Rotary Steerable Drilling Technology for Test Wells in Niuye Block I in Shengli Shale Oil Field

-

摘要:

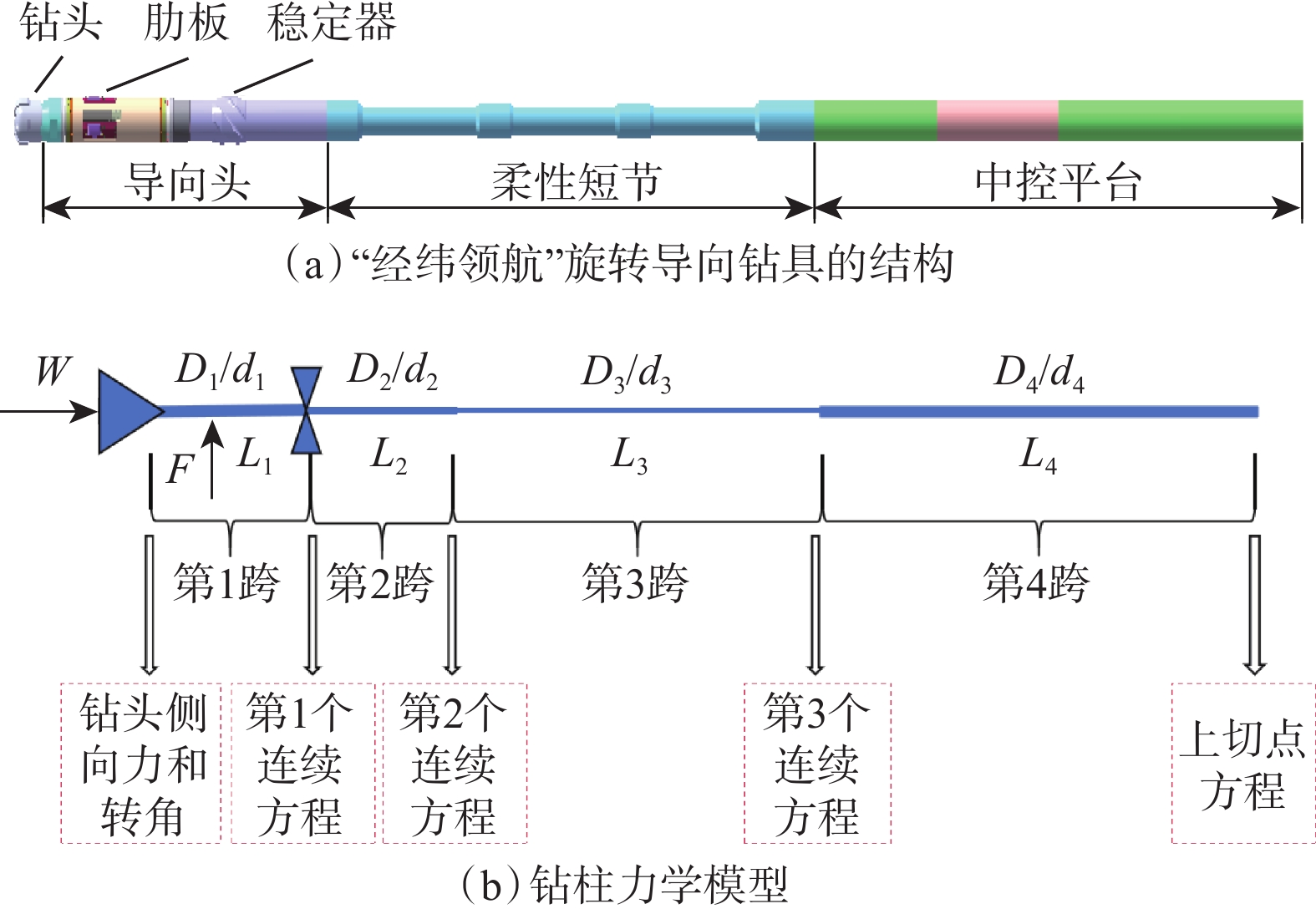

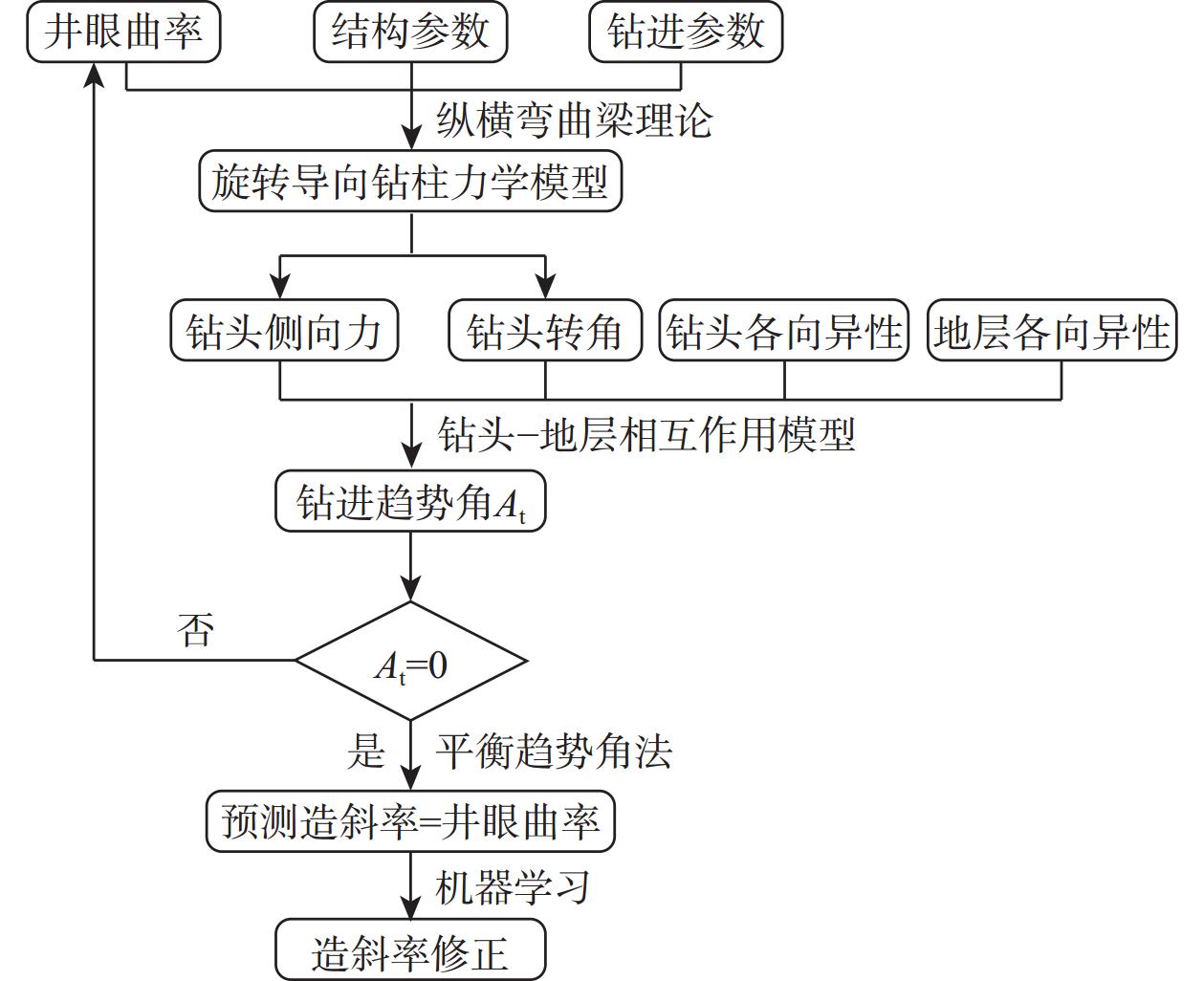

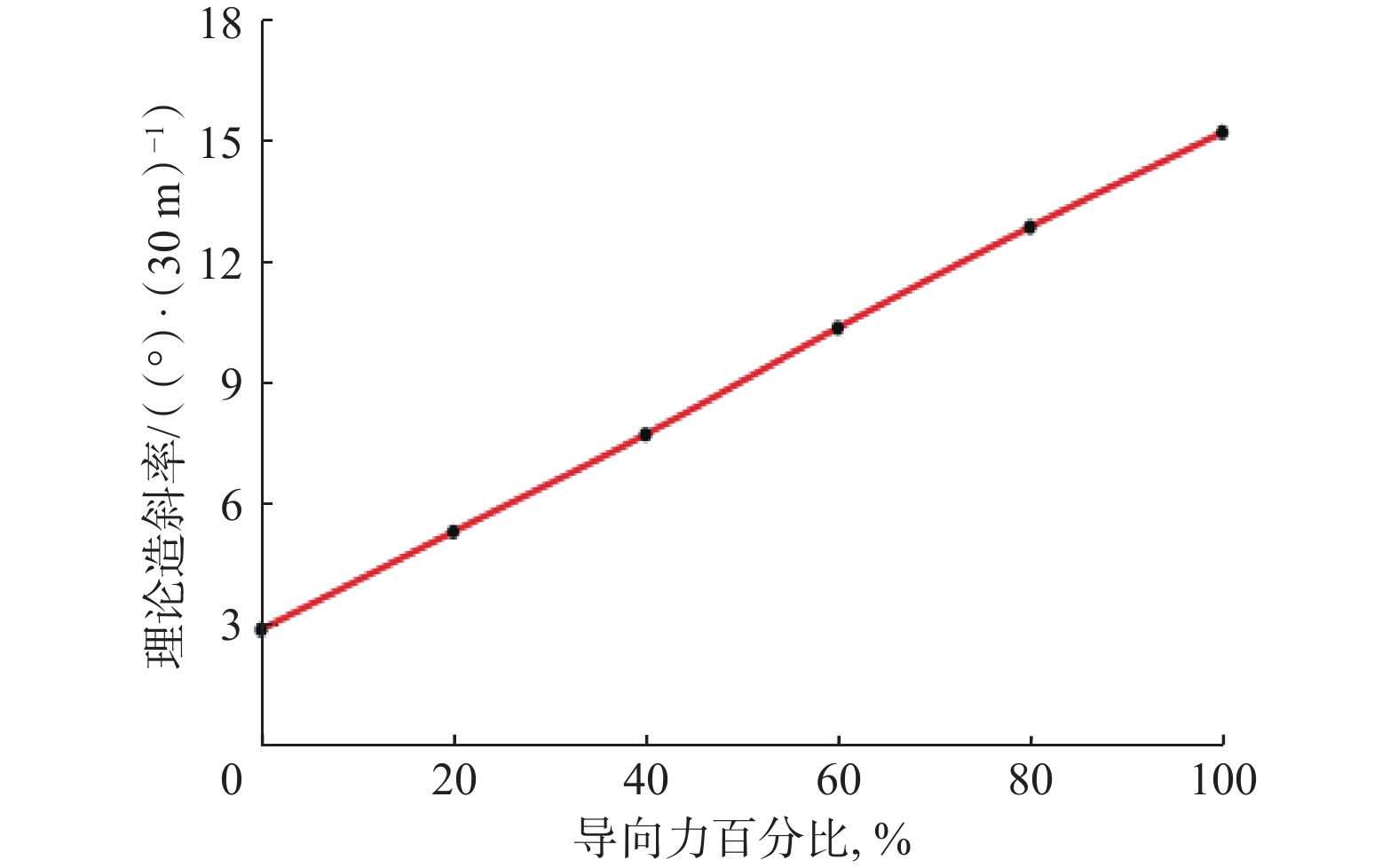

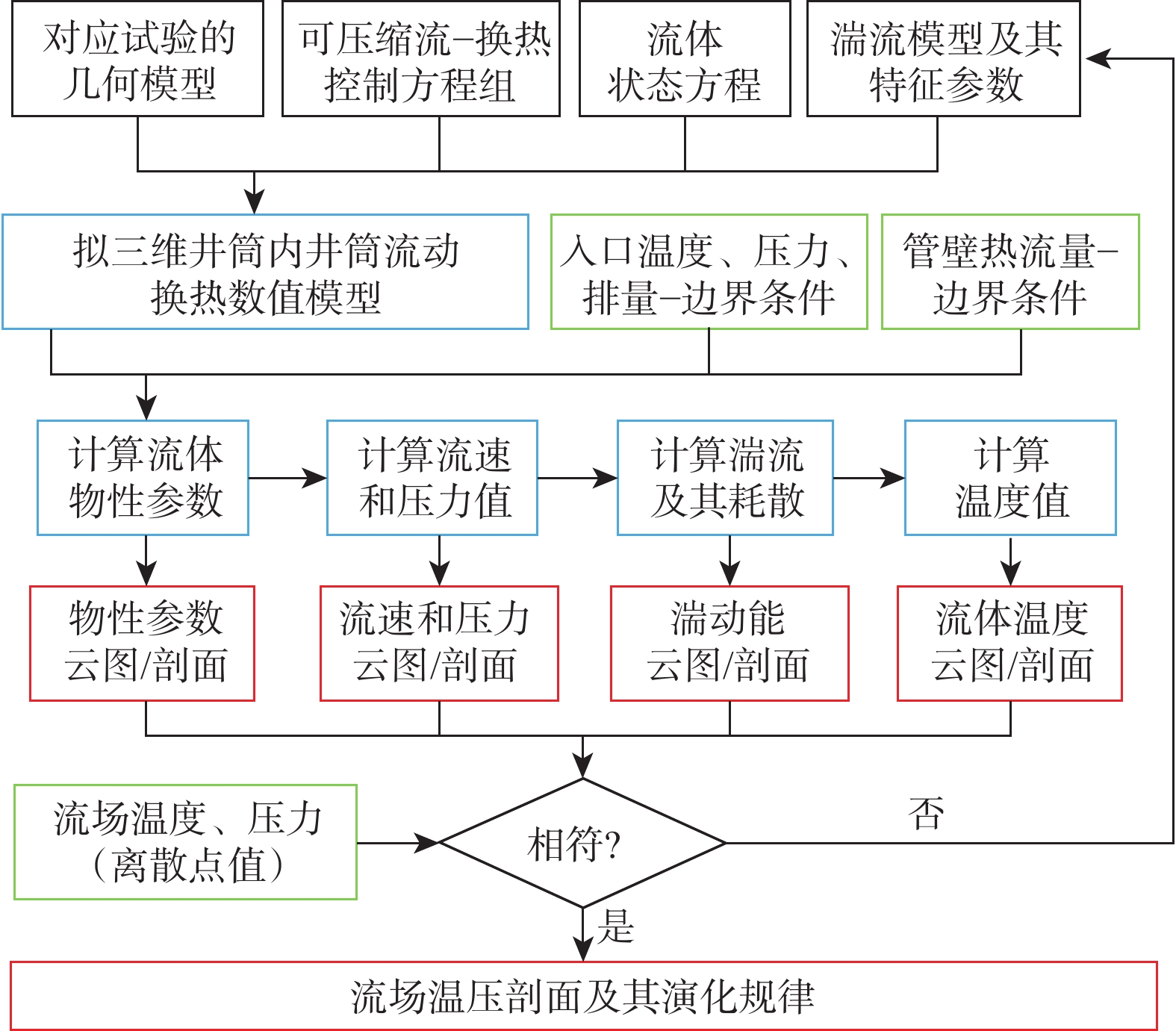

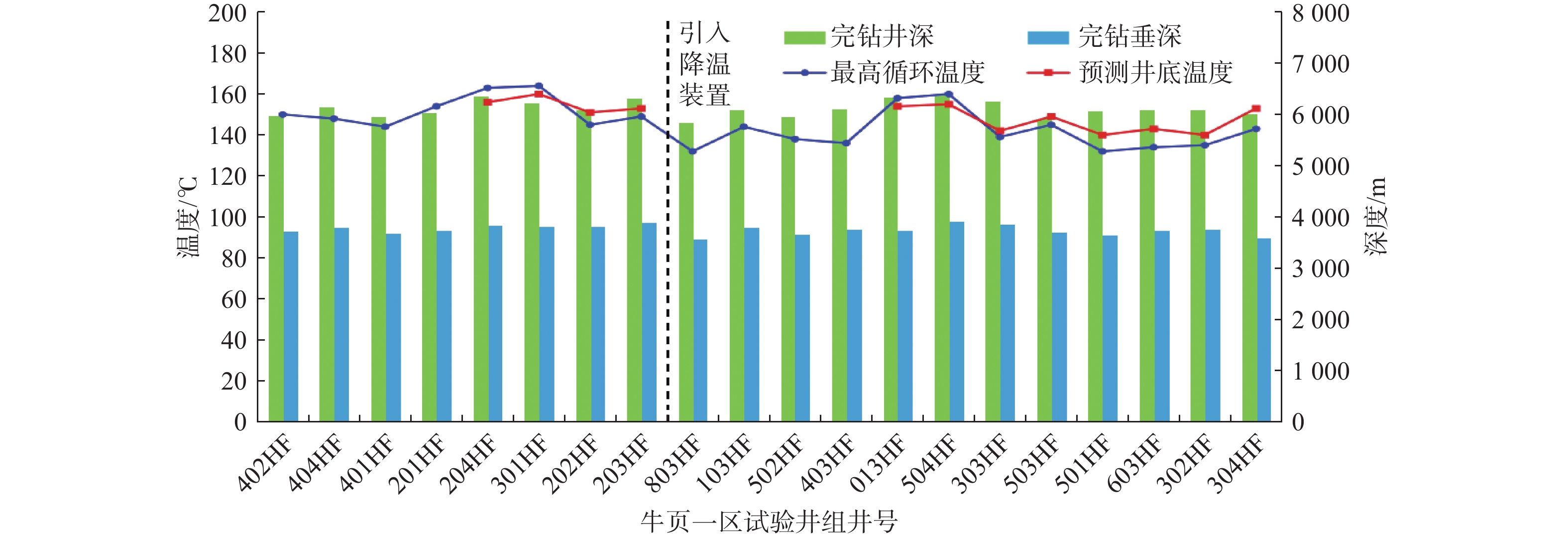

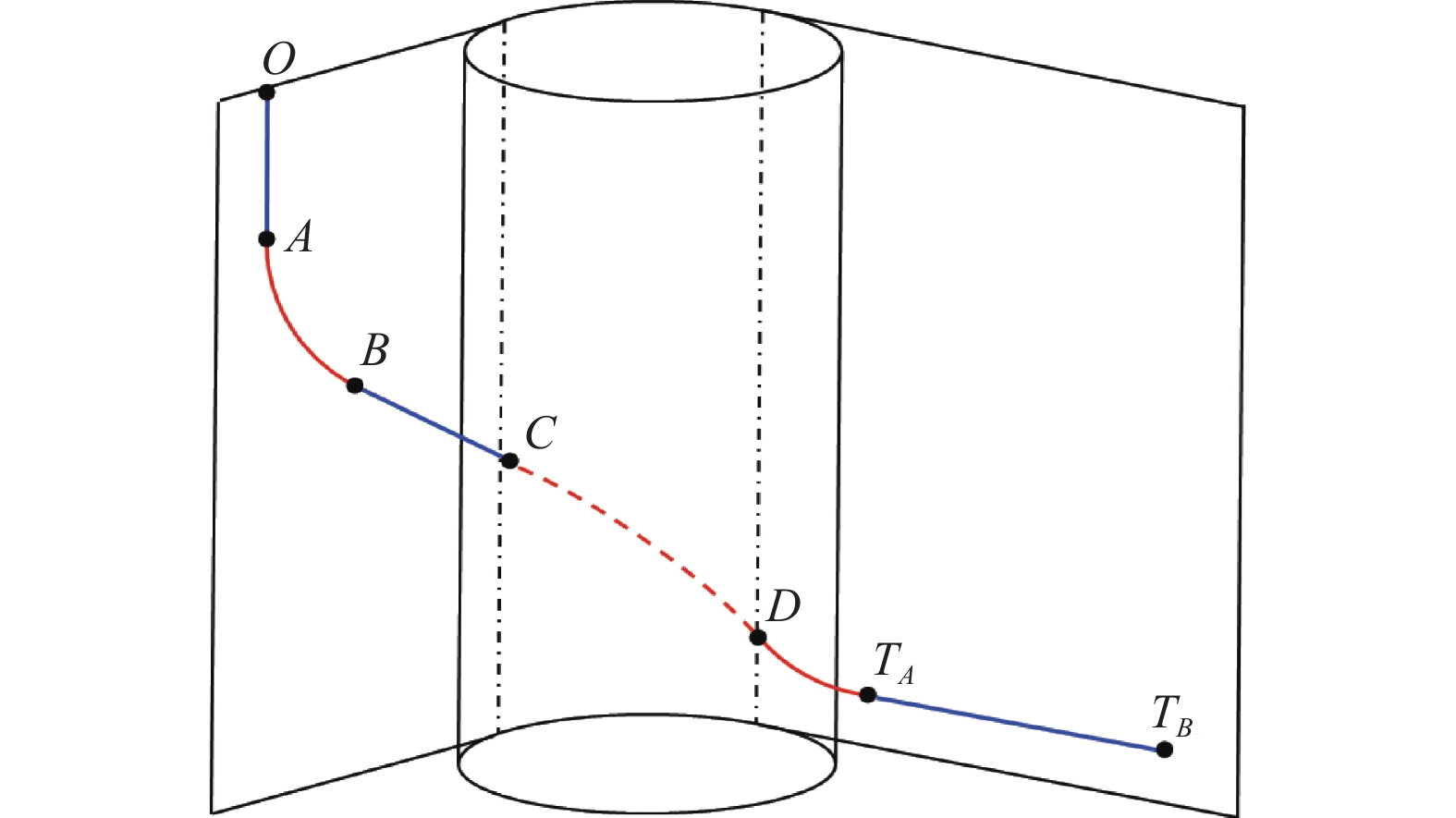

胜利页岩油牛页一区地质工程条件复杂,为了提升该区块试验井组定向钻井施工质量,开展了旋转导向钻井技术研究。通过开展旋转导向及配套工具优选、三维井眼轨道优化及井眼轨迹控制、造斜率预测及修正、井温风险预测模型等技术研究与应用探索,建立了钻具组合优选模板、井眼轨迹控制策略、导向力标准指令集、高温作业管控程序等方法,形成了页岩油旋转导向钻井标准作业模式,并在牛页一区20口井进行了现场应用。应用效果表明,该作业模式有效提升了机械钻速,增大了单趟钻进尺与单井旋转导向进尺,实现了牛页一区2 000 m长水平段一趟钻完成。研究结果为胜利济阳坳陷页岩油高效开发提供了新的技术途径。

Abstract:The geological and engineering conditions of Niuye Block I in the Shengli Shale Oil Field are complex. To enhance the quality of directional drilling in test wells within this block, a study on rotary steerable drilling technology was conducted. Through research and practical exploration of technologies such as rotary steerable systems, tool optimization, 3D trajectory optimization, trajectory control, built-up rate prediction and correction, and well temperature risk prediction models, several methods were developed. These included an optimization template for bottom hole assembly, trajectory control strategies, standard instruction sets for steering forces, and procedures for high-temperature operations. As a result, a standard operational mode for rotary steerable drilling in shale oil was established and applied in 20 wells in Niuye Block I. The application results demonstrate that this operational mode effectively improves the rate of penetration (ROP), increases the footage per single run and well using the rotary steerable system, and enables the construction of a 2,000-meter-long horizontal section in a single run. These findings provide a new technical approach for the efficient development of shale oil in Jiyang Depression of Shengli Shale Oil Field.

-

-

表 1 经纬领航系统与Geo-Pilot

7600系统 应用效果对比Table 1 Comparison of application effects between MatriNavi and Geo-Pilot 7600

导向系统 入井趟数 进尺/m 单趟钻进尺/m 循环时间/h 纯钻时间/h 机械钻速/(m∙h−1) 最高循环温度/℃ 经纬领航 15 17 442 1 162.80 2 088.14 1 167.4 14.94 144 Geo-Pilot 7600 15 12 376 825.06 1 884.50 898.3 13.77 138 表 2 “经纬领航”系统与TK56和SDi516钻头配套的应用效果

Table 2 Comparison of application effects between TK56 and SDi516 using MatriNavi

钻头型号 造斜率/

((°)∙(30m)−1)机械钻速/(m∙h−1) 单趟钻进尺/m TK56 4.25 15.33 1 179 SDi516 3.48 13.44 899 表 3 不同层位与机械钻速下的导向力标准指令集

Table 3 Standard instruction set for steering force at different layers and ROPs

层位 目标造斜率/

((°)∙(30m)−1)不同钻速的导向力百分比,% 10~15 m/h 15~20 m/h >20 m/h 沙三下 4.0~4.5 21~25 32~38 4.5~5.0 32~38 38~45 5.0~6.0 40~44 45~51 >6.0 44~48 51~57 沙四纯上 4.0~4.5 30~34 32~38 38~45 4.5~5.0 32~38 38~42 45~48 5.0~6.0 41~48 51~54 54~61 >6.0 48~52 54~58 >63 表 4 不同阶段的现场应用效果对比

Table 4 Comparison of field application effects in different stages

阶段 应用

井数机械钻速/

(m∙h−1)单趟钻进尺/

m单井进尺/

m摸索阶段 12 13.79 862.11 1 220.50 试验阶段 4 14.63 976.40 1 293.17 推广阶段 4 15.52 1 345.43 2 354.50 -

[1] 马永生,冯建辉,牟泽辉,等. 中国石化非常规油气资源潜力及勘探进展[J]. 中国工程科学,2012,14(6):22–30. doi: 10.3969/j.issn.1009-1742.2012.06.004 MA Yongsheng, FENG Jianhui, MU Zehui, et al. The potential and exploring progress of unconventional hydrocarbon resources in Sinopec[J]. Strategic Study of CAE, 2012, 14(6): 22–30. doi: 10.3969/j.issn.1009-1742.2012.06.004

[2] 孙焕泉,蔡勋育,周德华,等. 中国石化页岩油勘探实践与展望[J]. 中国石油勘探,2019,24(5):569–575. doi: 10.3969/j.issn.1672-7703.2019.05.004 SUN Huanquan, CAI Xunyu, ZHOU Dehua, et al. Practice and prospect of Sinopec shale oil exploration[J]. China Petroleum Exploration, 2019, 24(5): 569–575. doi: 10.3969/j.issn.1672-7703.2019.05.004

[3] 李阳,曹小朋,赵清民,等. 济阳坳陷陆相断陷盆地页岩油开发的几点思考[J]. 石油钻探技术,2024,52(4):1–7. doi: 10.11911/syztjs.2024074 LI Yang, CAO Xiaopeng, ZHAO Qingmin, et al. Thoughts on shale oil development in continental fault basin in Jiyang Depression[J]. Petroleum Drilling Techniques, 2024, 52(4): 1–7. doi: 10.11911/syztjs.2024074

[4] 孙焕泉,周德华,赵培荣,等. 中国石化地质工程一体化发展方向[J]. 油气藏评价与开发,2021,11(3):269–280. SUN Huanquan, ZHOU Dehua, ZHAO Peirong, et al. Geology-engineering integration development direction of Sinopec[J]. Petroleum Reservoir Evaluation and Development, 2021, 11(3): 269–280.

[5] 张锦宏. 中国石化页岩油工程技术新进展[J]. 油气藏评价与开发,2023,13(1):1–8. ZHANG Jinhong. Progress in Sinopec shale oil engineering technology[J]. Petroleum Reservoir Evaluation and Development, 2023, 13(1): 1–8.

[6] 赵波,陈二丁. 胜利油田页岩油水平井樊页平1井钻井技术[J]. 石油钻探技术,2021,49(4):53–58. doi: 10.11911/syztjs.2021078 ZHAO Bo, CHEN Erding. Drilling technologies for horizontal shale oil Well Fan Yeping 1 in the Shengli Oilfield[J]. Petroleum Drilling Techniques, 2021, 49(4): 53–58. doi: 10.11911/syztjs.2021078

[7] 宋明水. 济阳坳陷页岩油勘探实践与现状[J]. 油气地质与采收率,2019,26(1):1–12. SONG Mingshui. Practice and current status of shale oil exploration in Jiyang Depression[J]. Petroleum Geology and Recovery Efficiency, 2019, 26(1): 1–12.

[8] 田启忠,戴荣东,王继强,等. 胜利油田页岩油丛式井提速提效钻井技术[J]. 石油钻采工艺,2023,45(4):404–409. TIAN Qizhong, DAI Rongdong, WANG Jiqiang, et al. An efficient and fast shale oil cluster well drilling technology for Shengli Oilfield[J]. Oil Drilling & Production Technology, 2023, 45(4): 404–409.

[9] 佘朝毅. 四川盆地深层页岩气钻井关键技术新进展及发展展望[J]. 天然气工业,2024,44(3):1–9. doi: 10.3787/j.issn.1000-0976.2024.03.001 SHE Chaoyi. New progress and development prospect of key technologies for drilling of deep shale gas wells in the Sichuan Basin[J]. Natural Gas Industry, 2024, 44(3): 1–9. doi: 10.3787/j.issn.1000-0976.2024.03.001

[10] 赵文庄,韦海防,杨赟. CG STEER旋转导向在长庆页岩油H100平台的应用[J]. 钻采工艺,2021,44(5):1–6. doi: 10.3969/J.ISSN.1006-768X.2021.05.01 ZHAO Wenzhuang, WEI Haifang, YANG Yun. Application of CG STEER rotary steerable tool in Changqing shale oil H100 platform[J]. Drilling & Production Technology, 2021, 44(5): 1–6. doi: 10.3969/J.ISSN.1006-768X.2021.05.01

[11] 袁建强. 济阳坳陷页岩油多层立体开发关键工程技术[J]. 石油钻探技术,2023,51(1):1–8. doi: 10.11911/syztjs.2023001 YUAN Jianqiang. Key engineering technologies for three-dimensional development of multiple formations of shale oil in Jiyang Depression[J]. Petroleum Drilling Techniques, 2023, 51(1): 1–8. doi: 10.11911/syztjs.2023001

[12] 韩来聚,杨春旭. 济阳坳陷页岩油水平井钻井完井关键技术[J]. 石油钻探技术,2021,49(4):22–28. doi: 10.11911/syztjs.2021073 HAN Laiju, YANG Chunxu. Key technologies for drilling and completion of horizontal shale oil wells in the Jiyang Depression[J]. Petroleum Drilling Techniques, 2021, 49(4): 22–28. doi: 10.11911/syztjs.2021073

[13] 张辉,付豪,秦永和,等. PDC钻头对推靠式旋转导向工具的适配性[J]. 中国石油大学学报(自然科学版),2023,47(2):73–80. doi: 10.3969/j.issn.1673-5005.2023.02.008 ZHANG Hui, FU Hao, QIN Yonghe, et al. Adaptability of PDC drill bit with push-the-bit rotary steerable tools for inclined drilling[J]. Journal of China University of Petroleum (Edition of Natural Science), 2023, 47(2): 73–80. doi: 10.3969/j.issn.1673-5005.2023.02.008

[14] 赵廷峰,叶雨晨,席传明,等. 七段式三维水平井井眼轨道设计方法[J]. 石油钻采工艺,2023,45(1):25–30. ZHAO Tingfeng, YE Yuchen, XI Chuanming, et al. Design of seven-section 3D horizontal well trajectory[J]. Oil Drilling & Production Technology, 2023, 45(1): 25–30.

[15] 李志鹏,杨勇,杜玉山,等. 渤南洼陷 “济阳” 夹层型页岩油评价及水平井一体化设计[J]. 中国石油大学学报(自然科学版),2023,47(2):24–35. doi: 10.3969/j.issn.1673-5005.2023.02.003 LI Zhipeng, YANG Yong, DU Yushan, et al. Integrated design of horizontal wells and evaluation in Jiyang interlayer shale oil of Bonan Sag[J]. Petroleum Drilling Techniques, 2023, 47(2): 24–35. doi: 10.3969/j.issn.1673-5005.2023.02.003

[16] 史玉才,滕志想,白璟,等. 改进的静态推靠式旋转导向钻具组合力学模型[J]. 中国石油大学学报(自然科学版),2018,42(5):75–80. doi: 10.3969/j.issn.1673-5005.2018.05.008 SHI Yucai, TENG Zhixiang, BAI Jing, et al. Improved mechanical model of the static push-the-bit rotary steerable bottom-hole assembly[J]. Journal of China University of Petroleum (Edition of Natural Science), 2018, 42(5): 75–80. doi: 10.3969/j.issn.1673-5005.2018.05.008

[17] 王恒,孙明光,张进双,等. 静态推靠式旋转导向工具造斜率预测分析[J]. 石油机械,2021,49(2):15–21. WANG Heng, SUN Mingguang, ZHANG Jinshuang, et al. Buildup rate prediction of a static push-the-bit rotary steerable tool[J]. China Petroleum Machinery, 2021, 49(2): 15–21.

[18] 高德利,徐秉业,刘希圣. 钻头与地层相互作用模型及其应用[J]. 石油钻探技术,1992,20(1):13–17. GAO Deli, XU Bingye, LIU Xisheng. Drill bit and formation interaction model and its application[J]. Petroleum Drilling Techniques, 1992, 20(1): 13–17.

[19] 许红恩. 长水平段水平井稳斜钻具组合造斜特性预测研究[D]. 青岛:中国石油大学(华东),2013. XU Hongen. Study on the build-up character prediction of holding assembly in long horizontal section horizontal well[D]. Qingdao: China University of Petroleum(East China), 2013.

[20] 宋维强,倪红坚,王瑞和,等. 超临界二氧化碳控压钻井控压方法[J]. 石油勘探与开发,2016,43(5):787–792. SONG Weiqiang, NI Hongjian, WANG Ruihe, et al. Pressure controlling method for managed pressure drilling with supercritical carbon dioxide as the circulation fluid[J]. Petroleum Exploration and Development, 2016, 43(5): 787–792.

下载:

下载: