了高温封堵剂HTD的现场试验。试验前,经过电位法通道监测研究,确定窜漏通道上3口关联井是F-109井、F-145井和F-110井(见图4,图例中ρ为电阻率,Ω·m),需对油井窜漏通道进行高温封堵。

现场试验前,3口关联井(F-109井、F-145井和F-110井)处于关井状态,井口油套压均为0。进行现场试验时,前置液采用无机和有机复合堵剂,交替注入800~1 100 m3该堵剂,后置封口采用高温封堵剂HTD,用量15~20 m3,施工时泵注压力由0逐步升高,并稳定在4.5~5.0 MPa(见图5)。

措施后,F-109井区地面不再发生蒸汽窜漏,受地面窜漏影响的14口井恢复了正常注汽吞吐生产,平均单井日注汽量100 m3,注汽压力3.5~5.5 MPa,产油量得到提高。截至2020年底,该区域产油能力提高至62.12 t/d,平均日增油22.7 t,说明高温封堵剂HTD有效封堵了蒸汽地面窜漏和地下窜流通道,增大了蒸汽波及体积,提高了油井产能,施工有效期长达2年以上,取得了良好的经济效益。

4. 结 论

1)针对新疆风城油田稠油热采中蒸汽地下窜流和地表汽窜的问题,以有机胺为催化剂合成了油溶性酚醛树脂OSR,并与环氧树脂、有机硅偶联剂、稀释剂等复配,研制了新型酚醛环氧树脂类高温封堵剂HTD。

2)在石英砂用量为70%时,高温封堵剂HTD与石英砂固结体的固结强度最高;胶结温度在180 ℃以上时固结体的抗压强度高于12.8 MPa,与砂岩地层胶结良好,说明适宜胶结温度在180 ℃以上。

3)高温封堵剂HTD与石英砂的固结体,在260~300 ℃温度下经过长时间养护后仍具有很高的抗压强度(高于12 MPa),说明HTD的抗温能力可达300 ℃以上。

4)在220~300 ℃温度下,高温封堵剂HTD对高渗透率填砂管岩心的封堵率大于99.5%,突破压力梯度大于35 MPa/m,可满足风城油田稠油热采抑制蒸汽窜流的要求。

5)现场试验结果表明,高温封堵剂HTD可有效封堵蒸汽地表窜漏和地下窜流通道,增大蒸汽波及体积,提高产油水平,施工有效期长达2年以上,取得了良好的经济效益。

-

[1] 门相勇,王陆新,王越,等. 新时代我国油气勘探开发战略格局与2035年展望[J]. 中国石油勘探,2021,26(3):1–8. MEN Xiangyong, WANG Luxin, WANG Yue, et al. Strategic pattern of China’s oil and gas exploration and development in the new era and prospects for 2035[J]. China Petroleum Exploration, 2021, 26(3): 1–8.

[2] 邹才能,赵群,王红岩,等. 非常规油气勘探开发理论技术助力我国油气增储上产[J]. 石油科技论坛,2021,40(3):72–79. ZOU Caineng, ZHAO Qun, WANG Hongyan, et al. Theory and technology of unconventional oil and gas exploration and development helps China increase oil and gas reserves and production[J]. Petroleum Science and Technology Forum, 2021, 40(3): 72–79.

[3] 袁光杰,付利,王元,等. 我国非常规油气经济有效开发钻井完井技术现状与发展建议[J]. 石油钻探技术,2022,50(1):1–12. YUAN Guangjie, FU Li, WANG Yuan, et al. The up-to-date drilling and completion technologies for economic and effective development of unconventional oil & gas and suggestions for further improvements[J]. Petroleum Drilling Techniques, 2022, 50(1): 1–12.

[4] 邹才能,杨智,张国生,等. 非常规油气地质学理论技术及实践[J]. 地球科学,2023,48(6):2376–2397. ZOU Caineng, YANG Zhi, ZHANG Guosheng, et al. Theory, technology and practice of unconventional petroleum geology[J]. Earth Science, 2023, 48(6): 2376–2397.

[5] 苏义脑,路保平,刘岩生,等. 中国陆上深井超深井钻完井技术现状及攻关建议[J]. 石油钻采工艺,2020,42(5):527–542. SU Yinao, LU Baoping, LIU Yansheng, et al. Status and research suggestions on the drilling and completion technologies for onshore deep and ultra deep wells in China[J]. Oil Drilling & Production Technology, 2020, 42(5): 527–542.

[6] 汪海阁,黄洪春,毕文欣,等. 深井超深井油气钻井技术进展与展望[J]. 天然气工业,2021,41(8):163–177. WANG Haige, HUANG Hongchun, BI Wenxin, et al. Deep and ultra-deep oil/gas well drilling technologies: progress and prospect[J]. Natural Gas Industry, 2021, 41(8): 163–177.

[7] 李根生,宋先知,田守嶒. 智能钻井技术研究现状及发展趋势[J]. 石油钻探技术,2020,48(1):1–8. LI Gensheng, SONG Xianzhi, TIAN Shouceng. Intelligent drilling technology research status and development trends[J]. Petroleum Drilling Techniques, 2020, 48(1): 1–8.

[8] LI Gensheng, SONG Xianzhi, TIAN Shouceng, et al. Intelligent drilling and completion: a review[J]. Engineering, 2022, 18(11): 33–48.

[9] 李根生,宋先知,祝兆鹏,等. 智能钻完井技术研究进展与前景展望[J]. 石油钻探技术,2023,51(4):35–47. LI Gensheng, SONG Xianzhi, ZHU Zhaopeng, et al. Research progress and the prospect of intelligent drilling and completion technologies[J]. Petroleum Drilling Techniques, 2023, 51(4): 35–47.

[10] 杨传书. 数字孪生技术在钻井领域的应用探索[J]. 石油钻探技术,2022,50(3):10–16. YANG Chuanshu. Exploration for the application of digital twin technology in drilling engineering[J]. Petroleum Drilling Techniques, 2022, 50(3): 10–16.

[11] 张好林,杨传书,李昌盛,等. 钻井数字孪生系统设计与研发实践[J]. 石油钻探技术,2023,51(3):58–65. ZHANG Haolin, YANG Chuanshu, LI Changsheng, et al. Design and research practice of a drilling digital twin system[J]. Petroleum Drilling Techniques, 2023, 51(3): 58–65.

[12] SUGIURA J, SAMUEL R, OPPELT J, et al. Drilling modeling and simulation: current state and future goals[R]. SPE 173045, 2015.

[13] MAYANI M G, ROMMETVEIT R, OEDEGAARD S I, et al. Drilling automated realtime monitoring using digital twin[R]. SPE 192807, 2018.

[14] LAGRANGE E. Developing a digital twin: the roadmap for oil and gas optimization[R]. SPE 195790, 2019.

[15] THORESEN K E, KYLLINGSTAD Å, HOVLAND S, et al. Using an advanced digital twin to improve downhole pressure control[R]. SPE 194088, 2019.

[16] VARADARAJAN P A, ROGUIN G, ABOLINS N, et al. A digital twin for real-time drilling hydraulics simulation using a hybrid approach of physics and machine learning[R]. OTC 31278, 2021.

[17] SHATIRY M S A, HARUN F, HUSNI Z H, et al. A review of the digital twin technology application in energy industry for performance improvement[J]. AIP Conference Proceedings, 2023, 2827(1): 040012.

[18] 张霖. 关于数字孪生的冷思考及其背后的建模和仿真技术[J]. 系统仿真学报,2020,32(4):1–10. ZHANG Lin. Cold thinking on digital twins and the modeling and simulation techniques behind them[J]. Journal of System Simulation, 2020, 32(4): 1–10.

[19] TAO Fei, LIU Ang, HU Tianliang, et al. Digital twin driven smart design[M]. London: Academic Press, 2020.

[20] 庄存波,刘检华,熊辉,等. 产品数字孪生体的内涵、体系结构及其发展趋势[J]. 计算机集成制造系统,2017,23(4):753–768. ZHUANG Cunbo, LIU Jianhua, XIONG Hui, et al. Connotation, architecture and trends of product digital twin[J]. Computer Integrated Manufacturing Systems, 2017, 23(4): 753–768.

[21] 张霖,陆涵. 从建模仿真看数字孪生[J]. 系统仿真学报,2021,33(5):995–1007. ZHANG Lin, LU Han. Discussing digital twin from of modeling and simulation[J]. Journal of System Simulation, 2021, 33(5): 995–1007.

[22] 王巍,刘永生,廖军,等. 数字孪生关键技术及体系架构[J]. 邮电设计技术,2021(8):10–14. WANG Wei, LIU Yongsheng, LIAO Jun, et al. Key technology and architecture of digital twin[J]. Designing Techniques of Posts and Telecommunications, 2021(8): 10–14.

[23] 本刊编辑部. 美欧军工领域发力数字孪生技术应用[J]. 国防科技工业,2019(2):36–37. Editorial Department of This Magazine. The US and Europe are making efforts to apply digital twin technology in the military industry[J]. Defence Science & Technology Industry, 2019(2): 36–37.

[24] 方伟光,聂兆伟,刘宸宁,等. 数字孪生驱动的武器装备智能保障技术研究[J]. 系统工程与电子技术,2023,45(4):1247–1260. FANG Weiguang, NIE Zhaowei, LIU Chenning, et al. Research on digital twin driven intelligent weaponry support technology[J]. Systems Engineering and Electronics, 2023, 45(4): 1247–1260.

[25] 胡权. 数字孪生体:第四次工业革命的通用目的技术[M]. 北京:人民邮电出版社,2021. HU Quan. Digital twin: general-purpose technologies (GPT) of the fourth industrial revolution[M]. Beijing: Posts and Telecommunications Press, 2021.

[26] 王林,乔建梅. 国外数字孪生技术发展及对我国的启示[J]. 上海信息化,2021(11):52–55. WANG Lin, QIAO Jianmei. The development of digital twin technology abroad and its implications for China[J]. Shanghai Informatization, 2021(11): 52–55.

[27] 陶飞,程颖,程江峰,等. 数字孪生车间信息物理融合理论与技术[J]. 计算机集成制造系统,2017,23(8):1603–1611. TAO Fei, CHENG Ying, CHENG Jiangfeng, et al. Theories and technologies for cyber-physical fusion in digital twin shop-floor[J]. Computer Integrated Manufacturing Systems, 2017, 23(8): 1603–1611.

[28] 苏兴华,詹胜,胡刚. 石油钻井数字孪生架构设计[J]. 信息系统工程,2021(11):26–30. SU Xinghua, ZHAN Sheng, HU Gang. Design of digital twin architecture for oil drilling[J]. China CIO News, 2021(11): 26–30.

[29] 杨少龙,孙延浩,向先波,等. 船舶数字孪生及其服务全生命周期研究综述[J]. 舰船科学技术,2020,42(21):1–8. YANG Shaolong, SUN Yanhao, XIANG Xianbo, et al. Ship digital twin and a review of life-cycle service[J]. Ship Science and Technology, 2020, 42(21): 1–8.

[30] 陶飞,刘蔚然,刘检华,等. 数字孪生及其应用探索[J]. 计算机集成制造系统,2018,24(1):1–18. TAO Fei, LIU Weiran, LIU Jianhua, et al. Digital twin and its potential application exploration[J]. Computer Integrated Manufacturing Systems, 2018, 24(1): 1–18.

[31] ROMMETVEIT R, BJØRKEVOLL K S, HALSEY G W, et al. eDrilling: a system for real-time drilling simulation, 3D visualization, and control[R]. SPE 106903, 2007.

[32] MAYANI M G, SVENDSEN M, OEDEGAARD S I. Drilling digital twin success stories the last 10 years[R]. SPE 191336, 2018.

[33] ROMMETVEIT R, GHOLAMI MAYANI M, NABAVI J, et al. Automatic realtime monitoring of drilling using digital twin technologies enhance safety and reduce costs[R]. SPE 197465, 2019.

[34] KEMAJOU V, SAMUEL R. Real-time well monitoring and engineering analysis of drilling activities: Intelligent rig state detection and prediction with uncertainty[C]//ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering. New York: ASME, 2020: V011T11A001.

[35] ISLAM N, ROSENER A, SOUZA W, et al. Smarter well engineering concepts aid in reducing planning time and increasing ROP[C]//First EAGE Digitalization Conference and Exhibition. Odijk: European Association of Geoscientists & Engineers, 2020: 1–5.

[36] BIMASTIANTO P, KHAMBETE S, ALSAADI H, et al. Digital twin implementation on current development drilling, benefits and way forward[R]. SPE 202795, 2020.

[37] 井玉霏. 石油钻机提升系统的数字孪生模型构建[D]. 西安:西安石油大学,2023. JING Yufei. Construction of digital twin model for lifting system of oil drilling rig[D]. Xi'an: Xi'an Shiyou University, 2023.

[38] SRIKONDA R, RASTOGI A, OESTENSEN H. Increasing facility uptime using machine learning and physics-based hybrid analytics in a dynamic digital twin[R]. OTC 30723, 2020.

[39] WU Bo, KOU Yufeng, LIU Jun, et al. Research on the application of digital twin technology in the structural safety assessment of deep-water semi-submersible platforms[R]. ISOPE-I 22-296, 2022.

[40] MURRAY P, WATTIS Z, BAIN B, et al. Towards a digital twin supporting risk based decision making for offshore installations[R]. SPE 195717, 2019.

[41] 蒋爱国,王金江,谷明,等. 数字孪生驱动半潜式钻井平台智能技术应用[J]. 船海工程,2019,48(5):49–52. JIANG Aiguo, WANG Jinjiang, GU Ming, et al. Application of intelligent technology of semi-submersible drilling platform driven by digital twin[J]. Ship & Ocean Engineering, 2019, 48(5): 49–52.

[42] STRAW M, MISTRY R, LEWIS S, et al. Predictive digital twin for performance and integrity[R]. OTC 31863, 2022.

[43] 刘文岭,韩大匡. 数字孪生油气藏:智慧油气田建设的新方向[J]. 石油学报,2022,43(10):1450–1461. LIU Wenling, HAN Dakuang. Digital twin system of oil and gas reservoirs: a new direction for smart oil and gas field construction[J]. Acta Petrolei Sinica, 2022, 43(10): 1450–1461.

[44] SHIRANGI M G, FURLONG E, SIMS K S. Digital twins for well planning and bit dull grade prediction[R]. SPE 200740, 2020.

[45] SHI Jibin, DOURTHE L, LI D, et al. Real-time reamer vibration predicting, monitoring, and decision-making using hybrid modeling and a process digital twin[R]. SPE 208795, 2022.

[46] BOUKREDERA F S, HADJADJ A, YOUCEFI M R. Drill string torsional vibrations modeling with dynamic drill pipe properties measurement and field validation[J]. Journal of Energy Resources Technology, 2022, 144(2): 024502. doi: 10.1115/1.4051299

[47] SHIRANGI M G, ETTEHADI R, ARAGALL R, et al. Digital twins for drilling fluids: advances and opportunities[R]. SPE 199681, 2020.

[48] SAINI G S, ASHOK P, VAN OORT E. Predictive action planning for hole cleaning optimization and stuck pipe prevention using digital twinning and reinforcement learning[R]. SPE 199548, 2020.

[49] ANJOS J L, ARANHA P E, MARTINS A L, et al. Digital twin for well integrity with real time surveillance[R]. OTC 30574, 2020.

[50] KARPOV R B, ZUBKOV D Y, MURLAEV A V, et al. Drilling performance and data quality control with live digital twin[R]. SPE 206527, 2021.

[51] 张鑫鑫,梁博文,张晓龙,等. 智能钻井装备与技术研究进展[J]. 煤田地质与勘探,2023,51(9):20–30. doi: 10.12363/issn.1001-1986.23.06.0324 ZHANG Xinxin, LIANG Bowen, ZHANG Xiaolong, et al. Research progress of intelligent drilling equipment and technology[J]. Coal Geology & Exploration, 2023, 51(9): 20–30. doi: 10.12363/issn.1001-1986.23.06.0324

[52] 赵恩普,刘晓晨. 浅析井场数据远程传输系统的设计与实现[J]. 中国管理信息化,2018,21(18):66–67. ZHAO Enpu, LIU Xiaochen. Design and implementation of remote transmission system for well site data[J]. China Management Informationization, 2018, 21(18): 66–67.

[53] 何治亮,赵向原,张文彪,等. 深层–超深层碳酸盐岩储层精细地质建模技术进展与攻关方向[J]. 石油与天然气地质,2023,44(1):16–33. HE Zhiliang, ZHAO Xiangyuan, ZHANG Wenbiao, et al. Progress and direction of geological modeling for deep and ultra-deep carbonate reservoirs[J]. Oil & Gas Geology, 2023, 44(1): 16–33.

[54] 叶新,潘清,董正宏. 多领域建模仿真方法综述[J]. 软件,2014,35(3):233–236. YE Xin, PAN Qing, DONG Zhenghong. Comparison of multi-domain modeling and simulation technology[J]. Software, 2014, 35(3): 233–236.

[55] ZHANG Chengkai, SONG Xianzhi, SU Yinao, et al. Real-time prediction of rate of penetration by combining attention-based gated recurrent unit network and fully connected neural networks[J]. Journal of Petroleum Science and Engineering, 2022, 213: 110396. doi: 10.1016/j.petrol.2022.110396

[56] 祝兆鹏,张瑞,宋先知,等. 数据拓展和增量更新的井底压力实时预测方法[J]. 石油机械,2023,51(6):1–10. ZHU Zhaopeng, ZHANG Rui, SONG Xianzhi, et al. Real-time prediction of bottom hole pressure based on data expansion and incremental update[J]. China Petroleum Machinery, 2023, 51(6): 1–10.

[57] 肖立志. 机器学习数据驱动与机理模型融合及可解释性问题[J]. 石油物探,2022,61(2):205–212. doi: 10.3969/j.issn.1000-1441.2022.02.002 XIAO Lizhi. The fusion of data-driven machine learning with mechanism models and interpretability issues[J]. Geophysical Prospecting for Petroleum, 2022, 61(2): 205–212. doi: 10.3969/j.issn.1000-1441.2022.02.002

[58] KARNIADAKIS G E, KEVREKIDIS I G, LU Lu, et al. Physics-informed machine learning[J]. Nature Reviews Physics, 2021, 3(6): 422–440. doi: 10.1038/s42254-021-00314-5

[59] CURINA F, TALAT QUSHCHI A, ALDANY A. A case study for the development and use of a well control simulator as a digital twin of a real scenario[R]. SPE 206530, 2021.

[60] FERRARA P, RICCI MACCARINI G, POLONI R, et al. Virtual reality: new concepts for virtual drilling environment and well digital twin[R]. IPTC 20267, 2020.

[61] CHATAR C, LOKESH R, KAMBOJ V, et al. Extended reality and gamification for drilling[R]. SPE 212532, 2023.

[62] 王文明,侯春来,武振宇,等. 海洋无隔水管修井的数字孪生框架与可视化交互[J]. 计算机集成制造系统,2021,27(2):423–431. WANG Wenming, HOU Chunlai, WU Zhenyu, et al. Frame and visualization for digital twin of marine riserless well intervention[J]. Computer Integrated Manufacturing Systems, 2021, 27(2): 423–431.

[63] 李浩,刘根,文笑雨,等. 面向人机交互的数字孪生系统工业安全控制体系与关键技术[J]. 计算机集成制造系统,2021,27(2):374–389. LI Hao, LIU Gen, WEN Xiaoyu, et al. Industrial safety control system and key technologies of digital twin system oriented to human-machine interaction[J]. Computer Integrated Manufacturing Systems, 2021, 27(2): 374–389.

[64] 金镭,秦雪伦,江如意,等. 油气行业数字孪生研究述评与展望[J]. 世界石油工业,2022,29(5):17–25. JIN Lei, QIN Xuelun, JIANG Ruyi, et al. Review and prospect of digital twin research in oil and gas industry[J]. World Petroleum Industry, 2022, 29(5): 17–25.

-

期刊类型引用(10)

1. 肖春燕,王犁,杨彪,王磊,鲁红升. 高强度可固化水溶性树脂封堵剂的制备及性能评价. 化学研究与应用. 2024(01): 151-156 .  百度学术

百度学术

2. 王猛,高其宇,郭田超. 一种油气田用耐高温凝胶调堵剂制备及性能研究. 粘接. 2024(03): 53-56 .  百度学术

百度学术

3. 张建亮,宋宏志,张卫行,戎凯旋,李毓,潘玉萍. 海上特超稠油油藏小井距蒸汽吞吐汽窜堵调工艺. 石油钻采工艺. 2024(02): 199-207 .  百度学术

百度学术

4. 孙玉豹,张兆年,吴春洲,王少华,陈立峰,邓俊辉. 稠油热采可降解封窜剂的制备及性能评价. 石油化工. 2023(02): 216-222 .  百度学术

百度学术

5. 周剑峰,杨涛,张菁燕,周文平,高璇. 早期水热养护对铝酸钙水泥结构稳定性的影响. 硅酸盐通报. 2023(03): 802-807+826 .  百度学术

百度学术

6. 陶建强. 边底水超稠油油藏改性石墨烯封堵技术的研究与应用. 精细石油化工. 2023(03): 9-12 .  百度学术

百度学术

7. 杨光,谢兴华,谢强,王学锐,李子玉. 油田封堵专用铝热剂的制备与性能研究. 爆破器材. 2023(04): 44-50 .  百度学术

百度学术

8. 尹家峰,王晓军,鲁政权,步文洋,孙磊,景烨琦,孙云超,闻丽. 辽河大民屯凹陷页岩油储层强封堵恒流变油基钻井液技术. 特种油气藏. 2023(04): 163-168 .  百度学术

百度学术

9. 徐庆,李达,张德龙,李景伟. 大庆稠油耐高温起泡复配体系室内评价研究. 长江大学学报(自然科学版). 2023(06): 84-92 .  百度学术

百度学术

10. 丁建新,席岩,蒋记伟,王海涛,李雪松,李辉. 高温及超高温下水泥石力学及孔渗特性变化规律. 钻井液与完井液. 2022(06): 754-760 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: