Optimal Design of a Downhole Seismic Generator

-

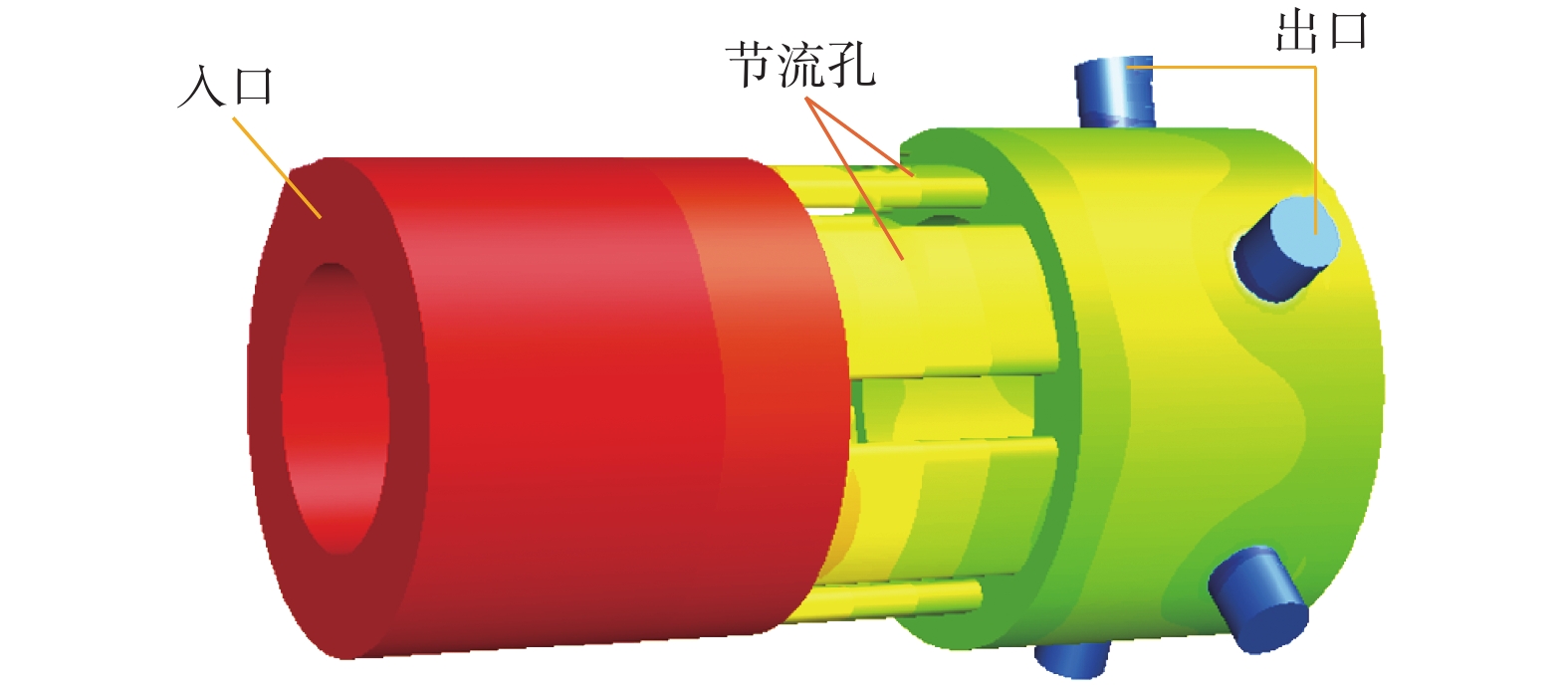

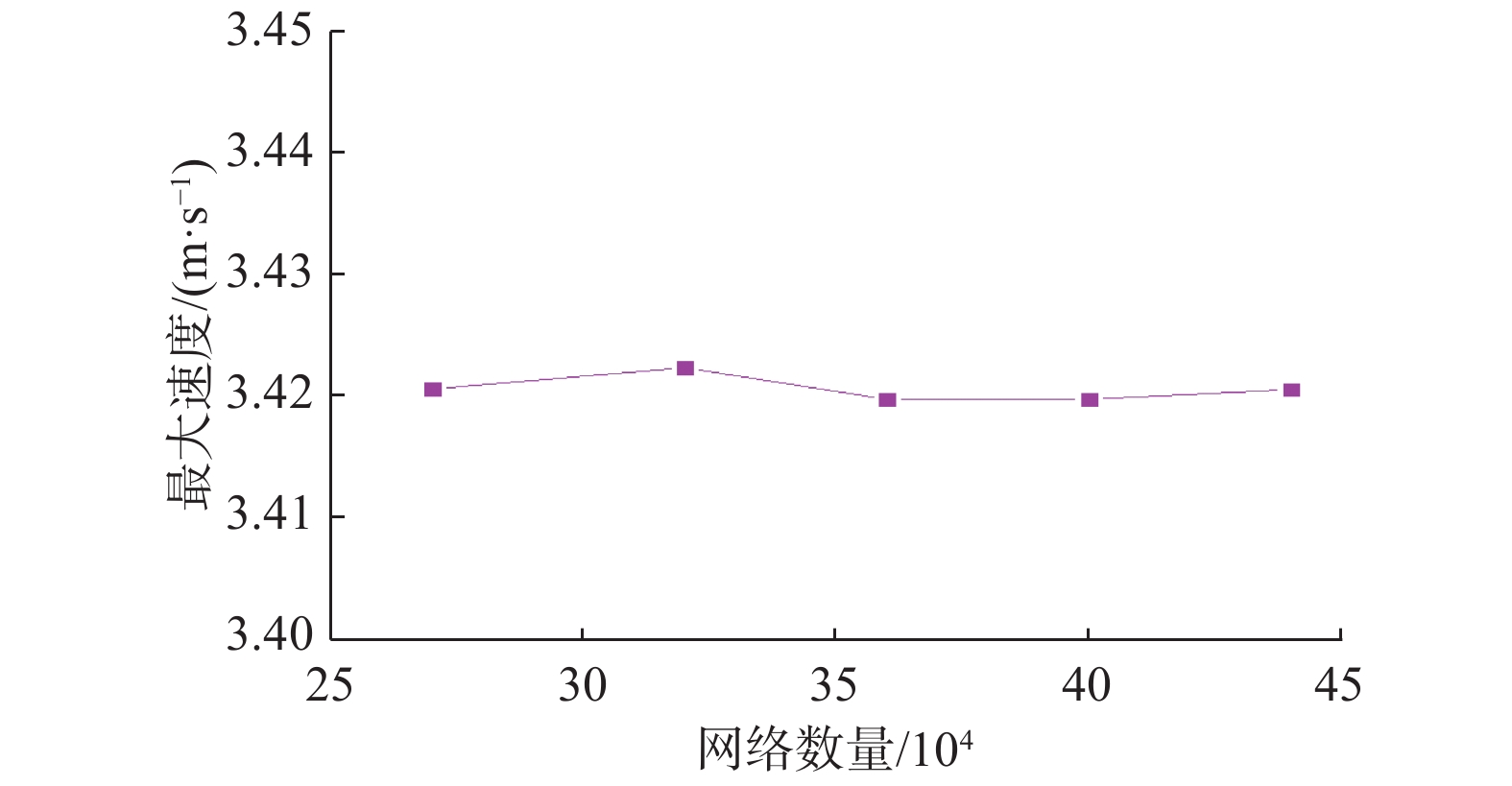

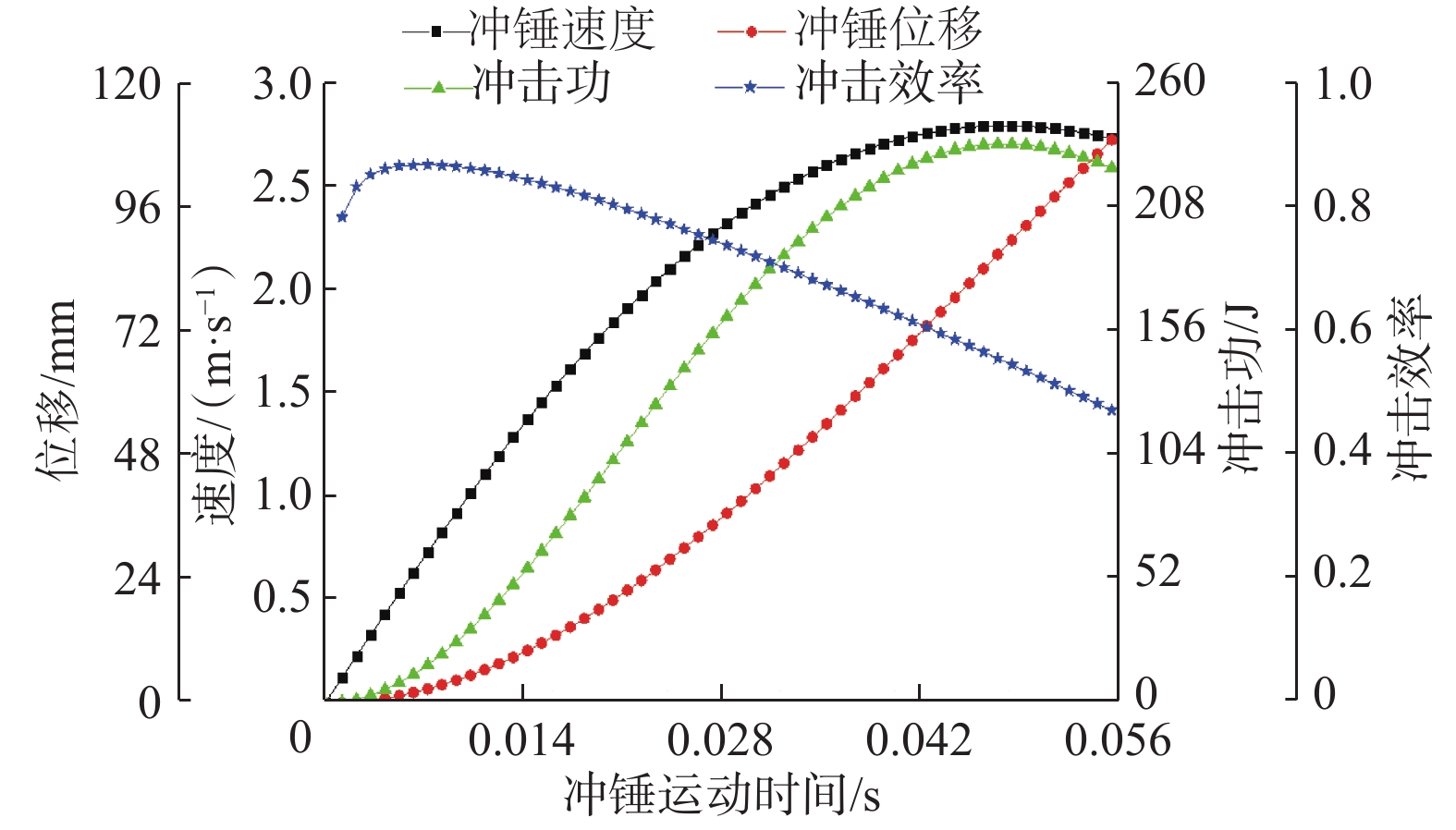

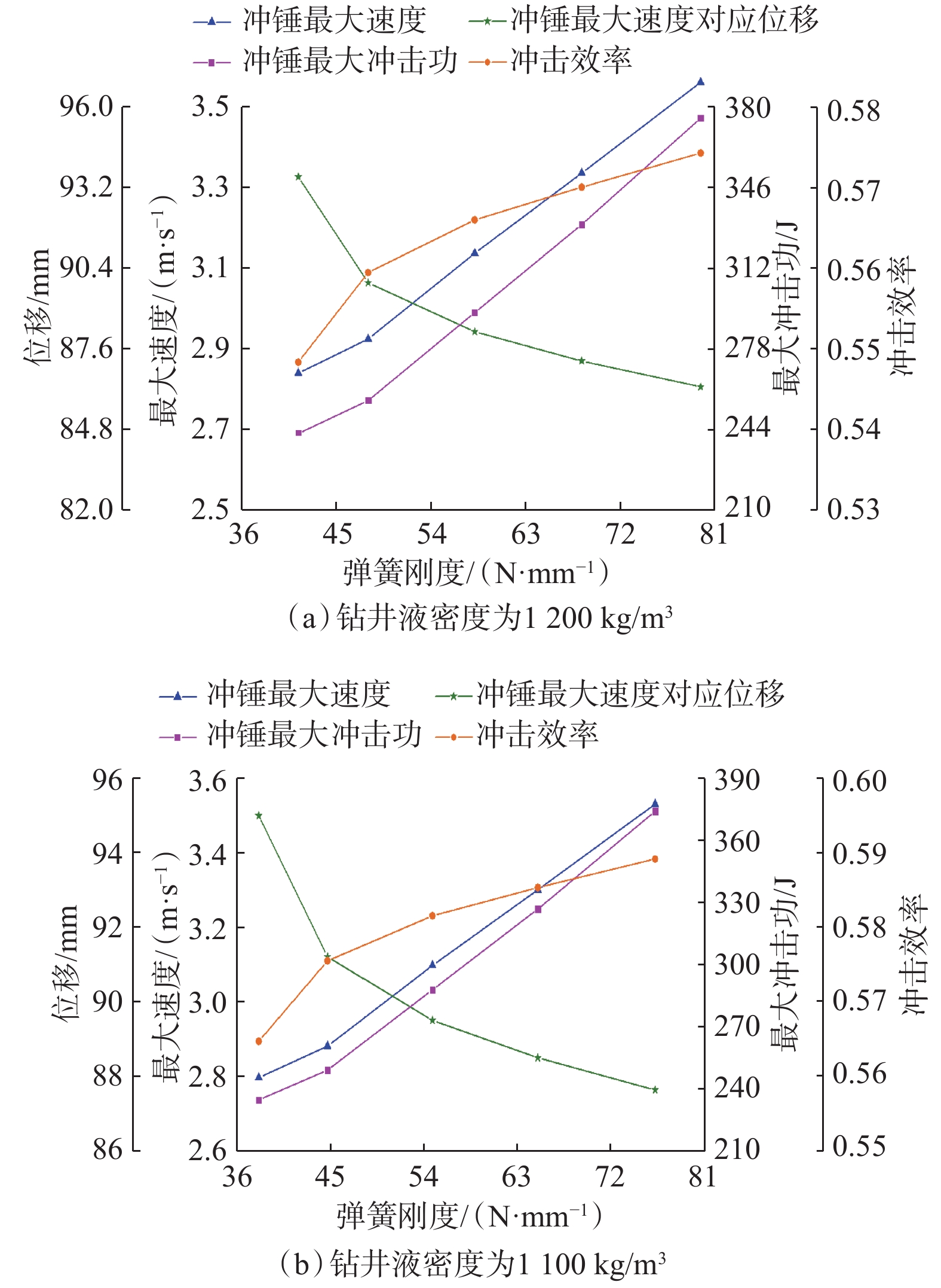

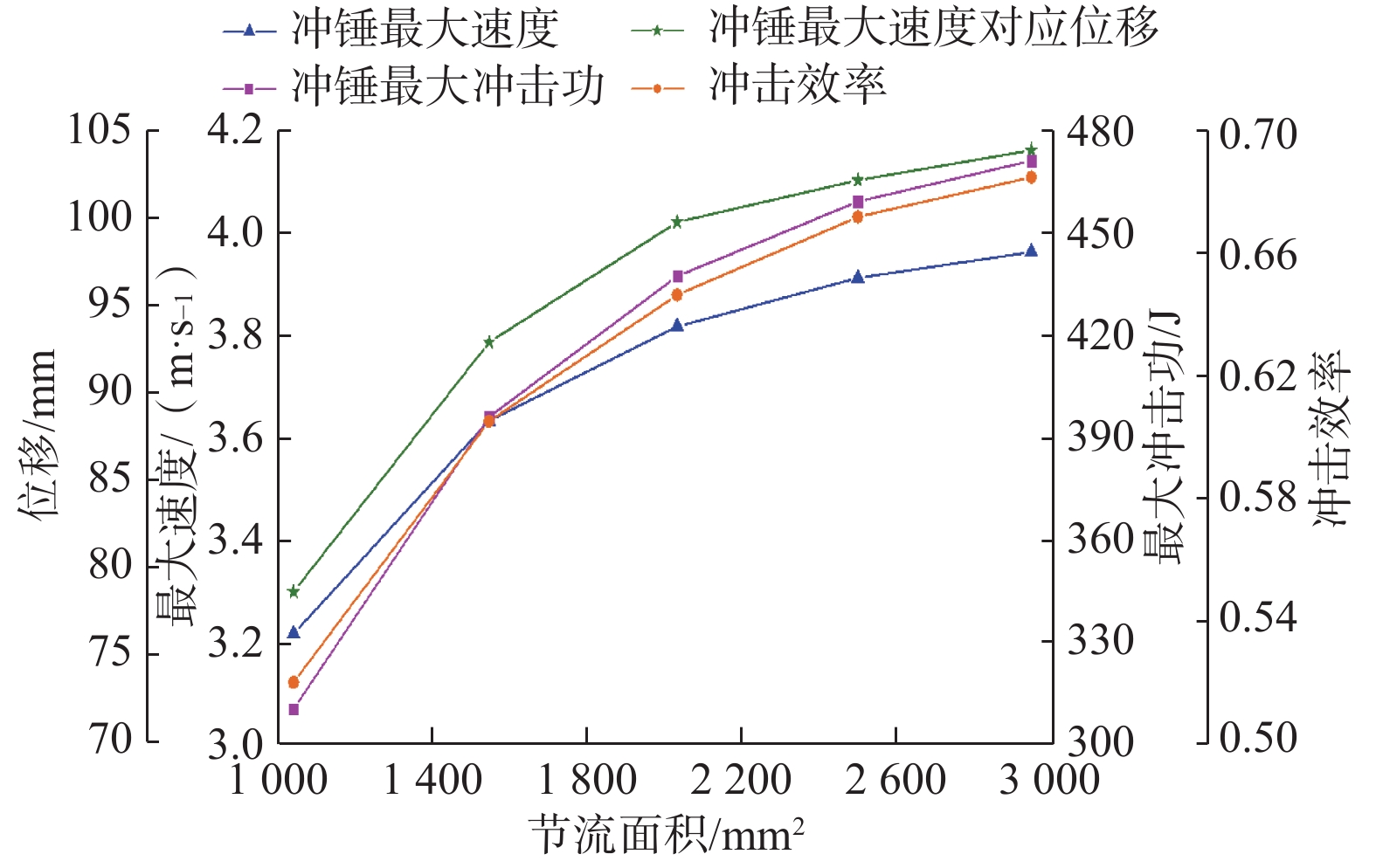

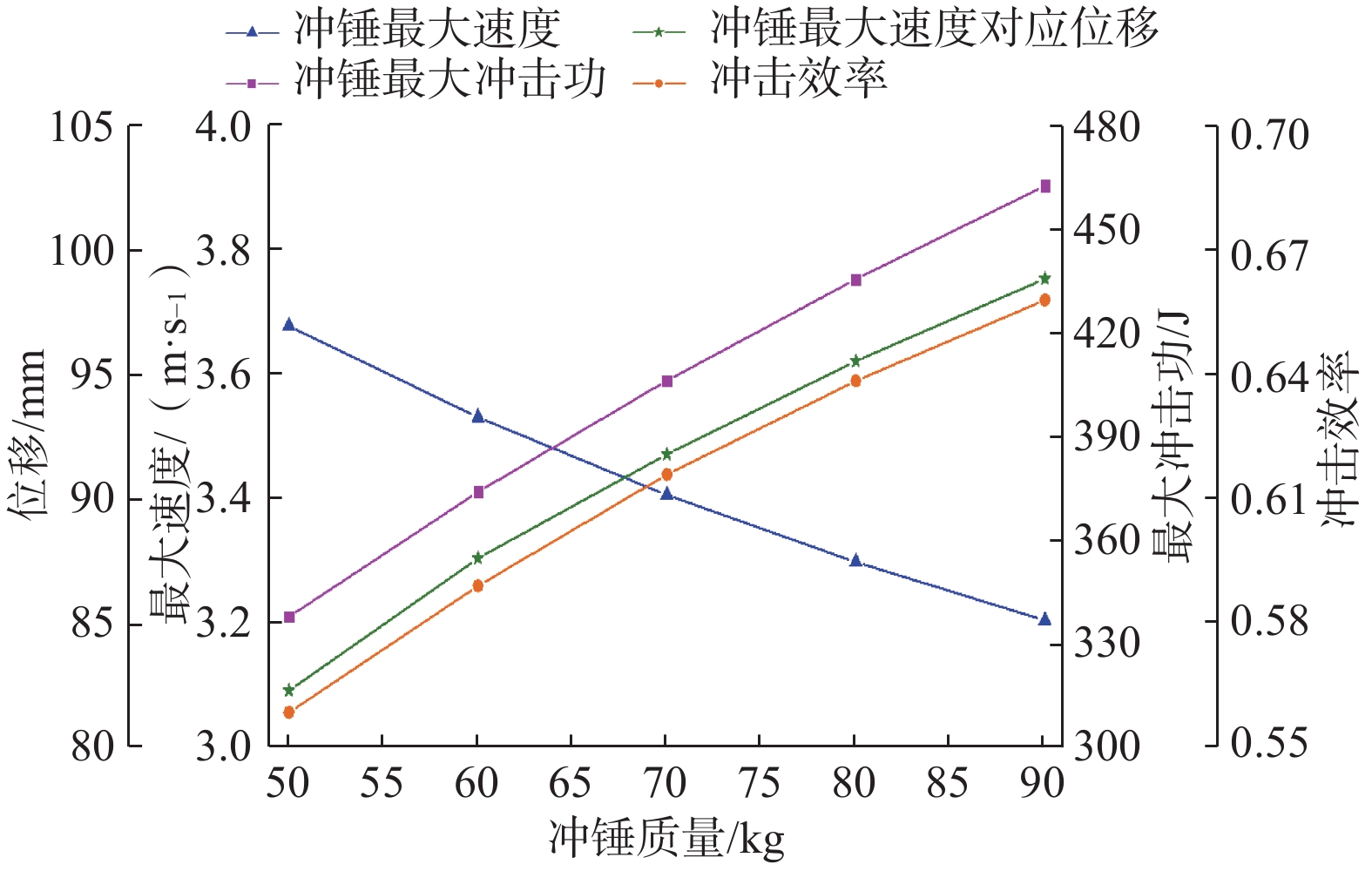

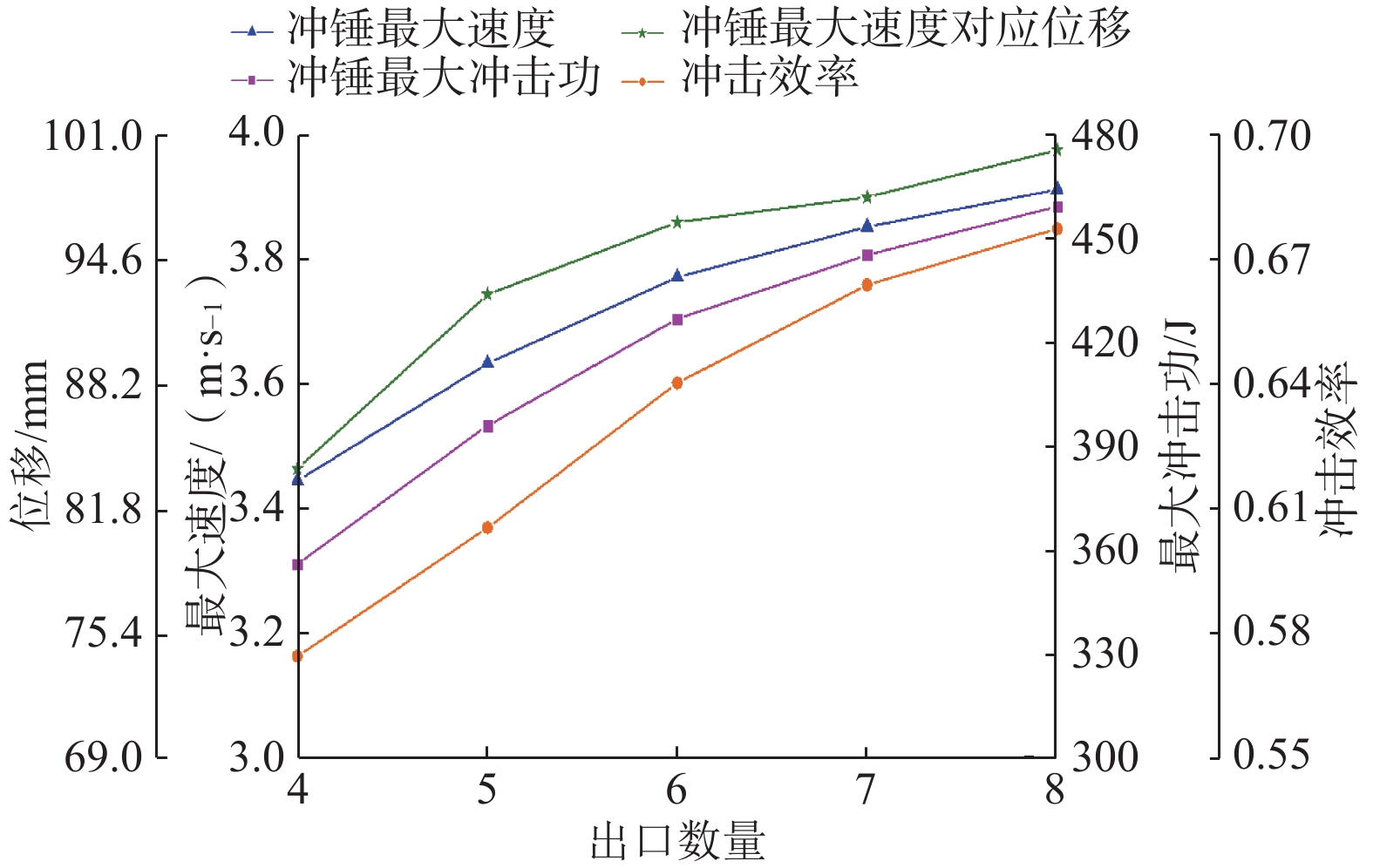

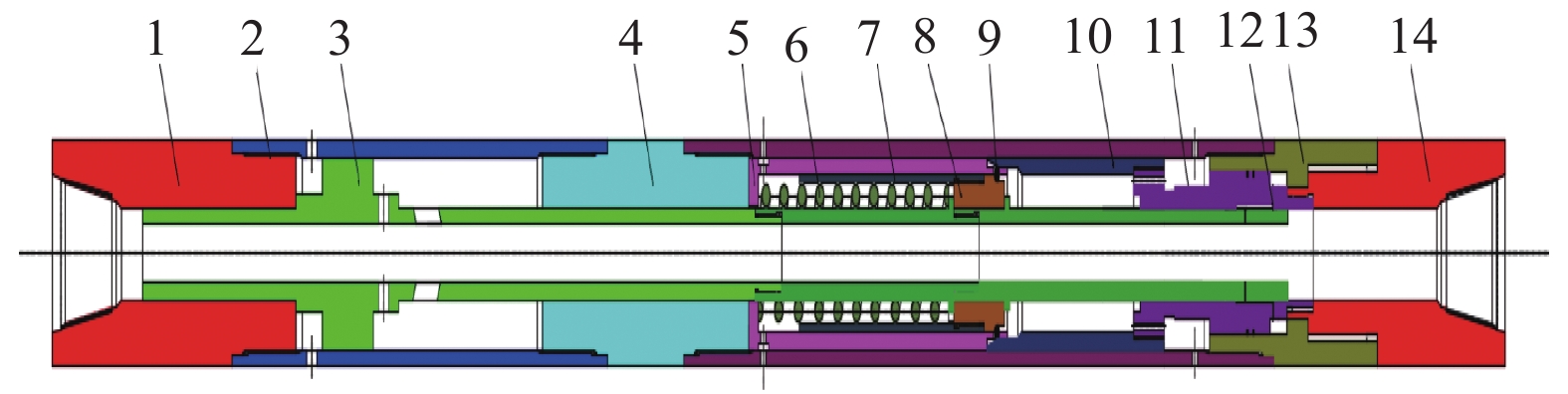

摘要: 针对随钻地震强度低、不利于井眼间防碰监测的问题,设计了一种蓄能式井下震源发生器。该发生器主要由活塞、弹簧、冲锤、铁砧和延时装置等组成,通过钻井液蓄能获得高效冲击功。为使其获得最佳输出性能,以冲锤为研究对象,建立了井下震源发生器冲锤流道模型,基于CFD动网格技术,利用CFD软件分析了弹簧刚度、冲锤质量、节流面积、出口直径和数量等设计参数及钻井液密度对井下震源发生器输出性能参数的影响规律,分析得知:节流面积、出口数量、出口直径和钻井液密度与井下震源发生器输出性能参数呈正相关关系;弹簧刚度越大,冲锤最大冲击功对应的位移越小;冲锤的质量越大则速度越小。基于单因素分析结果,以冲锤冲击功为优化目标,利用正交试验优选了设计参数组合方案。研究结果表明:各设计参数对井下震源发生器输出性能的影响不尽相同;出口直径和弹簧刚度对井下震源发生器输出性能的影响极为显著,节流面积、冲锤质量和出口数量对井下震源发生器输出性能的影响显著,而钻井液密度的影响不显著。根据研究结果筛选出了各设计参数水平的最优组合,研究结果还可以为井下震源发生器的设计提供依据。Abstract: Aiming at the problem of low seismic intensity while drilling, which is detrimental to the anti-collision monitoring between boreholes, an energy storage downhole seismic generator was designed.This generator is composed primarily of a piston, spring, impact hammer, anvil and a delay device. It was able to achieve high efficiency impact by means of the energy storage of drilling fluid. In order to achieve the optimal performance, taking the impact hammer as research object, the impact hammer flow passage model of downhole seismic generator was established. With the CFD software, the influence law on the output performance parameters of downhole seismic generator brought by the spring stiffness, impact hammer mass, throttling area, the outlet diameter, quantity and drilling fluid density were analyzed based on the CFD dynamic grid technology. The results showed that the throttling area, number of outlets, outlet diameter and drilling fluid density were positively correlated with the output performance parameters of downhole seismic generator. The greater the spring stiffness, the smaller the displacement corresponding to the maximum impact energy of the impact hammer. Correspondingly, the greater the mass of the impact hammer, the lower the velocity. Based on the results of single factor analysis, and by taking the impact energy of impact hammer as the optimization target, the optimal combination of design parameters was obtained by the orthogonal test. The results indicated that each design parameter had its unique effect on the output performance of downhole seismic generator. While the outlet diameter and spring stiffness play a prominent role on the output performance of the generator, the throttling area, hammer mass and number of outlets have a significant role on it, and the influence of drilling fluid density is not significant.Thus, the optimal combination of design parameters was selected based on the research results, which can provide a basis for the design of downhole seismic generator.

-

Keywords:

- seismic generator /

- optimized design /

- CFD dynamic grid /

- numerical simulation /

- orthogonal test

-

-

表 1 弹簧的相关参数

Table 1 Relevant parameters of spring

弹簧最小

变形量/mm弹簧最大

变形量/mm实际行程/

mm弹簧刚度/

(N∙mm–1)21.01 147.08 126.07 38.07 17.90 138.72 120.82 44.70 16.34 138.91 122.57 48.95 14.60 135.01 120.41 54.81 13.68 136.83 123.15 58.47 12.31 132.38 120.07 64.96 11.40 132.55 121.15 70.16 10.49 131.13 120.64 76.26 9.58 131.70 122.12 83.52 表 2 各影响因素的水平

Table 2 The level of each influencing factors

水平 因素 节流面积(A)/mm2 弹簧刚度(B)/(N·mm–1) 冲锤质量(C)/kg 出口数量(D) 出口直径(E)/mm 钻井液密度(F)/(kg·m–3) 1 1 520.53 76.3 60 5 20 1 000 2 2 442.06 44.7 80 7 15 1 200 3 2 875.19 54.8 90 9 25 1 100 表 3 正交试验方案及试验结果

Table 3 Orthogonal test scheme and the test results

试验序号 A B C D E F 冲击功/J 1 1 3 1 1 3 3 333.75 2 2 3 3 2 3 1 512.55 3 2 2 1 3 2 3 296.71 4 3 1 1 2 2 2 368.48 5 3 3 3 1 2 3 290.36 6 2 1 3 3 1 3 618.48 7 1 3 2 3 2 2 322.73 8 3 2 1 3 3 1 417.69 9 1 2 2 2 1 3 330.10 10 3 2 3 1 1 2 364.78 11 3 1 2 2 3 3 631.60 12 1 1 1 1 1 1 398.56 13 2 3 1 2 1 2 379.51 14 1 2 3 2 2 1 303.45 15 1 1 3 3 3 2 533.52 16 2 1 2 1 2 1 359.56 17 2 2 2 1 3 1 390.91 18 3 3 2 3 1 1 493.12 ¯K1 370.35 485.03 365.78 356.32 430.76 414.15 ¯K2 426.29 350.61 421.34 420.95 323.55 393.32 ¯K3 427.67 388.67 437.19 447.04 470.00 416.83 表 4 正交试验方差分析结果

Table 4 Variance analysis of orthogonal test

方差来源 A B C D E F Ⅲ型平方和 12 832.53 57 611.21 16 872.29 26 174.63 68 968.34 1 987.97 自由度 2 2 2 2 2 2 均方 6 416.26 28 805.61 8 436.15 13 087.32 34 484.17 993.99 F值 4.68 21.01 6.15 9.55 25.16 0.73 显著性 0.072* 0.004** 0.045* 0.020* 0.002** 0.529 主次顺序 E>B>D>C>A>F 最优水平 3 1 3 3 3 3 注:R2=0.964(调整后R2=0.878);*表示显著性较为显著;**表示显著性极为显著。 -

[1] 侯文杰.丛式井防碰设计与施工方法研究[D].大庆: 东北石油大学, 2017. HOU Wenjie. Research on the cluster well crash-proof design and construction method[D]. Daqing: Northeast Petroleum University, 2017.

[2] 乔宏实,娄小娟. 丛式井直井段防碰分析与预防[J]. 石化技术, 2016, 23(2): 204. doi: 10.3969/j.issn.1006-0235.2016.02.156 QIAO Hongshi, LOU Xiaojuan. Analysis and prevention of anti-collision to vertical section of cluttering well[J]. Petrochemical Industry Technology, 2016, 23(2): 204. doi: 10.3969/j.issn.1006-0235.2016.02.156

[3] DIAO Binbin, GAO Deli, LI Genkui. Development of static magnetic detection anti-collision system while drilling: proceedings of the 2016 International Conference on Artificial Intelligence and Engineering Applications[C]. Hongkong, November 12-13, 2016.

[4] AKLESTAD D L, WANG Chun, JIANG Lu, et al. Well trajectory planning using bounding box scan for ant-collision analysis: US20160102544[P]. 2014-06-12.

[5] 王新刚. 大位移水平井井眼轨道设计与应用[J]. 现代制造技术与装备, 2018(12): 20–22, 24. doi: 10.3969/j.issn.1673-5587.2018.12.011 WANG Xingang. Trajectory design of ERD-wells and its application[J]. Modern Manufacturing Technology and Equipment, 2018(12): 20–22, 24. doi: 10.3969/j.issn.1673-5587.2018.12.011

[6] BAILEY J R. Continuous bit positioning system: US4003017[P]. 1974-06-03.

[7] RECTOR J W, MARION B P. The use of drill‐bit energy as a downhole seismic source[J]. Geophysics, 1991, 56(5): 628–634. doi: 10.1190/1.1443079

[8] 刘刚,于长广,何保生,等. 机械式井下震源设计及试验研究[J]. 石油机械, 2013, 41(11): 17–20. doi: 10.3969/j.issn.1001-4578.2013.11.005 LIU Gang, YU Changguang, HE Baosheng, et al. Design and experimental study of mechanical downhole seismic source[J]. China Petroleum Machinery, 2013, 41(11): 17–20. doi: 10.3969/j.issn.1001-4578.2013.11.005

[9] 董照显.用于丛式井防碰监测的井下震源设计[D].青岛: 中国石油大学(华东), 2013. DONG Zhaoxian. The downhole seismic source design for anti-collision monitoring in cluster wells[D]. Qingdao: China University of Petroleum (East China), 2013.

[10] 邵冬冬,刘亚,吴波,等. 井底脉冲式不对称流场钻井工具的研制及应用[J]. 石油机械, 2016, 44(10): 30–32, 46. SHAO Dongdong, LIU Ya, WU Bo, et al. Development and application of downhole drilling tool with pulsed asymmetrical flow field[J]. China Petroleum Machinery, 2016, 44(10): 30–32, 46.

[11] 李博.阀式双作用液动冲击器的仿真[D].北京: 中国地质大学(北京), 2013. LI Bo. Simulation of valve-type double-acting hydraulic impactor[D].Beijing: China University of Geosciences(Beijing), 2013.

[12] 叶晓平,李博,刘晓阳,等. 差动式双作用液动冲击器冲锤动力学方程的研究和应用[J]. 地质与勘探, 2018, 54(4): 801–809. YE Xiaoping, LI Bo, LIU Xiaoyang, et al. Research and application of differential double-acting hydraulic hammer dynamics equations[J]. Geology and Exploration, 2018, 54(4): 801–809.

[13] WU Tao, WANG Wei, YAO Aiguo, et al. Research on impact stress and fatigue simulation of a new down-to-the-hole impactor based on ANSYS[J]. Journal of the Institution of Engineers (India): Series C, 2018, 99(3): 355–362. doi: 10.1007/s40032-016-0259-4

[14] 丁雯,彭振华,张园,等. 基于损伤力学的HL级抽油杆疲劳分析研究[J]. 石油钻探技术, 2019, 47(4): 47–53. DING Wen, PENG Zhenhua, ZHANG Yuan, et al. Fatigue analysis of HL rod Based on damage mechanics[J]. Petroleum Drilling Techniques, 2019, 47(4): 47–53.

[15] MAO Yanqin, PU Wenhao, ZHANG Hao, et al. Orthogonal experimental design of an axial flow cyclone separator[J]. Chemical Engineering and Processing: Process Intensification, 2019, 144: 107645. doi: 10.1016/j.cep.2019.107645

[16] HU Chaobin, ZHANG Xiaobing. Influence of multiple structural parameters on interior ballistics based on orthogonal test methods[J]. Defence Technology, 2019, 15(5): 690–697. doi: 10.1016/j.dt.2019.06.014

[17] 陈瑞,倪晋平. 基于正交试验的光电立靶光幕阵列结构参数优化方法[J]. 兵工学报, 2017, 38(11): 2234–2239. doi: 10.3969/j.issn.1000-1093.2017.11.021 CHEN Rui, NI Jinping. Optimization method of light-screen-array structure parameters of photoelectric target based on orthogonal test[J]. Acta Armamentarii, 2017, 38(11): 2234–2239. doi: 10.3969/j.issn.1000-1093.2017.11.021

[18] 陈德春,付刚,韩昊,等. 气井携液用涡流工具结构参数优化[J]. 石油钻采工艺, 2016, 38(3): 400–404. CHEN Dechun, FU Gang, HAN Hao, et al. Optimization of structural parameters for fluid-carrying swirl tool in gas wells[J]. Oil Drilling & Production Technology, 2016, 38(3): 400–404.

-

期刊类型引用(2)

1. 刘承婷,胡传峰,王智刚,董佩鑫,彭占刚,管恩东. 通道压裂支撑剂缝内分布规律研究. 河南科学. 2024(01): 8-15 .  百度学术

百度学术

2. 戴一凡,侯冰,廖志豪. 基于相场法的深层干热岩储层水力压裂模拟研究. 石油钻探技术. 2024(02): 229-235 .  本站查看

本站查看

其他类型引用(2)

下载:

下载: