Status and Prospect of Artificial Intelligence Application in Fracturing Technology

-

摘要:

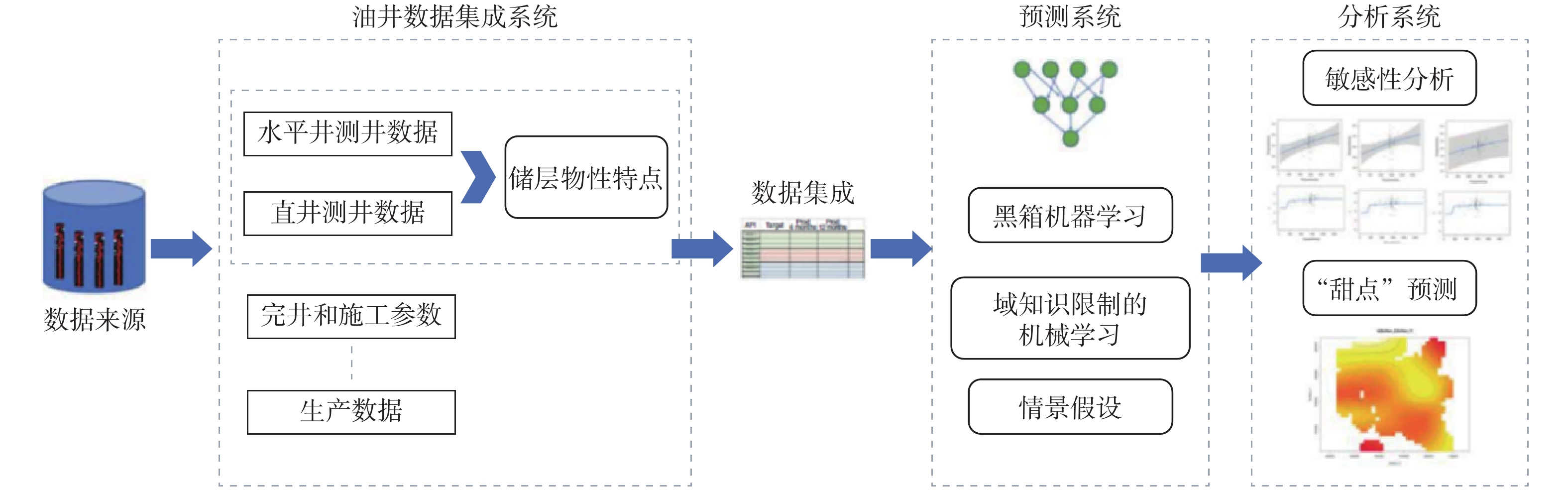

随着人工智能理论和计算机技术的快速发展,智能化和数字化已成为推动储层压裂技术发展的重要力量。针对压裂技术智能化发展,阐述了人工智能技术在地质参数预测、压裂参数优化设计、压裂施工实时诊断与调控、压裂工具及材料研发等方面的研究进展与应用情况,分析了当前智能压裂技术发展存在的主要问题与今后的重点发展方向,认识到智能压裂技术仍处于探索试验阶段,国外在“甜点”智能识别、压裂参数优化、现场施工智能化控制等方面的研究已走在前列,并在北美地区多个区块的压裂服务中成功应用,国内仅在压裂大数据机器学习、智能化压裂材料等方面进行了早期探索,在智能压裂装备、工具、实时监测诊断和现场智能化调控等方面的研究与应用较少,与国外存在较大差距。分析认为,数据样本可靠性差、一体化智能压裂方法与装备欠缺和多领域交叉人才缺乏等是影响智能压裂技术快速发展的关键问题,并预测随着万物互联技术的发展,将形成智能化完井压裂系统,不需要人工干预即可完成储层评估、“甜点”识别、压裂参数优化设计、现场调控和压后评估等工作,真正实现一体化智能储层改造。

Abstract:With the rapid development of artificial intelligence (AI) theory and computer technology, intelligence and digitalization have become important forces to promote the fracturing technology of reservoirs. In terms of the intelligent development of the fracturing technology, the research progress and application of AI technology in the prediction of geological parameters, optimization design of fracturing parameters, real-time diagnosis and control of fracturing construction, and development of fracturing tools and materials were introduced. The main problems existing in the development of the intelligent fracturing technology as well as the key development direction were analyzed. It suggests that the intelligent fracturing technology was still in the stage of exploration and trial. Foreign countries have taken the lead in the intelligent identification of sweet spots, optimization of fracturing parameters, and intelligent control of field construction, and they have obtained successful applications in fracturing services in several fields in North America. China has only carried out early exploration in fracturing big data machine learning, intelligent fracturing materials, and there was no significant progress in intelligent fracturing equipment and tools, real-time monitoring and diagnosis, and intelligent field control. Therefore, there is a gap between China and other countries. The key problems affecting the development of intelligent fracturing technology were proposed, including the poor reliability of data samples, the lack of integrated intelligent fracturing methods and equipment, and the shortage of interdisciplinary talents. It was also predicted that with the development of the Internet of Everything technology, an intelligent completion fracturing system would be developed, which could complete reservoir evaluation, the sweet spot identification, optimization design of fracturing parameters, field control, post-fracture, etc. without human intervention. At that point, the integrated intelligent reservoir stimulation could be truly realized.

-

-

-

[1] 戴汝为. 人工智能概述[J]. 中国经济和信息化,1989(8):14–17. DAI Ruwei. Introduction to artificial intelligence[J]. China Economy & Informatization, 1989(8): 14–17.

[2] 王海峰. 国际大数据产业技术创新高峰论坛[DB/OL]. (2017− 09−15)[2021−12−16]. http://www.sohu.com/a/192144148_473283.html. WANG Haifeng. International big data industry technology innovation summit forum[DB/OL]. (2017-09-15)[2021-12-16]. http://www.sohu.com/a/192144148_473283.html.

[3] 刘伟,闫娜. 人工智能在石油工程领域应用及影响[J]. 石油科技论坛,2018,37(4):32–40. doi: 10.3969/j.issn.1002-302x.2018.04.006 LIU Wei, YAN Na. Application and influence of artificial intelligence in petroleum engineering area[J]. Petroleum Science and Technology Forum, 2018, 37(4): 32–40. doi: 10.3969/j.issn.1002-302x.2018.04.006

[4] MOHAGHEGH S D. Recent developments in application of artificial intelligence in petroleum engineering[J]. Journal of Petroleum Technology, 2005, 57(4): 86–91. doi: 10.2118/89033-JPT

[5] CARPENTER C. Embedded discrete fracture modeling with artificial intelligence in Permian basin[J]. Journal of Petroleum Technology, 2018, 70(5): 63–64. doi: 10.2118/0518-0063-JPT

[6] 林伯韬,郭建成. 人工智能在石油工业中的应用现状探讨[J]. 石油科学通报,2019,4(4):403–413. LIN Botao, GUO Jiancheng. Discussion on current application of artificial intelligence in petroleum industry[J]. Petroleum Science Bulletin, 2019, 4(4): 403–413.

[7] 蒋廷学,田占良. 模糊数学在压裂设计中的应用[J]. 天然气工业,1998,18(3):74–77. JIANG Tingxue, TIAN Zhanliang. Application of fuzzy mathematics to fracturing design[J]. Natural Gas Industry, 1998, 18(3): 74–77.

[8] 吴建发,郭建春,赵金洲. 模糊分析方法优选压裂井层[J]. 天然气工业,2005,25(2):84–86. doi: 10.3321/j.issn:1000-0976.2005.02.027 WU Jianfa, GUO Jianchun, ZHAO Jinzhou. Optimizing well and horizon for fracturing by fuzzy analysis method[J]. Natural Gas Industry, 2005, 25(2): 84–86. doi: 10.3321/j.issn:1000-0976.2005.02.027

[9] 李玉伟,艾池,胡超洋,等. 应用模糊综合评判和灰色关联度分析评价水平井多级压裂效果[J]. 数学的实践与认识,2014,44(2):51–56. LI Yuwei, AI Chi, HU Chaoyang, et al. Evaluating multistage fracturing effect of horizontal wells using fuzzy comprehensive evaluation and grey relational grade analysis[J]. Mathematics in Practice and Theory, 2014, 44(2): 51–56.

[10] HINTON G E, SALAKHUTDINOV R R. Reducing the dimensionality of data with neural networks[J]. Science, 2006, 313(5786): 504–507. doi: 10.1126/science.1127647

[11] NAEINI E Z, GREEN S, RAUCH-DAVIES M. An integrated deep learning solution for petrophysics, pore pressure, and geomechanics property prediction[R]. URTEC-2019−111-MS, 2019.

[12] GONG Yiwen, MEHANA M, XIONG Fengyang, et al. Towards better estimations of rock mechanical properties integrating machine learning techniques for application to hydraulic fracturing[R]. SPE 195884, 2019.

[13] GUEVARA J, ZADROZNY B, BUORO A, et al. A machine-learning methodology using domain-knowledge constraints for well-data integration and well-production prediction[J]. SPE Reservoir Evaluation & Engineering, 2019, 22(4): 1185–1200.

[14] TRAN N L, GUPTA I, DEVEGOWDA D, et al. Machine learning workflow to identify brittle, fracable and producible rock in horizontal wells using surface drilling data[R]. SPE 201456, 2020.

[15] GU Ming, GOKARAJU D, CHEN Dingding, et al. Shale fracturing characterization and optimization by using anisotropic acoustic interpretation, 3D fracture modeling, and supervised machine learning[J]. Petrophysics, 2016, 57(6): 573–587.

[16] Oil Review Middle East Group. Halliburton brings automation to hydraulic fracturing[J]. Oil Review Middle East, 2018, 21(6): 52.

[17] PENNA M, SHIVASHANKAR, ARJUN B, et al. Smart fleet monitoring system using Internet of Things(IoT)[C]//2017 2nd IEEE International Conference on Recent Trends in Electronics, Information & Communication Technology (RTEICT). Piscataway: IEEE, 2017: 1232−1236.

[18] 蒋廷学,周珺,廖璐璐. 国内外智能压裂技术现状及发展趋势[J]. 石油钻探技术,2022,50(3):1–9. doi: 10.11911/syztjs.2022065 JIANG Tingxue, ZHOU Jun, LIAO Lulu. Development status and future trends of intelligent fracturing technologies[J]. Petroleum Drilling Techniques, 2022, 50(3): 1–9. doi: 10.11911/syztjs.2022065

[19] 盛茂,李根生,田守嶒,等. 人工智能在油气压裂增产中的研究现状与展望[J]. 钻采工艺,2022,45(4):1–8. SHENG Mao, LI Gensheng, TIAN Shouceng, et al. Research status and prospect of artificial intelligence in reservoir fracturing stimulation[J]. Drilling & Production Technology, 2022, 45(4): 1–8.

[20] AHMED S A, ELKATATNY S, ALI A Z, et al. Artificial neural network ANN approach to predict fracture pressure[R]. SPE 194852, 2019.

[21] PALMER C E. Using AI and machine learning to indicate shale anisotropy and assist in completions design[D]. Morgantown: West Virginia University, 2020.

[22] TRAN N L, GUPTA I, DEVEGOWDA D, et al. Application of interpretable machine-learning workflows to identify brittle, fracturable, and producible rock in horizontal wells using surface drilling data[J]. SPE Reservoir Evaluation & Engineering, 2020, 23(4): 1328–1342.

[23] DOWNIE R, DAVES D. Improving hydraulic fracturing performance and interpreting fracture geometry based on drilling measurements[R]. SPE 194357, 2019.

[24] MA Zheren, DAVANI E, MA Xiaodan, et al. Finding a trend out of chaos, a machine learning approach for well spacing optimi-zation[R]. SPE 201698, 2020.

[25] 刘长印,孔令飞,张国英,等. 人工智能系统在压裂选井选层方面的应用[J]. 钻采工艺,2003,26(1):37–38. LIU Changyin, KONG Lingfei, ZHANG Guoying, et al. Application of artificial intelligence system in selection of well and layer for fracturing[J]. Drilling & Production Technology, 2003, 26(1): 37–38.

[26] PANKAJ P, GEETAN S, MACDONALD R, et al. Application of data science and machine learning for well completion optimiza-tion[R]. OTC 28632, 2018.

[27] URBAN-RASCON E, AGUILERA R. Machine learning applied to SRV modeling, fracture characterization, well interference and production forecasting in low permeability reservoirs[R]. SPE 199082, 2020.

[28] GARJAN Y S, GHANEEZABADI M. Machine learning interpretability application to optimize well completion in Montney[R]. SPE 200019, 2020.

[29] LUO Guofan, TIAN Yao, BYCHINA M, et al. Production optimization using machine learning in Bakken shale[R]. URTEC-2902505-MS, 2018.

[30] BEN Yuxing, PERROTTE M, EZZATABADIPOUR M, et al. Real-time hydraulic fracturing pressure prediction with machine lear-ning[R]. SPE 199699, 2020.

[31] SHEN Yuchang, CAO Dingzhou, RUDDY K, et al. Near real-time hydraulic fracturing event recognition using deep learning me-thods[J]. SPE Drilling & Completion, 2020, 35(3): 478–489.

[32] ZHANG He, CHEN Mingzhu, LI Guoliang. Study on the early warning of fracturing sand plugging based on improved BP neural network[J]. International Journal of Science, 2017, 4(7): 252–261.

[33] 方博涛. 压裂实时动态预警系统研究与设计[D]. 成都: 西南石油大学, 2015. FANG Botao. Research and design of fracturing real-time dynamic early warning system[D]. Chengdu: Southwest Petroleum Univer-sity, 2015.

[34] HU Jinqiu, KHAN F, ZHANG Laibin, et al. Data-driven early warning model for screenout scenarios in shale gas fracturing opera-tion[J]. Computers & Chemical Engineering, 2020, 143: 107116.

[35] 石艺. 国际石油2015年十大科技进展 (四):全电动智能井系统取得重大进展[J]. 石油钻采工艺,2016,38(1):92. SHI Yi. Top 10 scientific and technological progress of 2015 (IV): significant progress was made in the all-electric intelligent well system[J]. Oil Drilling & Production Technology, 2016, 38(1): 92.

[36] 何明格, 杨云山, 桑宇, 等. 一种基于电磁波双向通讯的无线控制套管滑套: CN201611144483.8[P]. 2017-04-26. HE Mingge, YANG Yunshan, SANG Yu, et al. A wireless control sleeve sliding sleeve based on electromagnetic wave bidirectional communication: CN201611144483.8[P]. 2017-04-26.

[37] 魏爱拴,刘禹铭,王明杰,等. 可溶球智能压裂投球器的研制[J]. 石化技术,2018,25(7):315. WEI Aishuan, LIU Yuming, WANG Mingjie, et al. Development of soluble ball intelligent fracturing pitcher[J]. Petrochemical Industry Technology, 2018, 25(7): 315.

[38] 台广锋,潘社卫,舒峰,等. 工厂化压裂连续输砂装置智能控制系统研究[J]. 矿冶,2015,24(5):67–71. doi: 10.3969/j.issn.1005-7854.2015.05.017 TAI Guangfeng, PAN Shewei, SHU Feng, et al. Study on an intelligent control system of the sand conveyance device for factory fracturing[J]. Mining and Metallurgy, 2015, 24(5): 67–71. doi: 10.3969/j.issn.1005-7854.2015.05.017

[39] MANSOUR A K, TALEGHANI A D, LI Guoqiang. Smart expandable LCMs: a theoretical and experimental study[R]. AADE-17-NTCE-074, 2017.

[40] ALEXANDER S, DUNNILL C W, BARRON A R. Assembly of porous hierarchical copolymers/resin proppants: new approaches to smart proppant immobilization via molecular anchors[J]. Journal of Colloid and Interface Science, 2016, 466: 275–283. doi: 10.1016/j.jcis.2015.12.038

[41] CHANG F F, BERGER P D, LEE C H. In-situ formation of proppant and highly permeable blocks for hydraulic fracturing[R]. SPE 173328, 2015.

[42] MILLER C, ZENG Tongzhou, MOHANTY K. Evaluation of chemical blends for shale EOR[R]. SPE 195819, 2019.

[43] SANTOS L, TALEGHANI A D, LI Guoqiang. Expandable diverting agents to improve efficiency of refracturing treatments[R]. URTEC-2697493-MS, 2017.

[44] 王磊,沈一丁,薛小佳,等. 新型酸性清洁压裂液的研制[J]. 石油天然气学报,2010,32(6):135–138. doi: 10.3969/j.issn.1000-9752.2010.06.031 WANG Lei, SHEN Yiding, XUE Xiaojia, et al. Study on the properties of acid clean fracturing fluid[J]. Journal of Oil and Gas Technology, 2010, 32(6): 135–138. doi: 10.3969/j.issn.1000-9752.2010.06.031

[45] 高峰,胡军,程芳,等. 速溶型智能转向酸的开发与应用[J]. 油田化学,2021,38(1):42–46. doi: 10.19346/j.cnki.1000-4092.2021.01.008 GAO Feng, HU Jun, CHENG Fang, et al. Development and application of instant and intelligent diverting acid[J]. Oilfield Chemistry, 2021, 38(1): 42–46. doi: 10.19346/j.cnki.1000-4092.2021.01.008

-

期刊类型引用(4)

1. 闫炎,韩礼红,刘永红,杨尚谕,曹婧,牟易升. 全尺寸PDC钻头旋转冲击破岩过程数值模拟. 石油机械. 2023(06): 36-42 .  百度学术

百度学术

2. 李思琪,田胜雷,闫铁,李玮,赵欢,陈卓. PDC钻头单齿切削天然裂缝地层断裂机理. 东北石油大学学报. 2020(04): 22-29+6-7 .  百度学术

百度学术

3. 曹艳玲,吴波,王峰,王树星,范振华,霍延虎. 石英岩高陡边坡植物根系环境重塑研究——以长岛石英岩为例. 矿产勘查. 2020(10): 2324-2329 .  百度学术

百度学术

4. 查春青,柳贡慧,李军,李玉梅,席岩. 复合冲击破岩钻井新技术提速机理研究. 石油钻探技术. 2017(02): 20-24 .  本站查看

本站查看

其他类型引用(6)

下载:

下载: