Key Technology for Speeding up and Improving Efficiency of Ultra-Deep Slim-Hole Directional Drilling in Tarim Basin

-

摘要:

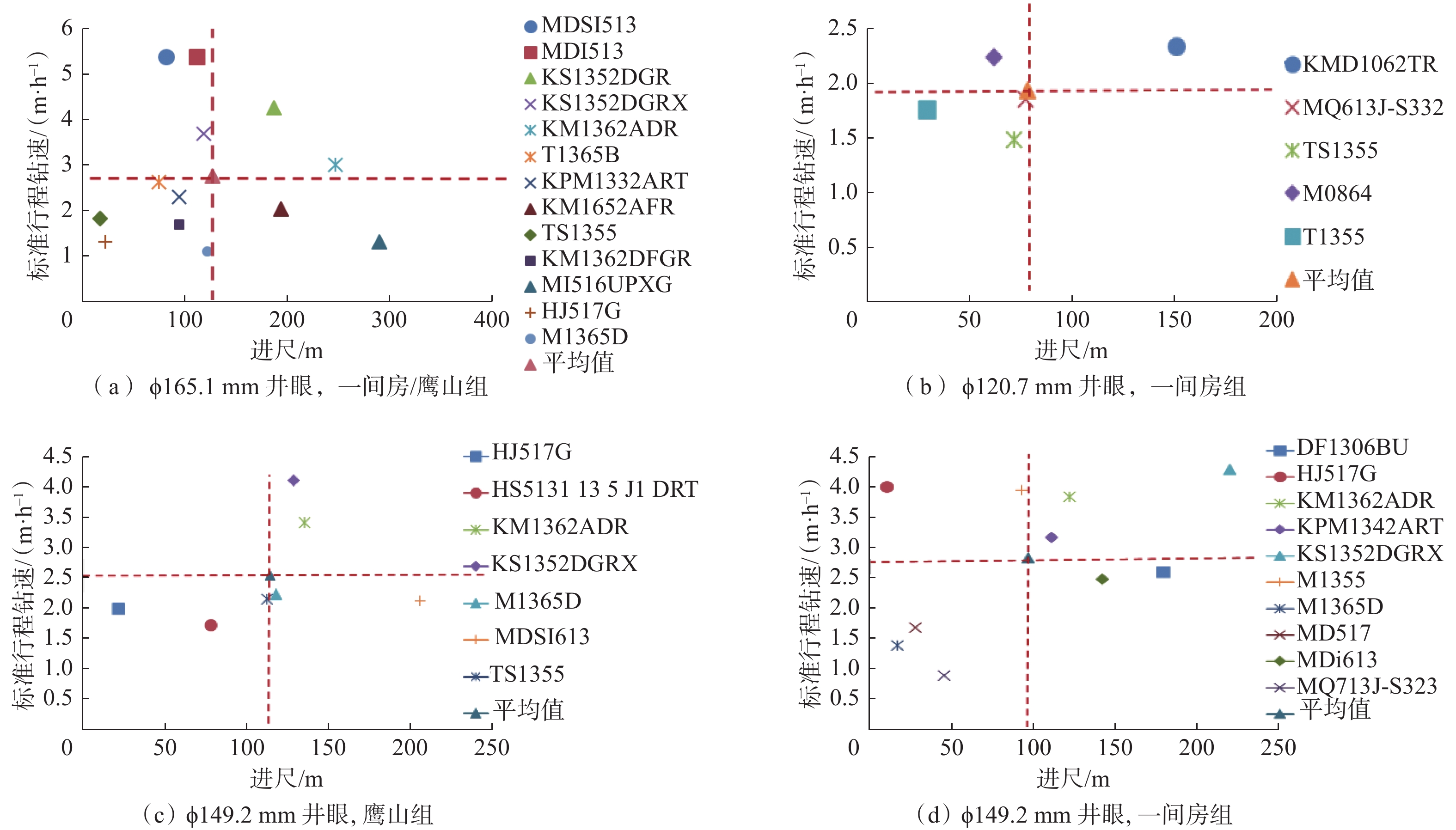

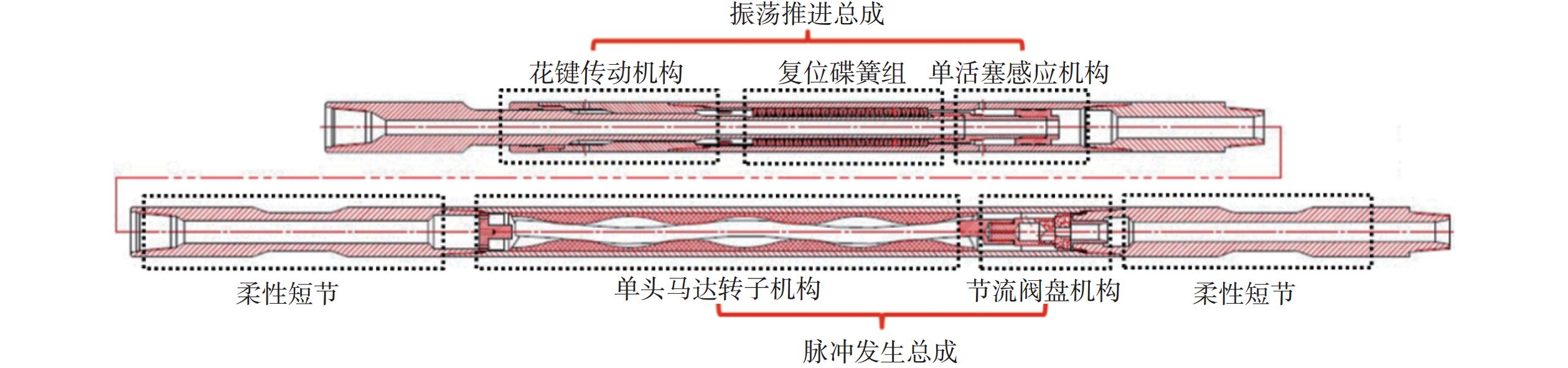

针对塔里木盆地台盆区超深小井眼定向钻井机械钻速低、钻头使用寿命短、常规螺杆钻具脱胶脱扣、钻井液稳定性差和产层喷漏同存等难题,研究形成了塔里木盆地超深小井眼定向钻井提速提效关键技术。以标准行程钻速和钻头进尺为指标,采用统计分析法优选了适用于目的层的ϕ149.2 mm/ϕ165.1 mm KS1352DGRX型钻头和ϕ120.7 mm KDM1062TR型钻头;对比国内外抗高温螺杆现状,确定了井底温度低于180 ℃时推荐使用国产抗高温螺杆,高于180 ℃时推荐使用全金属螺杆或进口耐高温螺杆;采用理论分析结合数值模拟的方法,优化设计了小尺寸降摩减阻工具,并优化了其安放位置;优选抗盐高温高压降滤失剂和抑制剂,研选除氧剂等,制定合理pH值调控和钙离子补充措施,形成了抗温200 ℃钻井液;分析了顺北油气田产层钻进喷漏同层的特点,确定了“降密度+井口控压+优化排量”的井控基本原则。塔里木盆地5口井应用了超深小井眼定向钻井提速提效关键技术,小井眼段平均机械钻速提高了113.24%,平均井径扩大率5.57%,平均钻井周期缩短了35.03%,均未发生井下故障和复杂情况。超深小井眼定向钻井提速提效技术为塔里木盆地勘探开发提供了技术支撑。

Abstract:In view of the problems such as low rate of penetration (ROP), short bit life, degumming and threading off of conventional screw drill tool, poor stability of drilling fluid, and simultaneous occurrence of blowout and leakage in pay zones in ultra-deep slim-hole directional drilling in the platform basin area of the Tarim Basin, the key technology for speeding up and improving efficiency in ultra-deep slim-hole directional drilling in Tarim Basin was developed. The technology used the standard drilling rate of a trip and bit footage as indicators and employed statistical analysis method to select bit KS1352DGRX with a diameter of ϕ149.2 mm / ϕ165.1 mm and bit KDM1062TR with a diameter of ϕ120.7 mm applicable to the target layer. By comparing the current situation of high-temperature resistant screws in China and abroad, Chinese high-temperature resistant screws were recommended for bottomhole temperatures below 180 °C. Otherwise, it was recommended to use metal screws or imported high-temperature resistant screws. The small-sized friction and drag reduction tools were designed using theoretical analysis combined with numerical simulation methods, and the tools’ position was optimized. Optimal salt-resistant, high-temperature, and high-pressure filtrate reducers and inhibitors were selected, and deoxidizers were developed. Reasonable pH control and calcium ion supplementation measures were made, and a temperature-resistant drilling fluid system for 200 °C was formed. The characteristics of blowout and leakage in the same layer in the pay zones of Shunbei Oilfield were analyzed, and the basic principle of well control featuring “density reduction + wellhead pressure control + optimized displacement” was determined. The key technology for speeding up and improving efficiency in ultra-deep slim-hole directional drilling in Tarim Basin was applied in five wells. The average ROP of the slim-hole section was increased by 113.24%, and the average hole diameter expansion rate was 5.57%. The average drilling cycle was shortened by 35.03%, and none of the wells had bottom hole failures and other complex conditions. The key technology for speeding up and improving efficiency in ultra-deep slim-hole directional drilling have provided the technical supports for the exploration and development of Tarim Basin.

-

近年来,随着油气资源勘探水平的不断提高和油气需求的不断增加,低渗透油气藏的开发引起了国内外石油领域专家和相关企业的高度关注。该类油气藏需要利用水力压裂方法提高储层的渗流能力,才能高效开发[1]。提高压裂效率和效果,需要了解水力压裂产生裂缝的分布情况。

近年来,国内外监测水力裂缝的技术方法发展较快。D. Xue和G. D. Hu等人[2-3]采用常规感应测井(>10 kHz)方法推测钻孔周围裂缝的长度、电阻率和倾角;D. Pardo和C. Torres-Verdin[4]采用数值模拟方法评估了采用低频(<1 kHz)电磁感应方法监测垂直裂缝长度的可行性;Yang Kai等人[5]针对水力压裂裸眼井的情况,定量分析了发射–接收间距、工作频率以及裂缝形状、横截面积、倾角和导电率对比度对测井响应信号的影响。目前,定性分析、评价与检测水力裂缝的方法虽有报道,但从理论上看,对裂缝监测进行系统化、综合性的研究还很少。传统的井温测井、同位素测井、注硼中子寿命测井等方法在监测水力裂缝方面存在施工时间受限、准确性差等缺陷,且同位素测井、注硼中子寿命测井等核测井方法还会对地层造成一定污染,不适合推广应用[6-7]。声波测井监测水力裂缝的方法有主动声波监测和被动声波监测2种:被动声波监测法具有随机性强和声波数据处理量大等缺点;主动声波监测法易受天然裂缝和井壁干扰,传感器的布置方式也会影响监测精度。主动声波监测法可以监测裂缝在最大应力平面内的扩展,但无法解释三维空间裂缝转向的问题[8]。利用电磁法监测水力裂缝方位的最大优势是可以注入导电性支撑剂,用支撑剂指示方位信息。目前利用声波和微地震监测到的裂缝方位信息稍显不足。

为研究上述问题,笔者以电磁场理论为基础,基于有限元软件平台,建立了直井的三维地层与裂缝几何模型,并利用有限元法对裂缝模型进行正演模拟计算。在此基础上,对测井仪器上多个接收线圈得到的感应电动势的振幅和相位进行了深入研究,探讨了裂缝模型的响应情况;然后,分析了测井曲线随裂缝长度、高度,支撑剂电导率及裂缝与井眼之间角度的变化规律,进一步分析了测井仪器对水力裂缝探测的影响,为水力压裂效果评价及测井仪器参数选择提供了理论依据。

1. 解析模型的建立

1.1 时谐电磁场理论

由于电磁波测井仪的发射线圈使用交流电来产生电磁波,所研究的电磁场是时谐场。也就是说,电磁波的振幅和相位随时间呈正弦或余弦变化。因此,选用微分方程组来求解[9-13],即:

{∇×H=J+∂D/∂t∇×E=−∂B/∂t∇⋅D=ρ∇⋅B=0 (1) 式中:H为磁场强度,A/m;J为传导电流密度,

A/m2 ;D为电位移,C/m2 ;E为电场强度,V/m;B为总磁场,A/m;t为时间,s;ρ为自由电荷体密度,C/m2 。用复相位因子表示法,式(1)可以简化成:

{∇×H=(σ+iωμ)E+Jimp∇×E=−iωμH∇⋅(εE)=ρ∇⋅(μH)=0 (2) 式中:σ为媒介的电导率,S/m;ω为发射源角频率,rad/s;ε为介电常数,F/m;

Jimp 为发射线圈上外加电流密度,A/m2 ;μ为磁导率,H/m;i=√−1 。由于

∇×∇×E=−∇2E ,则电磁波波动方程为:∇2E+k2E=iμωJimp (3) 式中:

k2=μω2(ε−iσω) ,k为波数。令

k=α−iβ ,α为相位常数,β为衰减常数,其表达式分别为:α=ω√12μ(√ε2+σ2ω2+ε) (4) β=ω√12μ(√ε2+σ2ω2−ε) (5) 1.2 边界条件

求解麦克斯韦方程的关键是选择合理的边界条件[14],边界条件与界面两边的电磁场有关。笔者主要考虑理想导体边界条件、发射线圈边界条件和阻抗边界条件。

1)理想导体边界条件。从理论上讲,任何边界处的电场强度切向分量和磁场强度法向分量是连续的[15]。因此,电场强度的切向分量和磁场强度的法向分量不可能在理想导电体的表面上,其表面上只能存在电场强度法向分量和磁场强度切向分量。即理想导电体表面上的边界条件为:

n×E=0 (6) 2)发射线圈边界条件。由于发射线圈模型中通入外加电流

Jimp ,为方便计算,根据地磁场的等效原理,可将Jimp 等效为面电流Jimps ,建立发射线圈模型。故发射线圈边界满足:n×(∇×E)=−iμωJimps (7) 3)阻抗边界条件。阻抗边界形成于2个不完全导体的介电界面上。非理想导体具有损耗和电阻,因此阻抗边界条件为:

n×(∇×E)=−k2E (8) 假设在均质各向同性介质中,接收线圈R1的电动势为

V1 ,接收线圈R2的电动势为V2 。根据式(6)、式(7)、式(8)和式(4)求得接收线圈R1和R2的感应电动势V1 和V2 :V1=iCeikL1L31(1+ikL1) (9) V2=iCeikL2L32(1+ikL2) (10) 式中:C为常数,

C=ωμnTnRIS22π ;L1 为接收线圈R1与发射线圈的距离,m;L2 为接收线圈R2与发射线圈的距离,m;nT 为发射线圈的匝数;nR 为接收线圈的匝数;S为接收线圈(发射线圈)的横截面积;m2;I为发射线圈的电流幅度,A。振幅比

ΔV 和相位差ΔΦ 的表达式分别为[16]:ΔV=20lg|V2||V1| (11) ΔΦ=Φ1−Φ2 (12) 将式(9)和式(10)代入式(11)得:

ΔV=10{[lg(αL1)2+(1+βL1)]2−lg[(αL2)2+(1+βL2)2]}+60(lgL2−lgL1)+8.686β(L2−L1) (13) 将式(9)和式(10)代入式(12)得:

ΔΦ=α(L2−L1)+arctan1+βL2αL2−arctan1+βL1αL1 (14) 式(13)和式(14)为电磁波信号振幅比和相位差的解析表达式[17-18]。

2. 解析模型可行性验证

笔者所建地层模型为100 m×100 m的均质各向同性地层,不考虑井眼和钻铤的影响,采用单发双收电磁波测井仪。假设发射线圈电流幅度为1 A,发射频率为400 kHz,源距离L1和L2分别为1.00和1.20 m,相对磁导率为1,发送线圈和接收线圈的匝数均为100匝,线圈半径为0.03 m。利用有限元软件求得均匀各向同性地层振幅比和相位差与地层电导率之间的关系曲线,并与式(13)和式(14)的计算结果进行对比,结果如图1。

从图1可以看出:利用有限元软件模拟求得的曲线与利用式(13)和式(14)计算出的曲线基本重合;当地层电导率小于1 S/m时,随着地层电导率增大,振幅比增大缓慢;当地层电导率大于1 S/m时,振幅比快速增大;随着地层电导率增大,相位差均匀增大。模拟计算结果与解析计算结果高度一致,验证了解析模型的正确性。

3. 裂缝模型正演算例

在实际测井时,垂直井眼周围分布着大量的不规则裂缝。笔者旨在研究电磁波测井探测水力裂缝的正演效果,暂不考虑多条裂缝同时存在的情况。水力裂缝模型采用裂缝长度远远大于裂缝高度的形式。假设仪器发射线圈为T,两个接收线圈分别为R1和R2。发射线圈T与接收线圈R1和R2之间的距离分别为L1和L2(L2> L1)。为了更好地检验电磁波测井的实用性,采用不规则裂缝模型,其剖面如图2(a)所示。采用四面体进行网格划分,结果如图2(b)所示。假设不规则裂缝为1条,位于地下50.00 m处。电磁波测井仪参数:发射频率为400 kHz;源距L1为1.00 m、L2为1.20 m;发射线圈T的匝数为100匝、半径为0.03 m;线圈中的电流为1 A。裂缝模型参数:地层电导率为0.1 S/m,裂缝电导率为200.0 S/m,裂缝相对最长处为15.00 m,裂缝相对最高处为1.00 m。

利用有限元软件并结合式(13)和式(14),计算不同位置处的振幅比和相位差,结果如图3所示。

从图3可以看出:尖峰现象明显,且峰值位于距离地面50.00 m处,与理论位置一致;振幅比和相位差曲线在–50.00 m位置附近处的波形不规则,此现象应与裂缝形态具有一定的相关性。虽然出现一部分小的干扰曲线,但不影响正演模拟结果。这表明,电磁波测井适用于横截面为不规则图形的裂缝模型,可以准确正演出裂缝位置。

4. 影响因素分析

4.1 水力裂缝敏感性分析

采用控制变量法研究裂缝高度、支撑剂电导率、裂缝长度和裂缝与井眼之间不同角度对电磁波测井仪探测结果的影响。选取垂直于井眼的横切面为椭圆形的单一裂缝进行分析。假设单个椭圆形裂缝位于地下50.00 m处,电磁波测井仪参数:发射频率为400 kHz;源距L1为1.00 m,L2为1.20 m;发射线圈匝数为100匝、半径为0.03 m;发射线圈电流为1 A。模型参数:地层模型范围为100 m×100 m,相对磁导率为1。

4.1.1 裂缝高度

设地层与钻井液的电导率为0.1 S/m,裂缝电导率为100.0 S/m,裂缝长度为50.00 m。在地层和裂缝电导率不变的情况下,裂缝高度h 依次设为10.00,5.00,2.00,1.50,1.00和0.50 m,计算不同裂缝高度下的振幅比和相位差,结果如图4所示。

从图4可以看出:裂缝高度对于振幅比影响较大,当电磁波测井仪靠近裂缝时,裂缝高度越大,尖峰现象越明显;裂缝高度对于相位差影响较大,当电磁波测井仪接近裂缝时,尖峰现象更加明显。对比不同裂缝高度下的振幅比与相位差发现,相位差分层现象明显,更容易通过其分辨不同高度的裂缝。

4.1.2 支撑剂电导率

向裂缝中注入含有高导电性的支撑剂可以增加裂缝的电导率。假设裂缝高度为0.50 m,长度为20.00 m。假设支撑剂电导率σz分别为50,100,150,200,50和300 S/m,高导电性支撑剂均匀填充于水力裂缝。在地层电导率、裂缝长度及高度不变的情况下,计算不同电导率支撑剂下的振幅比和相位差,结果如图5所示。

由图5可知:含有高导电支撑剂裂缝的振幅比高,尖峰现象明显;随着支撑剂电导率增大,相位差减小,尖峰现象越来越明显;支撑剂电导率对振幅比的影响较小,对相位差的影响较大。相位差曲线可以更好地反映含有不同电导率支撑剂裂缝的信息,可以通过其更好地分辨不同电导率的裂缝。

4.1.3 裂缝长度

假设裂缝高度为0.10 m,支撑剂和地层电导率分别为200和0.1 S/m。在裂缝高度、地层和支撑剂电导率不变的情况下,计算裂缝长度Lf为0,1.00,10.00,50.00和100.00 m时的振幅比和相位差,结果见图6。

由图6可知:随着裂缝长度增加,振幅比增大,尖峰现象越来越明显;随着裂缝长度增加,相位差减小,尖峰现象越来越明显。

4.1.4 裂缝与井眼夹角

假设地层与钻井液电导率为0.1 S/m,裂缝电导率为100.0 S/m,裂缝轴对称中心点位于地下50.00 m处,裂缝长度为20.00 m、宽度为0.10 m。计算裂缝与井眼的夹角α分别为30°、45°、60°和75°时的振幅比和相位差,结果如图7所示。

从图7可以看出:当裂缝和井眼的夹角为45°、60°、75°时,振幅比与相位差曲线的尖峰现象明显且呈现一定的规律,当裂缝和井眼夹角为30°时,尖峰现象出现偏差;随着裂缝和井眼夹角增大,振幅比减小,相位差增大。综上所述,裂缝和井眼的夹角在30°~90°时,正演响应较为明显。

4.2 电磁波测井仪敏感性分析

4.2.1 仪器源距

选用单一的椭圆形裂缝模型进行计算分析。假设裂缝位于地下50.00 m处,裂缝长度为20.00 m、宽度为0.50 m,地层与钻井液电导率为0.1 S/m,裂缝电导率为100.0 S/m,发射频率为400 kHz,发射线圈匝数为100匝、半径为0.03 m,线圈中的电流为1 A,接收线圈间的间距为0.20 m,计算发射线圈与接收线圈距离l为0.25,0.50,0.75,1.00,1.25和1.50 m时的振幅比和相位差,结果如图8所示。

由图8可知:振幅比与相位差曲线的尖峰现象明显;随发射线圈与接收线圈距离增大,振幅比和相位差减小。所以,在电磁波测井时,应优先选择发射线圈与接收线圈距离较近的电磁波测井仪,以获得更好的探测结果。

4.2.2 发射频率

假设地层与钻井液电导率为0.1 S/m,裂缝位于地下50.00 m处,裂缝电导率为100.0 S/m,裂缝长度为20.00 m、宽度为0.50 m,发射线圈匝数为100匝、半径为0.03 m,线圈中的电流为1 A,接收线圈间的距离为0.20 m,发射线圈与接收线圈的距离为1.00 m,计算发射频率f为400 kHz,1.0,1.5和2.0 MHz时的振幅比和相位差,结果如图9所示。

由图9可知:随着发射频率增大,振幅比增大,但增大幅度较小,不同发射频率下的振幅比曲线不易区分;随着发射频率增大,相位差减小,且减小幅度较大,发射频率为400 kHz时的相位差峰值最大。

5. 结论及建议

1)采用有限元算法建立了电磁波测井仪器与地层模型,利用电磁波测井探测直井水力裂缝的正演模拟具有较高的准确性。正演模拟结果对于识别裂缝位置等信息、判断裂缝的有效性、确定裂缝系统区域的有效性具有一定的参考价值,有利于找到油气储层。

2)采用控制变量法分析了裂缝高度、长度,支撑剂电导率,裂缝与井眼夹角对电磁波测井响应的影响。相位差曲线分层明显,通过相位差曲线可以分辨不同高度及含不同电导率支撑剂的裂缝。对电磁波测井响应影响最大的因素为支撑剂电导率,其次为裂缝高度与长度。

3)电磁波测井时,应优先选择发射线圈与接收线圈距离较近的电磁波测井仪,以获得更好的探测结果。

4)本文只是对直井水力裂缝正演进行了定性分析,建议结合油田的实际情况和测井资料,根据实际地质条件,与油田的实际测井资料进行比较,进一步优化电磁波测井仪结构,并进行正演模拟,以建立适合我国地层的测井解释资料数据库。

-

表 1 国内外耐高温螺杆统计结果

Table 1 Chinese and foreign high temperature-resistant screws

材质 公司 橡胶代号 最高适应温度/℃ 橡胶 威德福 Everheat系列 204 斯伦贝谢 HT-HR 190 贝克休斯 190~200 国民油井 UF180、280XT 190 哈里伯顿 190 Roper pump ER2-HR 193 Roper pump Dragonslayer HP 218 立林 ZGYN-180 180 全金属 加拿大TOT 200~250 德国 200~500 表 2 抗温200 ℃钻井液老化前后的基本性能

Table 2 Basic Properties of drilling fluid system before and after aging with a temperature resistance of 200 °C

条件 表观黏度/(mPa·s) 塑性黏度/(mPa·s) 动切力/Pa 静切力/Pa API滤失量/mL 高温高压滤失量1)/mL 初切 终切 室温/48 h 50.0 40.0 10.0 4.0 5.0 1.0 8.2 200 ℃/48 h 62.5 54.0 10.5 3.0 6.0 1.6 12.0 注:1)高温高压滤失量为180 ℃条件下测试结果。 表 3 塔里木盆地小井眼关键技术应用井基本情况

Table 3 Basic situation of wells applying slim-hole key technology in Tarim Basin

井号 项目区域 井深/m 完钻层位 小井眼段应用效果 设计 实际 设计钻井

周期/d实际钻井

周期/d节约钻井

周期/d钻井周期

缩短,%复杂

时间/h复杂时效,% 顺北1-X 顺北 8649.37 8765.00 鹰山组 29.00 22.88 6.21 21.10 0 0 TH-X 塔河 6729.50 6725.22 奥陶系 14.00 9.61 4.39 31.36 0 0 顺北5-X 顺北 8481.45 8475.00 鹰山组 37.00 25.41 11.59 31.32 0 0 顺南X侧 顺北 7245.50 7246.00 鹰山组 61.00 36.54 24.26 40.10 0 0 顺北8-X 顺北 8310.48 8110.00 鹰山组 28.00 15.36 12.64 45.14 0 0 表 4 顺北8-X井与邻井小井眼段钻速对比

Table 4 Comparison of ROP in slim-hole sections of Well Shunbei 8-X with adjacent wells

井号 开钻次序 入井深度/m 出井深度/m 实际纯钻时间/h 实际进尺/m 实际机械钻速/(m∙h−1) 顺北8-X 四开 7 660 8 110 147.0 450 3.06 顺北8-2X 四开 7 296 8 396 652.7 1 100 1.69 -

[1] 高利君,李宗杰,李海英,等. 塔里木盆地超深层碳酸盐岩规模储层分类对比及特征分析[J]. 地质论评,2020,66(增刊1):54-56. GAO Lijun, LI Zongjie, LI Haiying, et al. Classification and characteristic analysis of super-deep carbonate reservoirs in Tarim Basin[J]. Geological Review, 2020, 66(supplement 1): 54-56.

[2] 马永生,蔡勋育,云露,等. 塔里木盆地顺北超深层碳酸盐岩油气田勘探开发实践与理论技术进展[J]. 石油勘探与开发,2022,49(1):1–17. doi: 10.11698/PED.2022.01.01 MA Yongsheng, CAI Xunyu, YUN Lu, et al. Practice and theoretical and technical progress in exploration and development of Shunbei ultra-deep carbonate oil and gas field, Tarim Basin, NW China[J]. Petroleum Exploration and Development, 2022, 49(1): 1–17. doi: 10.11698/PED.2022.01.01

[3] 刘彪,潘丽娟,张俊,等. 顺北区块超深小井眼水平井优快钻井技术[J]. 石油钻探技术,2016,44(6):11–16. LIU Biao, PAN Lijuan, ZHANG Jun, et al. The optimized drilling techniques used in ultra-deep and slim-hole horizontal wells of the Shunbei Block[J]. Petroleum Drilling Techniques, 2016, 44(6): 11–16.

[4] 尤东华,曹自成,徐明军,等. 塔里木盆地奥陶系鹰山组多类型白云岩储层成因机制[J]. 石油与天然气地质,2020,41(1):92–101. doi: 10.11743/ogg20200109 YOU Donghua, CAO Zicheng, XU Mingjun, et al. Genetic mechanism of multi-type dolomite reservoirs in Ordovician Yingshan Formation, Tarim Basin[J]. Oil & Gas Geology, 2020, 41(1): 92–101. doi: 10.11743/ogg20200109

[5] 陈宗琦,刘湘华,白彬珍,等. 顺北油气田特深井钻井完井技术进展与发展思考[J]. 石油钻探技术,2022,50(4):1–10. doi: 10.11911/syztjs.2022069 CHEN Zongqi, LIU Xianghua, BAI Binzhen, et al. Technical progress and development consideration of drilling and completion engineering for ultra-deep wells in the Shunbei Oil & Gas Field[J]. Petroleum Drilling Techniques, 2022, 50(4): 1–10. doi: 10.11911/syztjs.2022069

[6] 温杰文. 超深小井眼地层测试工艺技术研究及应用[J]. 钻采工艺,2019,42(6):50–53. doi: 10.3969/J.ISSN.1006-768X.2019.06.15 WEN Jiewen. Research and application of formation test technology in ultra-deep slimholes[J]. Drilling & Production Technology, 2019, 42(6): 50–53. doi: 10.3969/J.ISSN.1006-768X.2019.06.15

[7] 漆立新. 塔里木盆地顺北地区海相超深碳酸盐岩油气勘探物探技术需求与创新应用[J]. 石油物探,2023,62(3):381–394. doi: 10.12431/issn.1000-1441.2023.62.03.001 QI Lixin. Technical demand and innovative application of geophysical exploration technology for marine ultra-deep carbonate rocks in Shunbei Area, Tarim Basin[J]. Geophysical Prospecting for Petroleum, 2023, 62(3): 381–394. doi: 10.12431/issn.1000-1441.2023.62.03.001

[8] 张煜,李海英,陈修平,等. 塔里木盆地顺北地区超深断控缝洞型油气藏地质−工程一体化实践与成效[J]. 石油与天然气地质,2022,43(6):1466–1480. doi: 10.11743/ogg20220615 ZHANG Yu, LI Haiying, CHEN Xiuping, et al. Practice and effect of geology-engineering integration in the development of ultra-deep fault-controlled fractured-vuggy oil/gas reservoirs, Shunbei Area, Tarim Basin[J]. Oil & Gas Geology, 2022, 43(6): 1466–1480. doi: 10.11743/ogg20220615

[9] 马鸿彦,孔凡刚,杨金生,等. 超深超高温潜山气井AT-6X井小井眼侧钻技术[J]. 石油钻采工艺,2020,42(2):143–149. MA Hongyan, KONG Fangang, YANG Jinsheng, et al. Slim-hole sidetracking techniques used in Well AT-6X, a gas well in the ultradeep and ultrahigh temperature buried hill[J]. Oil Drilling & Production Technology, 2020, 42(2): 143–149.

[10] 康海涛,白俊成,蔡云平,等. 马深1井超深小钻孔井眼准备及套管下入技术[J]. 石油钻采工艺,2016,38(5):583–587. KANG Haitao, BAI Juncheng, CAI Yunping, et al. The preparing and running casing technology of super deep and slim hole in Well Mashen-1[J]. Oil Drilling & Production Technology, 2016, 38(5): 583–587.

[11] 李亚南,于占淼,晁文学,等. 顺北评2H超深小井眼侧钻水平井技术[J]. 石油钻采工艺,2018,40(2):169–173. LI Yanan, YU Zhanmiao, CHAO Wenxue, et al. Ultra-deep slim horizontal well sidetracking technology applied in Well Shunbeiping 2H[J]. Oil Drilling & Production Technology, 2018, 40(2): 169–173.

[12] 康鹏,李琰,戴永鹏,等. 哈拉哈塘ϕ104.8 mm小井眼超深定向井难点分析及改进方向[J]. 钻采工艺,2019,42(3):122–124. doi: 10.3969/J.ISSN.1006-768X.2019.03.36 KANG Peng, LI Yan, DAI Yongpeng, et al. Challenges of ultradeep directional drilling in ϕ104.8 mm ultra-slim hole at Halahatang and improvements to be made[J]. Drilling & Production Technology, 2019, 42(3): 122–124. doi: 10.3969/J.ISSN.1006-768X.2019.03.36

[13] 孙明光. 顺北油田超深小井眼水平井定向钻井技术[J]. 钻采工艺,2020,43(2):19–22. doi: 10.3969/J.ISSN.1006-768X.2020.02.05 SUN Mingguang. Directional drilling technique for ultra-deep horizontal slimhole wells in Shunbei Oilfield[J]. Drilling & Production Technology, 2020, 43(2): 19–22. doi: 10.3969/J.ISSN.1006-768X.2020.02.05

[14] 彭军,夏梦,曹飞,等. 塔里木盆地顺北一区奥陶系鹰山组与一间房组沉积特征[J]. 岩性油气藏,2022,34(2):17–30. doi: 10.12108/yxyqc.20220202 PENG Jun, XIA Meng, CAO Fei, et al. Sedimentary characteristics of Ordovician Yingshan Formation and Yijianfang Formation in Shunbei-1 Area, Tarim Basin[J]. Lithologic Reservoirs, 2022, 34(2): 17–30. doi: 10.12108/yxyqc.20220202

[15] 于洋,南玉民,李双贵,等. 顺北油田古生界钻井提速技术[J]. 断块油气田,2019,26(6):780–783. YU Yang, NAN Yumin, LI Shuanggui, et al. Technology for increasing drilling speed of Paleozoic stratum in Shunbei Oilfield[J]. Fault-Block Oil & Gas Field, 2019, 26(6): 780–783.

[16] 李文霞,王居贺,王治国,等. 顺北油气田超深高温水平井井眼轨迹控制技术[J]. 石油钻探技术,2022,50(4):18–24. doi: 10.11911/syztjs.2022073 LI Wenxia, WANG Juhe, WANG Zhiguo, et al. Wellbore trajectory control technologies for ultra-deep and high-temperature horizontal wells in the Shunbei Oil & Gas Field[J]. Petroleum Drilling Techniques, 2022, 50(4): 18–24. doi: 10.11911/syztjs.2022073

[17] 舒义勇,孙俊,曾东,等. 塔里木油田跃满西区块高温恒流变钻井液研究与现场试验[J]. 石油钻探技术,2021,49(5):39–45. doi: 10.11911/syztjs.2021037 SHU Yiyong, SUN Jun, ZENG Dong, et al. Study and field test of drilling fluid with constant rheology at high temperature in West Yueman Block, Tarim Oilfield[J]. Petroleum Drilling Techniques, 2021, 49(5): 39–45. doi: 10.11911/syztjs.2021037

[18] 陈志,陈兴明,汪宏林,等. 塔中高含硫喷漏同层堵漏技术研究[J]. 石化技术,2017,24(2):33–34. doi: 10.3969/j.issn.1006-0235.2017.02.028 CHEN Zhi, CHEN Xingming, WANG Honglin, et al. Application of plugging in Tazhong high sulfur reservoir with coexistence of blowout and mud loss[J]. Petrochemical Industry Technology, 2017, 24(2): 33–34. doi: 10.3969/j.issn.1006-0235.2017.02.028

[19] 何成江,姜应兵,文欢,等. 塔河油田缝洞型油藏“一井多控”高效开发关键技术[J]. 石油钻探技术,2022,50(4):37–44. HE Chengjiang, JIANG Yingbing, WEN Huan, et al. Key technologies for high-efficiency one-well multi-control development of fractured-vuggy reservoirs in Tahe Oilfield[J]. Petroleum Drilling Techniques, 2022, 50(4): 37–44.

[20] 王建云,韩涛,赵宽心,等. 塔深5井超深层钻井关键技术[J]. 石油钻探技术,2022,50(5):27–33. WANG Jianyun, HAN Tao, ZHAO Kuanxin, et al. Key drilling technologies for the ultra-deep Well Tashen 5[J]. Petroleum Drilling Techniques, 2022, 50(5): 27–33.

[21] 王玉伟,陈红汉,曹自成,等. 顺北地区流体活动对储层形成的控制作用[J]. 断块油气田,2023,30(1):44–51. WANG Yuwei, CHEN Honghan, CAO Zicheng, et al. Controlling effects of fluid activity on reservoir formation in Shunbei Area[J]. Ault-Block Oil & Gas Field, 2023, 30(1): 44–51.

[22] 刘湘华,杜欢,刘彪,等. 顺北Ⅳ号条带超深高温定向井钻井关键技术[J]. 石油钻采工艺,2022,44(6):665–670. LIU Xianghua, DU Huan, LIU Biao, et al. Key technology of directional drilling in the ultra-deep high-temperature IV Belt, the Shunbei Oilfield[J]. Oil Drilling & Production Technology, 2022, 44(6): 665–670.

[23] 李双贵,罗江,于洋,等. 顺北5号断裂带南部压力剖面建立及井身结构优化[J]. 石油钻探技术,2023,51(1):9–15. LI Shuanggui, LUO Jiang, YU Yang, et al. Establishing pressure profiles and casing program optimization in the Southern Shunbei No.5 Fault Zone[J]. Petroleum Drilling Techniques, 2023, 51(1): 9–15.

-

期刊类型引用(7)

1. 杨森锋,董胜伟,罗书洵,赵敏,张向阳. 新型纳米渗吸剂性能评价及应用. 精细石油化工. 2025(01): 4-8 .  百度学术

百度学术

2. 杨静,张献伟,李锦锋,龚嘉顺,张梦雅,杨峰,薛井泉,白峰. 下寺湾油田致密油地质工程一体化压裂技术. 石油化工应用. 2025(05): 15-20 .  百度学术

百度学术

3. 张云逸. 页岩油水平井穿层压裂先导性试验——以鄂尔多斯盆地庆城油田华H100平台为例. 中国石油勘探. 2023(04): 92-104 .  百度学术

百度学术

4. 慕立俊,拜杰,齐银,薛小佳. 庆城夹层型页岩油地质工程一体化压裂技术. 石油钻探技术. 2023(05): 33-41 .  本站查看

本站查看

5. 谢建勇,崔新疆,李文波,朱靖生,伍晓虎,褚艳杰,陈依伟,汤涛,朱思静,吴承美,张金风. 准噶尔盆地吉木萨尔凹陷页岩油效益开发探索与实践. 中国石油勘探. 2022(01): 99-110 .  百度学术

百度学术

6. 蔡萌,唐鹏飞,魏旭,刘宇,张浩,张宝岩,耿丹丹. 松辽盆地古龙页岩油复合体积压裂技术优化. 大庆石油地质与开发. 2022(03): 156-164 .  百度学术

百度学术

7. 樊平天,刘月田,冯辉,周东魁,李平,周丰,秦静,余维初,史黎岩. 致密油新一代驱油型滑溜水压裂液体系的研制与应用. 断块油气田. 2022(05): 614-619 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: