Development and Application of Intelligent Control Devices for BOPs

-

摘要:

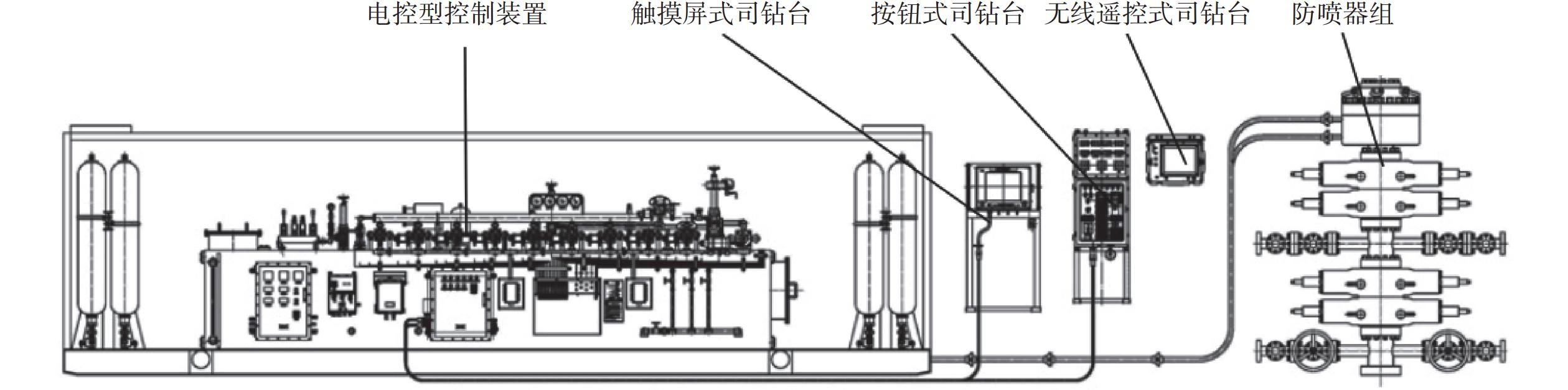

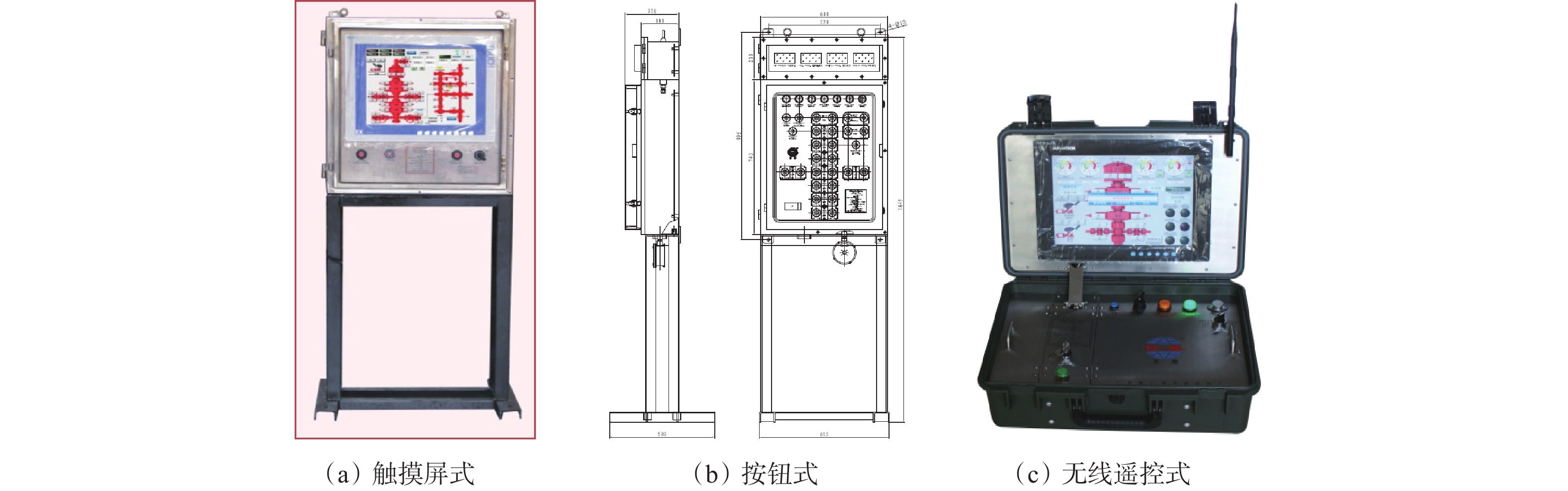

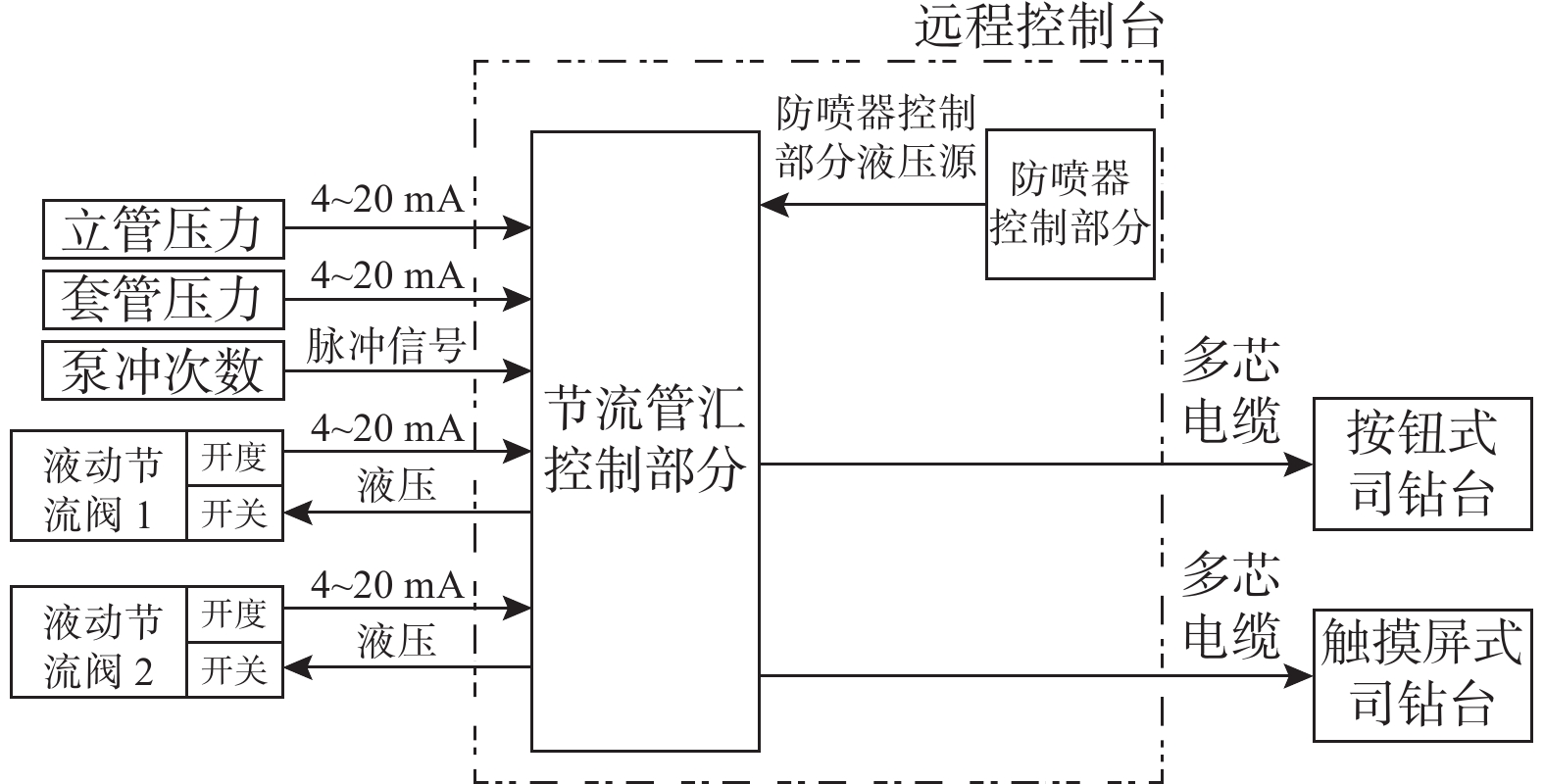

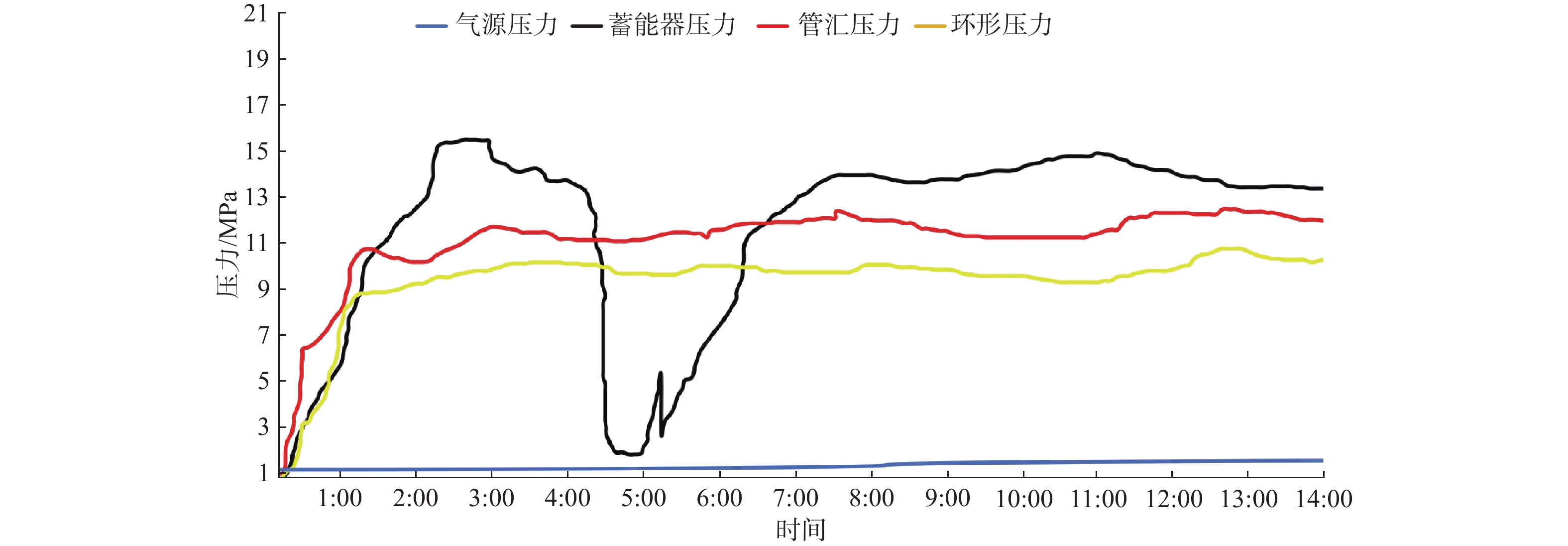

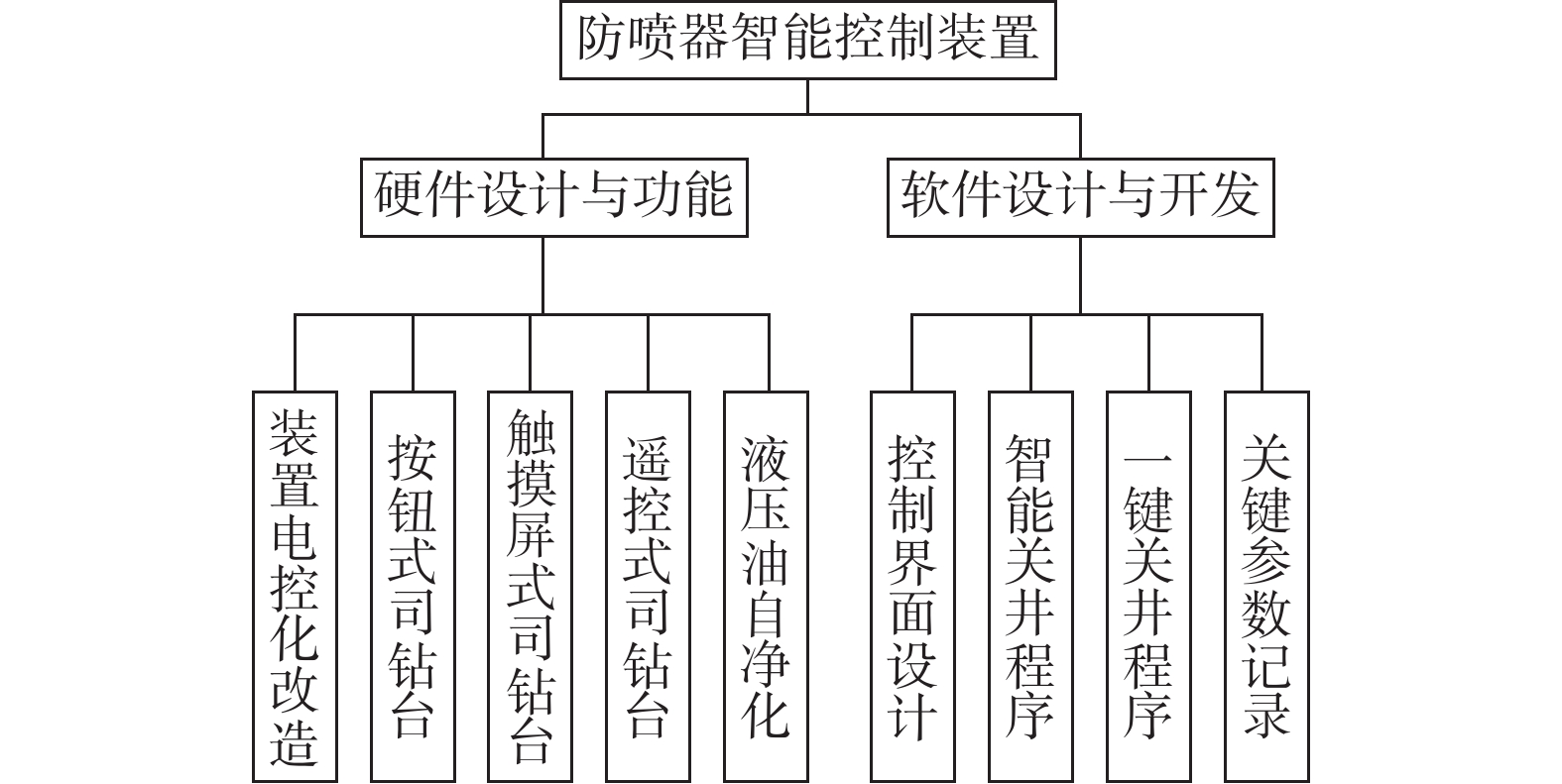

防喷器控制装置是控制井口防喷器组、井口阀门的主要设备,是钻井、修井过程中防止井喷、溢流和压井过程中必不可少的装置,但目前大量使用防喷器控制装置的控制手段单一,自动化程度低,关井需要多岗位配合操作,关井速度慢,且容易出现误操作。为此,通过对原有控制装置硬件改造升级及功能扩展,研制了防喷器智能控制装置,开发了智能关井控制软件,实现了钻井现场关井过程中防喷器、管汇阀门等控制对象的统一联动。现场50余口井的应用表明,防喷器智能控制装置具有自动化程度高、控制手段多样等特征,可大幅度提高关井效率和准确度,提升井控本质安全,具有良好的推广应用前景。

Abstract:The control device of blow-out preventers (BOPs) is the primary equipment for controlling the wellhead BOP assembly and wellhead valves. It is an essential device to prevent well blowouts, overflows and proceed well killing process during drilling and workover operations. However, current widely used control devices for BOPs have limited control methods and low automation level, and also require multi-position coordination for well shut-in operations, thus the well shut-in speed is slow and it is prone to misoperations. Therefore, through hardware upgrades and function expansions of existing control devices, an intelligent control device for BOPs was developed, and an intelligent well shut-in control software was developed to achieve unified coordination among various controlled objects such as BOPs and manifold valves during well shut-in operations at drilling sites. The application of more than 50 wells on site shows that this intelligent control device for BOPs has the characteristics of high level of automation, diverse control methods, etc. It could significantly improve well shut-in efficiency and accuracy and enhance intrinsic safety in well control, and have promising prospects for widespread application.

-

Keywords:

- BOP /

- control device /

- well control /

- intelligent shut-in /

- remote control

-

-

[1] 周宏宇,吴永良. 地面防喷器控制系统改进方案探讨[J]. 海洋石油,2020,40(1):84–89. ZHOU Hongyu, WU Yongliang. Research of improvement of ground blowout preventer control system[J]. Offshore Oil, 2020, 40(1): 84–89.

[2] SHAFIEE M, ELUSAKIN T, ENJEMA E. Subsea blowout preventer (BOP): design, reliability, testing, deployment, and operation and maintenance challenges[J]. Journal of Loss Prevention in the Process Industries, 2020, 66: 104170. doi: 10.1016/j.jlp.2020.104170

[3] 孟少辉,陈慧慧,蒋楠,等. 一种带气动试压功能的防喷器控制装置[J]. 液压气动与密封,2015,35(6):64–66. MENG Shaohui, CHEN Huihui, JIANG Nan, et al. A BOP control system with pneumatic pressure test function[J]. Hydraulics Pneumatics & Seals, 2015, 35(6): 64–66.

[4] 李正军,盖靖安. 防喷器远程控制装置自卸压四位四通转阀的研究与设计[J]. 石油钻采工艺,2022,44(6):706–710. LI Zhengjun, GE Jing’an. Research and design of four-position four-way rotary valve with automated pressure relief for blowout preventer remote control devices[J]. Oil Drilling & Production Technology, 2022, 44(6): 706–710.

[5] 刘玉华,寇镭,张瑾鹏. 防喷器控制装置的常见故障分析[J]. 中国设备工程,2023(12):166–168. LIU Yuhua, KOU Lei, ZHANG Jinpeng. Analysis of common malfunctions in the control device of blowout preventer[J]. China Plant Engineering, 2023(12): 166–168.

[6] PÁRRAGA QUISPE J L, ZHU Lei, ESTEFEN S F, et al. Ram performance and hydraulic modeling of subsea blowout preventer control system[J]. SPE Drilling & Completion, 2022, 37(4): 267–281.

[7] 李根生,宋先知,田守嶒. 智能钻井技术研究现状及发展趋势[J]. 石油钻探技术,2020,48(1):1–8. LI Gensheng, SONG Xianzhi, TIAN Shouceng. Intelligent drilling technology research status and development trends[J]. Petroleum Drilling Techniques, 2020, 48(1): 1–8.

[8] 王敏生,光新军. 智能钻井技术现状与发展方向[J]. 石油学报,2020,41(4):505–512. WANG Minsheng, GUANG Xinjun. Status and development trends of intelligent drilling technology[J]. Acta Petrolei Sinica, 2020, 41(4): 505–512.

[9] 伍贤柱,胡旭光,韩烈祥,等. 井控技术研究进展与展望[J]. 天然气工业,2022,42(2):133–142. WU Xianzhu, HU Xuguang, HAN Liexiang, et al. Research progress and prospect of well control technology[J]. Natural Gas Industry, 2022, 42(2): 133–142.

[10] 刘先明,胡益铭,张尧,等. 自动化关井技术研究现状及展望[J]. 钻采工艺,2023,46(4):45–50. LIU Xianming, HU Yiming, ZHANG Yao, et al. Research status and prospects on automated shut-in technology[J]. Drilling & Production Technology, 2023, 46(4): 45–50.

[11] JIA Jia, SU Yinao, SHEN Yue, et al. Influence of the blowout preventer shut-off process on wellbore pressure[J]. Chemistry and Technology of Fuels and Oils, 2021, 57(3): 571–581.

[12] 韦龙贵,张伟国,罗黎敏,等. 数字化井控技术研究现状及发展趋势[J]. 钻采工艺,2024,47(4):86–93. WEI Longgui, ZHANG Weiguo, LUO Limin, et al. Research status and development trends of digital well control technology[J]. Drilling & Production Technology, 2024, 47(4): 86–93.

[13] 张跃锋,茶拉,刘梦祥. 防喷器控制装置的研发与应用前景[J]. 石油机械,2011,39(5):64–66. ZHANG Yuefeng, CHA La, LIU Mengxiang. Research and application prospects of spray preventer control device[J]. China Petroleum Machinery, 2011, 39(5): 64–66.

[14] 姜东亮,郝斌,王欢,等. 电控型地面防喷器控制装置研制[J]. 石油矿场机械,2018,47(3):27–32. JIANG Dongliang, HAO Bin, WANG Huan, et al. Design of electrically controlled control device of ground blowout preventer[J]. Oil Field Equipment, 2018, 47(3): 27–32.

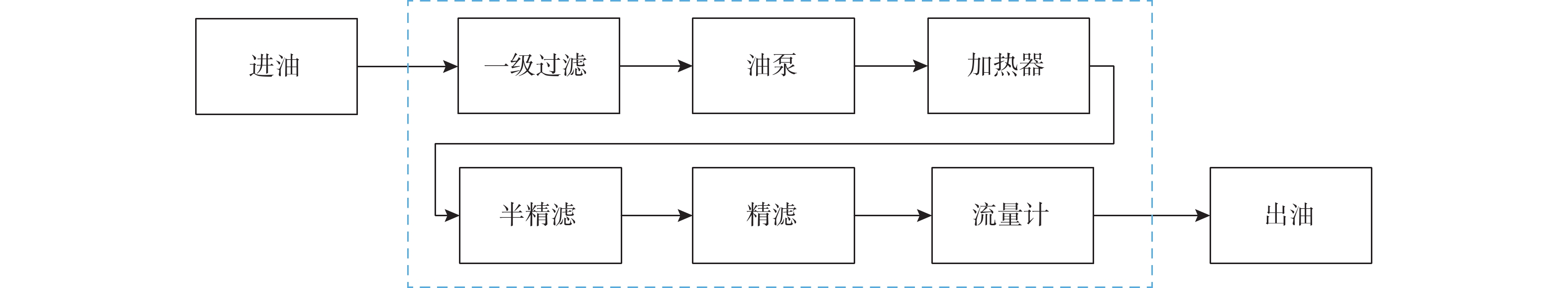

[15] 高敏,郝子轩. 防喷器控制系统新型液压油过滤装置研制[J]. 润滑与密封,2018,43(6):145–148. GAO Min, HAO Zixuan. Development of new hydraulic oil filter device for blowout preventer control system[J]. Lubrication Engineering, 2018, 43(6): 145–148.

[16] 刘书杰,杨向前,郭华,等. 井控系统智能化关井技术研究[J]. 煤炭技术,2017,36(6):303–305. LIU Shujie, YANG Xiangqian, GUO Hua, et al. Research forintelligent shut in well technology[J]. Coal Technology, 2017, 36(6): 303–305.

[17] 曹阳,方晓庆,张俊蓝,等. “三高” 气井井控配套新装置[J]. 天然气工业,2022,42(7):95–100. CAO Yang, FANG Xiaoqing, ZHANG Junlan, et al. New support devices of well control for “three-high” gas wells[J]. Natural Gas Industry, 2022, 42(7): 95–100.

[18] 李真祥,朱弘. 中国石化集团川渝地区井控技术现状及展望[J]. 钻采工艺,2024,47(4):29–34. LI Zhenxiang, ZHU Hong. Current situation and prospects of well control technology in the Sichuan Chongqing region of Sinopec Group[J]. Drilling & Production Technology, 2024, 47(4): 29–34.

-

期刊类型引用(8)

1. 姜振学,梁志凯,申颍浩,唐相路,吴伟,李卓,薛子鑫,石学文,郭婕. 川南泸州地区页岩气甜点地质工程一体化关键要素耦合关系及攻关方向. 地球科学. 2023(01): 110-129 .  百度学术

百度学术

2. 唐波涛,曾冀,陈伟华,陈一鑫,王涛,刘成,冯逢. 川中秋林地区致密砂岩水平井多簇射孔优化设计方法及应用效果. 油气藏评价与开发. 2022(02): 337-344 .  百度学术

百度学术

3. 田福春,刘学伟,张胜传,张高峰,邵力飞,陈紫薇. 大港油田陆相页岩油滑溜水连续加砂压裂技术. 石油钻探技术. 2021(04): 118-124 .  本站查看

本站查看

4. 王天驹,陈赞,王蕊,吴春方,徐鸿志,郝志伟. 致密砂岩油藏体积压裂簇间距优化新方法. 新疆石油地质. 2019(03): 351-356 .  百度学术

百度学术

5. 黄进,吴雷泽,游园,黄晓凯,聂彬,张辉. 涪陵页岩气水平井工程甜点评价与应用. 石油钻探技术. 2016(03): 16-20 .  本站查看

本站查看

6. 刘雨,艾池. 多级压裂诱导应力作用下天然裂缝开启规律研究. 石油钻探技术. 2015(01): 20-26 .  本站查看

本站查看

7. 曾青冬,姚军. 基于颗粒流的页岩破裂机理试验研究. 石油钻探技术. 2015(01): 33-37 .  本站查看

本站查看

8. 赵崇镇. 深层砂砾岩水平井组立体缝网压裂优化技术. 石油钻探技术. 2014(05): 95-99 .  本站查看

本站查看

其他类型引用(6)

下载:

下载: