Temperature and Pressure Coupling Field Distribution Law in Deepwater Drilling Wellbore under Gas Kick

-

摘要:

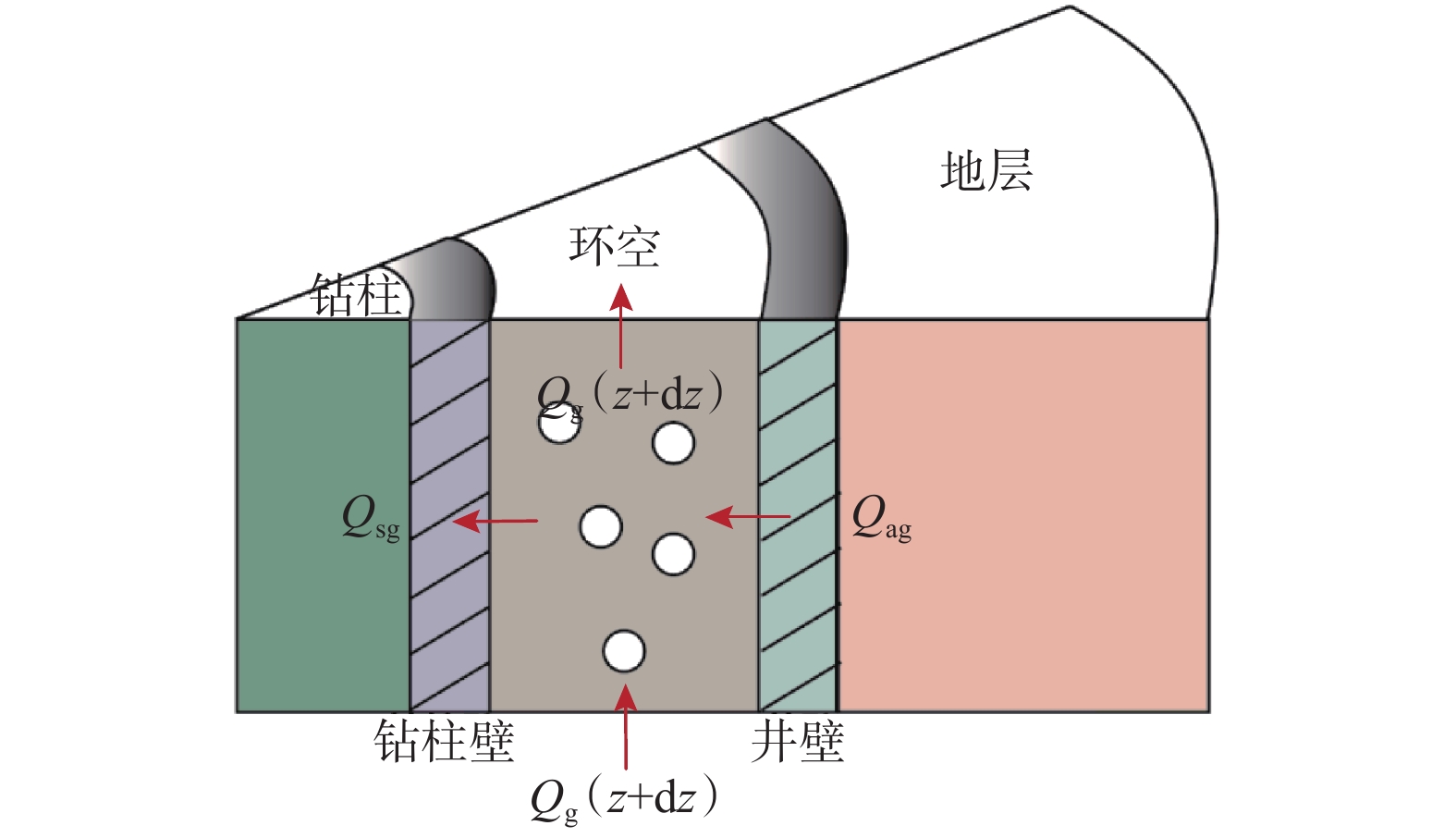

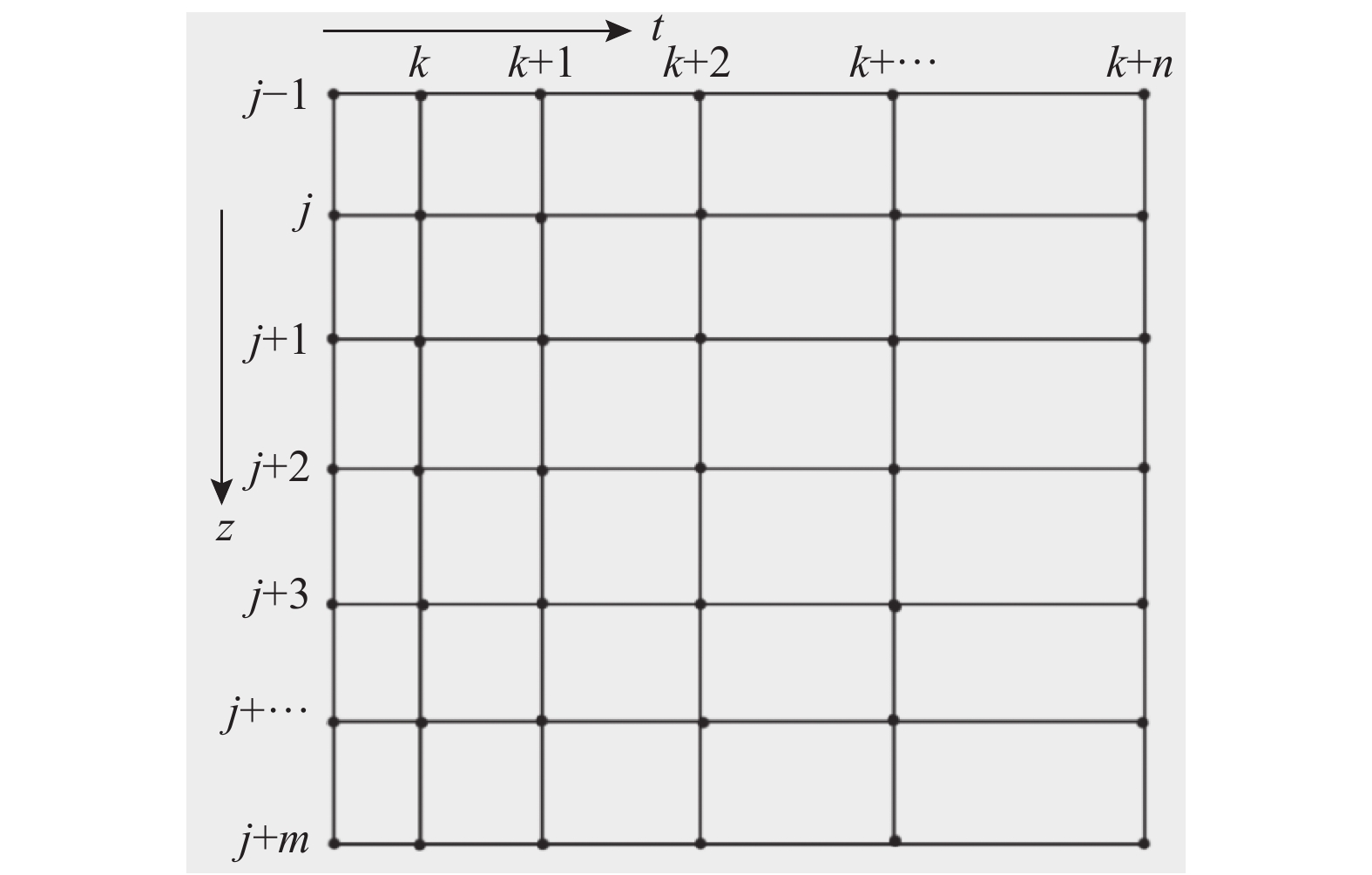

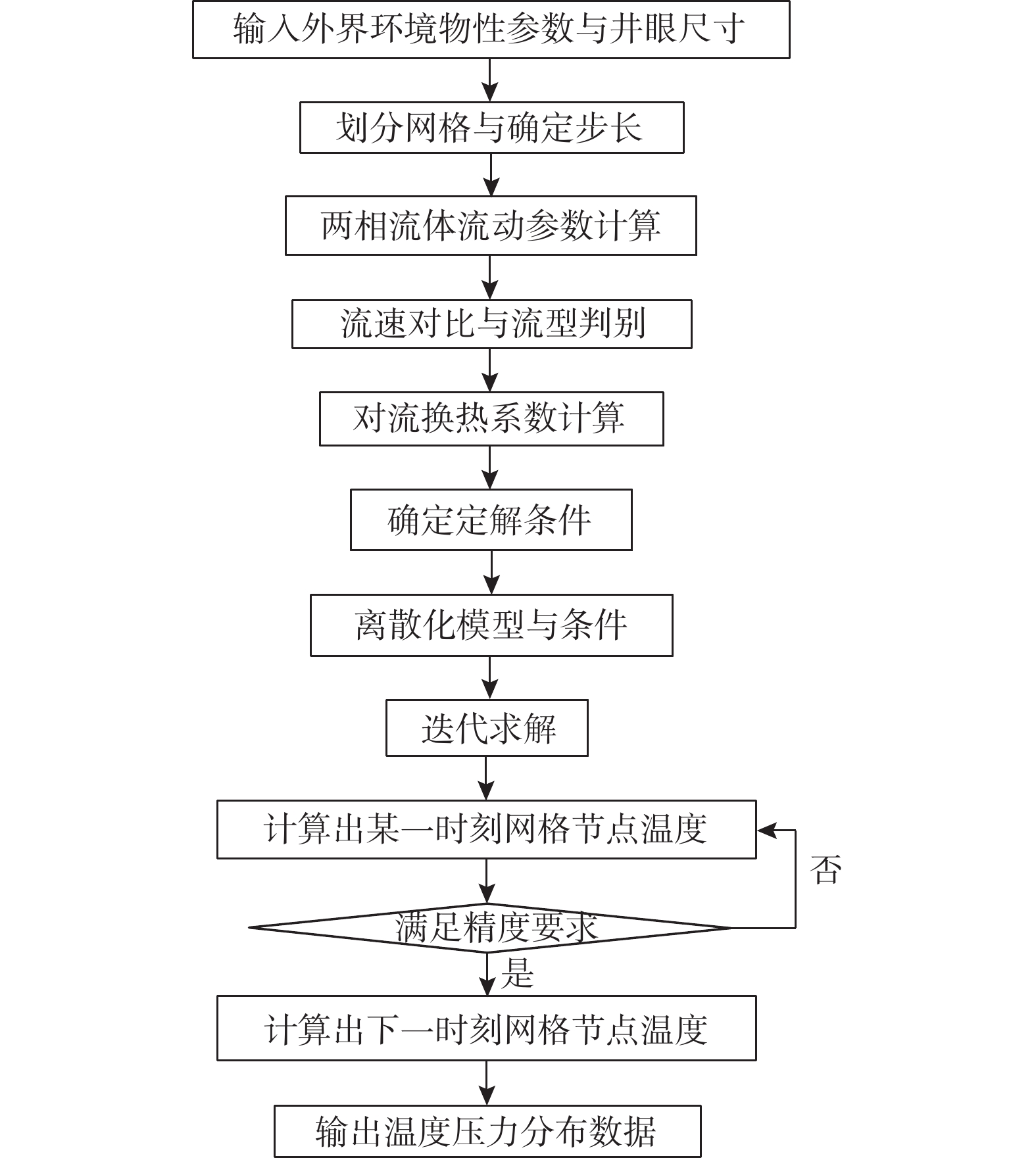

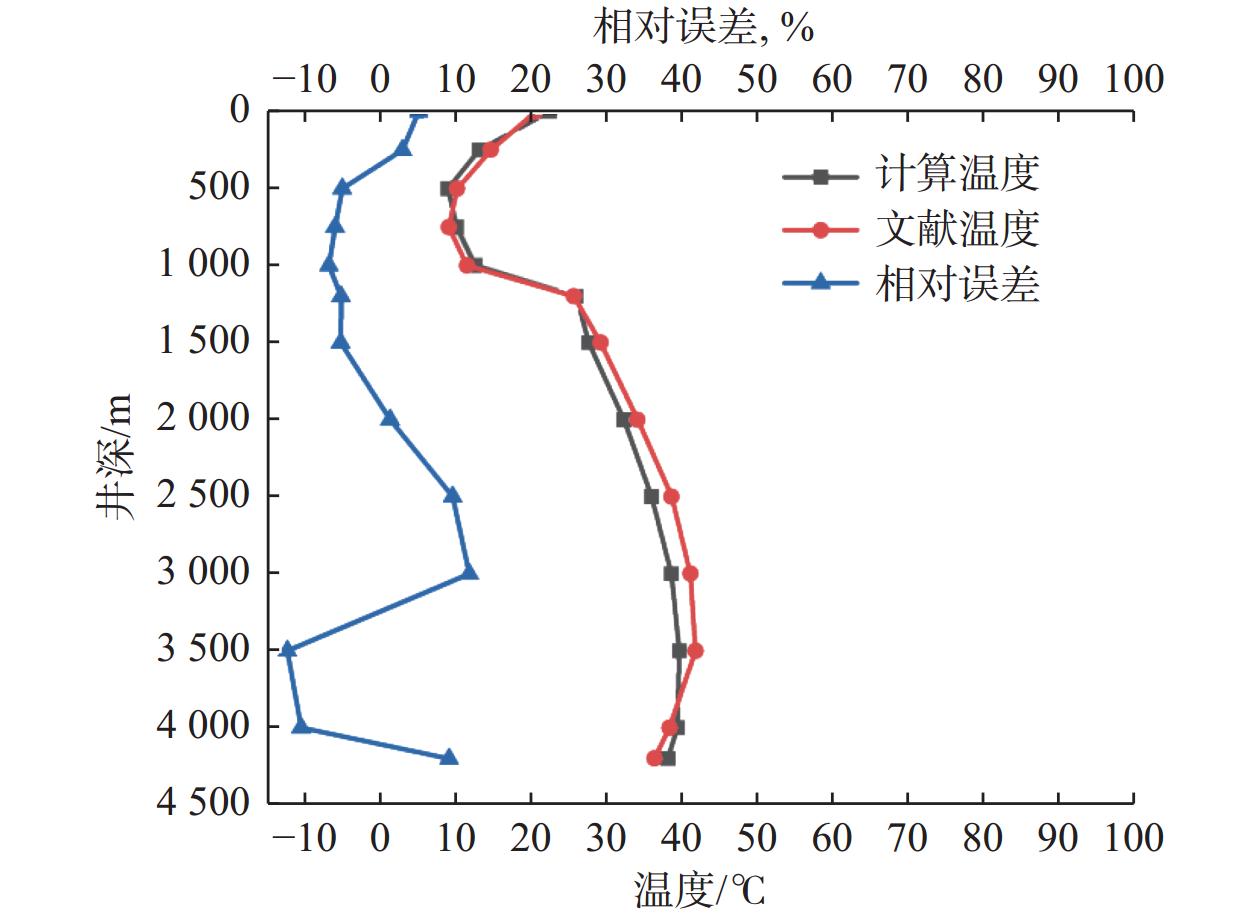

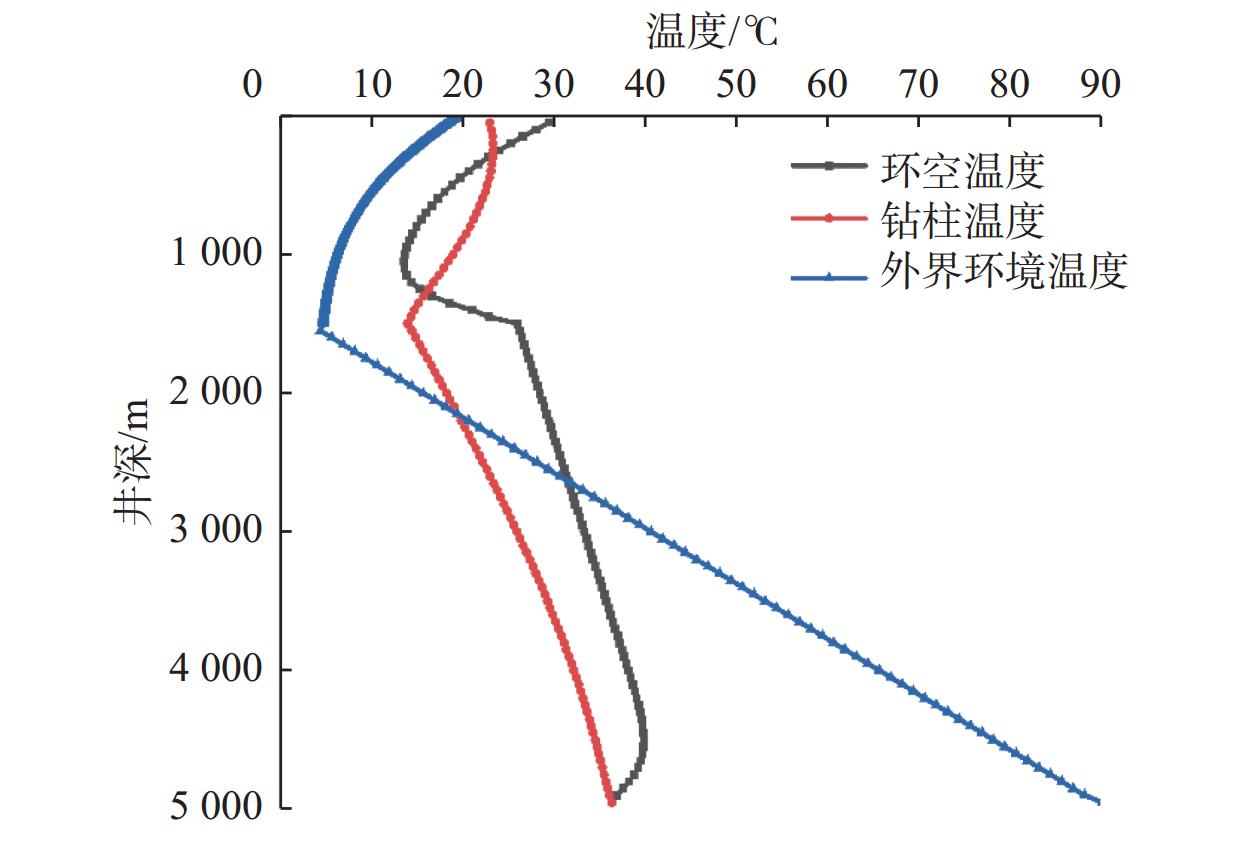

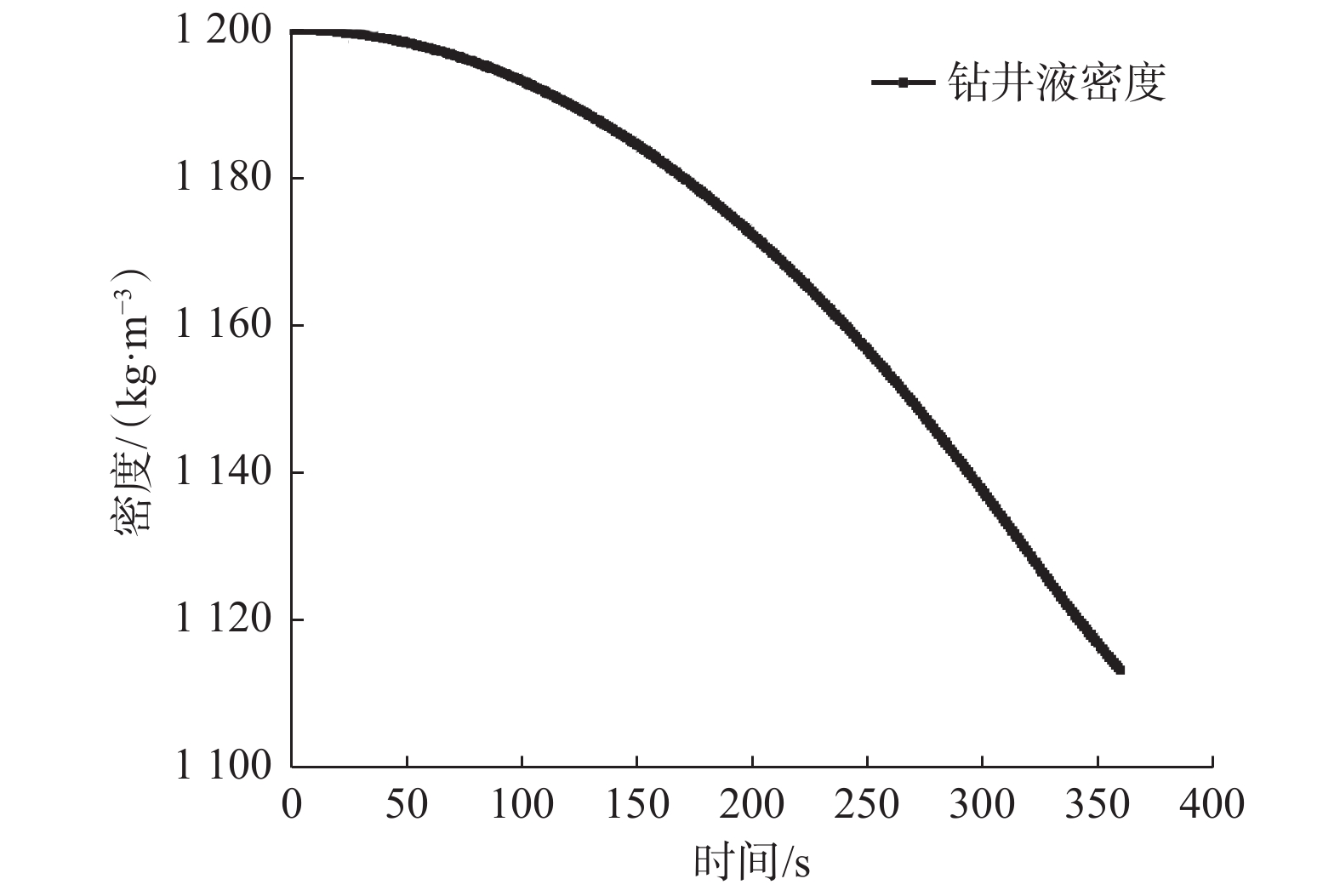

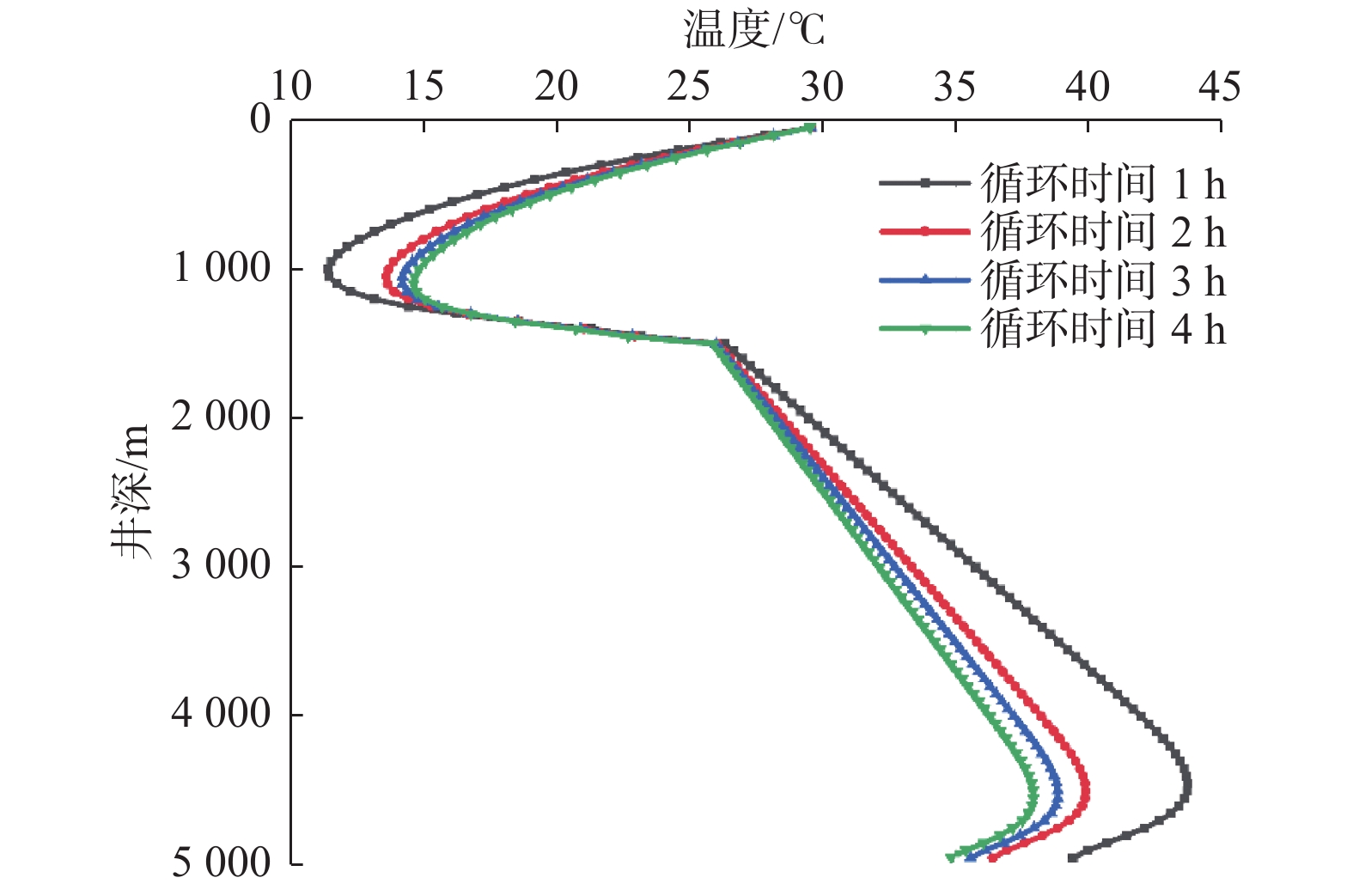

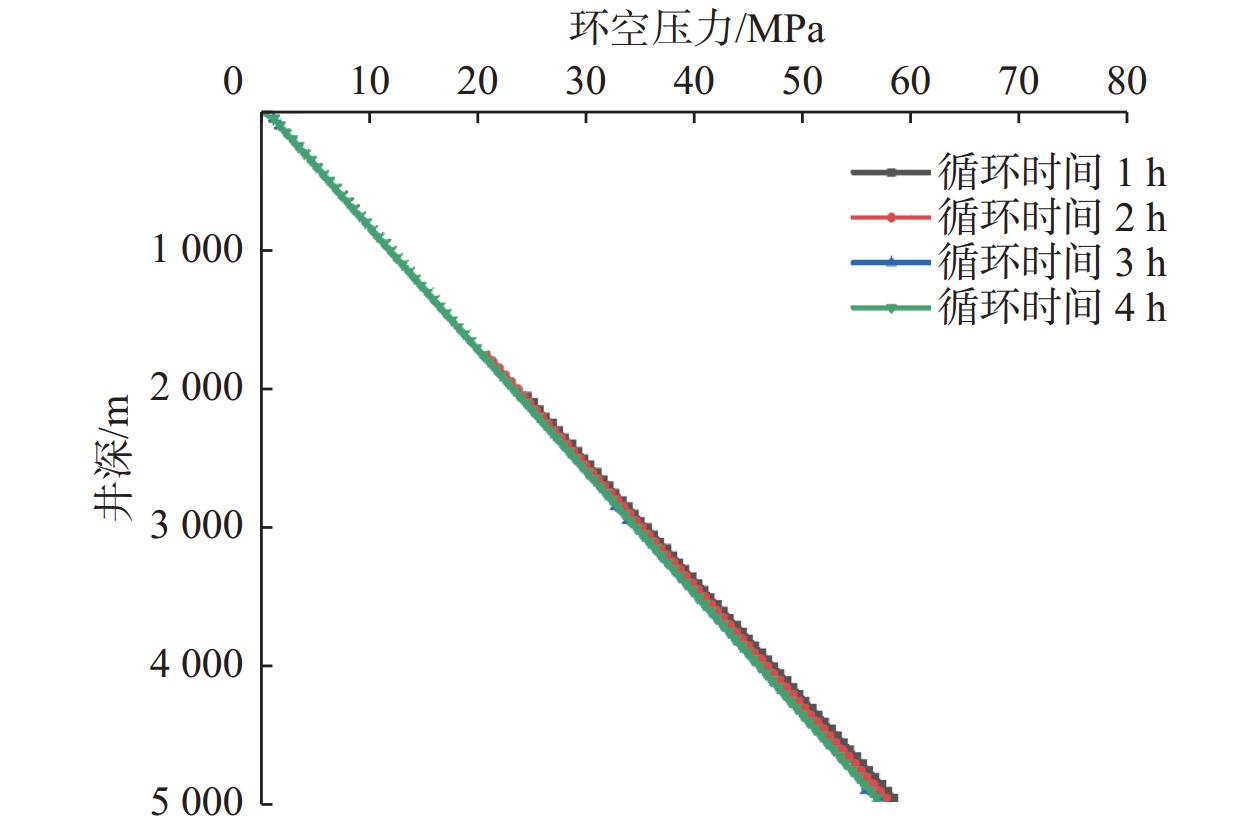

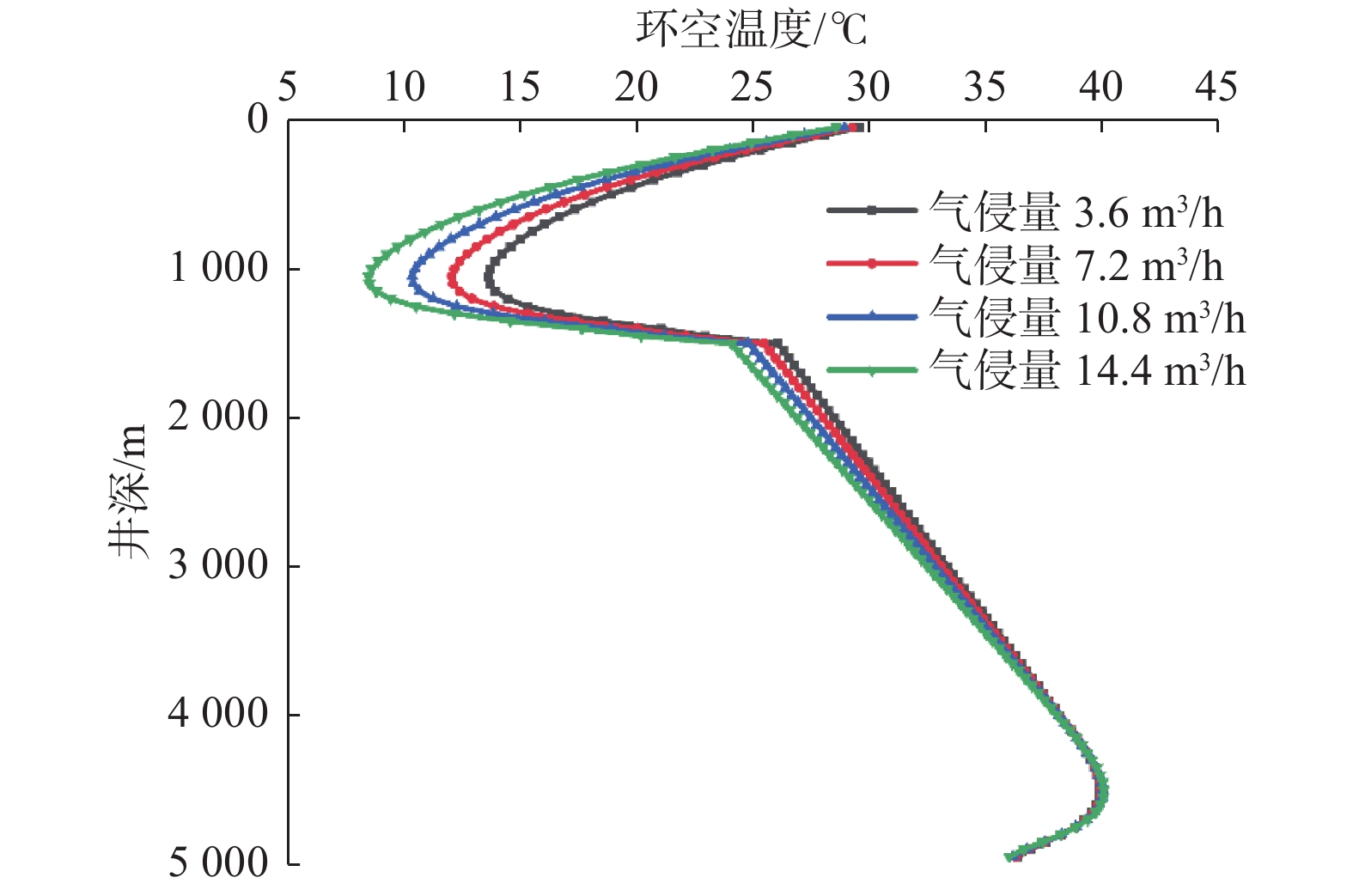

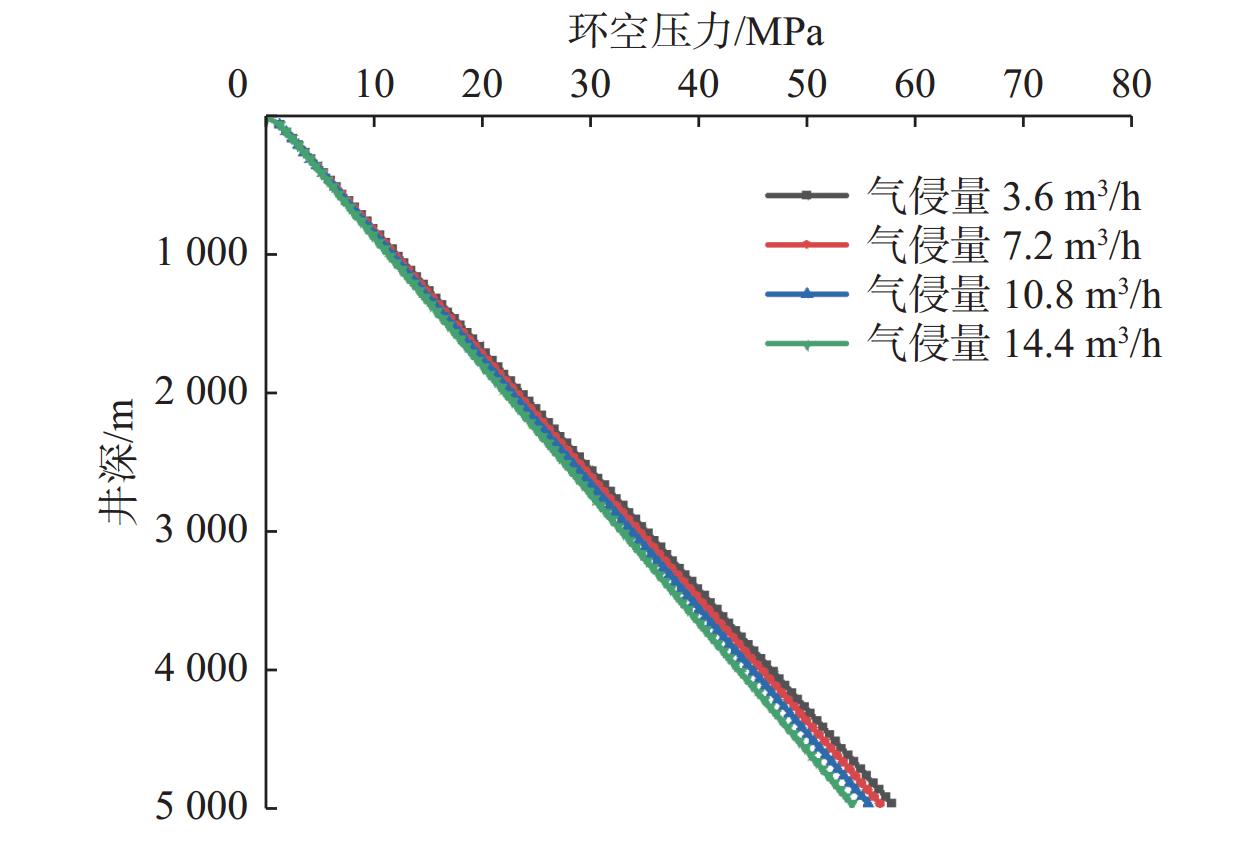

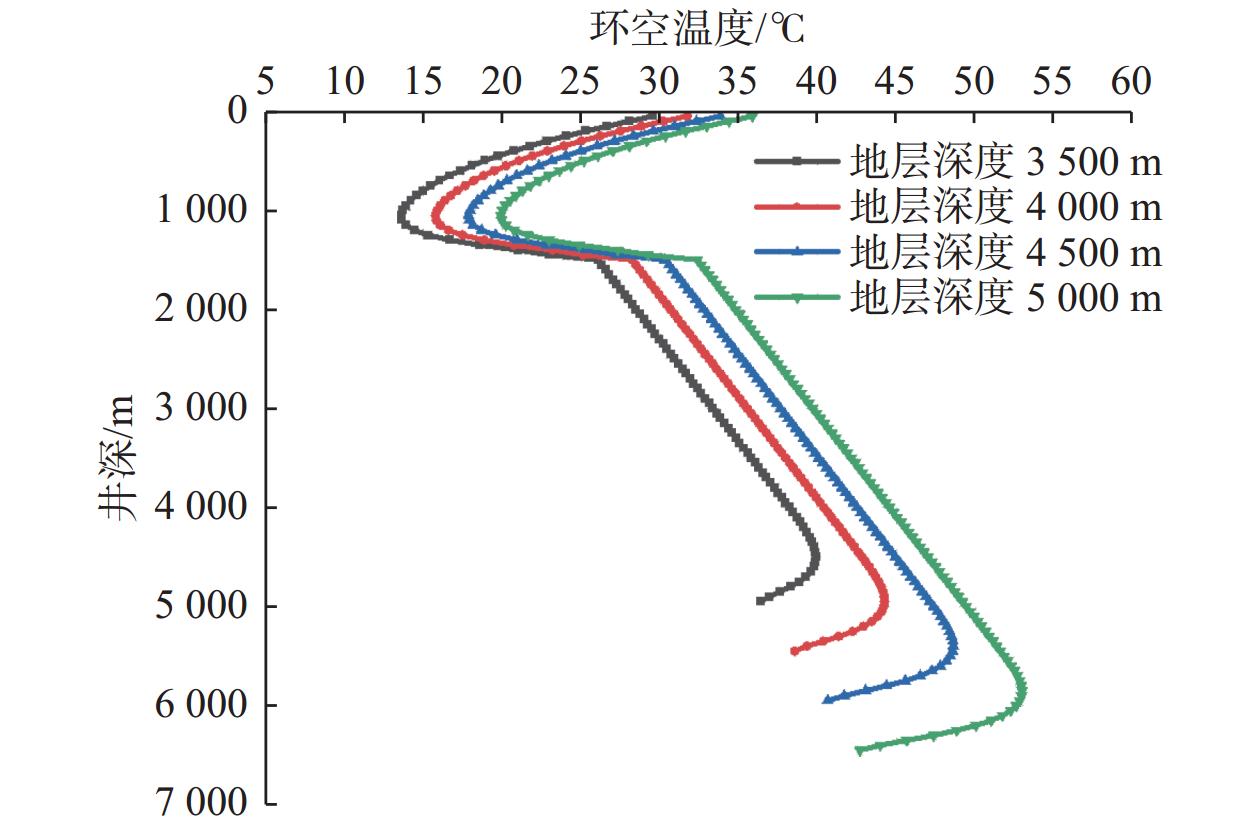

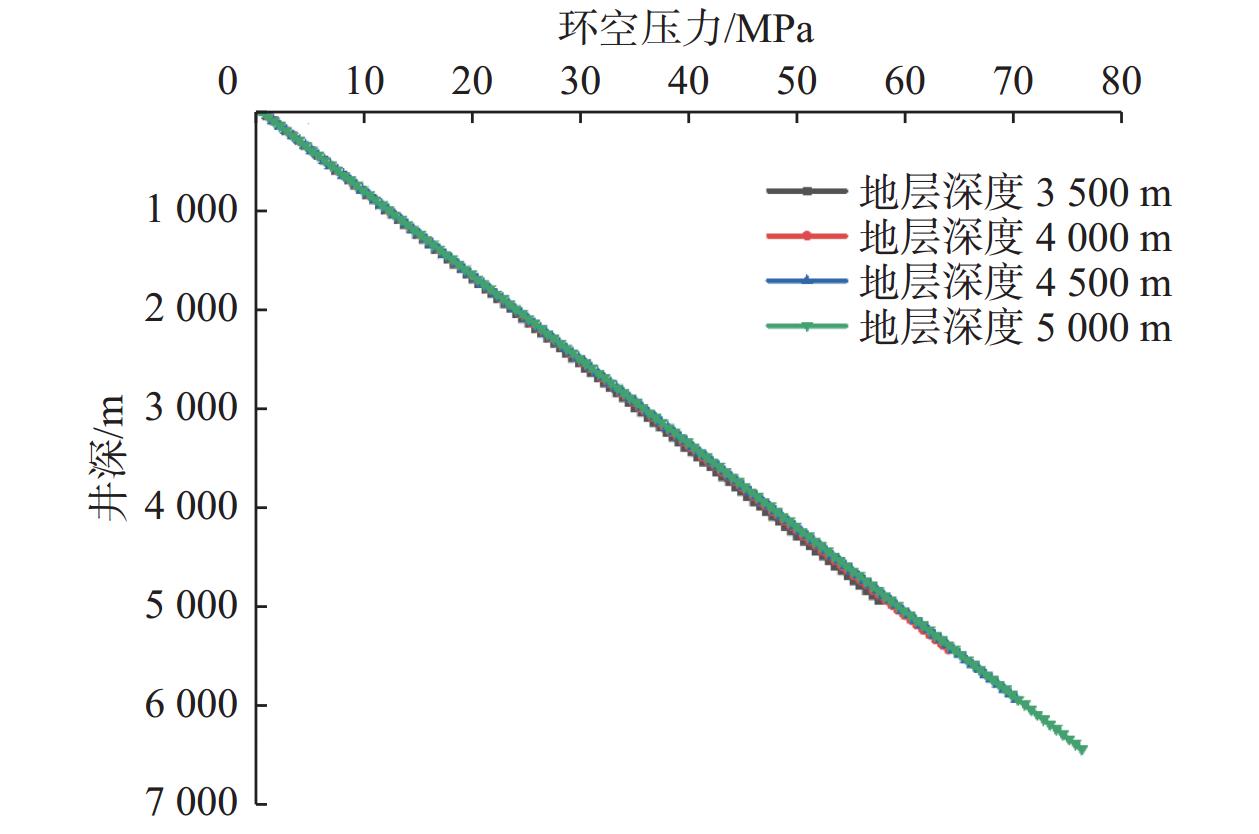

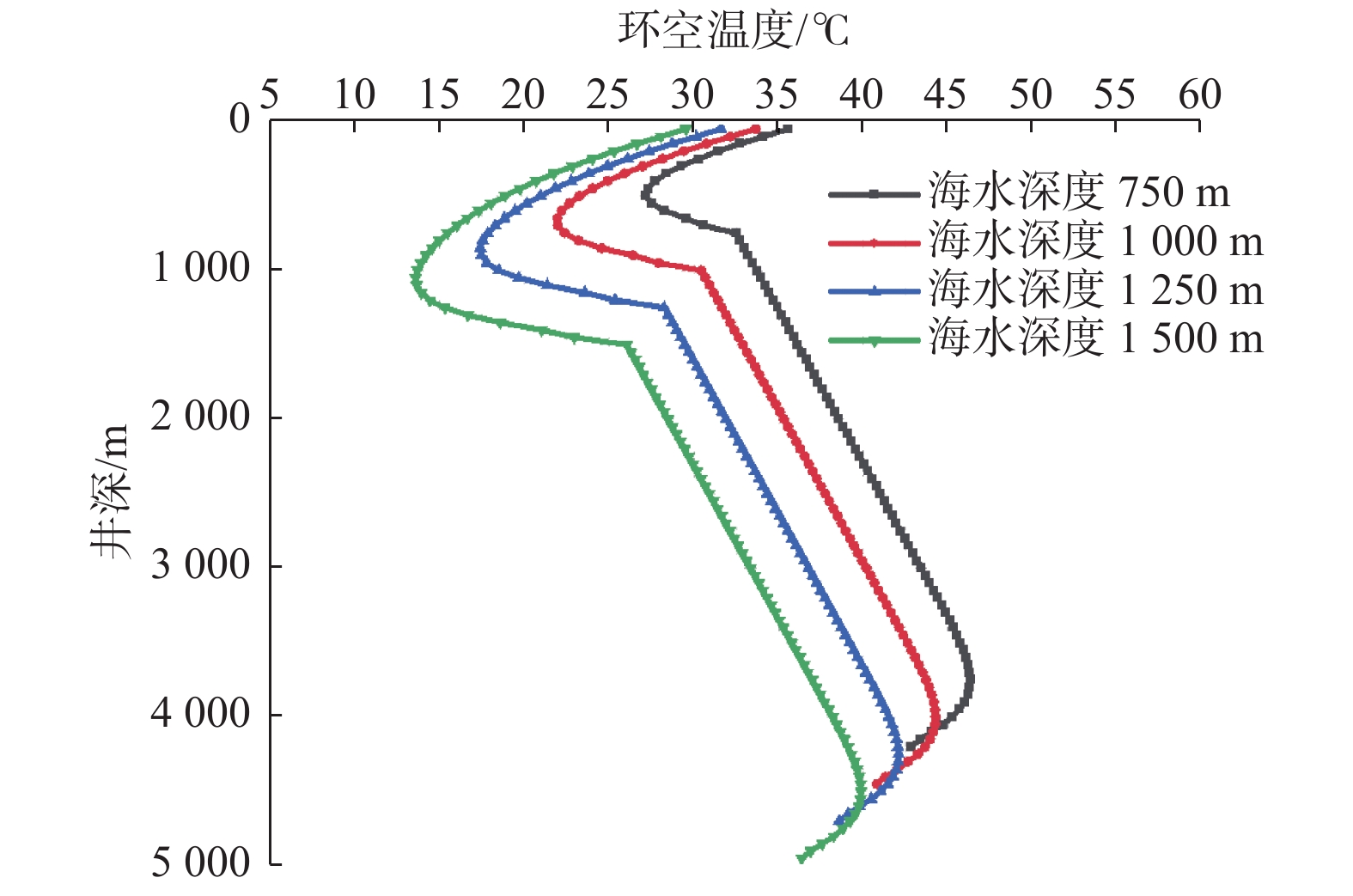

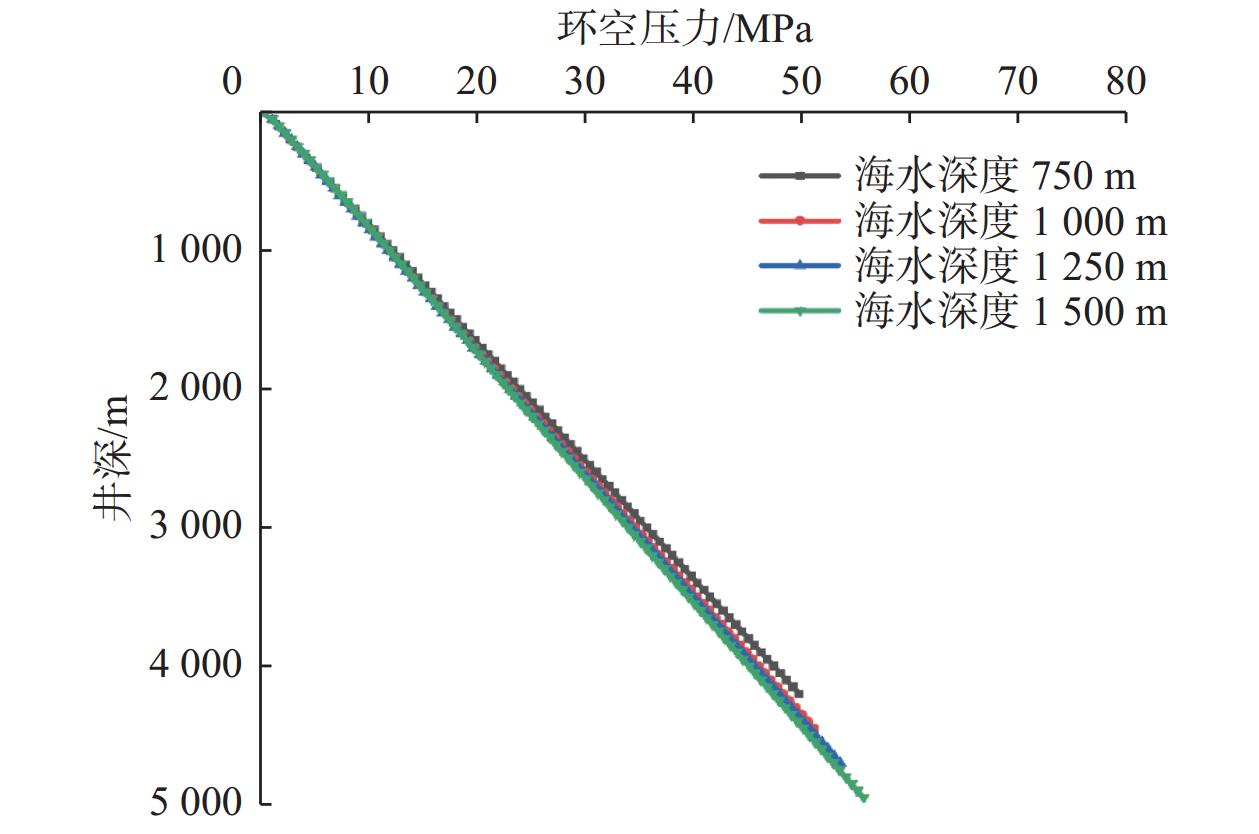

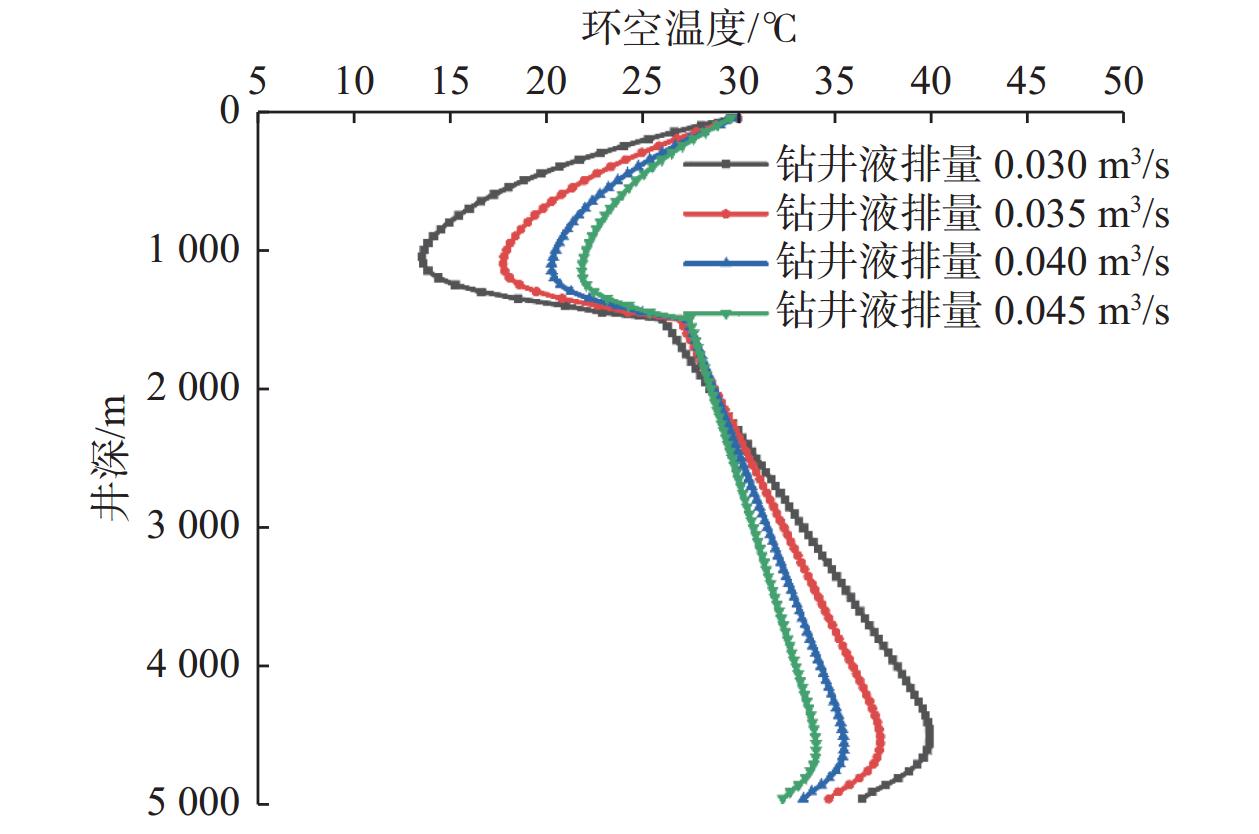

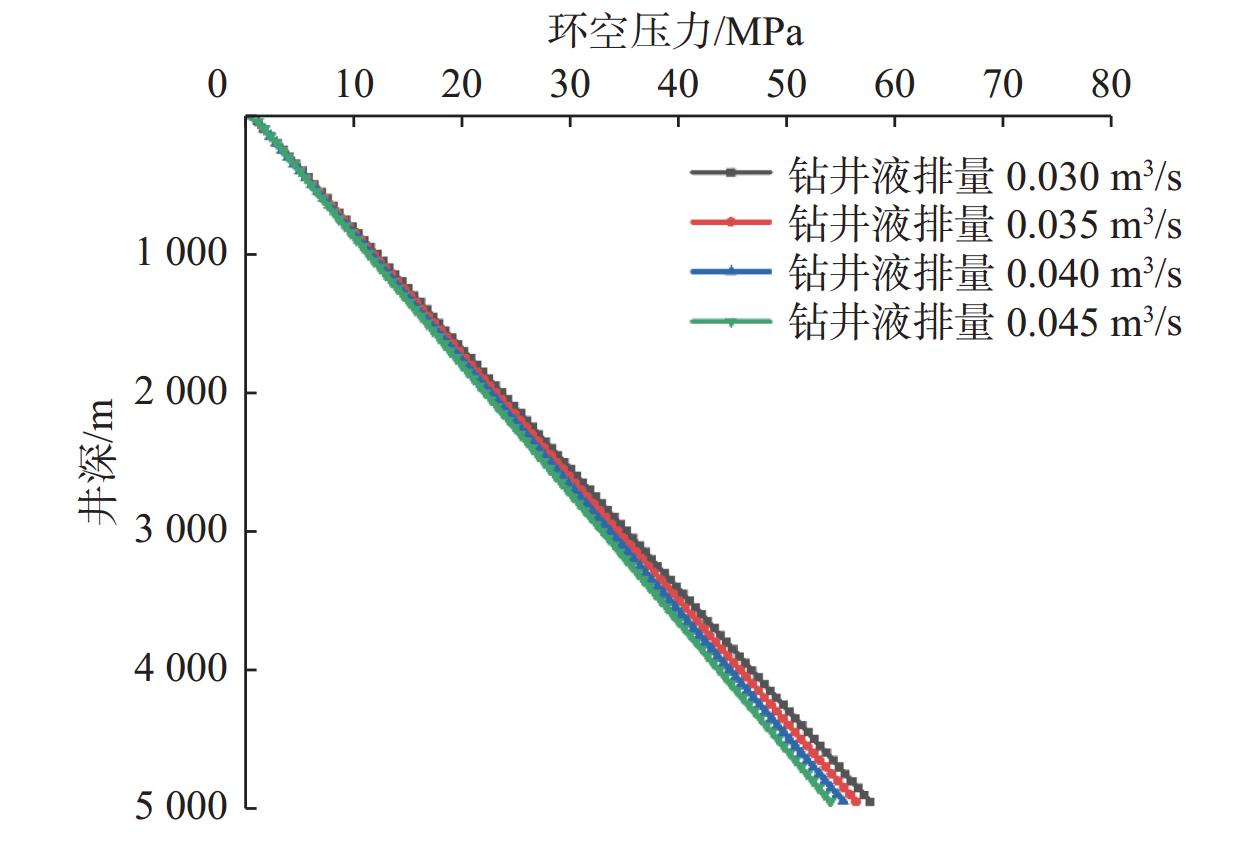

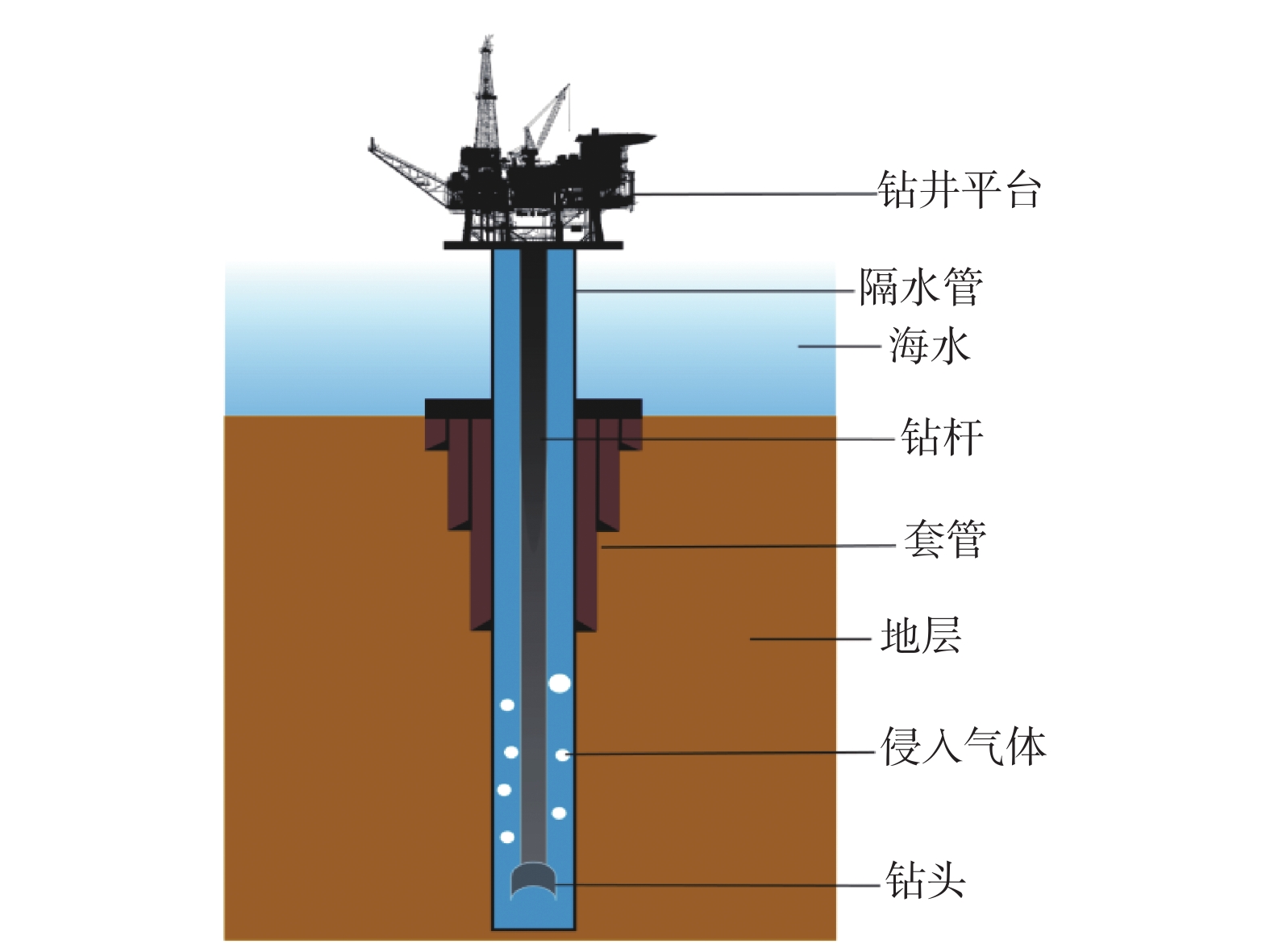

在深水钻井中,气体侵入会对井筒内的温度和压力分布产生显著影响,进而对深水钻井作业带来安全风险。针对深水钻井中的气侵问题,考虑井筒内流体与地层、海水间的传热,建立了气侵条件下的深水钻井井筒温压耦合场计算模型,分析了气侵条件下气液两相流对井筒温度场和压力场的影响,探讨了钻井液循环时间、气侵量、地层深度、海水深度以及钻井液排量等因素对井筒温度场和压力场的影响规律。研究发现:海水深度是影响深水井筒环空温度的主要因素,钻井液排量、地层深度是影响深水井筒环空温度的次要因素,钻井液循环时间与气侵量的影响最小;随着钻井液循环时间、气侵量和钻井液排量增加,井筒温度和压力都降低;随着地层深度增加,井筒温度和压力都升高;随着海水深度增加,井筒温度降低而压力升高。该研究结果对气侵条件下深水钻井井筒温压耦合场分布研究和深水钻井作业安全具有指导意义。

Abstract:Gas kick during deepwater drilling significantly affects the temperature and pressure distribution inside the wellbore, posing potential safety risks to deepwater drilling operations. To address the gas kick issue in deepwater drilling, the heat transfer among the fluid in the wellbore, the formation, and the seawater was considered, and the calculation model for the temperature and pressure coupling field in deepwater drilling wellbore under gas kick was established. The influence of gas-liquid two-phase flow on wellbore temperature and pressure fields under gas kick was analyzed. Additionally, the influence of factors such as drilling fluid circulation time, gas kick amount, formation depth, seawater depth, and flow rate of drilling fluid on wellbore temperature and pressure fields were explored. Results show that the seawater depth is the primary factor affecting the annular temperature of the deepwater wellbore. Drilling fluid flow rate and formation depth are secondary factors. The gas kick amount and circulation time of drilling fluid have the minimal impact. With the increase in the circulation time of drilling fluid, the gas kick amount and flow rate of drilling fluid, the wellbore temperature and pressure both decrease. With the increase in the formation depth, the wellbore temperature and pressure also rise. With the increase in the seawater depth, the wellbore temperature decreases, while the pressure increases. The results have a guiding significance for the temperature and pressure coupling field distribution in deepwater drilling wellbore and the safety of deepwater drilling operations.

-

-

表 1 热物性参数

Table 1 Thermophysical parameters

物质 密度/

(g∙cm–3)比热容/

(J∙(kg·℃)–1)导热系数/

(W∙(m·℃)–1)钻井液 1.200 1 675 1.73 管柱 7.800 400 43.75 海水 1.025 3 890 0.58 地层岩石 2.640 837 2.25 表 2 正交试验结果

Table 2 Orthogonal experiment results

组数 钻井液循环时间/h 气侵量/(m3∙h−1) 地层深度/m 海水深度/m 钻井液排量/(m3∙s−1) 环空井底温度/℃ 1 1 3.6 3 500 750 0.030 41.7 2 1 7.2 4 000 1 000 0.035 39.9 3 1 10.8 4 500 1 250 0.040 38.6 4 1 14.4 5 000 1 500 0.045 38.2 5 2 3.6 4 000 1 250 0.045 35.2 6 2 7.2 3 500 1 500 0.040 35.3 7 2 10.8 5 000 750 0.035 50.2 8 2 14.4 4 500 1 000 0.030 45.3 9 3 3.6 4 500 1 500 0.040 37.0 10 3 7.2 5 000 1 250 0.045 38.9 11 3 10.8 3 500 1 000 0.030 40.9 12 3 14.4 4 000 750 0.035 41.7 13 4 3.6 5 000 1 000 0.035 44.7 14 4 7.2 4 500 750 0.030 47.3 15 4 10.8 4 000 1 500 0.045 33.7 16 4 14.4 3 500 1 250 0.040 34.8 温度水平 K1水平 39.600 39.650 38.175 45.225 43.800 K2水平 41.500 40.350 37.625 42.700 44.125 K3水平 39.625 40.850 42.050 36.875 36.425 K4水平 40.125 40.000 43.000 36.050 36.500 最大值与最小值之差 1.900 1.200 5.375 9.175 7.700 主控因素等级 4 5 3 1 2 -

[1] 高德利,张广瑞,王宴滨. 中国海洋深水油气工程技术与装备创新需求预见及风险分析[J]. 科技导报,2022,40(13):6–16. GAO Deli, ZHANG Guangrui, WANG Yanbin. Innovation demand foresight and risk analysis of technologies and equipment for deepwater oil & gas engineering in China[J]. Science & Technology Review, 2022, 40(13): 6–16.

[2] 王宴滨,高德利,王金铎,等. 横流向涡激−参激耦合振动下深水钻井隔水管疲劳损伤预测[J]. 中国石油大学学报(自然科学版),2022,46(6):119–126. doi: 10.3969/j.issn.1673-5005.2022.06.013 WANG Yanbin, GAO Deli, WANG Jinduo, et al. Fatigue damage prediction of deepwater drilling riser under cross-flow vortex-parametric-coupled vibration[J]. Journal of China University of Petroleum (Edition of Natural Science), 2022, 46(6): 119–126. doi: 10.3969/j.issn.1673-5005.2022.06.013

[3] 李清平. 我国海洋深水油气开发面临的挑战[J]. 中国海上油气,2006,18(2):130–133. doi: 10.3969/j.issn.1673-1506.2006.02.013 LI Qingping. The situation and challenges for deepwater oil and gas exploration and exploitation in China[J]. China Offshore Oil and Gas, 2006, 18(2): 130–133. doi: 10.3969/j.issn.1673-1506.2006.02.013

[4] 高德利,王宴滨. 海洋深水钻井力学与控制技术若干研究进展[J]. 石油学报,2019,40(增刊2):102–115. GAO Deli, WANG Yanbin. Some research progress in deepwater drilling mechanics and control technology[J]. Acta Petrolei Sinica, 2019, 40(supplement 2): 102–115.

[5] 张来斌,谢仁军,殷启帅. 深水油气开采风险评估及安全控制技术进展与发展建议[J]. 石油钻探技术,2023,51(4):55–65. doi: 10.11911/syztjs.2023036 ZHANG Laibin, XIE Renjun, YIN Qishuai. Technical progress and development suggestions for risk assessment and safety control of deep-water oil and gas exploitation[J]. Petroleum Drilling Techniques, 2023, 51(4): 55–65. doi: 10.11911/syztjs.2023036

[6] 卢志红,高兴坤,曹锡玲. 气侵期间环空气液两相流模拟研究[J]. 石油钻采工艺,2008,30(1):25–28. doi: 10.3969/j.issn.1000-7393.2008.01.007 LU Zhihong, GAO Xingkun, CAO Xiling. Simulation study on two-phase gas-liquid flow during gas kick[J]. Oil Drilling & Production Technology, 2008, 30(1): 25–28. doi: 10.3969/j.issn.1000-7393.2008.01.007

[7] RAMEY H J, Jr. Wellbore heat transmission[J]. Journal of Petroleum Technology, 1962, 14(4): 427–435. doi: 10.2118/96-PA

[8] WILLHITE G P. Over-all heat transfer coefficients in steam and hot water injection wells[J]. Journal of Petroleum Technology, 1967, 19(5): 607–615. doi: 10.2118/1449-PA

[9] 王弥康. 注蒸汽井井筒热传递的定量计算[J]. 中国石油大学学报(自然科学版),1994,18(4):77–82. WANG Mikang. Quantitative calculation of wellbore heat transmission for steam injection wells[J]. Journal of China University of Petroleum(Edition of Natural Science), 1994, 18(4): 77–82.

[10] HASAN A R, KABIR C S. A simple model for annular two-phase flow in wellbores[J]. SPE Production & Operations, 2007, 22(2): 168–175.

[11] HASAN A R, KABIR C S. Wellbore heat-transfer modeling and applications[J]. Journal of Petroleum Science and Engineering, 2012, 86/87: 127–136. doi: 10.1016/j.petrol.2012.03.021

[12] EDWARDSON M J, GIRNER H M, PARKISON H R, et al. Calculation of formation temperature disturbances caused by mud circulation[J]. Journal of Petroleum Technology, 1962, 14(4): 416–426. doi: 10.2118/124-PA

[13] KABIR C S, HASAN A R, KOUBA G E, et al. Determining circulating fluid temperature in drilling, workover, and well control operations[J]. SPE Drilling & Completion, 1996, 11(2): 74–79.

[14] 宋国志. 深水钻井气侵过程中的井筒温度压力模拟研究[D]. 成都:西南石油大学,2016. SONG Guozhi. Simulation study of wellbore temperature and pressure during gas invasion in deepwater drilling[D]. Chengdu: Southwest Petroleum University, 2016.

[15] 龙之辉. 钻井中出现气侵时环空两相流基本特性探讨[J]. 钻采工艺,1992,15(2):27–29. LONG Zhihui. Exploration of the basic characteristics of two-phase flow in the annulus during gas invasion in drilling[J]. Drilling and Production Technology, 1992, 15(2): 27–29.

[16] 王江帅. 深水变梯度控压钻井井筒压力预测模型与优化控制[D]. 北京:中国石油大学(北京),2021. WANG Jiangshuai. Wellbore pressure prediction model and optimal control of variable gradient MPD in deep water[D]. Beijing: China University of Petroleum(Beijing), 2021.

[17] 周健,贾红军,李晓春,等. 控压钻井停止循环期间垂直环空连续气侵机理研究[J]. 钻采工艺,2015,38(2):17–19. doi: 10.3969/J.ISSN.1006-768X.2015.02.05 ZHOU Jian, JIA Hongjun, LI Xiaochun, et al. Research on vertical annulus continuous gas cutting during stopping managed pressure drilling circulation[J]. Drilling & Production Technology, 2015, 38(2): 17–19. doi: 10.3969/J.ISSN.1006-768X.2015.02.05

[18] 宋洵成,管志川. 深水钻井井筒全瞬态传热特征[J]. 石油学报,2011,32(4):704–708. doi: 10.7623/syxb201104022 SONG Xuncheng, GUAN Zhichuan. Full transient analysis of heat transfer during drilling fluid circulation in deep-water wells[J]. Acta Petrolei Sinica, 2011, 32(4): 704–708. doi: 10.7623/syxb201104022

[19] 李文龙,高德利,杨进,等. 深水超深井钻井井筒温度剖面预测[J]. 石油钻采工艺,2020,42(5):558–563. LI Wenlong, GAO Deli, YANG Jin, et al. Prediction of the borehole temperature profile in ultra-deep drilling under ocean deepwater conditions[J]. Oil Drilling & Production Technology, 2020, 42(5): 558–563.

[20] 刘劲歌,樊洪海,胡杭健,等. 深水油气开采过程中多环空温度变化特征与敏感性分析[J]. 钻采工艺,2017,40(6):49–52. doi: 10.3969/J.ISSN.1006-768X.2017.06.15 LIU Jinge, FAN Honghai, HU Hangjian, et al. To analyze temperature change rules and sensitivity in multi-annuli during deepwater oil/gas development[J]. Drilling & Production Technology, 2017, 40(6): 49–52. doi: 10.3969/J.ISSN.1006-768X.2017.06.15

[21] LIU Jinge, FAN Honghai, LIU Wenke, et al. Temperature increase behavior of multi-annuli in subsea wells[R]. OTC 26601, 2016.

[22] LIU Jinge, FAN Honghai, ZHU Liang, et al. Development of a transient method on predicting multi-annuli temperature of subsea wells[J]. Journal of Petroleum Science and Engineering, 2017, 157: 295–301. doi: 10.1016/j.petrol.2017.06.072

[23] FOURNEY W L, HOLLOWAY D C, SIMHA K R Y. Model investigation of wellbore pressure distribution in stem-induced fracturing[J]. SPE Production Engineering, 1987, 2(4): 243–249. doi: 10.2118/12883-PA

[24] SORELLE R R, JARDIOLIN R A, BUCKLEY P, et al. Mathematical field model predicts downhole density changes in static drilling fluids[R]. SPE 11118, 1982.

[25] WOOLEY G R. Computing downhole temperatures in circulation, injection, and production wells[J]. Journal of Petroleum Technology, 1980, 32(9): 1509–1522. doi: 10.2118/8441-PA

[26] 赵金洲,任书泉. 井筒内液体温度分布规律的数值计算[J]. 石油钻采工艺,1986,8(3):49–57. ZHAO Jinzhou, REN Shuquan. Numerical calculation of temperature distribution of liquid inside the wellbore[J]. Petroleum Drilling Techniques, 1986, 8(3): 49–57.

[27] 唐林,冯文伟,王林. 井内及井壁瞬态温度的确定[J]. 钻井液与完井液,1998,15(5):30–34. TANG Lin, FENG Wenwei, WANG Lin. Determining instantaneous state temperature in the borehole and the wall[J]. Drilling Fluid & Completion Fluid, 1998, 15(5): 30–34.

[28] 王雪瑞,孙宝江,刘书杰,等. 基于水化反应动力学的深水固井井筒温度与压力耦合预测模型[J]. 石油勘探与开发,2020,47(4):809–818. doi: 10.11698/PED.2020.04.18 WANG Xuerui, SUN Baojiang, LIU Shujie, et al. A coupled model of temperature and pressure based on hydration kinetics during well cementing in deep water[J]. Petroleum Exploration and Development, 2020, 47(4): 809–818. doi: 10.11698/PED.2020.04.18

[29] 田得强,李中,许亮斌,等. 深水高温高压气井钻井循环温度压力耦合计算与分析[J]. 中国海上油气,2022,34(5):149–157. TIAN Deqiang, LI Zhong, XU Liangbin, et al. Coupling calculation and analysis of circulating temperature pressure distribution in deepwater HTHP gas well drilling[J]. China Offshore Oil and Gas, 2022, 34(5): 149–157.

[30] 骆奎栋,李军,任美鹏,等. 深水钻井隔水管增压管线对井筒温度的影响[J]. 石油机械,2019,47(2):49–54. LUO Kuidong, LI Jun, REN Meipeng, et al. Effect of boost line in riser on the wellbore temperature in deep water drilling[J]. China Petroleum Machinery, 2019, 47(2): 49–54.

[31] 何世明,何平,尹成,等. 井下循环温度模型及其敏感性分析[J]. 西南石油大学学报(自然科学版),2002,24(1):57–60. HE Shiming, HE Ping, YIN Cheng, et al. A wellbore temperature model & its’ parametric sensitivity analysis[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2002, 24(1): 57–60.

[32] 曾祥林,刘永辉,李玉军,等. 预测井筒压力及温度分布的机理模型[J]. 西安石油学院学报(自然科学版),2003,18(2):40–44. ZENG Xianglin, LIU Yonghui, LI Yujun, et al. Mechanism model for predicting the distributions of wellbore pressure and temperature[J]. Journal of Xi’an Shiyou University(Natural Science Edition), 2003, 18(2): 40–44.

[33] 宁立伟. 钻井液物性参数对深水钻井井筒温度压力的影响[D]. 青岛:中国石油大学(华东),2008. NING Liwei. The effect of drilling fluid’s physical properties on the temperature and pressure in deepwater drilling[D]. Qingdao: China University of Petroleum(East China), 2008.

[34] CHEN Xin, HE Miao, XU Mingbiao, et al. Fully transient coupled prediction model of wellbore temperature and pressure for multi-phase flow during underbalanced drilling[J]. Geoenergy Science and Engineering, 2023, 223: 211540. doi: 10.1016/j.geoen.2023.211540

[35] 郭晓乐,龙芝辉,汪志明,等. 深水隔水管钻井井筒温压场耦合计算与分析[J]. 中国海上油气,2014,26(6):66–69. GUO Xiaole, LONG Zhihui, WANG Zhiming, et al. Study on coupling law of wellbore temperature and pressure fields in deep water drilling with riser system[J]. China Offshore Oil and Gas, 2014, 26(6): 66–69.

[36] 杨谋,孟英峰,李皋,等. 钻井全过程井筒-地层瞬态传热模型[J]. 石油学报,2013,34(2):366–371. doi: 10.7623/syxb201302021 YANG Mou, MENG Yingfeng, LI Gao, et al. A transient heat transfer model of wellbore and formation during the whole drilling process[J]. Acta Petrolei Sinica, 2013, 34(2): 366–371. doi: 10.7623/syxb201302021

[37] 王博. 深水钻井环境下的井筒温度压力计算方法研究[D]. 青岛:中国石油大学(华东),2007. WANG Bo. Research on the method of wellbore temperature and pressure calculation during deep-water drilling[D]. Qingdao: China University of Petroleum(East China), 2007.

-

期刊类型引用(4)

1. 付荣耀,孙鹞鸿,刘坤,高迎慧,徐旭哲,严萍. 大水泥岩样的电脉冲压裂实验研究. 强激光与粒子束. 2018(04): 131-135 .  百度学术

百度学术

2. 光新军,王敏生. 电弧等离子技术在石油工程中的应用前景. 石油钻采工艺. 2017(01): 119-124 .  百度学术

百度学术

3. 付海峰,张永民,王欣,严玉忠,管保山,刘云志,梁天成,翁定为. 基于脉冲致裂储层的改造新技术研究. 岩石力学与工程学报. 2017(S2): 4008-4017 .  百度学术

百度学术

4. 付荣耀,孙鹞鸿,樊爱龙,高迎慧,严萍,周健. 高压电脉冲在页岩气开采中的压裂实验研究. 强激光与粒子束. 2016(07): 192-196 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: