Completion Technologies for HTHP Gas Fields in the Yinggehai Basin

-

摘要:

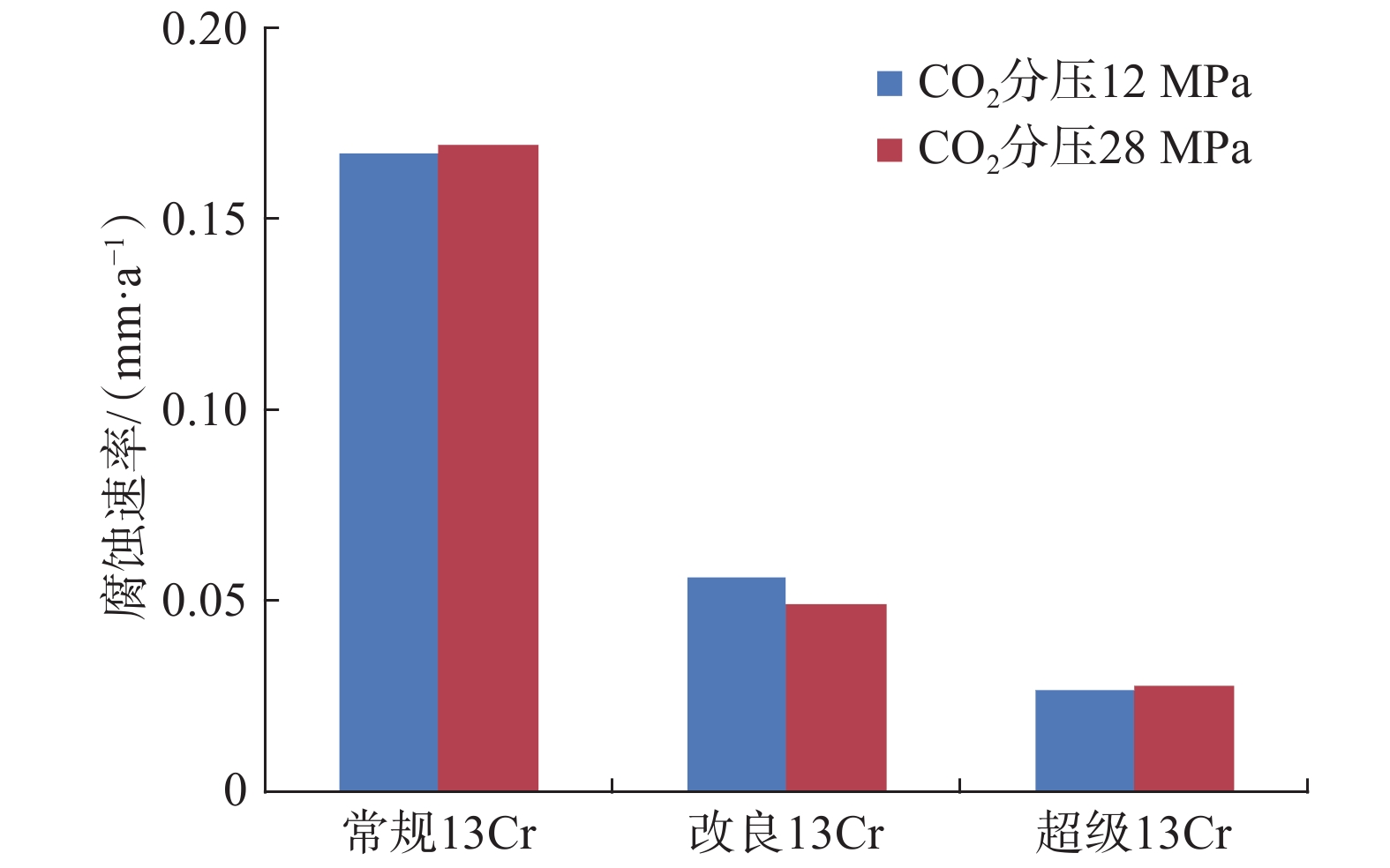

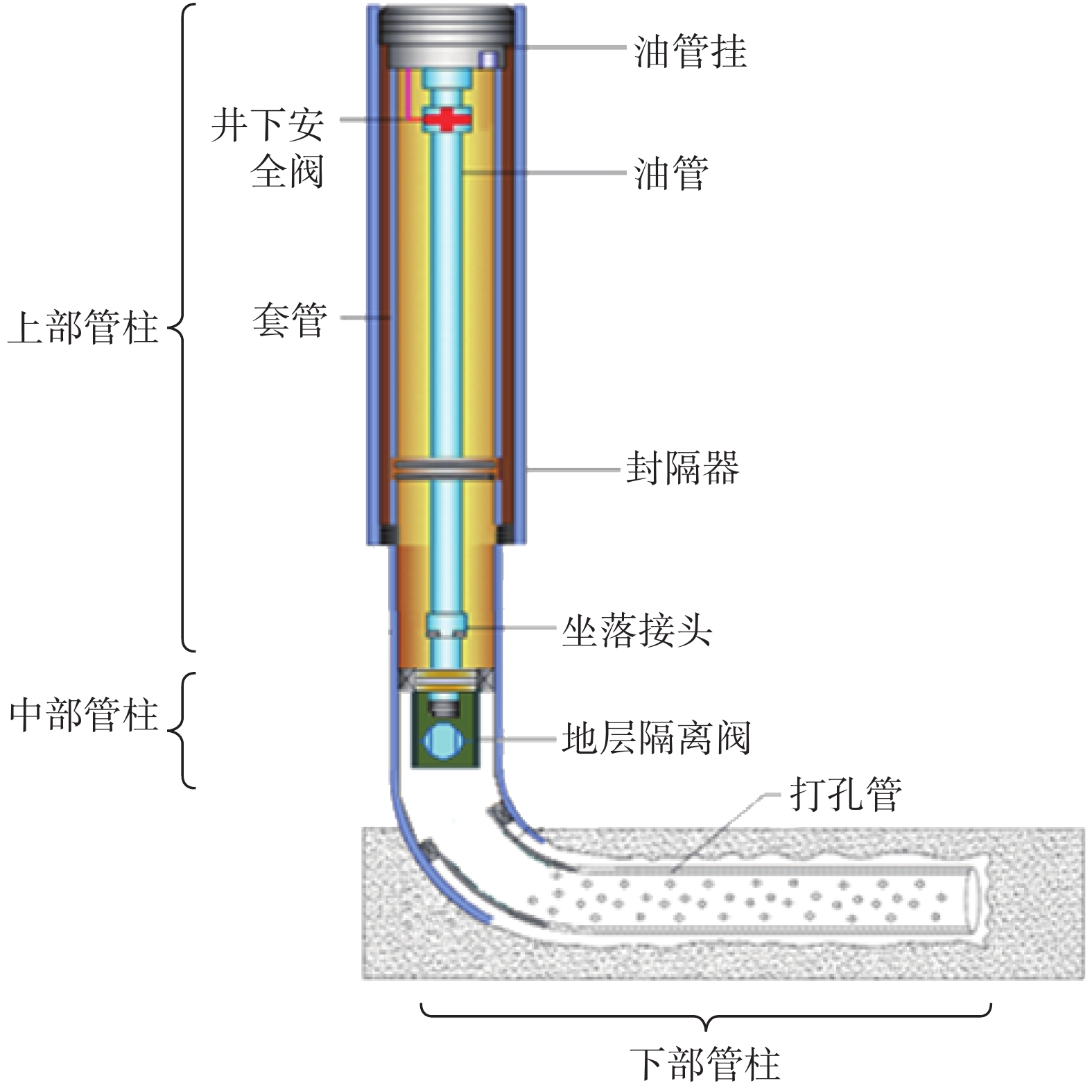

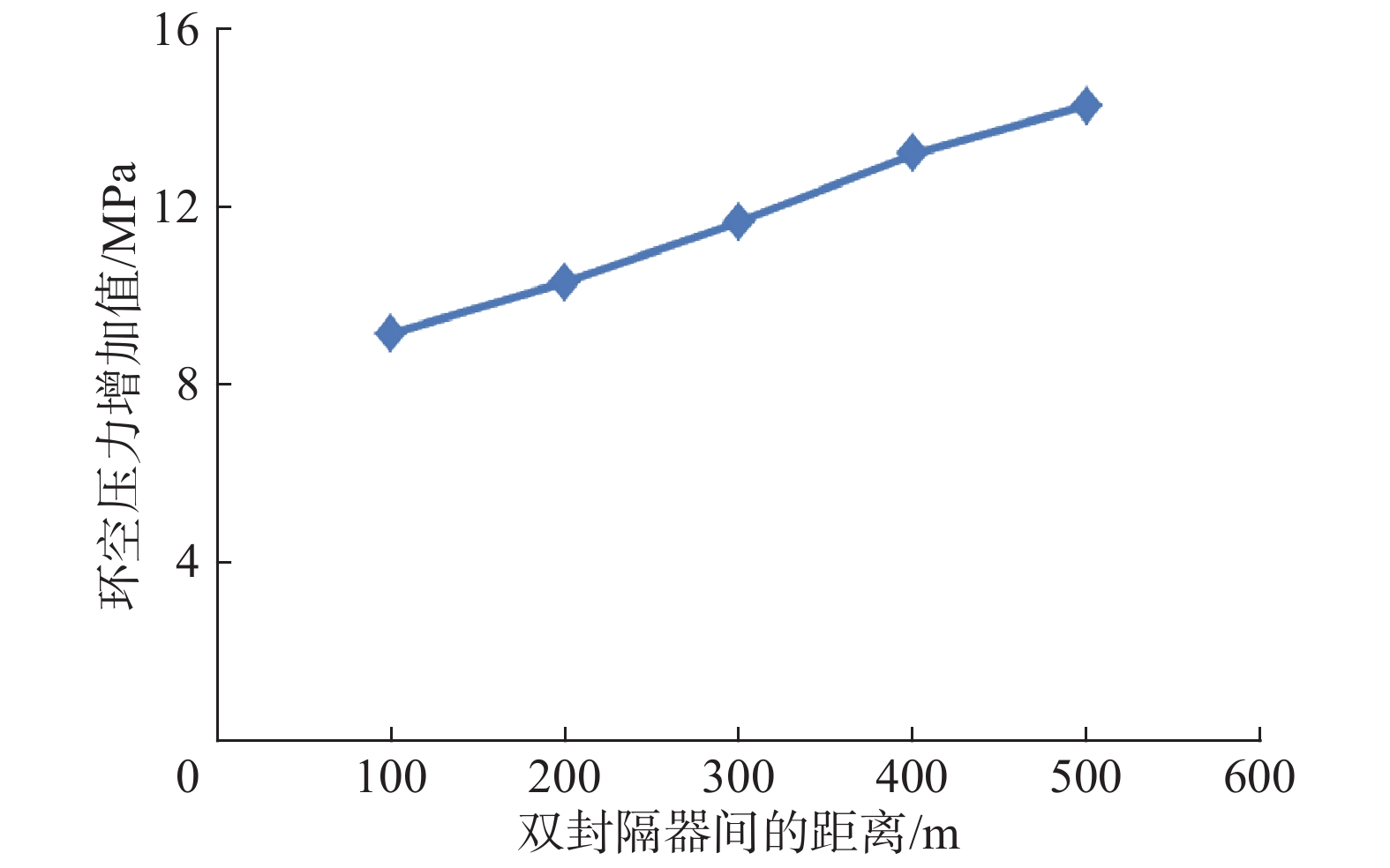

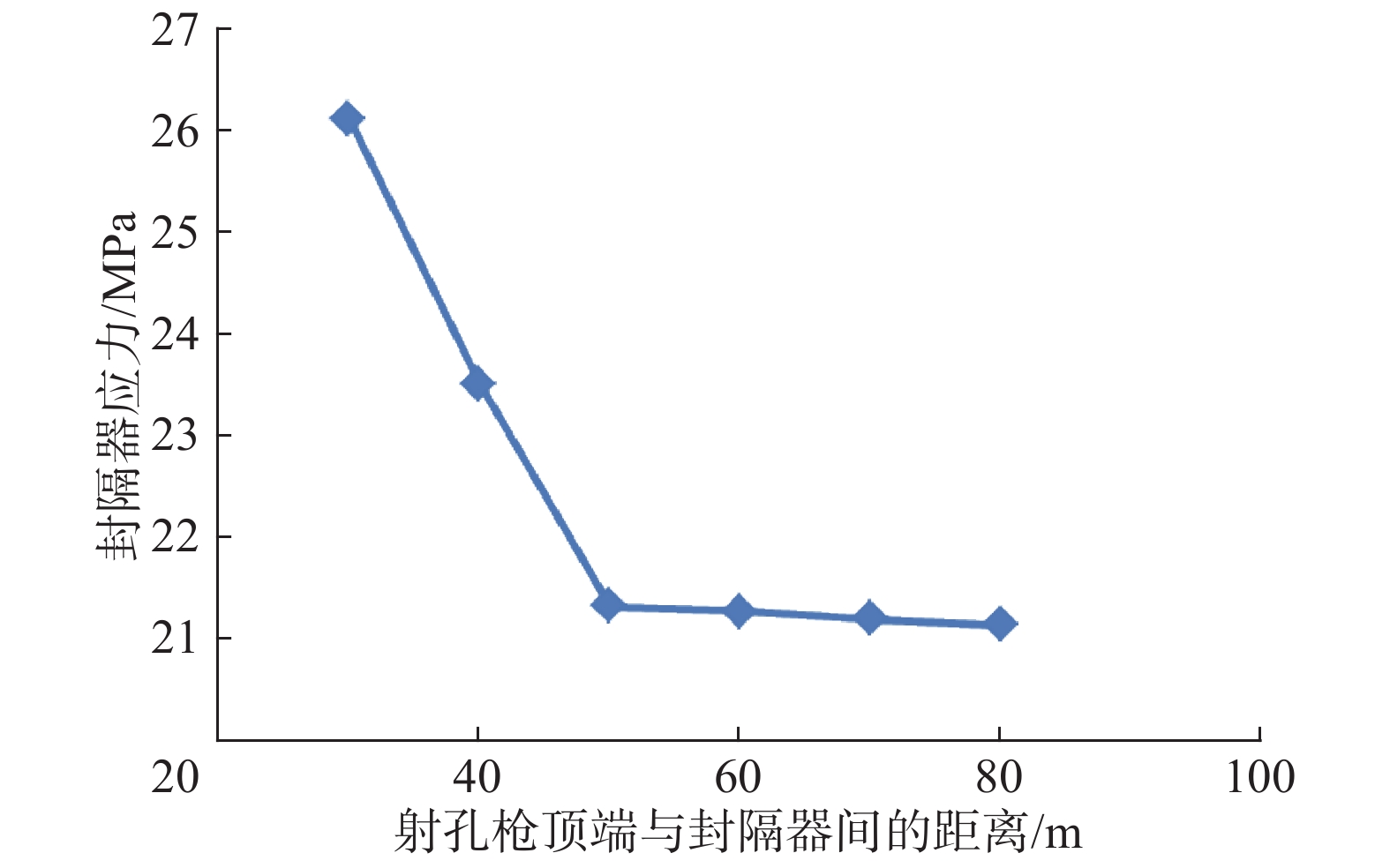

南海莺歌海盆地F气田为高温高压气田,其高温、高压、高含CO2的特点造成井筒的完整性难以保障。为此,根据储层特点,选择了合理的完井方式;依据安全性与经济性兼顾的原则,选择了改良13Cr材质的油套管;根据气田的特点及开发要求,设计了不同井型的生产管柱及射孔管柱,选择了合适的井口采油树及井下工具,并研制了新型环空保护液,最终形成了适用于海上高温高压高含酸性气体气田开发的完井技术。F气田10余口井应用了该技术,生产过程中未出现环空带压现象。实践表明,该完井技术能有效降低井筒带压风险,为规模开发莺歌海盆地高温高压气田提供技术支持。

Abstract:The F Gas Field in Yinggehai Basin of the South China Sea is an HTHP gas field, characteristics of high temperature, high pressure and high CO2 content has been the challenge to the integrity of wellbore, so the completion method was selected pertinently according to the characteristics of reservoirs. Based on the principle of keeping both the safety and the economy, the tubing/casing has been made by modified 13Cr material, and designed the different types of production strings. In terms of the characteristics of gas field and the development requirements, the selection of wellhead Christmas trees and downhole tools was carried out properly, the perforation pipe string was designed, and the proper annulus protection fluid was developed. In the end, it formed a completion technology suitable for the development of HTHP offshore gas fields with high acidic gas content. This completion technology has been applied in more than 10 wells of this gas field, and no sustained annulus pressure was observed during the production process, which indicated that the developed completion technology could effectively ensure the wellbore integrity of such gas fields, and provide supports for the large-scale development of HTHP gas fields in the Yinggehai Basin.

-

Keywords:

- high temperature /

- high pressure /

- high CO2 content /

- completion /

- production string /

- corrosion prevention /

- Yinggehai Basin

-

-

表 1 常规13Cr、改良13Cr和超级13Cr等3种管材的化学成分

Table 1 Chemical composition of three kinds of tubular, such as the conventional 13Cr, modified 13Cr and super 13Cr

管材 w(C),% w (Si),%. w (Mn),% w (P),% w (S),% w (Cr),% w (Ni),% w (Mo),% w (Cu),% 常规13Cr 0.15~0.22 1.00 0.25~1.00 0.02 0.010 12.0~14.0 0.50 0.25 改良13Cr 0.04 0.50 0.60 0.02 0.010 12.0~14.0 3.50~4.50 0.80~1.50 超级13Cr 0.04 0.50 0.60 0.02 0.005 12.0~14.0 4.50~5.50 1.80~2.50 表 2 甲酸盐环空保护液对13Cr管材的腐蚀试验结果

Table 2 Corrosion test results of formate annulus protective liquid on 13Cr tubular

环空保护液密度/

(kg·L–1)缓蚀剂及

加量腐蚀速率/

(mm·a–1)腐蚀形貌描述 1.25 2% JCI-1 0.137 均匀腐蚀 1.35 3% JLB 2.232 腐蚀严重,有坑蚀 1.46 2% JCI-1 10.291 腐蚀严重,有坑蚀 表 3 不同管材在高密度环空保护液的腐蚀速率

Table 3 Corrosion rates of different pipes in high-density annulus protection fluid

缓蚀剂及加量 钢材 腐蚀速率/(mm·a–1) 腐蚀形貌描述 5%JLB+

1%HLN超级13Cr 0.065 均匀腐蚀,无点蚀 改良13Cr 0.073 均匀腐蚀,无点蚀 13Cr 0.265 均匀腐蚀,无点蚀 -

[1] 李中. 南海高温高压气田开发钻完井关键技术现状及展望[J]. 石油钻采工艺, 2016, 38(6): 730–736. LI Zhong. Status and prospect of key drilling and completion technologies for the development of HTHP gasifeld in South China Sea[J]. Oil Drilling & Production Technology, 2016, 38(6): 730–736.

[2] 古小红,母建民,石俊生,等. 普光高含硫气井环空带压风险诊断与治理[J]. 断块油气田, 2013, 20(5): 663–666. GU Xiaohong, MU Jianmin, SHI Junsheng, et al. Diagnosing and managing on risk of annular casing pressure in high-sulfur gas well of Puguang Gas Field[J]. Fault-Block Oil & Gas Field, 2013, 20(5): 663–666.

[3] 张智,顾南,杨辉,等. 高含硫高产气井环空带压安全评价研究[J]. 钻采工艺, 2011, 34(1): 42–44, 115. doi: 10.3969/j.issn.1006-768X.2011.01.014 ZHANG Zhi, GU Nan, YANG Hui, et al. Safety assessment of annular pressure in gas wells with high SulphurProduction[J]. Drilling & Production Technology, 2011, 34(1): 42–44, 115. doi: 10.3969/j.issn.1006-768X.2011.01.014

[4] 何生厚. 普光高含H2S、CO2气田开发技术难题及对策[J]. 天然气工业, 2008, 28(4): 82–85. doi: 10.3787/j.issn.1000-0976.2008.04.026 HE Shenghou. Technical difficulties and Countermeasures for development of Puguang Gas Field with high H2S and CO2 content[J]. Natural Gas Industry, 2008, 28(4): 82–85. doi: 10.3787/j.issn.1000-0976.2008.04.026

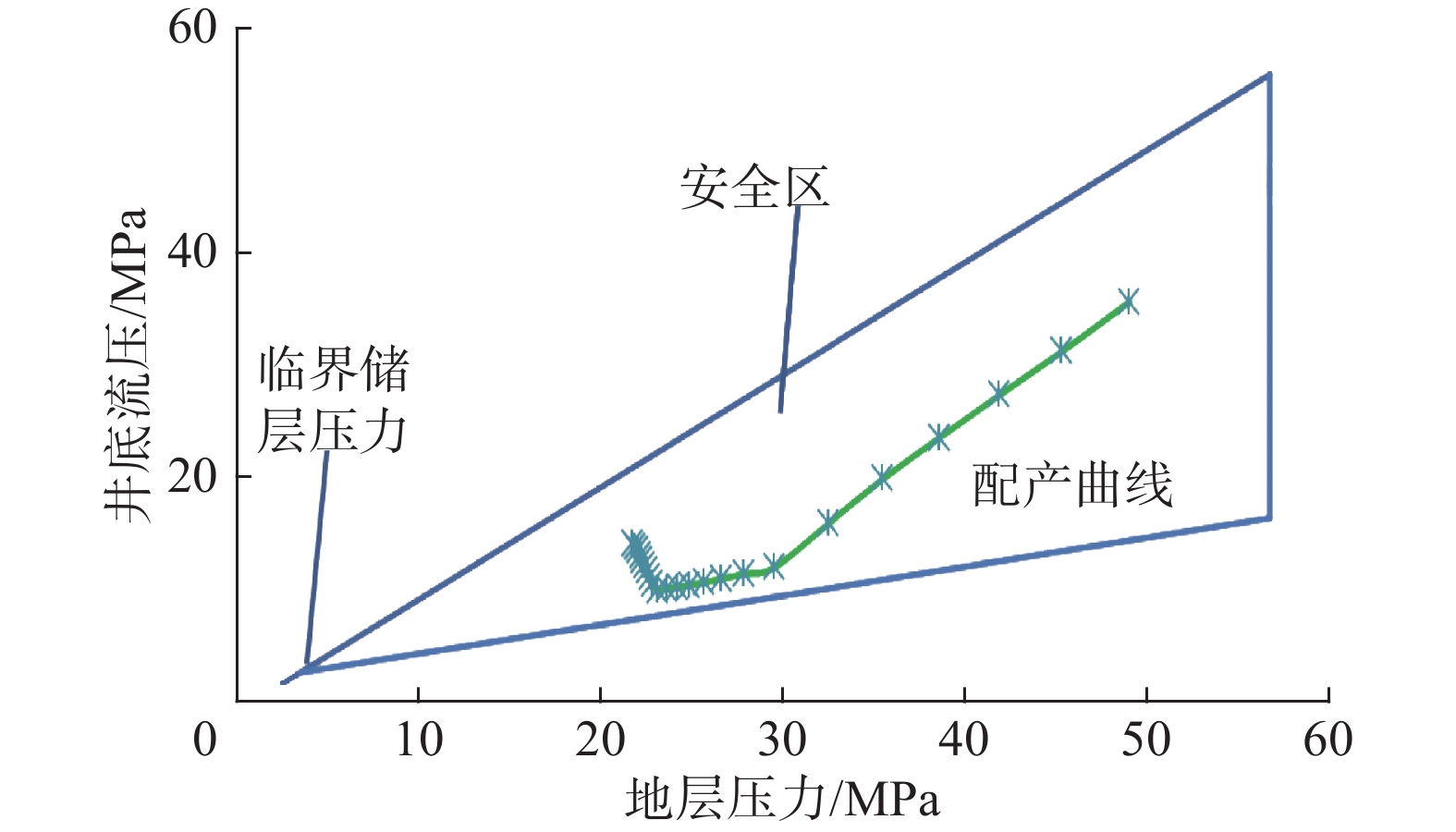

[5] 楼一珊,刘新锋,李忠慧. 采油过程中压力衰减对临界生产压差的影响研究[J]. 钻采工艺, 2006, 29(3): 40–41. doi: 10.3969/j.issn.1006-768X.2006.03.013 LOU Yishan, LIU Xinfeng, LI Zhonghui. Research on the influence of pressure attenuation on the critical production pressure differential during oil recovery[J]. Drilling & Production Technology, 2006, 29(3): 40–41. doi: 10.3969/j.issn.1006-768X.2006.03.013

[6] VAZIRI H, XIAO Y, PALMER I. Assessment of several sand prediction models with particular reference to HPHT wells[R]. SPE 78235, 2002.

[7] Q/HS 14010—2011 海上完井工程质量控制要求[S]. Q/HS14010—2011 Quality control requirements for offshore well completion engineering[S].

[8] 文敏,何保生,王平双,等. 海上高温高压气井生产管柱优化设计[J]. 石油天然气学报, 2014, 36(11): 234–238. doi: 10.3969/j.issn.1000-9752.2014.11.052 WEN Min, HE Baosheng, WANG Pingshuang, et al. Optimal design of production casingstring for offshore HPHT gas wells[J]. Journal of Oil and Gas Technology, 2014, 36(11): 234–238. doi: 10.3969/j.issn.1000-9752.2014.11.052

[9] 郭建华,佘朝毅,唐庚,等. 高温高压高酸性气井完井管柱优化设计[J]. 天然气工业, 2011, 31(5): 70–72. doi: 10.3787/j.issn.1000-0976.2011.05.018 GUO Jianhua, SHE Chaoyi, TANG Geng, et al. Optimal design and application of completion strings in a HTHP gas well[J]. Natural Gas Industry, 2011, 31(5): 70–72. doi: 10.3787/j.issn.1000-0976.2011.05.018

[10] 张崇,黄亮,任冠龙,等. 海上高温高压井完井管柱安全性设计[J]. 科学技术与工程, 2016, 16(12): 248–253. doi: 10.3969/j.issn.1671-1815.2016.12.041 ZHANG Chong, HUANG Liang, REN Guanlong, et al. Safety design of well completion string in offshore HTHP well[J]. Science Technology and Engineering, 2016, 16(12): 248–253. doi: 10.3969/j.issn.1671-1815.2016.12.041

[11] 车争安,张智,施太和,等. 高温高压含硫气井环空流体热膨胀带压机理[J]. 天然气工业, 2010, 30(2): 88–90. CHE Zheng'an, ZHANG Zhi, SHI Taihe, et al. Mechanism of annular fluid thermal expansion pressure in HTHP sour gas wells[J]. Natural Gas Industry, 2010, 30(2): 88–90.

[12] ISO 14310—2008 Petroleum and natural gas industries: downhole equipment: packers and bridge plugs[S].

[13] ISO 13679—2002 Petroleum and natural gas industries: procedures for testing and tubing connections[S].

[14] API SPEC 6A—2018 Specification for wellhead and tree equipment[S].

[15] 高永德,王书华,王宪超,等. 封隔器在射孔管柱中的安全距离评估[J]. 测井技术, 2016, 40(3): 382–384. GAO Yongde, WANG Shuhua, WANG Xianchao, et al. Assessment packer in perforating string in safety distance[J]. Well Logging Technology, 2016, 40(3): 382–384.

[16] 王尔钧,魏安超,舒福昌,等. 东方1-1气田高温高压下封隔液抗CO2腐蚀研究[J]. 石油钻采工艺, 2016, 38(6): 813–816. WANG Erjun, WEI Anchao, SHU Fuchang, et al. Study on CO2 corrosion resitiance of packer fluid under high pressure and high temperature in Dongfang 1-1 Gas Field[J]. Oil Drilling & Production Technology, 2016, 38(6): 813–816.

-

期刊类型引用(14)

1. 魏建平,蔡玉波,刘勇,余大炀,黄逸,李兴,高梦雅. 非刀具破岩理论与技术研究进展与趋势. 煤炭学报. 2024(02): 801-832 .  百度学术

百度学术

2. 白冰,陈勉,金衍. 超临界CO_2渗流的流-固-热多场耦合机理研究. 中国科学:物理学 力学 天文学. 2023(02): 101-113 .  百度学术

百度学术

3. 白冰,陈勉,金衍. 超临界CO_2吸附效应对页岩地层井壁稳定影响研究. 岩石力学与工程学报. 2023(S1): 3508-3518 .  百度学术

百度学术

4. 黄程,霍丽如,吴辰泓. 基于非常规油气开发的CO_2资源化利用技术进展及前景. 非常规油气. 2022(01): 1-9 .  百度学术

百度学术

5. 孙晓,王海柱,李英杰,郑永,陆群. 超临界CO_2水平环空携砂试验研究. 石油钻探技术. 2022(03): 17-23 .  本站查看

本站查看

6. 李木坤,王刚,程卫民,浦仕杰,倪红坚,时贤. 超临界二氧化碳射流破岩的热流固耦合机理. 石油勘探与开发. 2021(06): 1258-1268 .  百度学术

百度学术

7. 乔兰,郝家旺,李占金,邓乃夫,李庆文. 基于微波加热技术的硬岩破裂方法探究. 煤炭学报. 2021(S1): 241-252 .  百度学术

百度学术

8. LI Mukun,WANG Gang,CHENG Weimin,PU Shijie,NI Hongjian,SHI Xian. Heat-fluid-solid coupling mechanism of supercritical carbon dioxide jet in rock-breaking. Petroleum Exploration and Development. 2021(06): 1450-1461 .  必应学术

必应学术

9. 杨晓峰,黄彦如,庞勇. 超临界二氧化碳射流火星采样技术研究. 航天器工程. 2020(02): 102-108 .  百度学术

百度学术

10. 白鑫,张东明,王艳,王登科,蒋志刚,王小兵. 液态CO_2相变射流压力变化及其煤岩致裂规律. 中国矿业大学学报. 2020(04): 661-670 .  百度学术

百度学术

11. 熊钰,莫军,李佩斯,蒋军,张烈辉. 致密气藏储层干化剂在超临界CO_2中的溶解性及增溶研究. 化学研究与应用. 2019(01): 72-78 .  百度学术

百度学术

12. 罗攀登,李涵宇,翟立军,李春月,吕欣润,牟建业. 塔河油田超临界CO_2压裂井筒与裂缝温度场. 断块油气田. 2019(02): 225-230 .  百度学术

百度学术

13. 王香增,郑永,吴金桥. 超临界CO_2射流特性数值模拟研究. 石油机械. 2019(09): 90-97 .  百度学术

百度学术

14. 王毅博,王熙,柳愿. 超临界二氧化碳在非常规油气藏开采中的应用研究. 化工技术与开发. 2018(11): 29-32 .  百度学术

百度学术

其他类型引用(9)

下载:

下载: