Design and Optimization of the Crawling Mechanism of Rotary Sidewall Coring Device in Shale Gas Wells

-

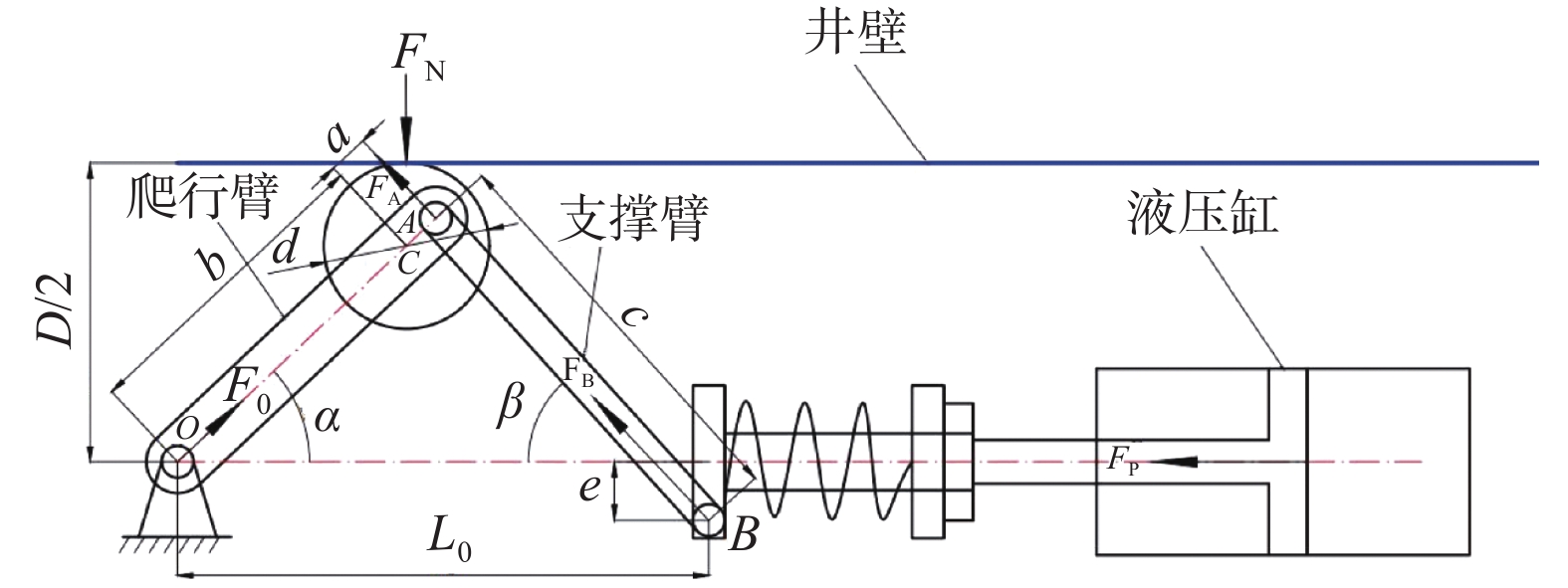

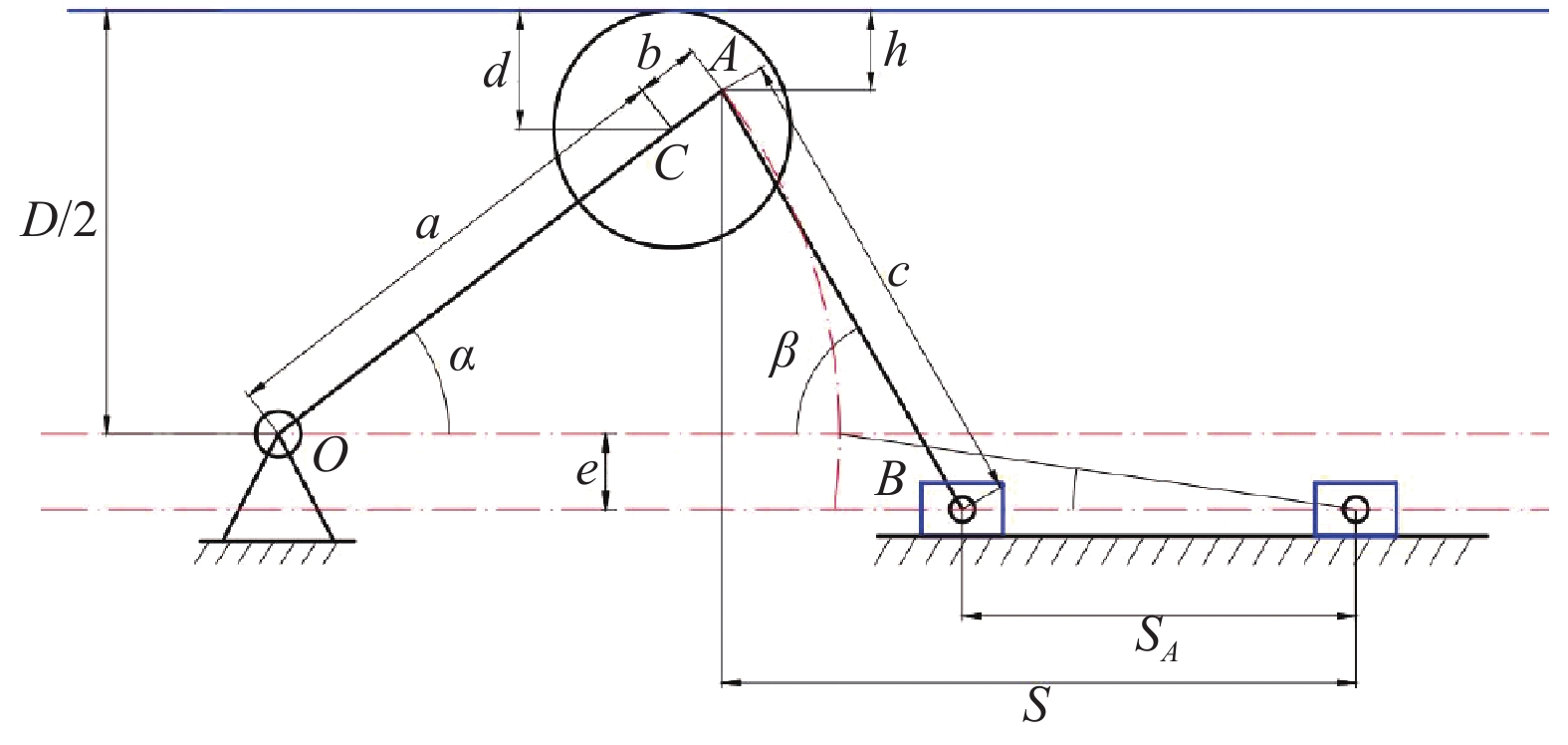

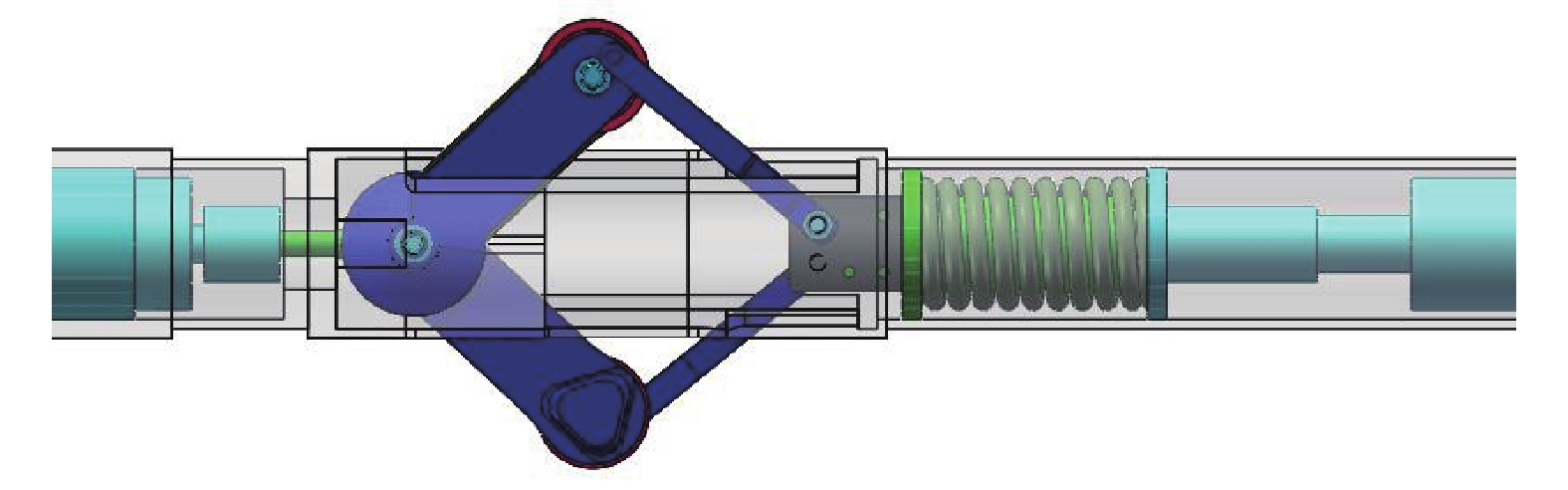

摘要: 为了解决页岩气井旋转式井壁取心器不能靠自重下至取心位置的问题,分析了取心器的工作要求,确定了取心器在水平井中所受阻力,设计了一种由行星齿轮、锥齿轮组合传动的旋转式井壁取心器爬行机构。建立了爬行轮正压力与各参数的函数关系、支撑臂伸出速度与各参数的函数关系;以支撑臂伸出速度和支撑臂推靠力为多目标优化函数,利用正交试验分析方法,确定了爬行臂长度、支撑臂长度、爬行臂转角和偏心距等因素的影响程度,并优化了爬行臂和支撑臂的结构尺寸。分析得到:爬行臂转角对支撑臂伸出速度和推靠力的影响最大;当爬行臂转角、爬行臂长度、偏心距和支撑臂长度分别为45°、150 mm、8 mm和140 mm时,爬行臂伸出速度和推靠力最优;爬行臂和支撑臂长度优化后,可以降低支撑臂所需推靠力,提高支撑臂伸出速度。研究认为,设计的页岩气井旋转式井壁取心器爬行机构,为井壁取心器提供了一种新的驱动方式。Abstract: With regard to the problem that the rotary sidewall coring device of shale gas wells cannot be lowered to the coring position with its own weight, the operating requirements of the coring device were analyzed, and the resistance to the coring device in the horizontal wells was determined. Then, a new crawling mechanism transmitted by planetary and bevel gears was designed for rotary sidewall coring device. The functional relationships of the positive pressure of the crawling wheel and the extension speed of the supporting arm with each parameter were established. With the extension speed and push-the-bit force of the supporting arm as the multi-objective optimization function, the order of priority of the influencing factors such as the length, rotation angle, and eccentricity of the crawling arm and the length of the supporting arm was determined through the orthogonal tests. Furthermore, the physical dimensions of the crawling arm and supporting arm were optimized. The analysis results demonstrated that the rotation angle of the crawling arm had the greatest influence on the extension speed and push-the-bit force of the supporting arm. When the rotation angle, length, and eccentricity of the crawling arm and the length of the supporting arm were 45°, 150 mm, 8 mm, and 140 mm, respectively, the extension speed and push-the-bit force of the crawling arm were optimal. The optimization of the lengths of the crawling and supporting arms facilitated the decline in the push-the-bit force needed by the supporting arm and the increase in the extension speed of the supporting arm. The crawling mechanism of the rotary sidewall coring device for shale gas wells provides a new driving method for the sidewall coring device.

-

-

表 1 正交试验各因素的水平

Table 1 Factor level of the orthogonal test

水平 因素 a/mm b/mm c/mm e/mm α/(°) 1 75 20 100 5 30 2 80 25 115 8 35 3 102 28 130 12 40 4 120 30 140 15 45 表 2 正交试验方案及结果

Table 2 Plan and results of the orthogonal test

序号 因素 vA/

(mm·s–1)FB/N a/mm b/mm c/mm e/mm α/(°) 1 75 20 100 5 30 43.034 1 476.282 2 75 25 115 8 35 49.923 948.763 3 75 28 130 12 40 54.784 760.183 4 75 30 140 15 45 59.831 613.171 5 80 20 115 12 45 59.442 546.541 6 80 25 100 15 40 53.611 401.823 7 80 28 140 5 35 57.392 1 244.544 8 80 30 130 8 30 47.480 1 326.465 9 102 20 130 15 35 55.684 817.832 10 102 25 140 12 30 52.055 1 222.991 11 102 28 100 8 45 102.036 29.503 12 102 30 115 5 40 80.807 473.042 13 120 20 140 8 40 82.741 673.195 14 120 25 130 5 45 98.571 404.759 15 120 28 115 15 30 60.058 582.237 16 120 30 100 12 35 78.109 143.874 表 3 支撑臂伸出速度极差分析结果

Table 3 The extension speed range analysis of the supporting arm

参数 不同因素水平对应的支撑臂伸出速度vA /(mm·s–1) a b c e α k1 51.799 60.225 69.197 69.951 50.657 k2 54.481 63.540 62.558 70.545 60.277 k3 72.645 68.568 64.130 61.098 67.985 k4 79.870 66.557 63.005 57.296 79.970 R 28.071 8.343 6.639 13.249 29.313 表 4 支撑臂推靠力极差分析结果

Table 4 The push-the-bit force range analysis of the supporting arm

参数 不同因素水平对应的支撑臂推靠力FB/N a b c e α k1 949.550 878.460 512.870 899.650 1 151.990 k2 879.325 744.580 637.650 744.480 788.750 k3 635.830 374.120 827.310 668.400 577.040 k4 451.000 638.910 938.470 603.750 398.490 R 498.550 504.340 425.600 295.900 753.500 表 5 优化前后试验指标对比

Table 5 Comparison between test indicators before and after optimization

优化前后 a/mm b/mm c/mm e/mm α/(°) vA/(mm·s–1) FB/N 优化前 75 20 100 5 30 43.034 1 259.222 80 25 115 8 35 52.829 893.596 102 28 130 12 40 72.393 554.946 120 30 140 15 45 92.284 339.869 优化后 120 30 140 8 45 99.060 408.230 -

[1] 王建龙,冯冠雄,刘学松,等. 长宁页岩气超长水平段水平井钻井完井关键技术[J]. 石油钻探技术,2020,48(5):9–14. WANG Jianlong, FENG Guanxiong, LIU Xuesong, et al. Key technology for drilling and completion of shale gas horizontal wells with ultra-long horizontal sections in Changning Block[J]. Petroleum Drilling Techniques, 2020, 48(5): 9–14.

[2] 李传武,兰凯,杜小松,等. 川南页岩气水平井钻井技术难点与对策[J]. 石油钻探技术,2020,48(3):16–21. LI Chuanwu, LAN Kai, DU Xiaosong, et al. Difficulties and countermeasures in horizontal well drilling for shale gas in Southern Sichuan[J]. Petroleum Drilling Techniques, 2020, 48(3): 16–21.

[3] 张宇奇.旋转式井壁取心机器人的设计与研究[D].成都: 西华大学, 2019. ZHANG Yuqi. Design and research of rotary shaft core robot[D]. Chengdu: Xihua University, 2019.

[4] 张朝界.页岩气长水平段取芯爬行机器人机构设计与研究[D].成都: 西华大学, 2020. ZHANG Chaojie. Design and research on the mechanism of long horizontal shale gas coring crawling robot[D]. Chengdu: Xihua University, 2020.

[5] HALLUNDBÆK J. Well tractors for highly deviated and horizontal wells[J]. SPE 28871, 1994.

[6] 刘清友,李维国. Sondex水平井井下爬行工具介绍[J]. 国外测井技术,2008,23(5):57–59. LIU Qingyou, LI Weiguo. Introduction of sondex horizontal well downhole crawling tool[J]. World Well Logging Technology, 2008, 23(5): 57–59.

[7] HENDERSON B, HOPWOOD C, HAMILTON C, et al. Cost saving benefits of using a fully bi-directional tractor system[R]. SPE 65467, 2000.

[8] BUYERS M, FRASER S B. Reciprocating running tool: US06345669[P]. 2002-02-12.

[9] 高进伟, 刘猛, 李海凤. 水平井井下自适应爬行器的研制[J]. 石油机械, 2005, 33(增刊1): 100-104. GAO Jingwei, LIU Meng, LI Haifeng. Development of an adaptive crawler in horizontal wells[J]. China Petroleum Machinery, 2005, 33(supplement 1): 100-104.

[10] 周劲辉,张勇,李翠. 水平井自扶正式电缆牵引器的设计[J]. 石油机械,2015,43(2):79–82. ZHOU Jinghui, ZHANG Yong, LI Cui. Design of self-righting cable tractor in horizontal well[J]. China Petroleum Machinery, 2015, 43(2): 79–82.

[11] 唐德威,王新杰,邓宗全,等. 水平油井检测仪器拖动器[J]. 哈尔滨工业大学学报,2007,39(9):1395–1397. TANG Dewei, WANG Xinjie, DENG Zongquan, et al. Driver of horizontal oil well detecting instruments[J]. Journal of Harbin Institute of Technology, 2007, 39(9): 1395–1397.

[12] 张勇.水平井电缆牵引器的机械设计研究[D].北京: 中国石油大学(北京), 2016. ZHANG Yong. Research on mechanical design of cable tractor in horizontal wells[D]. Beijing: China University of Petroleum (Beijing), 2016.

[13] 姜立标,刘坚雄,程铖. 基于正交试验的矿用自卸车转向机构优化设计[J]. 中国机械工程,2013,24(15):2036–2041. JIANG Libiao, LIU Jianxiong, CHENG Cheng. Optimization design of mining dump truck steering mechanism based on orthogonal test[J]. China Mechanical Engineering, 2013, 24(15): 2036–2041.

[14] 邢相伟,彭彦平,庞桂兵,等. 基于正交试验法沾浆机浆拐结构的优化改进[J]. 大连工业大学学报,2015,34(2):153–156. XING Xiangwei, PENG Yanping, PANG Guibing, et al. Optimization of agitator structure of slurry mixer by orthogonal test method[J]. Journal of Dalian Polytechnic University, 2015, 34(2): 153–156.

下载:

下载: