Ultra-High Temperature and High Pressure Liner Cementing Technology in Well Chuanshen 1

-

摘要:

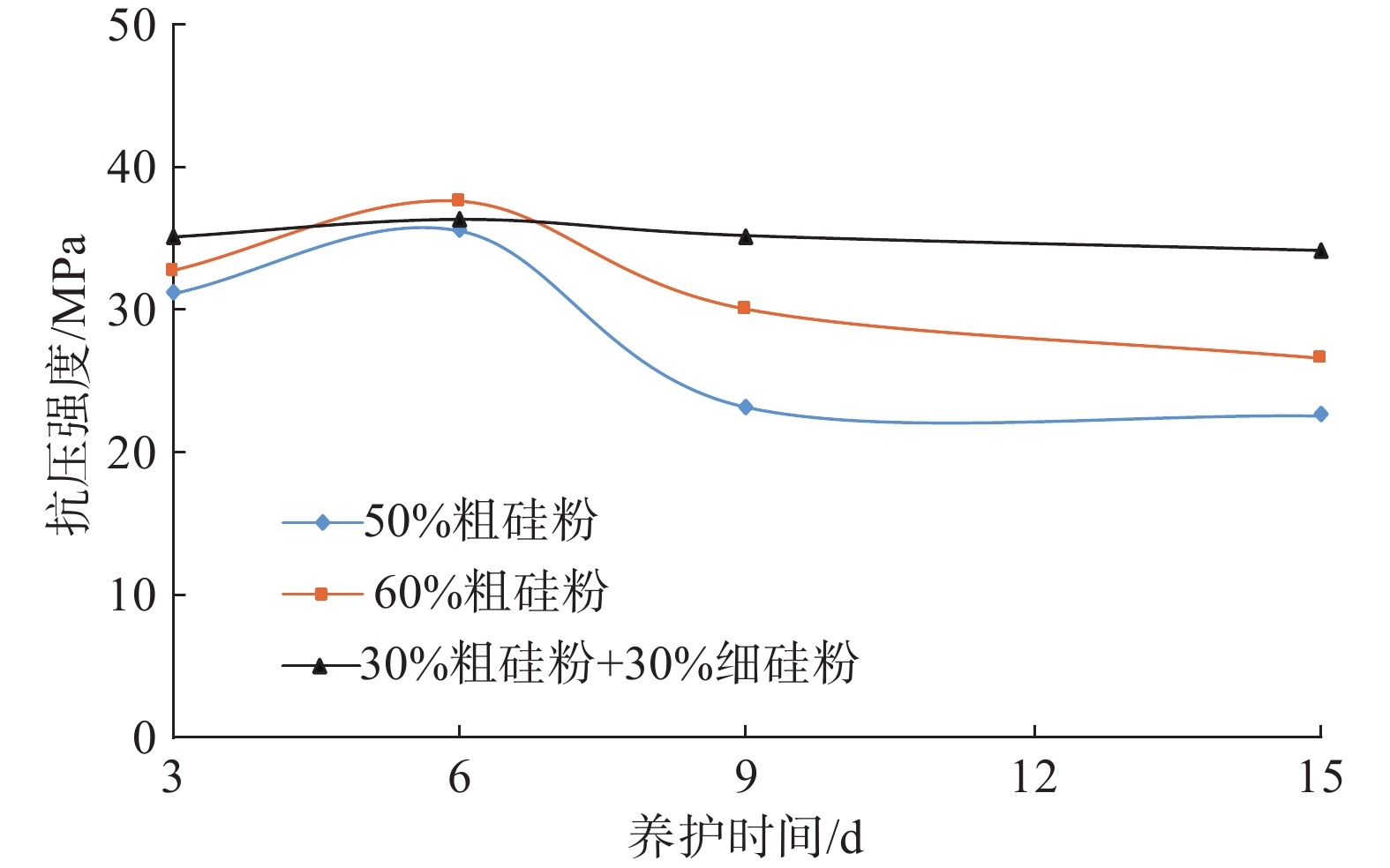

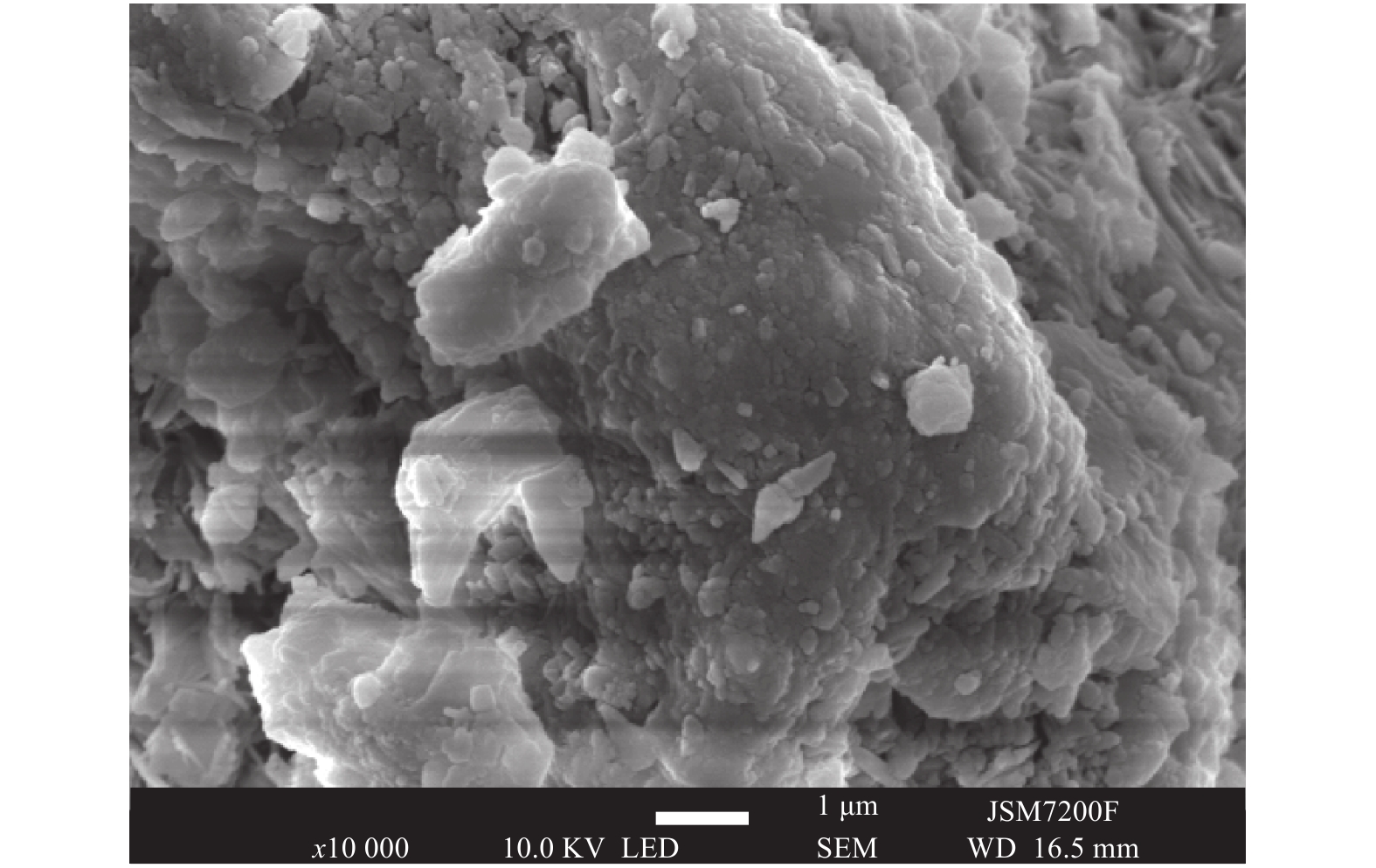

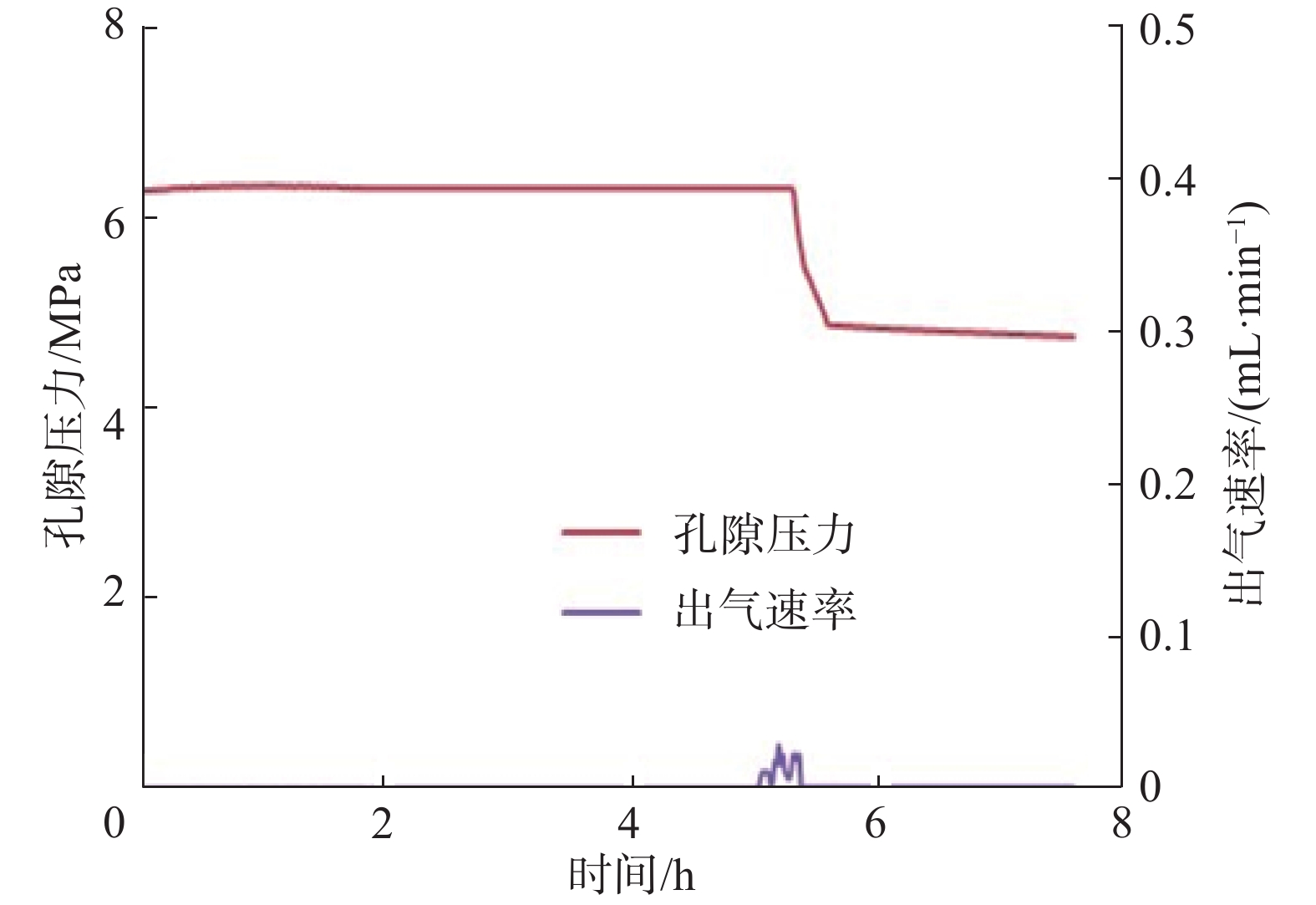

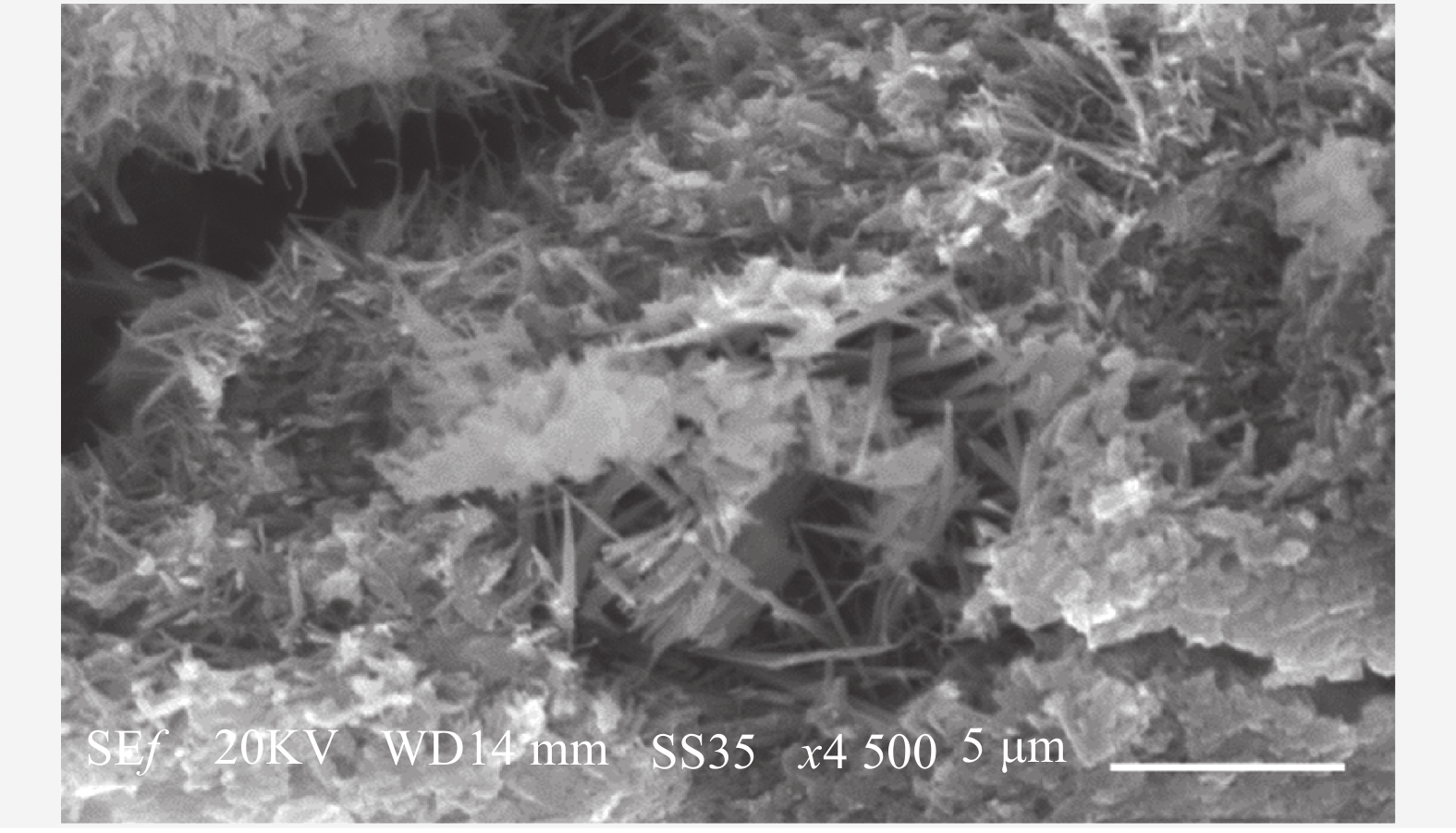

针对川深1井四开井段超高温高压地层尾管固井长效密封的需求,通过增大硅粉加量和合理匹配硅粉粒径抑制水泥石强度衰退,优选高温苯丙胶乳、纳米液硅等改善水泥浆的防气窜能力、力学性能、稳定性等,设计了适用于超高温高压地层的高密度防气窜水泥浆。其性能为:密度2.05 kg/L,防气窜系数SPN值小于0.43,气窜模拟未见气窜现象发生;水泥石在180 ℃下养护14 d抗压强度达到了41 MPa,未见强度衰退现象;水泥石气测渗透率0.008 1 mD,单轴弹性模量为7.54 GPa。川深1井四开井段采用高密度防气窜水泥浆,并采取“替净”、“压稳”和“封严”等固井技术措施,有效封隔了高压气层,为后期作业提供了良好的井筒环境。这表明,超高温高压地层通过优选合适的水泥浆,并采取相应的技术措施,可以解决超高温高压地层的固井技术难点,提高固井质量。

Abstract:The Well Chuanshen-1 encountered an ultra-high temperature and high pressure (ultra-HTHP) formation in the fourth drilling section. In order to ensure the long-term sealing of setting cement in this section, it is preferable to restrain the strength deterioration of setting cement by increasing the silicon powder dosage and by reasonably matching the particle sizes of silicon powder. In addition, the high-temperature styrene-acrylic latex and the nano-liquid silicon have been selected to improve the anti-gas channeling ability, mechanical properties and stability of cement slurry. For this purpose, a high-density anti-gas channeling cement slurry suitable for ultra-HTHP formation was designed, with a density of 2.05 kg/L and an anti-gas channeling coefficient SPN lower than 0.43. In this case, no gas channeling was observed in gas channeling simulation; the compressive strength of set cement reached 41 MPa at 180 °C for 14 d, and no strength deterioration of cement stone was found; the gas measurement permeability of the set cement was 0.008 1 mD, and the uniaxial elastic modulus of set cement was 7.54 GPa. The high-density anti-gas channeling cement slurry was applied in the fourth drilling section of Well Chuanshen-1, and the cementing measures such as "thoroughly displacement", "stable well killing" and "sealing securely" were adopted, which effectively isolated the high-pressure gas layers and provided a good wellbore environment for the successive operations. This process proved that the ultra-high temperature and high pressure formation could be smoothly cemented by using the suitable cement slurry and taking proper technical measures, and an in following those procedures, it could be possible in the future to assure high cementing quality.

-

-

表 1 AMPS降滤失剂高温老化后的特性黏数损失率

Table 1 Intrinsic viscosity loss rate of AMPS fluid loss additive after high temperature aging

降滤失剂 特性黏数 特性黏数损失率,% 老化前 老化后 BS100 6.276 2.824 73.58 HS-J 5.381 2.978 62.70 SUP102L 2.124 1.776 25.79 -

[1] 牛新明,张克坚,丁士东,等. 川东北地区高压防气窜固井技术[J]. 石油钻探技术, 2008, 36(3): 10–15. doi: 10.3969/j.issn.1001-0890.2008.03.003 NIU Xinming, ZHANG Kejian, DING Shidong, et al. Gas migration prevention cementing technologies in northeast Sichuan Area[J]. Petroleum Drilling Techniques, 2008, 36(3): 10–15. doi: 10.3969/j.issn.1001-0890.2008.03.003

[2] 刘威,熊良宵,潘海峰. 高温循环作用下水泥砂浆的力学性能研究[J]. 硅酸盐通报, 2016, 35(7): 2314–2317. LIU Wei, XIONG Liangxiao, PAN Haifeng. Mechanical properties of cement mortar under high temperature cycles[J]. Bulletin of the Chinese Ceramic Society, 2016, 35(7): 2314–2317.

[3] 周仕明,李根生,方春飞. 元坝地区ϕ146.1 mm尾管固井技术难点与对策[J]. 石油钻探技术, 2010, 38(4): 41–44. ZHOU Shiming, LI Gensheng, FANG Chunfei. Difficulties and countermeasures for ϕ146.1 mm liner cementing in Yuanba Area[J]. Petroleum Drilling Techniques, 2010, 38(4): 41–44.

[4] 路飞飞,李斐,田娜娟,等. 复合加砂抗高温防衰退水泥浆体系[J]. 钻井液与完井液, 2017, 34(4): 85–89. doi: 10.3969/j.issn.1001-5620.2017.04.016 LU Feifei, LI Fei, TIAN Najuan, et al. High temperature anti strength retrogression cement slurry with compounded silica powder[J]. Drilling Fluid & Completion Fluid, 2017, 34(4): 85–89. doi: 10.3969/j.issn.1001-5620.2017.04.016

[5] 严思明,严圣东,吴亚楠,等. 功能材料对固井水泥石力学性能的影响[J]. 石油钻采工艺, 2018, 40(2): 174–178. YAN Siming, YAN Shengdong, WU Yanan, et al. Effect of functional materials on mechanical properties of hardened cement paste[J]. Oil Drilling & Production Technology, 2018, 40(2): 174–178.

[6] 高元,桑来玉,杨广国,等. 胶乳纳米液硅高温防气窜水泥浆体系[J]. 钻井液与完井液, 2016, 33(3): 67–72. doi: 10.3969/j.issn.1001-5620.2016.03.014 GAO Yuan, SANG Laiyu, YANG Guangguo, et al. Cement slurry treated with latex Nano liquid silica anti-gas-migration agent[J]. Drilling Fluid & Completion Fluid, 2016, 33(3): 67–72. doi: 10.3969/j.issn.1001-5620.2016.03.014

[7] 程小伟,刘开强,李早元,等. 油井水泥浆液–固态演变的结构与性能[J]. 石油学报, 2016, 37(10): 1287–1292. doi: 10.7623/syxb201610009 CHENG Xiaowei, LIU Kaiqiang, LI Zaoyuan, et al. Structure and properties of oil well cement slurry during liquid-solid transition[J]. Acta Petrolei Sinica, 2016, 37(10): 1287–1292. doi: 10.7623/syxb201610009

[8] 陆沛青,桑来玉,谢少艾,等. 苯丙胶乳水泥浆防气窜效果与失重规律分析[J]. 石油钻探技术, 2019, 47(1): 52–58. LU Peiqing, SANG Laiyu, XIE Shaoai, et al. Analysis of the anti-gas channeling effect and weight loss law of styrene-acrylic latex cement slurry[J]. Petroleum Drilling Techniques, 2019, 47(1): 52–58.

[9] 符军放,张浩,项先忠,等. 硅溶胶在固井水泥浆中的应用性能研究[J]. 西安石油大学学报(自然科学版), 2013, 28(3): 78–82. doi: 10.3969/j.issn.1673-064X.2013.03.017 FU Junfang, ZHANG Hao, XIANG Xianzhong, et al. Study on the performance of colloidal silica for cementing slurry[J]. Journal of Xi’an Shiyou University (Natural Science Edition), 2013, 28(3): 78–82. doi: 10.3969/j.issn.1673-064X.2013.03.017

[10] 李早元,郭小阳,罗发强,等. 油井水泥环降脆增韧作用机理研究[J]. 石油学报, 2008, 29(3): 438–441. doi: 10.3321/j.issn:0253-2697.2008.03.025 LI Zaoyuan, GUO Xiaoyang, LUO Faqiang, et al. Research on mechanism of increasing flexibility and decreasing brittleness of cement sheath in oil well[J]. Acta Petrolei Sinica, 2008, 29(3): 438–441. doi: 10.3321/j.issn:0253-2697.2008.03.025

[11] 郭进忠,罗霄,华苏东,等. 抗冲击防窜水泥浆体系性能研究[J]. 钻井液与完井液, 2010, 27(4): 59–61. doi: 10.3969/j.issn.1001-5620.2010.04.020 GUO Jinzhong, LUO Xiao, HUA Sudong, et al. Study on tough and anti-channeling cement slurry[J]. Drilling Fluid & Completion Fluid, 2010, 27(4): 59–61. doi: 10.3969/j.issn.1001-5620.2010.04.020

-

期刊类型引用(7)

1. 张衍君,曾会,陶秀娟,张洋,周德胜. 致密储层体积压裂裂缝漏失及控制综述. 科学技术与工程. 2022(26): 11277-11286 .  百度学术

百度学术

2. 杨倩云,王宝田,杨华,刘学明. 形状记忆聚合物型温控膨胀堵漏剂的制备及应用. 钻井液与完井液. 2021(02): 189-195 .  百度学术

百度学术

3. 吴彦飞,张定军,杨斌,董莉,赵文锦,陈振斌. P(AA-AM)@SA@淀粉复合暂堵剂颗粒的制备及性能研究. 应用化工. 2019(03): 521-524 .  百度学术

百度学术

4. 田军,刘文堂,李旭东,刘云飞,郭建华. 快速滤失固结堵漏材料ZYSD的研制及应用. 石油钻探技术. 2018(01): 49-54 .  本站查看

本站查看

5. 刘金华,刘四海,龙大清,陈曾伟,靳瑞环. 明1井交联成膜与化学固结承压堵漏技术. 石油钻探技术. 2017(02): 54-60 .  本站查看

本站查看

6. 韩子轩,林永学,柴龙,李大奇. 裂缝性气藏封缝堵气技术研究. 钻井液与完井液. 2017(01): 16-22 .  百度学术

百度学术

7. 邱正松,刘均一,周宝义,暴丹,窦同伟,肖成才. 钻井液致密承压封堵裂缝机理与优化设计. 石油学报. 2016(S2): 137-143 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: