Calculation Method for Complex Fracture Network Area of Shale Fracturing Based on Octree Grid

-

摘要:

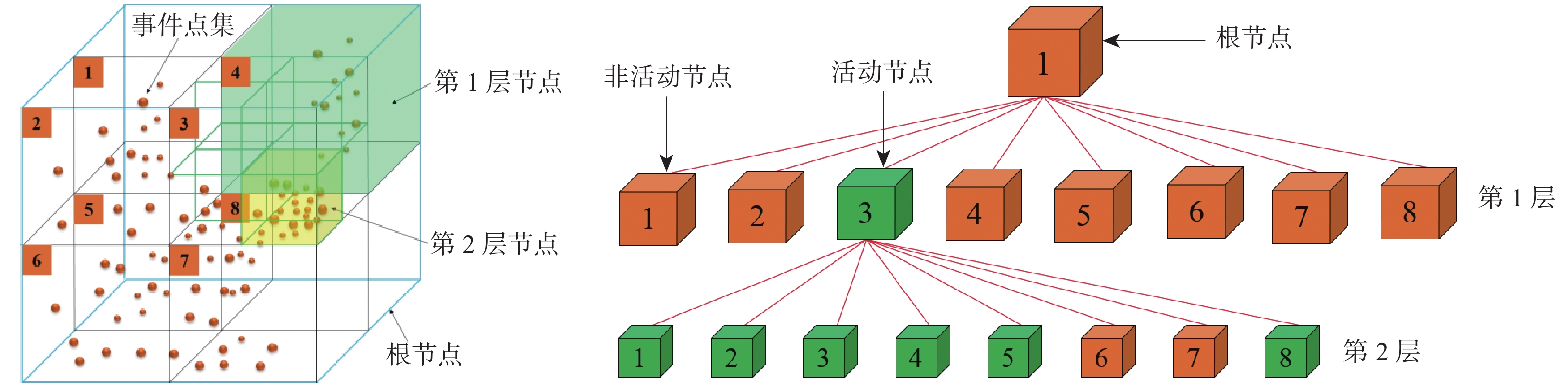

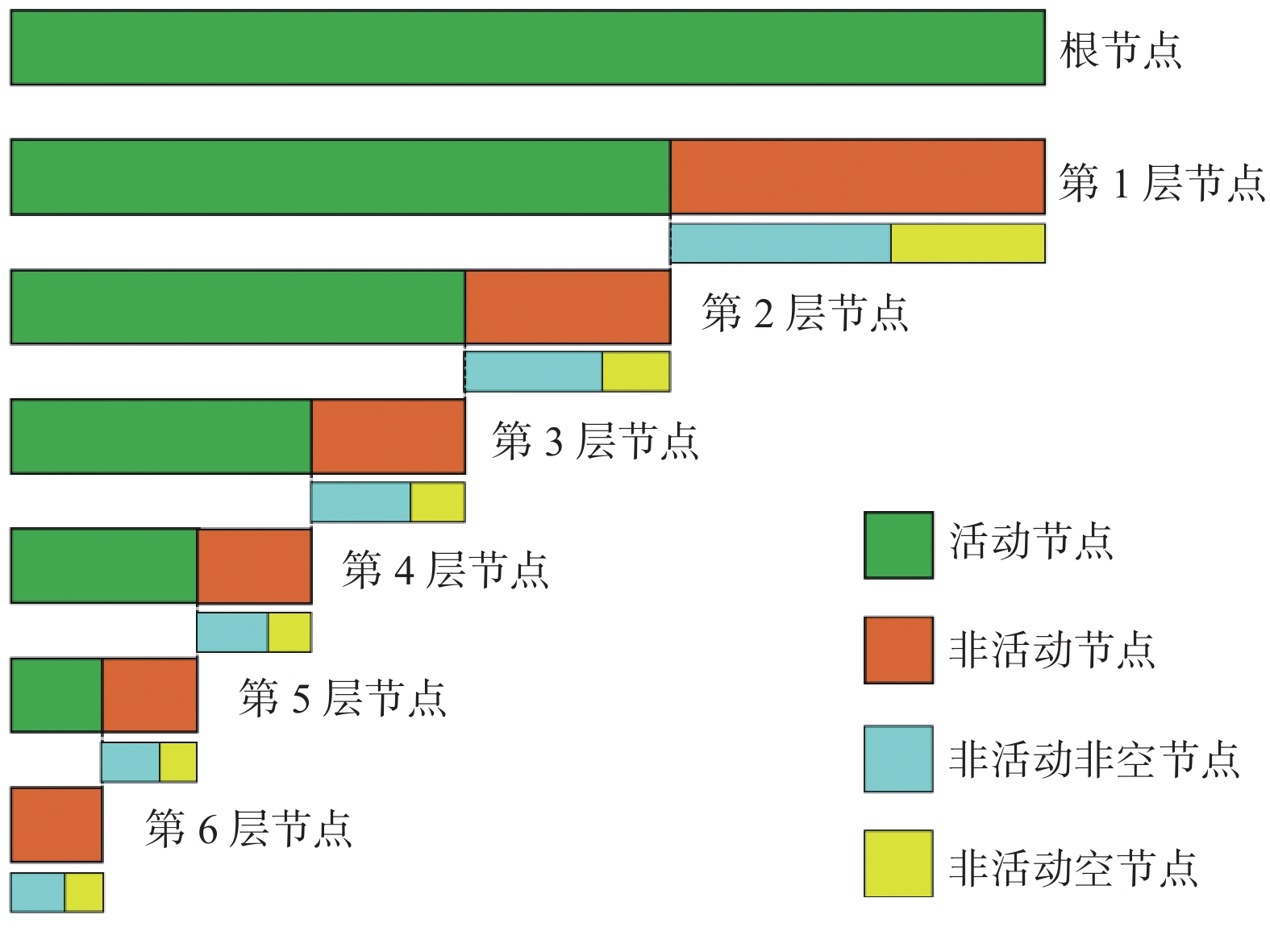

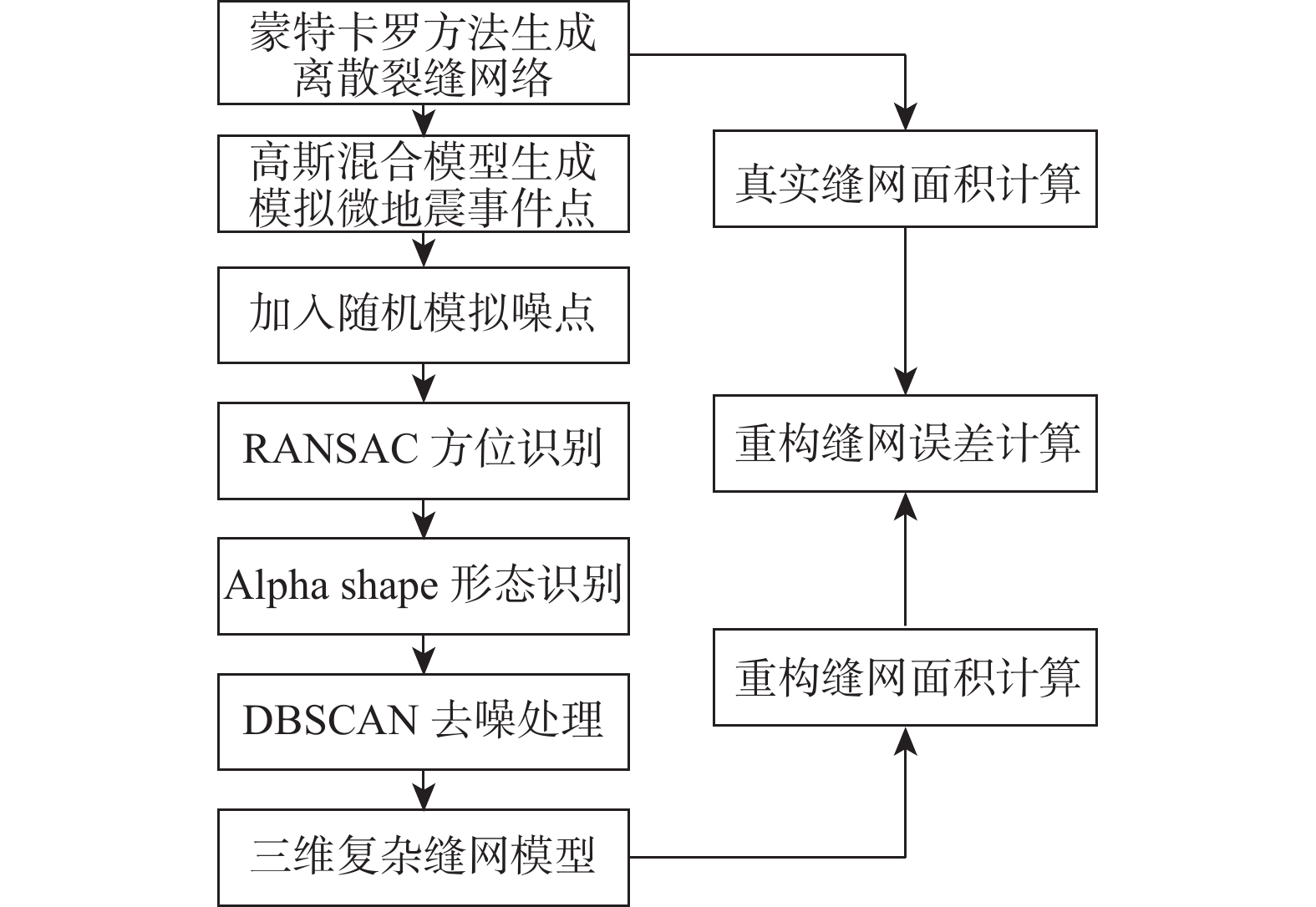

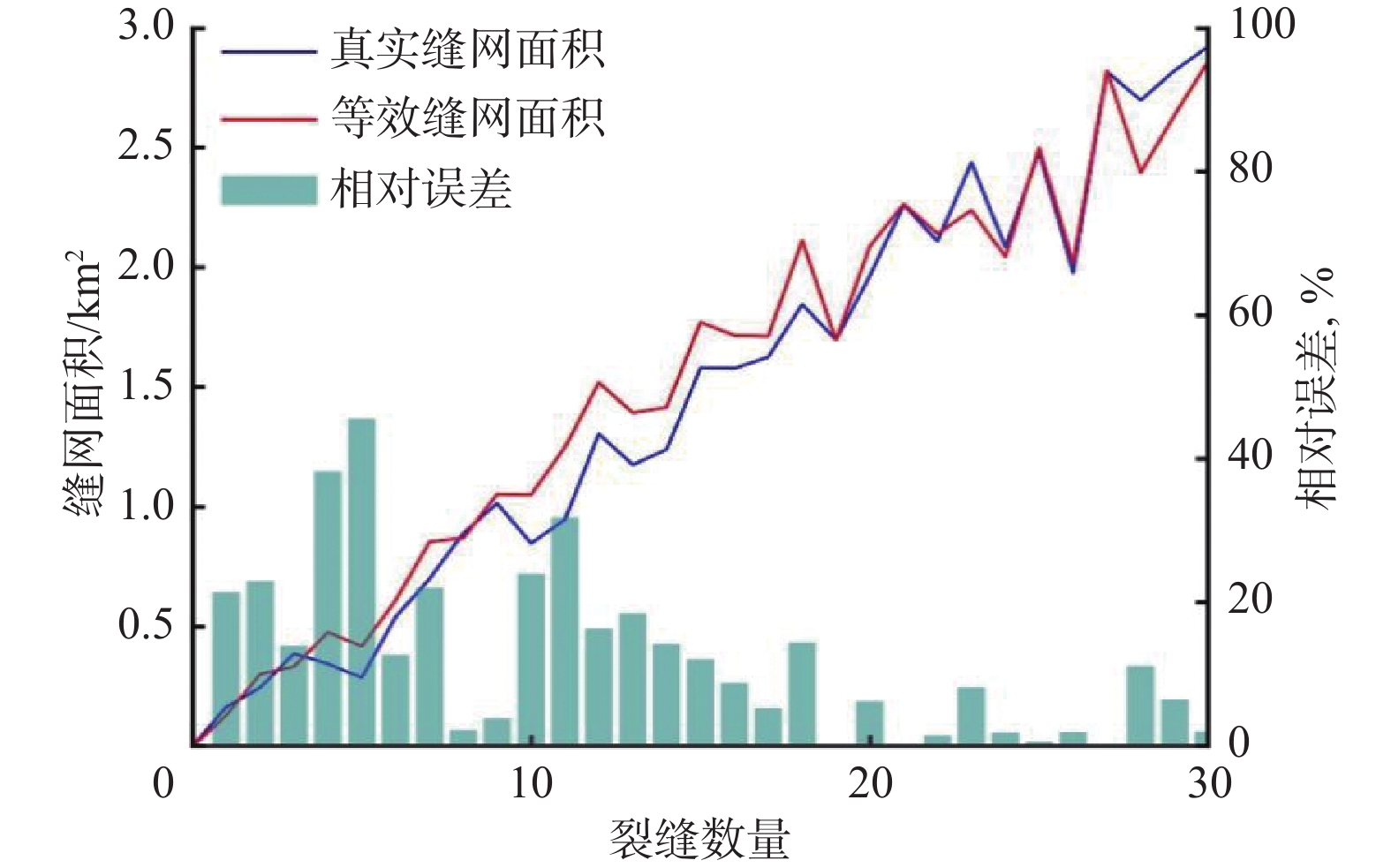

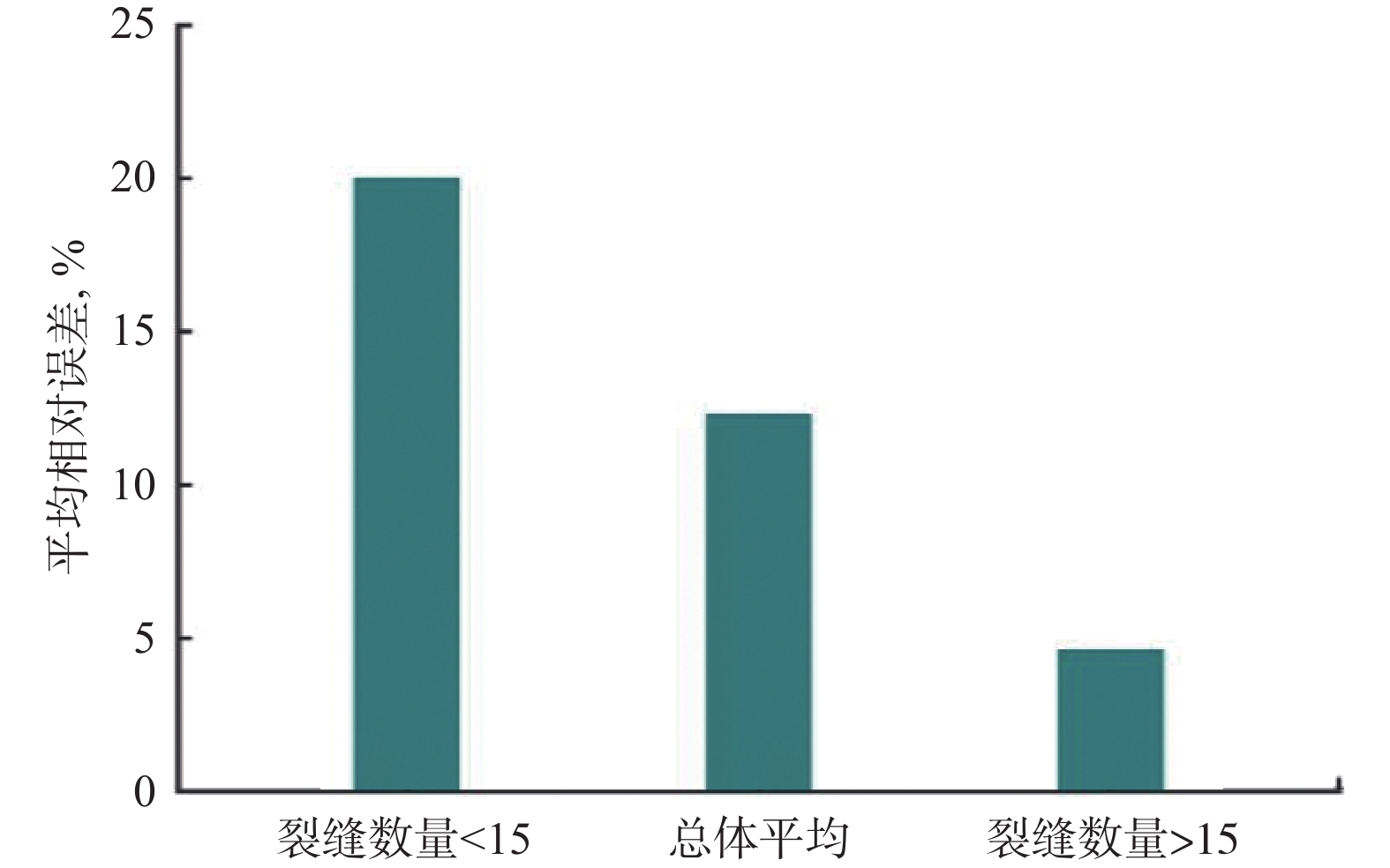

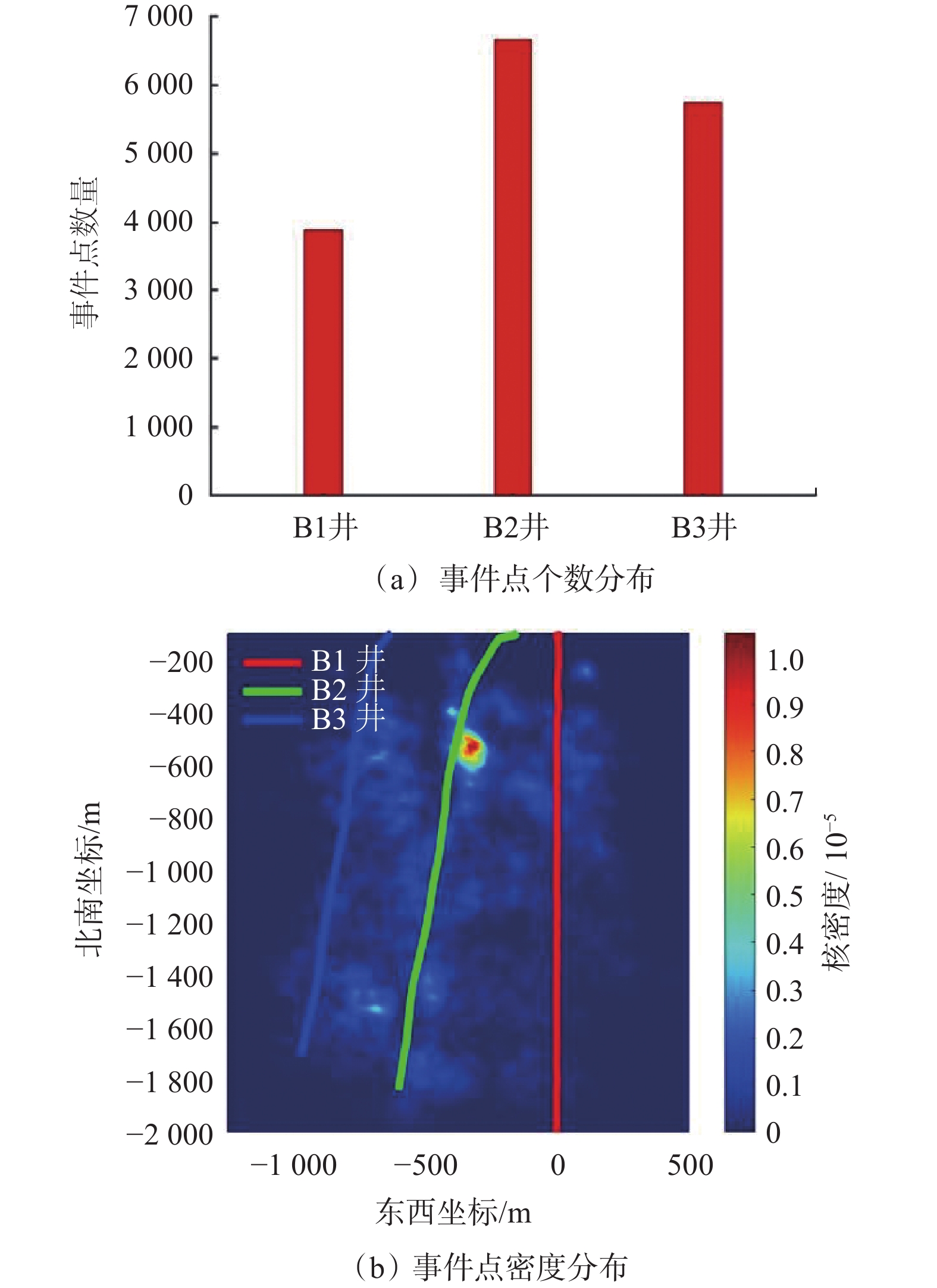

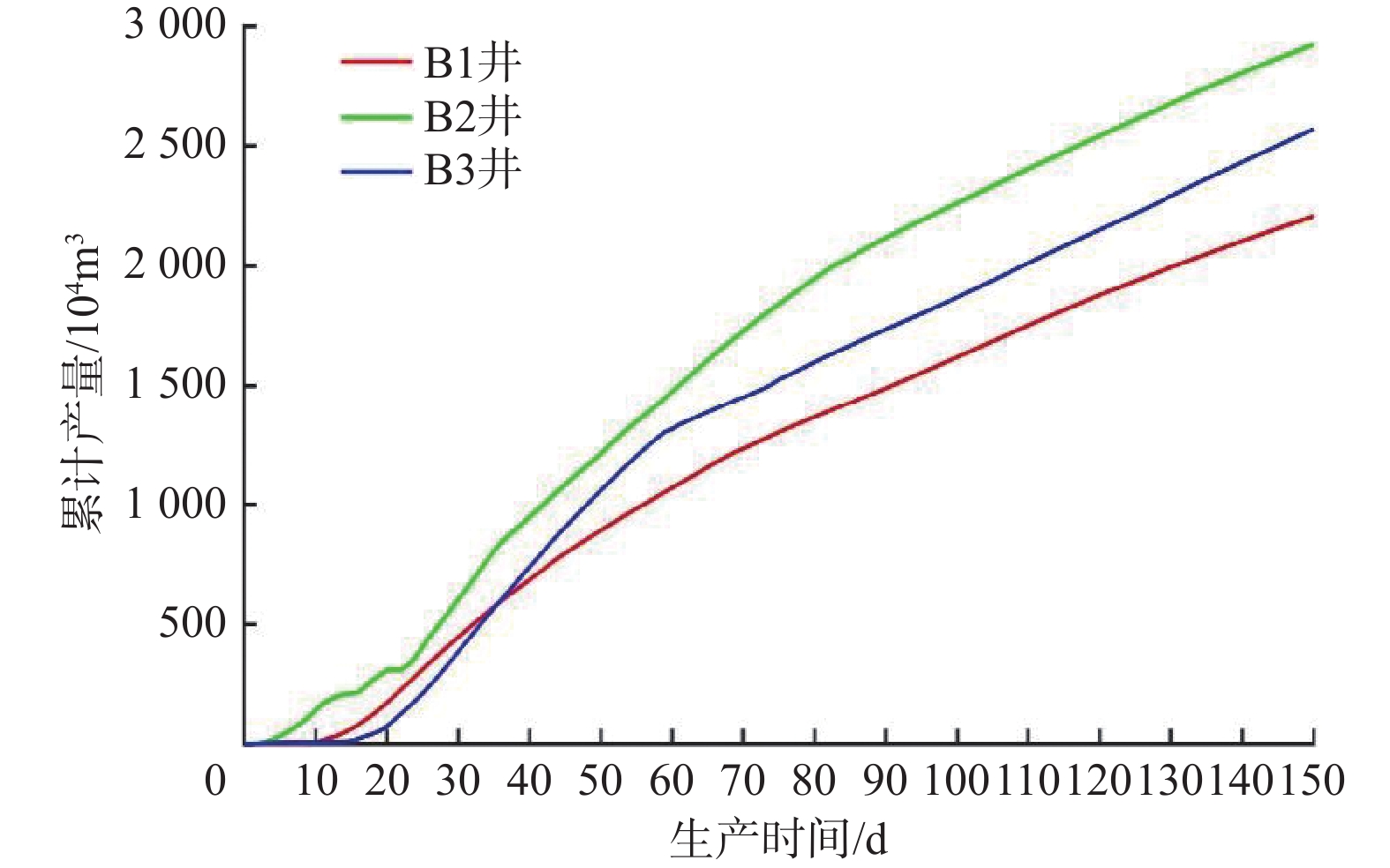

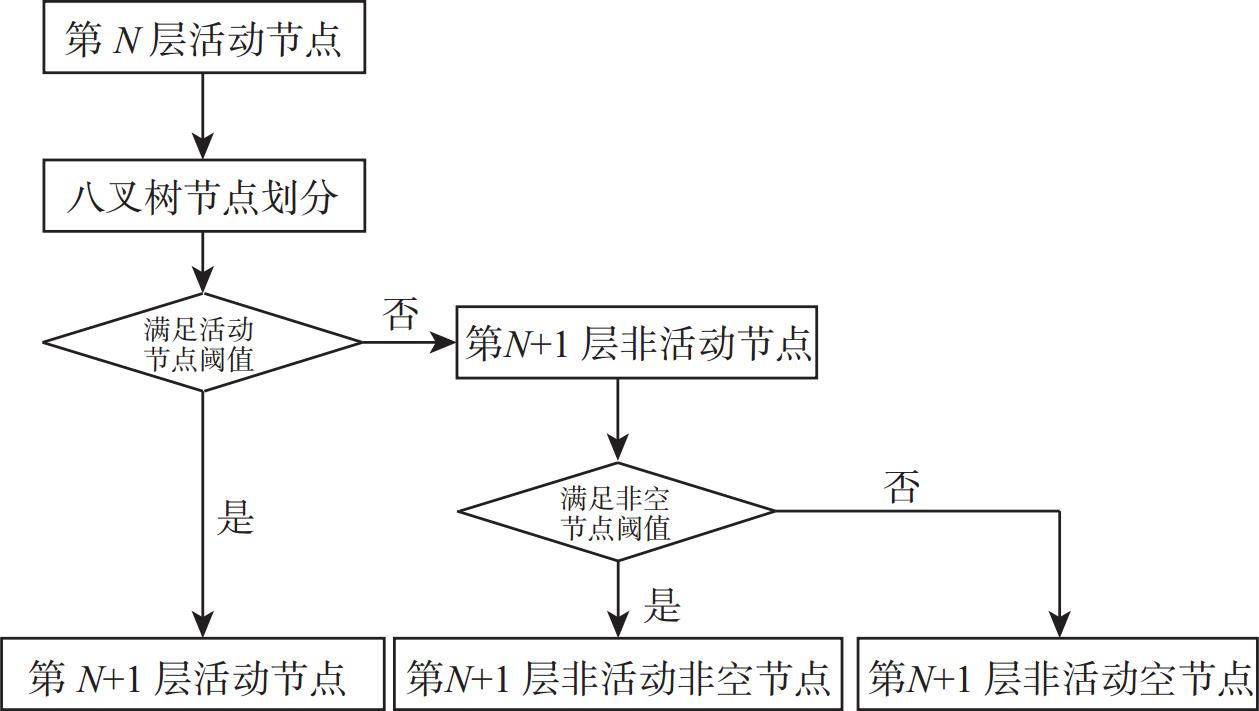

深层页岩气主要采用切割压裂技术开发,但基于微地震监测计算储层改造体积的压裂效果评价方法只适用于中深层页岩气体积压裂,不适用评价深层页岩气密切割压裂效果。为此,基于八叉树网格,建立了一种压裂复杂缝网面积估算模型,通过估算压裂复杂缝网面积评价深层页岩气密切割压裂效果。压裂复杂缝网面积估算模型将微地震事件分解为八叉树网格,并基于网格等效面积方法构建了三维复杂缝网面积等效模型,实现了在无需重构缝网的情况下对缝网面积的高效估算。为了定量评价所建模型的计算误差,建立了基于高斯混合模型的合成微地震事件点生成方法。模拟结果表明,压裂复杂缝网面积估算模型具有良好的计算效率和估算精度。现场应用实例表明,与传统的储层改造体积评价方法相比,储层改造缝网面积法能够更加精细地表征深层页岩气密切割压裂的效果。

Abstract:Deep shale gas is mainly developed by cutting fracturing technology. However, the fracturing effect evaluation method based on microseismic event monitoring for calculating stimulated reservoir volume (SRV) is only suitable for volume fracturing of shale gas wells in medium and deep formations, and it is not applicable for evaluating the tight cutting fracturing effectiveness of deep shale gas wells. Therefore, a model for estimating the area of complex fracture network based on the octree grid was established to evaluate the effectiveness of tight cutting fracturing in deep shale gas wells by estimating the complex fracture network area. This model decomposes microseismic events into octree grids and a three-dimensional complex fracture network area equivalent model based on the grid equivalent area method was constructed, by which the area of fracture network can be efficiently estimated without reconstructing the fracture network. In order to quantitatively evaluate the calculation error of this model, a set of synthetic microseismic event point generation methods based on the Gaussian mixture model was established. The simulation results show that this method has high calculation efficiency and estimation accuracy. Field application examples show that compared with the traditional SRV evaluation method, the method can more accurately evaluate the effectiveness of tight cutting fracturing in deep shale gas wells.

-

-

-

[1] 陈作,李双明,陈赞,等. 深层页岩气水力裂缝起裂与扩展试验及压裂优化设计[J]. 石油钻探技术,2020,48(3):70–76. doi: 10.11911/syztjs.2020060 CHEN Zuo, LI Shuangming, CHEN Zan, et al. Hydraulic fracture initiation and extending tests in deep shale gas formations and fracturing design optimization[J]. Petroleum Drilling Techniques, 2020, 48(3): 70–76. doi: 10.11911/syztjs.2020060

[2] 冯发勇,梁志彬,姚昌宇. 东胜气田锦 30 井区变黏压裂液体积压裂技术[J]. 石油钻采工艺,2022,44(6):740–745. FENG Fayong, LIANG Zhibin, YAO Changyu. SRV-oriented fracturing with viscosity-variable fracturing fluids in the Jin-30 well district, Dongsheng gas field[J]. Oil Drilling & Production Technology, 2022, 44(6): 740–745.

[3] 张矿生,薛小佳,陶亮,等. 页岩油水平井体积压裂缝网波及体积评价新方法及应用[J]. 特种油气藏,2023,30(5):127–134. ZHANG Kuangsheng, XUE Xiaojia, TAO Liang, et al. New method for evaluating the volume fracturing fracture network sweep volume in shale oil horizontal wells and its application[J]. Special Oil & Gas Reservoirs, 2023, 30(5): 127–134.

[4] 慕立俊,拜杰,齐银,等. 庆城夹层型页岩油地质工程一体化压裂技术[J]. 石油钻探技术,2023,51(5):33–41. MU Lijun, BAI Jie, QI Yin, et al. Geological engineering inte-grated fracturing technology for Qingcheng interlayer shale oil [J]. Petroleum Drilling Techniques, 2023, 51(5): 33–41.

[5] 胡东风,任岚,李真祥,等. 深层超深层页岩气水平井缝口暂堵压裂的裂缝调控模拟[J]. 天然气工业,2022,42(2):50–58. doi: 10.3787/j.issn.1000-0976.2022.02.006 HU Dongfeng, REN Lan, LI Zhenxiang, et al. Simulation of fracture control during fracture-opening temporary plugging fracturing of deep/ultra deep shale-gas horizontal wells[J]. Natural Gas Industry, 2022, 42(2): 50–58. doi: 10.3787/j.issn.1000-0976.2022.02.006

[6] GAO Qian, GHASSEMI A. Finite element simulations of 3D planar hydraulic fracture propagation using a coupled hydro-mechanical interface element[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2020, 44(15): 1999–2024. doi: 10.1002/nag.3116

[7] DAHI-TALEGHANI A, OLSON J E. Numerical modeling of multistranded-hydraulic-fracture propagation: accounting for the interaction between induced and natural fractures[J]. SPE Journal, 2011, 16(3): 575–581. doi: 10.2118/124884-PA

[8] OLSON J E. Multi-fracture propagation modeling: applications to hydraulic fracturing in shales and tight gas sands[R]. ARMA 08-327, 2008.

[9] ZHANG Fengshou, DAMJANAC B, MAXWELL S. Investigating hydraulic fracturing complexity in naturally fractured rock masses using fully coupled multiscale numerical modeling[J]. Rock Mechanics and Rock Engineering, 2019, 52(12): 5137–5160. doi: 10.1007/s00603-019-01851-3

[10] ZHUANG Xiaoying, ZHOU Shuwei, SHENG Mao, et al. On the hydraulic fracturing in naturally-layered porous media using the phase field method[J]. Engineering Geology, 2020, 266: 105306. doi: 10.1016/j.enggeo.2019.105306

[11] FISHER M K, HEINZE J R, HARRIS C D, et al. Optimizing horizontal completion techniques in the Barnett Shale using microseismic fracture mapping[R]. SPE 90051, 2004.

[12] HUGOT A, DULAC J C, GRINGARTEN E, et al. Connecting the dots: microseismic-derived connectivity for estimating volumes in low-permeability reservoirs[R]. URTEC 2153402, 2015.

[13] WU Yonghui, CHENG Linsong, KILLOUGH J, et al. Integrated characterization of the fracture network in fractured shale gas reservoir: stochastic fracture modeling, simulation and assisted history matching[J]. Journal of Petroleum Science and Engineering, 2021, 205: 108886. doi: 10.1016/j.petrol.2021.108886

[14] ZHOU Zhiwei, SU Yuliang, WANG Wendong, et al. Integration of microseismic and well production data for fracture network calibration with an L-system and rate transient analysis[J]. Journal of Unconventional Oil and Gas Resources, 2016, 15: 113–121. doi: 10.1016/j.juogr.2016.07.001

[15] YU Xin, RUTLEDGE J, LEANEY S, et al. Integration of microseismic data and an unconventional fracture modeling tool to generate the hydraulically induced fracture network: a case study from the Cardium Formation, West Central Alberta, Canada[R]. URTEC 2154594, 2015.

[16] MCCLURE M W, BABAZADEH M, SHIOZAWA S, et al. Fully coupled hydromechanical simulation of hydraulic fracturing in 3D discrete-fracture networks[J]. SPE Journal, 2016, 21(4): 1302–1320. doi: 10.2118/173354-PA

[17] WENG X, KRESSE O, COHEN C, et al. Modeling of hydraulic-fracture-network propagation in a naturally fractured formation[J]. SPE Production & Operations, 2011, 26(4): 368–380.

[18] MEAGHER D. Geometric modeling using octree encoding[J]. Computer Graphics and Image Processing, 1982, 19(2): 129–147. doi: 10.1016/0146-664X(82)90104-6

[19] SAMET H. Foundations of multidimensional and metric data structures[M]. San Francisco: Morgan Kaufmann Publishers Inc. , 2006.

[20] PULLI K, DUCHAMP T, HOPPE H, et al. Robust meshes from multiple range maps[C]//Proceedings. International Conference on Recent Advances in 3-D Digital Imaging and Modeling (Cat. No. 97TB100134). Piscataway, NJ: IEEE Press, 1997: 205-211.

[21] AYALA D, BRUNET P, JUAN R, et al. Object representation by means of nonminimal division quadtrees and octrees[J]. ACM Transactions on Graphics (TOG), 1985, 4(1): 41–59. doi: 10.1145/3973.3975

[22] FADAKAR ALGHALANDIS Y. ADFNE: Open source software for discrete fracture network engineering, two and three dimensional applications[J]. Computers & Geosciences, 2017, 102: 1–11.

[23] LIU Xing, JIN Yan, LIN Botao, et al. An integrated 3D fracture network reconstruction method based on microseismic events[J]. Journal of Natural Gas Science and Engineering, 2021, 95: 104182. doi: 10.1016/j.jngse.2021.104182

-

期刊类型引用(1)

1. 李璟. 面向机械设备钢材料磨损测量的改进线结构光方法研究. 国外电子测量技术. 2025(02): 193-198 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: