Application and Prospect of Digital Twin in Oil and Gas Drilling & Completion Engineering

-

摘要:

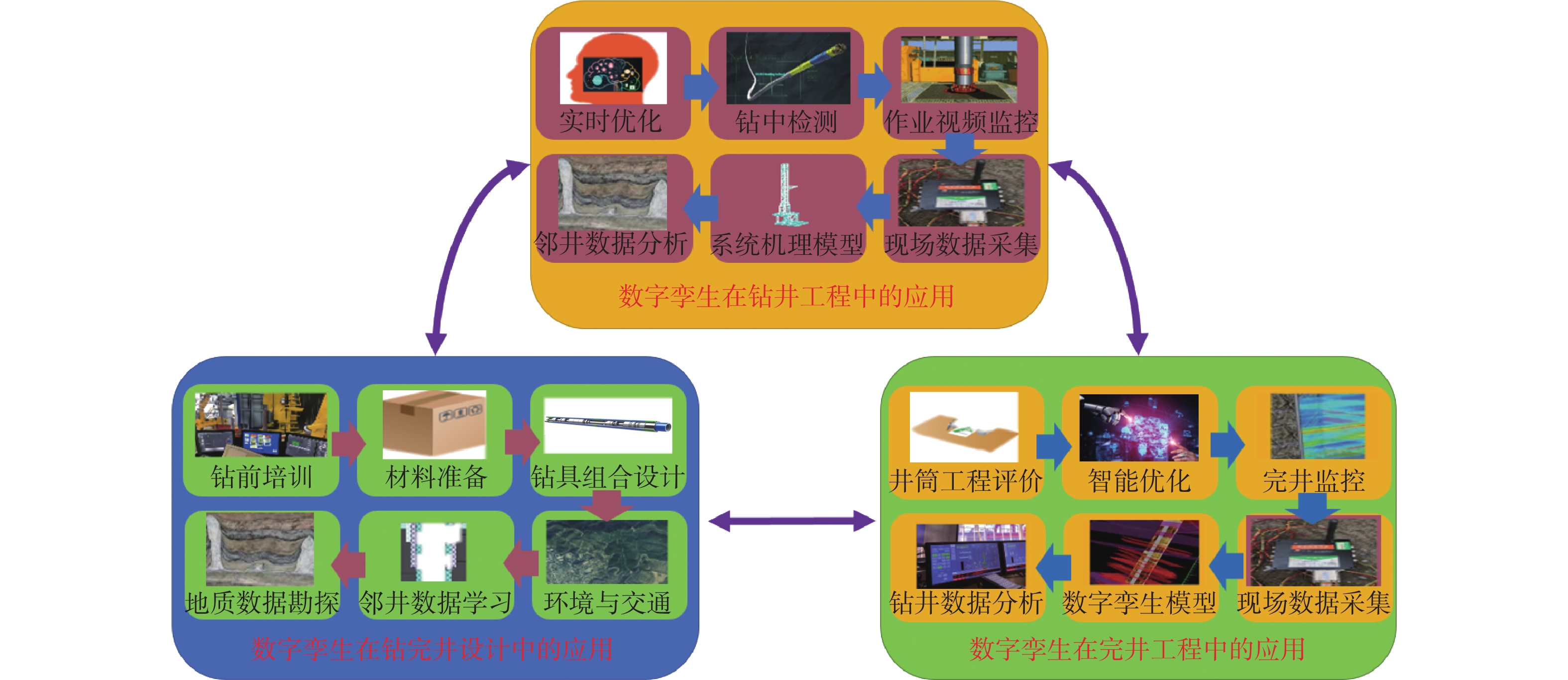

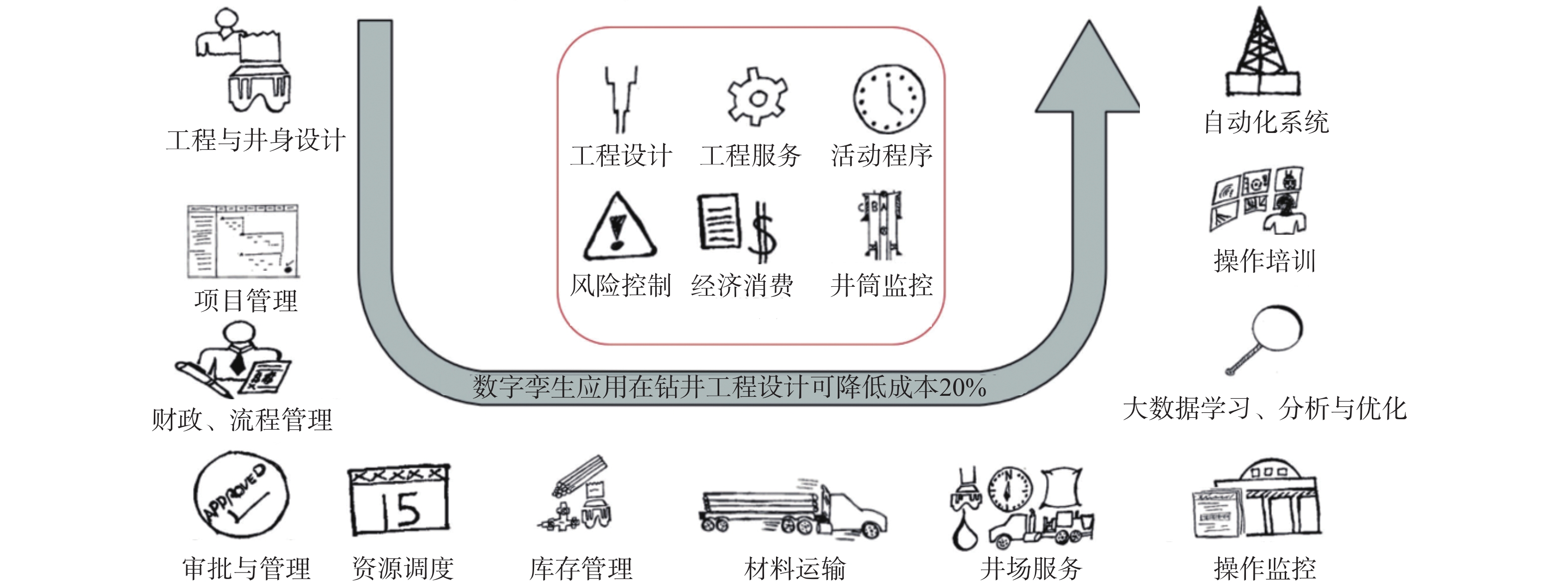

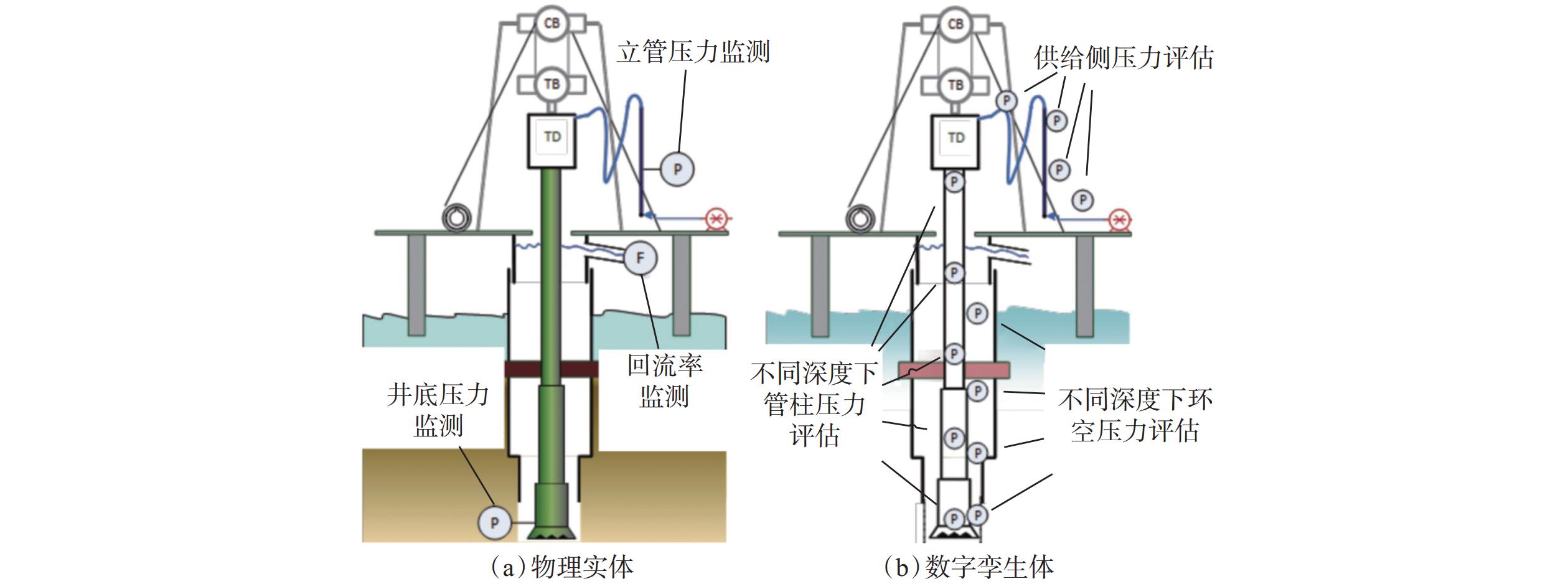

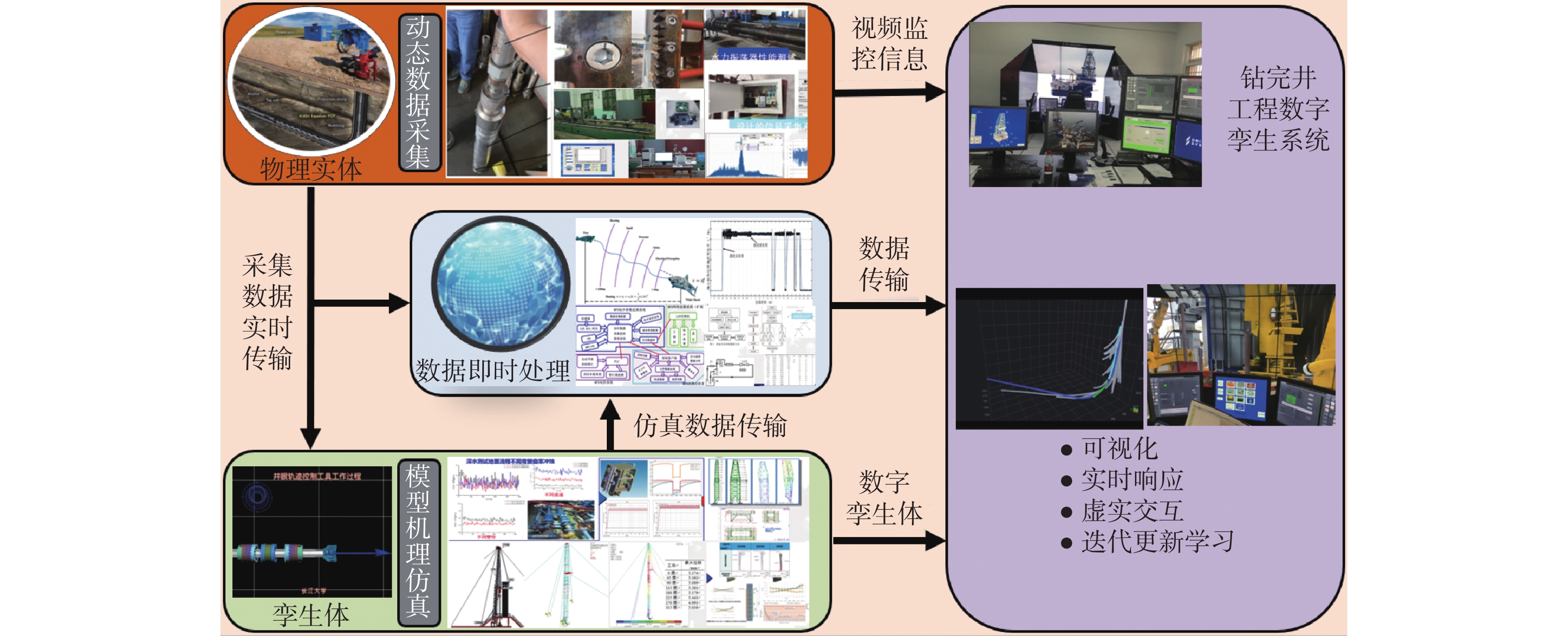

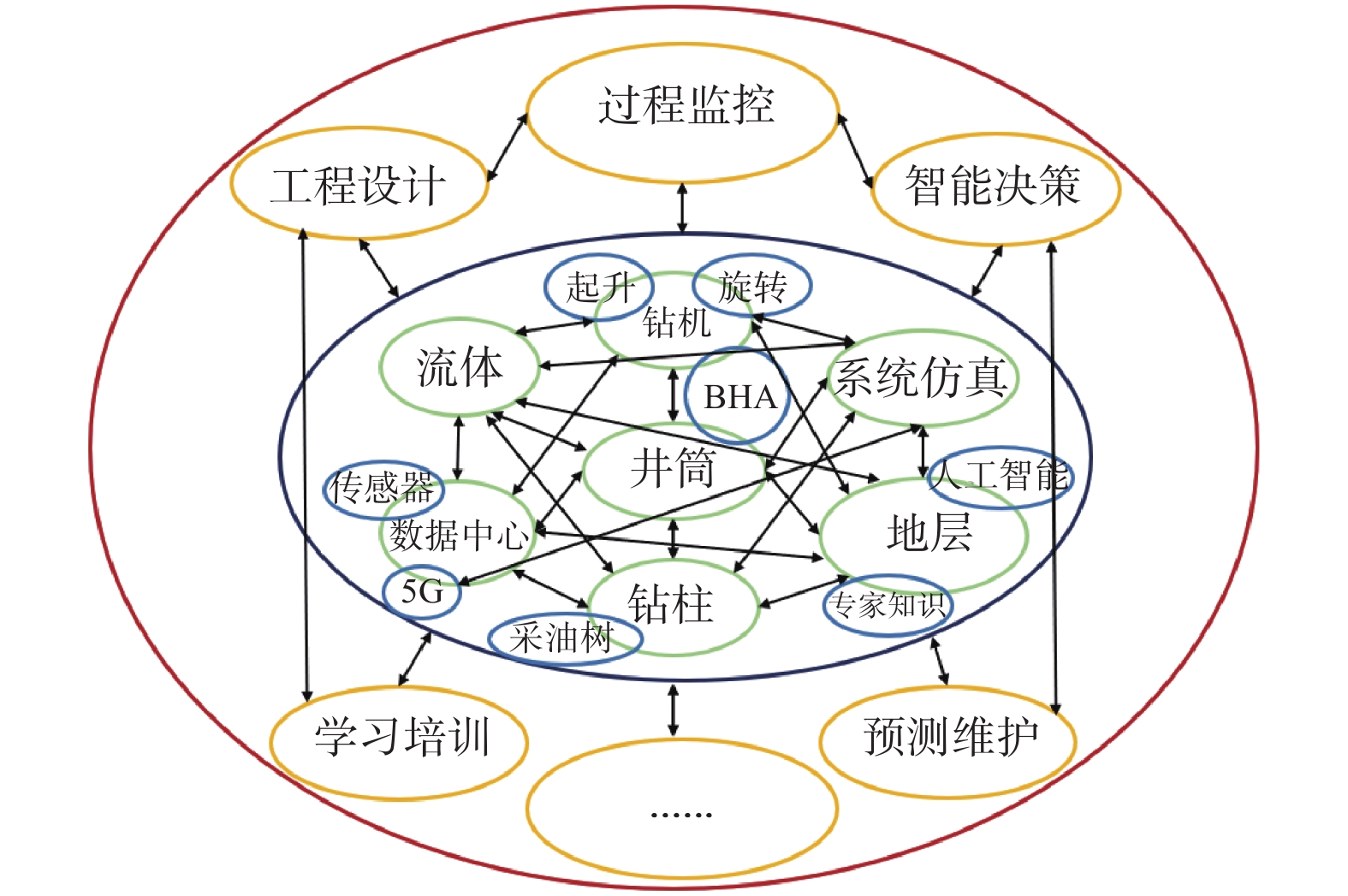

数字孪生技术在数据实时分析、工程设计优化和设备健康诊断等方面已展现出巨大潜力,成为油气行业数字化转型发展、加速油气行业新一代技术创新的关键技术,但受钻完井工程中软硬件不完善与研究方法不明确的制约,目前尚处于起步阶段。在论述油气田钻完井工程数字孪生技术的概念和技术特点的基础上,重点介绍了数字孪生技术在钻完井工程的钻前设计、过程监控、作业培训方面的最新应用进展,提出了数字孪生技术在钻完井工程中的应用构成方案,探讨了数字孪生的关键技术方法;并分析了数字孪生技术在钻完井工程及其相关行业应用中存在的问题,提出了油气行业数字孪生技术发展建议。这可为数字孪生技术在油气行业的应用提供理论基础与方法指导,加速油气行业数字化进程,提升油气田开发效率,推动智慧油田全面构建。

Abstract:Digital twin has shown great potential in real-time data analysis, engineering design optimization, and equipment health diagnosis and has become a key technology for achieving the digital transformation development of the oil and gas industry and accelerating the next generation of technological innovation in the oil and gas industry. However, due to the imperfect software and hardware in drilling & completion engineering and the unclear research methods, the technology is still in the initial stage. On the basis of discussing the concept and technical characteristics of digital twin in the drilling & completion engineering of oil and gas fields, the latest application progress of digital twin in pre-drilling design, monitoring during drilling, and completion, and operation training of the drilling & completion engineering was introduced, and the application scheme of digital twin in drilling & completion engineering was proposed. The key technologies and methods of digital twin were discussed, and the problems existing in the application of digital twin in drilling & completion engineering and related industries were analyzed. In addition, some suggestions for the development of digital twin in the oil and gas industry were put forward. The results can provide a theoretical basis and method guidance for the application of digital twin in the oil and gas industry, so as to accelerate the digitization process of the oil and gas industry, improve the development efficiency of oil and gas fields, and promote the comprehensive construction of smart oil fields.

-

Keywords:

- oil well /

- gas well /

- drilling /

- completion /

- digital twin /

- technology status /

- development proposal

-

油气勘探开发过程中,通过随钻描述钻遇地层的岩屑信息可以直接揭示地层的岩性、物性、源岩特性及含油气性等特征。传统的岩屑录井方法主要是现场地质技术人员根据钻井速度,按照一定的取样间隔捞取岩屑样品并经过清洗、晾晒,通过直接观察或借助于放大镜、显微镜等工具观察岩屑样品,进而识别岩屑的岩性和判断地层的含油气性等。随着快速钻井技术的发展与广泛应用,钻井速度大幅度提高,岩屑粒径变小,给传统的岩屑录井带来了以下困难:1)钻速提高缩短了岩屑样品的取样时间,增大了岩屑捞取的工作强度,且捞取不及时会有降低样品可靠性的风险;2)采用PDC钻头或其他优快钻井技术钻进时产生的岩屑粒径很小,肉眼难以识别。因此,为确保岩屑录井的及时性与准确性,研究岩屑的在线检测十分必要[1–2]。

激光诱导击穿光谱(laser induced breakdown spectroscopy,LIBS)技术自引入国内以来取得了很大进展,在很多行业得到了广泛应用:在检测方法方面,分析了LIBS检测的影响因素,并制定了对应的消除措施,建立了样品中元素的检测模型,实现了元素信息的定量检测[3–18];在石油录井方面,建立了岩屑元素的量化检测模型,开发了相关软件,研制了检测设备,为录井施工现场解决岩屑识别技术难题提供了技术支持[19–27],但其采用的均为离线检测方式。利用LIBS技术识别岩性还存在一些技术问题,比如岩屑需要人工取样、不能连续识别地层岩性等,制约了其应用。为进一步发挥LIBS技术在快速钻井条件下识别地层岩性的作用,笔者提出了基于LIBS技术的岩屑岩性在线识别技术的构想,并开展了相关试验,验证了其可行性。

1. LIBS技术基本原理及特点

1.1 基本原理

LIBS是一种原子发射光谱技术,根据电子能级跃迁发射的原子(离子)谱线进行定性和定量分析,其测量原理如图1所示。其中,激光器选用Nd:YAG激光器,探测器选用增强型光电耦合型探测器ICCD。

激光器产生的激光光束(通常几十到几百毫焦)经过透镜后聚焦到样品表面,聚焦点处的样品吸收激光能量后产生等离子体。利用透镜采集部分等离子体发射光并由光纤传送到光谱仪,光谱仪进一步处理光谱信号,并转换成数字信号传输到计算机进行光谱分析。根据原子(离子)谱线的波长分析元素的种类,根据谱线强度分析元素的含量。

1.2 技术特点

1)多元素同时检测。LIBS技术采用强激光激发样品,常见元素均能被激发出诱导击穿光谱,因此可以定性、定量检测分析出样品中的元素信息。

2)分析周期短、实时性强。应用LIBS技术分析样品的时间与激光器的频率、光谱仪的积分时间有关,激光器频率和光谱仪的积分时间小于100 ms,样品的分析时间也为毫秒级,具有较强的实时性。

3)具有剥离检测特性。LIBS技术在无损检测的基础上,通过调整激光器功率、光路聚焦焦距,可以对样品表面进行剥离处理,以检测其真实信息。

2. 基于LIBS的岩性识别技术进展与不足

为了解决钻井过程中细小岩屑岩性识别困难的问题,国内外利用LIBS的技术特点,开展了基于LIBS的岩性识别技术研究。国内多所高校开展了利用LIBS技术量化检测岩屑元素含量信息的研究工作,初步实现了8种元素的量化检测和岩性识别。中国石化与中国科学院合作,进行了技术攻关,形成了基于LIBS的岩性识别技术——通过优选硬件系统参数,利用高能激光直接照射岩屑样品,可以检测出样品中的26种特征元素,通过元素含量比和岩性特征谱图等岩性识别模型,实现砂岩、泥岩、页岩、灰岩、白云岩、膏岩、盐岩、煤和沥青等9种岩性或矿物的准确识别。该技术已在多个油气田的勘探开发中应用,对快速准确识别钻遇地层的岩性、提高岩性剖面符合率发挥了重要作用。

但基于LIBS的岩性识别技术也存在着一些不足,主要表现在以下几个方面:

1)岩性识别符合率有待进一步提高。应用LIBS进行岩性识别时,需要人工采集、清洗岩屑样品,快速钻井条件下岩屑粒径细小不易捞取,在清洗过程中容易流失,岩屑样品代表性差,直接影响岩屑岩性识别符合率。

2)地层岩性识别成果不连续。岩屑样品按照钻进时间间隔采集数据,但地层岩性识别结果是按照单位进尺给出结果,钻遇地层岩性识别结果不连续,难以及时准确发现薄层岩性的变化情况,因此需要进一步提高和完善基于LIBS的岩性识别技术。

3)现有设备的性能需要进一步提高。激光岩性分析仪对每包岩屑样品进行多点检测,并对检测结果进行分析,输出该样品的岩性。目前,其硬件系统不具备在线识别功能,其软件也在岩屑样品对应井深归位方面存在不足。

3. 基于LIBS的岩屑岩性在线识别技术可行性试验

3.1 试验平台

在基于LIBS的岩性识别技术的基础上,模拟录井施工现场环境,构建了试验平台,如图2所示。

试验平台中,探头固定在样品台上方,用于激发样品产生等离子体,同时具有收光功能。样品台为一传输带,岩屑样品置于传输带上方,通过转动传输带模拟施工现场岩屑的运动状态。在计算机系统控制下,激光器发出的激光通过光纤传输到探头并诱导样品台上的岩屑样品产生等离子体,同时采集LIBS光谱信号并由光纤传输到光谱仪,光谱仪进行分光处理及转换后传输到计算机,进一步分析LIBS信息和识别样品的岩性。

3.2 试验结果

3.2.1 岩屑样品状态试验

利用试验平台,检测不同状态条件下的岩屑样品,即对处于干/湿状态、疏松和压实状态的同一岩屑样品进行了检测,得到了同一岩屑样品不同状态下的LIBS信息。同一岩屑样品干/湿状态下的LIBS信息对比如图3所示,同一岩屑样品疏松和压实状态下的LIBS信息对比如图4所示。

由图3可知,同一个样品在干/湿状态下的LIBS信息特征具有较好的一致性,拟合优度R2=0.917 7;由图4可知,岩屑样品压实状态下的光谱强度高于疏松状态下的光谱强度,但二者的特征信息之间存在较好的相关性,拟合优度R2=0.932 6。

试验结果表明,岩屑样品的状态只影响其LIBS信息强度的高低,不影响其自身的LIBS特征。因此,基于LIBS的岩屑岩性在线识别结果与岩屑样品检测时的状态无关。

3.2.2 剥蚀试验

页岩气钻井中广泛应用油基钻井液,油基钻井液条件下岩屑样品表面污染严重,难以清洗处理,影响样品岩性识别的准确率。借鉴LIBS具有剥蚀的特性,进行了油基钻井液岩屑样品LIBS剥蚀表面污染层的试验。通过调整激光器功率及光路,对油基钻井液岩屑样品表面进行剥蚀处理,得到了波长287.30~288.61 nm岩屑样品原始状态下及多次剥蚀后的检测数据,结果见表1。

表 1 油基钻井液岩屑样品剥蚀检测结果对比Table 1. Comparison of the denudation effects of cutting samples in oil-based drilling fluid波长/nm 原始状态 检测数据/光子 第1次① 第2次① 第3次① 第4次① 287.30 189 297 332 385 361 287.35 185 237 234 229 222 287.41 273 409 516 344 219 287.47 136 226 324 185 278 287.52 153 218 386 297 184 287.58 159 205 366 236 228 287.64 210 159 198 225 334 287.70 268 205 411 303 368 287.75 232 199 256 284 458 287.81 127 163 205 198 240 287.87 235 191 337 209 257 287.92 232 136 175 341 380 287.98 410 352 405 412 456 288.04 947 869 1 133 996 1 130 288.10 3 870 5 917 6 030 6 430 6 934 288.15 8 111 12 936 12 372 14 075 15 359 288.21 3 334 3 436 3 645 3 767 4 659 288.27 854 727 880 811 1 166 288.32 532 448 669 646 604 288.38 468 379 467 421 604 288.44 269 283 364 364 269 288.49 101 268 190 232 153 288.55 204 132 337 402 269 288.61 190 189 309 146 355 注:①为剥蚀次数。 由表1可知,原始状态下的检测数据与第1次剥蚀后数据之间的拟合优度R2=0.573 5,第1次剥蚀后检测数据与第2次剥蚀后检测数据之间的拟合优度R2=0.694 3,第2次剥蚀后检测数据与第3次剥蚀后检测数据之间的拟合优度R2=0.733 0,第3次剥蚀后检测数据与第4次剥蚀后检测数据之间的拟合优度R2=0.928 7;岩屑样品同一表面位置在经过3次剥蚀后,LIBS信息稳定,表明第4次剥蚀检测到的LIBS信息是岩屑样品的真实信息。试验结果表明,LIBS技术可以有效消除油基钻井液对岩屑表面的污染,利用LIBS的剥蚀特性,可以剥蚀掉上返地面岩屑样品表面的污染物,消除油基钻井液的影响。

4. 结论与建议

1)试验证明,基于LIBS的岩屑岩性在线识别可行。该技术可以解决现有LIBS岩性识别技术存在的检测数据不连续、岩性识别成果易受干扰等问题,且检测速度非常快。

2)LIBS在线识别岩屑岩性与岩屑样品的状态无关,可以直接原位检测岩屑样品的LIBS信息,有利于在线识别岩屑岩性。

3)通过调整激光器功率和优化光路,利用LIBS的剥蚀特性,可以在油基钻井液条件下准确识别岩屑的岩性,为页岩气开发提供技术支撑。

4)基于LIBS的岩屑岩性在线识别技术是基于光谱检测分析而进行的,岩屑样品的LIBS信息弱,对检测设备光路稳定性要求较高。因此,为提高岩屑岩性识别的准确性,在应用该技术时建议采取必要的防振措施,以确保光路系统稳定。

-

-

[1] FEDER J. Will this be the decade of full digital twins for well construction?[J]. Journal of Petroleum Technology, 2021, 73(3): 34–37. doi: 10.2118/0321-0034-JPT

[2] SAID M M, PILGRIM R, RIDEOUT G, et al. Theoretical development of a digital-twin based automation system for oil well drilling rigs[R]. SPE 208902, 2022.

[3] 贾承造. 中国石油工业上游发展面临的挑战与未来科技攻关方向[J]. 石油学报,2020,41(12):1445–1464. doi: 10.7623/syxb202012001 JIA Chengzao. Development challenges and future scientific and technological researches in China's petroleum industry upstream[J]. Acta Petrolei Sinica, 2020, 41(12): 1445–1464. doi: 10.7623/syxb202012001

[4] GLAESSGEN E, STARGEL D. The digital twin paradigm for future NASA and U. S. air force vehicles[C]//53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference. Reston: American Institute of Aeronautics and Astronautics, 2012: AIAA 2012–2018.

[5] ZBOROWSKI M. Finding meaning, application for the much-discussed “digital twin”[J]. Journal of Petroleum Technology, 2018, 70(6): 26–32. doi: 10.2118/0618-0026-JPT

[6] 陶飞,张贺,戚庆林,等. 数字孪生模型构建理论及应用[J]. 计算机集成制造系统,2021,27(1):1–15. TAO Fei, ZHANG He, QI Qinglin, et al. Theory of digital twin modeling and its application[J]. Computer Integrated Manufacturing Systems, 2021, 27(1): 1–15.

[7] QI Qinglin, TAO Fei, HU Tianliang, et al. Enabling technologies and tools for digital twin[J]. Journal of Manufacturing Systems, 2021, 58(Part B): 3–21.

[8] WANG Mengmeng, WANG Chengye, HNYDIUK-STEFAN A, et al. Recent progress on reliability analysis of offshore wind turbine support structures considering digital twin solutions[J]. Ocean Engineering, 2021, 232: 109168. doi: 10.1016/j.oceaneng.2021.109168

[9] 李德仁. 基于数字孪生的智慧城市[J]. 互联网天地,2021(7):12. LI Deren. Smart city based on digital twins[J]. China Internet, 2021(7): 12.

[10] 胡春宏,郭庆超,张磊,等. 数字孪生流域模型研发若干问题思考[J]. 中国水利,2022(20):7–10. doi: 10.3969/j.issn.1000-1123.2022.20.012 HU Chunhong, GUO Qingchao, ZHANG Lei, et al. Thinking on some problems in the development of professional models for digital twin basins[J]. China Water Resources, 2022(20): 7–10. doi: 10.3969/j.issn.1000-1123.2022.20.012

[11] 杨传书. 数字孪生技术在钻井领域的应用探索[J]. 石油钻探技术,2022,50(3):10–16. doi: 10.11911/syztjs.2022068 YANG Chuanshu. Exploration for the application of digital twin technology in drilling engineering[J]. Petroleum Drilling Techniques, 2022, 50(3): 10–16. doi: 10.11911/syztjs.2022068

[12] 张好林,杨传书,李昌盛,等. 钻井数字孪生系统设计与研发实践[J]. 石油钻探技术,2023,51(3):58–65. doi: 10.11911/syztjs.2023011 ZHANG Haolin, YANG Chuanshu, LI Changsheng, et al. Design and research practice of a drilling digital twin system[J]. Petroleum Drilling Techniques, 2023, 51(3): 58–65. doi: 10.11911/syztjs.2023011

[13] WEYER S, MEYER T, OHMER M, et al. Future modeling and simulation of CPS-based factories: an example from the automotive industry[J]. IFAC-PapersOnLine, 2016, 49(31): 97–102. doi: 10.1016/j.ifacol.2016.12.168

[14] TAO Fei, ZHANG He, LIU Ang, et al. Digital twin in industry: state-of-the-art[J]. IEEE Transactions on Industrial Informatics, 2019, 15(4): 2405–2415. doi: 10.1109/TII.2018.2873186

[15] MACPHERSON J. Technology focus: drilling systems automation and management[J]. Journal of Petroleum Technology, 2020, 72(2): 60. doi: 10.2118/0220-0060-JPT

[16] FEDER J. Upstream digitalization is proving itself in the real world[J]. Journal of Petroleum Technology, 2020, 72(4): 26–28. doi: 10.2118/0420-0026-JPT

[17] FEDER J. BHA-design approach improves drilling performance and wellbore quality[J]. Journal of Petroleum Technology, 2020, 72(12): 57–58. doi: 10.2118/1220-0057-JPT

[18] IMOMOH V B, TOYOBO O, OKAFOR R. Creating a digital twin of part of the earth subsurface through reservoir navigation service[R]. SPE 203621, 2020.

[19] WEI Li, PU Ding, HUANG Min, et al. Applications of digital twins to offshore oil/gas exploitation: from visualization to evaluation[J]. IFAC-PapersOnLine, 2020, 53(5): 738–743. doi: 10.1016/j.ifacol.2021.04.166

[20] BHOWMIK S, NAIK H. Subsea structure and pipeline design automation using digital field twin[R]. OTC 30909, 2020.

[21] ISBELL M R, MANOCHA M R, MANGOLD B R, et al. A novel use of digital technologies for more effective multi-party well planning and execution[R]. SPE 204050, 2021.

[22] NADHAN D, MAYANI M G, ROMMETVEIT R. Drilling with digital twins[R]. SPE 191388, 2018.

[23] 郭永峰. 国际巨头应用“数字孪生体”技术降低油气开采成本[J]. 中国石油企业,2021(7):68–69. GUO Yongfeng. International giants apply “digital twin” technology to reduce oil and gas extraction costs[J]. China Petroleum Enterprise, 2021(7): 68–69.

[24] FERRARA P, MACCARINI G R, POLONI R, et al. Virtual reality: new concepts for virtual drilling environment and well digital twin[R]. IPTC 20267, 2020.

[25] DOUGLAS A, RIOS V. How to achieve project and operational certainty using a digital twin[R]. SPE 195766, 2019.

[26] BURRAFATO S, MALIARDI A, FERRARA P, et al. Virtual reality in D & C: new approaches towards well digital twins[R]. OMC 2019-1240, 2019.

[27] 孙巧雷,冯定,刘旭辉,等. 油气装备新进展课程案例教学设计与实践:以海上“蓝鲸1号”半潜式钻井平台为例[J]. 中国现代教育装备,2023,13:137–139. SUN Qiaolei, FENG Ding, LIU Xuhui, et al. The case teaching design and practice of advance of oil field equipment: taking the offshore semi-submersible drilling and production platform "Blue Whale-1" as an example[J]. China Modern Educational Equipment, 2023, 13: 137–139.

[28] FEDER J. Recovering more than 70% from the Johan Sverdrup Field[J]. Journal of Petroleum Technology, 2020, 72(9): 62–63. doi: 10.2118/0920-0062-JPT

[29] FEDER J. Data exchange and collaboration realize automated drilling control potential[J]. Journal of Petroleum Technology, 2021, 73(2): 47–48. doi: 10.2118/0221-0047-JPT

[30] KARPOV R B, ZUBKOV D Y, MURLAEV A V, et al. Drilling performance and data quality control with live digital twin[R]. SPE 206527, 2021.

[31] SHI Jibin, DOURTHE L, LI D, et al. Real-time reamer vibration predicting, monitoring, and decision-making using hybrid modeling and a process digital twin[R]. SPE 208795, 2022.

[32] SHIRANGI M G, FURLONG E, SIMS K S. Digital twins for well planning and bit dull grade prediction[R]. SPE 200740, 2020.

[33] ARÉVALO P J, HUMMES O, FORSHAW M. Integrated real-time simulation in an earth model–automating drilling and driving efficiency[R]. SPE 204069, 2021.

[34] GAO Zhuo, HYDER S Z. Using autonomous control to stabilize well performance without the downhole pressure gauge[R]. SPE 211042, 2022.

[35] KALININ O, ELFIMOV M, BAYBOLOV T. Exploration drilling management system based on digital twins technology[R]. SPE 205994, 2021.

[36] JEFFERY C, CREEGAN A. Adaptive drilling application uses AI to enhance on-bottom drilling performance[J]. Journal of Petroleum Technology, 2020, 72(8): 45–47. doi: 10.2118/0820-0045-JPT

[37] dos SANTOS M V, DUARTE ROSA R M, de OLIVEIRA L A , et al. Development and deployment of digital twin for production and well integrity[R]. SPE 210260, 2022.

[38] ARÉVALO P J, FORSHAW M, STAROSTIN A, et al. Monitoring hole-cleaning during drilling operations: case studies with a real-time transient model[R]. SPE 210244, 2022.

[39] REYES R A, MACHADO M, TORRE M, et al. Digital wellhead integrated system for production management[R]. SPE 211158, 2022.

[40] KUCUKCOBAN S, KLUK D J, PESTANA R G, et al. A digital twin for computing dynamic watch circles on a dynamically positioned MODU[R]. OTC 31709, 2022.

[41] RODRIGUEZ D, CLARE P, SRIKONDA R, et al. Stampede digital twin: an advanced solution for process equipment condition monitoring[R]. SPE 210106, 2022.

[42] WU Bo, KOU Yufeng, LIU Jun, et al. Research on the application of digital twin technology in the structural safety assessment of deep-water semi-submersible platforms[R]. ISOPE I-22-296, 2022.

[43] CARPENTER C. Johan Sverdrup’s digital operations drive efficiency, safety[J]. Journal of Petroleum Technology, 2020, 72(9): 67–68. doi: 10.2118/0920-0067-JPT

-

期刊类型引用(5)

1. 徐勤亮,陈景皓,高强,汪利伟,李忠利. 低温环境下海洋输油橡胶软管的扭转性能. 科学技术与工程. 2024(25): 10755-10761 .  百度学术

百度学术

2. 王宇哲,张凯,杨甘生,李亚洲. 南极钻机的耐温材料和保温方式的优选. 钻探工程. 2023(S1): 82-89 .  百度学术

百度学术

3. 孟广伟,骆青,钟声,孟广福. 石油化工管道接头橡胶防腐密封材料研究. 化学与粘合. 2022(04): 336-340 .  百度学术

百度学术

4. 王宴滨,张辉,高德利,柯珂,刘文红. 低温环境下钻柱材料力学特性试验及强度设计. 石油钻探技术. 2021(03): 35-41 .  本站查看

本站查看

5. 顾铖璋. 深冷环境下密封橡胶的力学性能研究. 橡胶科技. 2021(08): 375-381 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: