Key Drilling Technologies for Increasing ROP in Ultra-Deep Well Yuanshen 1

-

摘要:

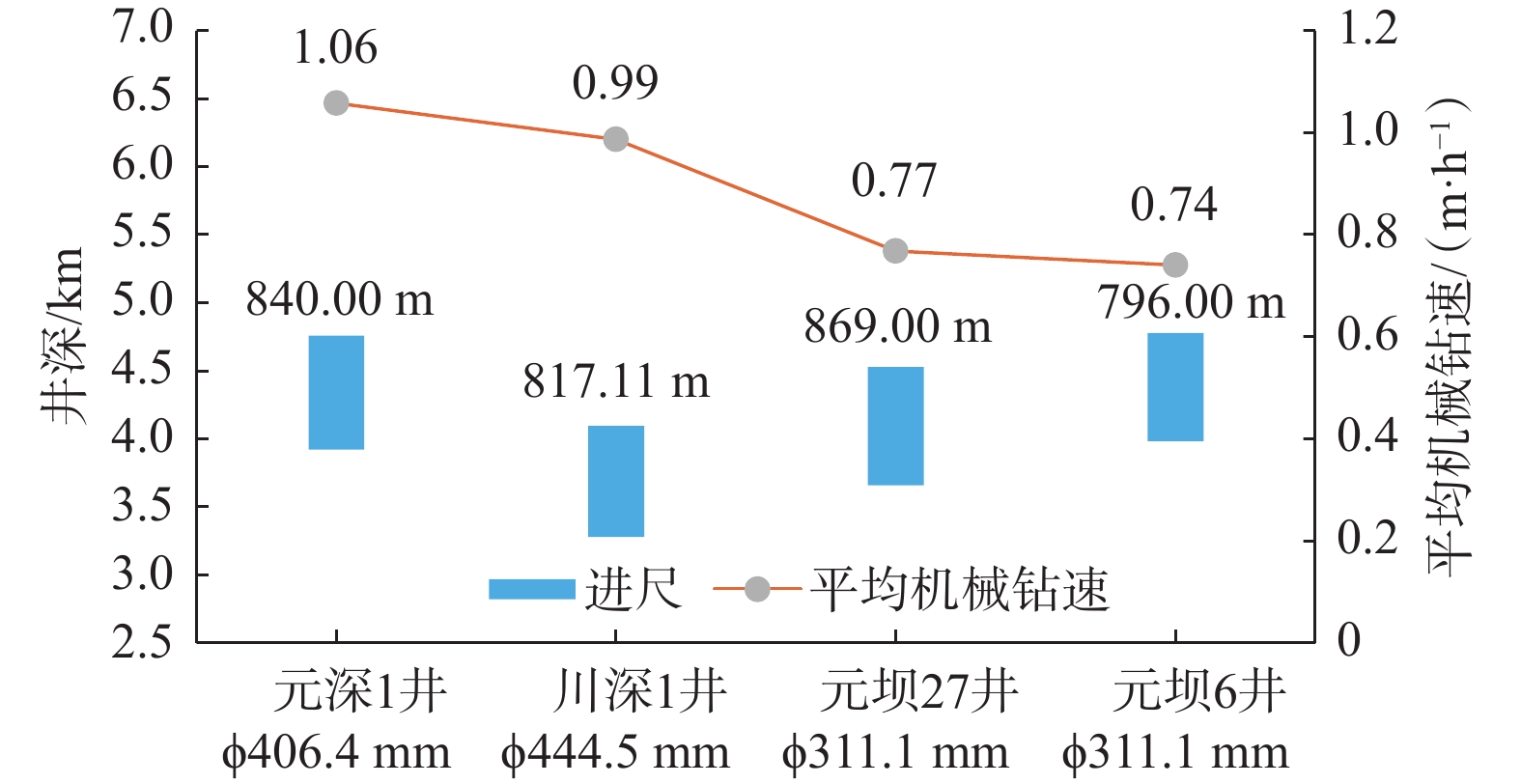

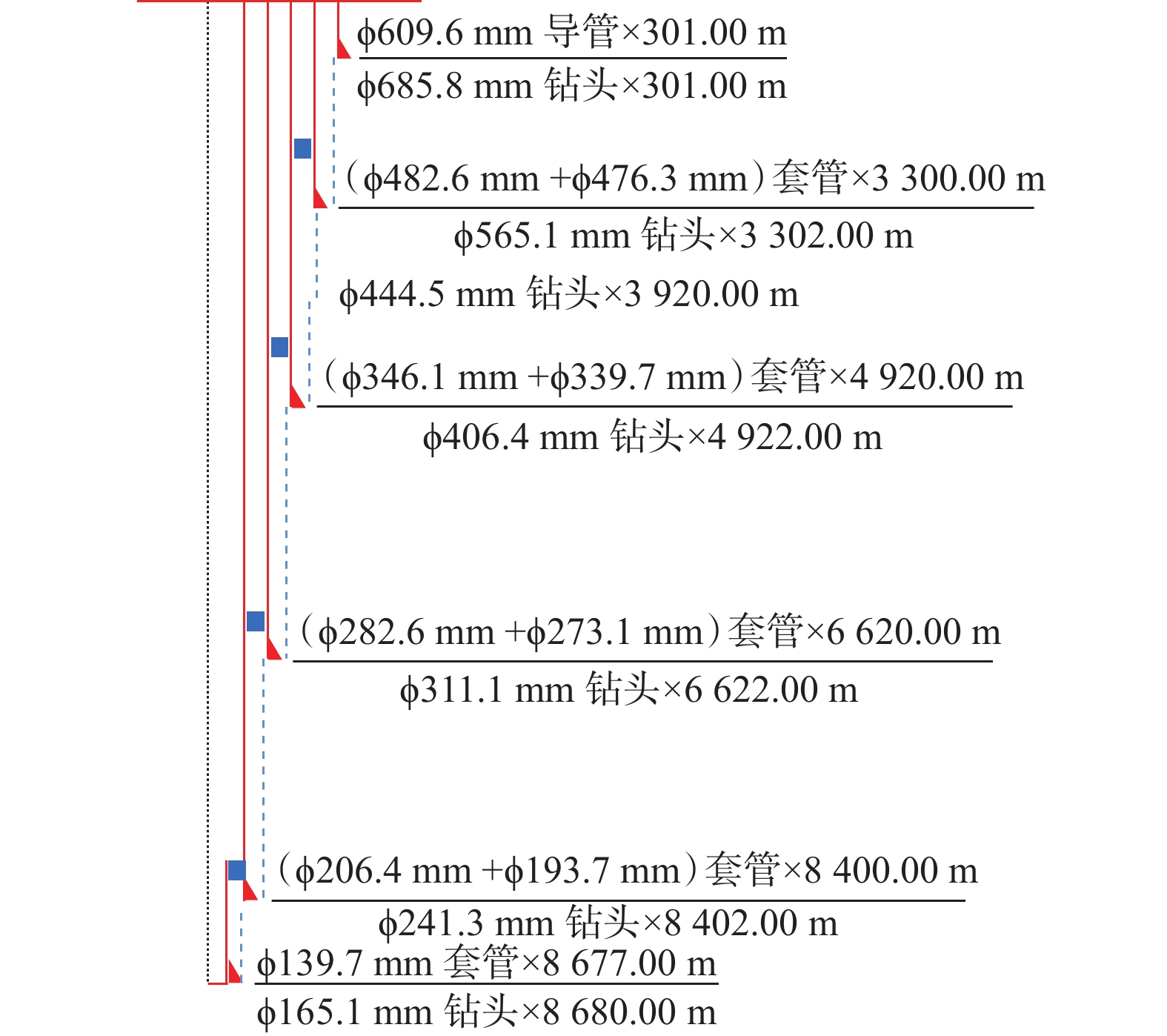

元深1井是部署在川北低缓构造带上的重点探井,钻井过程中面临地层压力体系复杂、井眼易坍塌、钻井液易漏失、陆相地层研磨性强、井控风险高等技术难题。根据地质特征,借鉴邻井钻井经验,应用泡沫钻井技术,提高浅部地层大尺寸井眼机械钻速;应用“涡轮钻具+孕镶金刚石钻头”和“旋冲钻具+混合式钻头”提速技术,解决陆相高研磨性地层机械钻速低的难题;应用耐高温防漏堵漏钻井液,配套“高效PDC钻头+大扭矩螺杆”提速技术,实现海相多压力体系复杂地层安全快速钻进;用微心PDC钻头钻进目的层,在满足岩屑录井需要的同时,提高了钻井效率。该井顺利钻至井深8 866.00 m完钻,创中国石化四川盆地直井井深最深纪录,为四川盆地超深井钻井积累了经验。

Abstract:Well Yuanshen 1 is a key exploration well located in the gentle structural belt of northern Sichuan. The drilling process encountered several technical challenges, including complex formation pressure systems, borehole collapse, drilling fluid loss, strong terrestrial formation abrasiveness, and high risk of well control, etc. Based on the geological characteristics and drilling experiences of adjacent wells, a series of drilling technologies were implemented to increase the rate of penetration (ROP). Foam drilling technology was utilized to improve the ROP in large boreholes within shallow formations. For the highly abrasive terrestrial formations, the technologies of “turbodrill+impregnated diamond bit”and“rotary percussion drilling rig+hybrid drilling bit”were employed to enhance ROP. The combination of high-temperature, leak-proof drilling fluid with “high-efficiency polycrystalline diamond compact (PDC) bit+high torque screw” technology enabled safe and rapid drilling in the complex formations of the marine multi-pressure system. The microcore PDC bit was used to drill into the target zone, enhancing drilling efficiency while meeting the needs of cuttings logging. The well was successfully drilled to a depth of 8 866.00 meters, setting a Sinopec’s record for the deepest vertical well in the Sichuan Basin. This achievement provided technical experience for ultra-deep well drilling in the Sichuan Basin.

-

Keywords:

- ultra-deep well /

- deep well drilling /

- rate of penetration /

- Well Yuanshen 1 /

- Yuanba Gas Field

-

-

表 1 元深1井泡沫钻井提速效果统计结果

Table 1 Statistics of foam drilling effect for increasing ROP in Well Yuanshen 1

钻井方式 钻进井段/m 进尺/m 纯钻时

间/h平均机械

钻速/( m·h−1)泡沫钻井 0~300.00 300.00 66.0 4.55 300.00~1176.00 871.00 122.0 7.14 1176.00~1435.00 259.00 37.0 7.00 1435.00~1836.00 401.00 87.0 4.61 1836.00~2000.00 164.00 19.5 8.41 常规钻井 2000.00~2307.00 307.00 87.0 3.53 -

[1] 李辉,朱祥,李毕松,等. 四川盆地北部震旦系天然气勘探潜力分析[J]. 特种油气藏,2018,25(1):52–57. doi: 10.3969/j.issn.1006-6535.2018.01.011 LI Hui, ZHU Xiang, LI Bisong, et al. Sinian natural gas exploration potential analysis in the northern Sichuan Basin[J]. Special Oil & Gas Reservoirs, 2018, 25(1): 52–57. doi: 10.3969/j.issn.1006-6535.2018.01.011

[2] 何治亮,金晓辉,沃玉进,等. 中国海相超深层碳酸盐岩油气成藏特点及勘探领域[J]. 中国石油勘探,2016,21(1):3–14. HE Zhiliang, JIN Xiaohui, WO Yujin, et al. Hydrocarbon accumulation characteristics and exploration domains of ultra-deep marine carbonates in China[J]. China Petroleum Exploration, 2016, 21(1): 3–14.

[3] 贾利春,李枝林,张继川,等. 川南海相深层页岩气水平井钻井关键技术与实践[J]. 石油钻采工艺,2022,44(2):145–152. JIA Lichun, LI Zhilin, ZHANG Jichuan, et al. Key technology and practice of horizontal drilling for marine deep shale gas in southern Sichuan Basin[J]. Oil Drilling & Production Technology, 2022, 44(2): 145–152.

[4] 王明筏,文虎,倪楷,等. 四川盆地北部大隆组页岩气地质条件及勘探潜力[J]. 西南石油大学学报(自然科学版),2023,45(1):13–23. WANG Mingfa, WEN Hu, NI Kai, et al. Geological conditions and exploration potential of shale gas in Dalong Formation in Northern Sichuan Basin[J]. Journal of Southwest Petroleum University (Science & Technology Edition), 2023, 45(1): 13–23.

[5] 尚墨翰,赵向原,胡向阳,等. 川东北元坝地区陆相储层天然裂缝发育特征及分布模式[J]. 断块油气田,2022,29(1):8–13. SHANG Mohan, ZHAO Xiangyuan, HU Xiangyang, et al. Development characteristics and distribution patterns of natural fractures of continental reservoir in Yuanba area, northeastern Sichuan Basin[J]. Fault-Block Oil %amp; Gas Field, 2022, 29(1): 8–13.

[6] 陶夏妍,黄天俊,张艺华,等. 四川盆地东北部三叠系飞仙关组迁移型鲕滩层序地层分析及相控储层预测[J]. 特种油气藏,2023,30(6):62–71. doi: 10.3969/j.issn.1006-6535.2023.06.009 TAO Xiayan, HUANG Tianjun, ZHANG yihua, et al. Sequence stratigraphical analysis and facies-controlled reservoir prediction of migratory oolitic beach in Triassic Feixianguan Formation, northeastern Sichuan Basin[J]. Special Oil & Gas Reservoirs, 2023, 30(6): 62–71. doi: 10.3969/j.issn.1006-6535.2023.06.009

[7] 舒逸,郑有恒,包汉勇,等. 四川盆地复兴地区下侏罗统页岩油气富集高产主控因素[J]. 世界石油工业,2023,30(5):26–38. SHU Yi, ZHENG Y H, BAO H Y, et al. Main controlling factors for high yield and enrichment of shale oil and gas in the Lower Jurassic in the Fuxing Area of Sichuan Basin[J]. World Petroleum Industry, 2023, 30(5): 26–38.

[8] 葛鹏飞,马庆涛,张栋. 元坝地区超深井井身结构优化及应用[J]. 石油钻探技术,2013,41(4):83–86. doi: 10.3969/j.issn.1001-0890.2013.04.018 GE Pengfei, MA Qingtao, ZHANG Dong. Optimization and application of ultra-deep well casing program in Yuanba Area[J]. Petroleum Drilling Techniques, 2013, 41(4): 83–86. doi: 10.3969/j.issn.1001-0890.2013.04.018

[9] 张金成,张东清,张新军. 元坝地区超深井钻井提速难点与技术对策[J]. 石油钻探技术,2011,39(6):6–10. doi: 10.3969/j.issn.1001-0890.2011.06.002 ZHANG Jincheng, ZHANG Dongqing, ZHANG Xinjun. Difficulties of improving rate of penetration and its technical solutions in Yuanba Area[J]. Petroleum Drilling Techniques, 2011, 39(6): 6–10. doi: 10.3969/j.issn.1001-0890.2011.06.002

[10] 邓虎,贾利春. 四川盆地深井超深井钻井关键技术与展望[J]. 天然气工业,2022,42(12):82–94. DENG Hu, JIA Lichun. Key technologies for drilling deep and ultra-deep wells in the Sichuan Basin: Current status, challenges and prospects[J]. Natural Gas Industry, 2022, 42(12): 82–94.

[11] 李涛,苏强,杨哲,等. 川西地区超深井钻井完井技术现状及攻关方向[J]. 石油钻探技术,2023,51(2):7–15. doi: 10.11911/syztjs.2022028 LI Tao, SU Qiang, YANG Zhe, et al. Current practices and research directions for drilling and completion technologies for ultra-deep wells in western Sichuan[J]. Petroleum Drilling Techniques, 2023, 51(2): 7–15. doi: 10.11911/syztjs.2022028

[12] 叶金龙,沈建文,吴玉君,等. 川深1井超深井钻井提速关键技术[J]. 石油钻探技术,2019,47(3):121–126. doi: 10.11911/syztjs.2019056 YE Jinlong, SHEN Jianwen, WU Yujun, et al. Key techniques of drilling penetration rate improvement in ultra-deep Well Chuanshen-1[J]. Petroleum Drilling Techniques, 2019, 47(3): 121–126. doi: 10.11911/syztjs.2019056

[13] 贾俊,康海涛,刘洪彬,等. MS1井超深海相地层取心实践与认识[J]. 钻采工艺,2021,44(1):142–146. doi: 10.3969/J.ISSN.1006-768X.2021.01.32 JIA Jun, KANG Haitao, LIU Hongbin, et al. Practice and recognitions of coring in the super deep marine strata of Well MS-1[J]. Drilling & Production Technology, 2021, 44(1): 142–146. doi: 10.3969/J.ISSN.1006-768X.2021.01.32

[14] 曹品鲁,马文英,张兆国,等. 可循环空气泡沫钻井技术在元坝10井的应用[J]. 石油钻探技术,2011,39(5):49–52. doi: 10.3969/j.issn.1001-0890.2011.05.011 CAO Pinlu, MA Wenying, ZHANG Zhaoguo, et al. Application of recycling air-foam drilling technology in Well Yuanba-10[J]. Petroleum Drilling Techniques, 2011, 39(5): 49–52. doi: 10.3969/j.issn.1001-0890.2011.05.011

[15] 彭齐,周英操,周波,等. 凸脊型非平面齿PDC钻头的研制与现场试验[J]. 石油钻探技术,2020,48(2):49–55. doi: 10.11911/syztjs.2020035 PENG Qi, ZHOU Yingcao, ZHOU Bo, et al. Development and field test of a non-planar cutter PDC bit with convex ridges[J]. Petroleum Drilling Techniques, 2020, 48(2): 49–55. doi: 10.11911/syztjs.2020035

[16] 王滨,李军,邹德永,等. 适合强研磨性硬地层PDC-金刚石孕镶块混合钻头设计与应用[J]. 特种油气藏,2018,25(1):169–174. doi: 10.3969/j.issn.1006-6535.2018.01.035 WANG Bin, LI Jun, ZOU Deyong, et al. Design and application of a PDC hybrid drill bit with impregnated diamond insert for the hard formation with strong abrasivity[J]. Special Oil & Gas Reservoirs, 2018, 25(1): 169–174. doi: 10.3969/j.issn.1006-6535.2018.01.035

[17] 高德利,刘维,万绪新,等. PDC钻头钻井提速关键影响因素研究[J]. 石油钻探技术,2023,51(4):20–34. doi: 10.11911/syztjs.2023022 GAO Deli, LIU Wei, WAN Xuxin, et al. Study on key factors influencing the ROP improvement of PDC bits[J]. Petroleum Drilling Techniques, 2023, 51(4): 20–34. doi: 10.11911/syztjs.2023022

[18] 解兰宏,张金成,张东清,等. 涡轮钻井技术在元坝等重点区块的应用[J]. 石油钻探技术,2011,39(6):15–18. doi: 10.3969/j.issn.1001-0890.2011.06.004 XIE Lanhong, ZHANG Jincheng, ZHANG Dongqing, et al. The application of turbo drilling technology in Yuanba key area[J]. Petroleum Drilling Techniques, 2011, 39(6): 15–18. doi: 10.3969/j.issn.1001-0890.2011.06.004

[19] 王甲昌,滕春鸣,张海平,等. 机械式旋转冲击钻井工具研制及试验[J]. 钻采工艺,2020,43(6):68–71. WANG Jiachang, TENG Chunming, ZHANG Haiping, et al. Development and experiment of rotary percussion positive displacement motor[J]. Drilling & Production Technology, 2020, 43(6): 68–71.

[20] 田京燕,徐玉超. 微心PDC钻头设计及现场试验[J]. 石油钻探技术,2019,47(1):65–68. doi: 10.11911/syztjs.2018134 TIAN Jingyan, XU Yuchao. Design and field application of a micro-coring PDC bit[J]. Petroleum Drilling Techniques, 2019, 47(1): 65–68. doi: 10.11911/syztjs.2018134

[21] 王涛,刘锋报,罗威,等. 塔里木油田防漏堵漏技术进展与发展建议[J]. 石油钻探技术,2021,49(1):28–33. doi: 10.11911/syztjs.2020080 WANG Tao, LIU Fengbao, LUO Wei, et al. The technical advance and development suggestions for leakage prevention and plugging technologies in the Tarim Oilfield[J]. Petroleum Drilling Techniques, 2021, 49(1): 28–33. doi: 10.11911/syztjs.2020080

[22] 刘书杰,刘和兴,王成文,等. 超深水裂缝储层自降解随钻堵漏剂性能研究[J]. 中国海上油气,2022,34(2):107–115. doi: 10.11935/j.issn.1673-1506.2022.02.013 LIU Shujie, LIU Hexing, WANG Chengwen, et al. Study on properties of self-degrading lost circulation agent while drilling in ultra-deepwater fractured reservoir[J]. China Offshore Oil and Gas, 2022, 34(2): 107–115. doi: 10.11935/j.issn.1673-1506.2022.02.013

-

期刊类型引用(3)

1. 徐浩,周文,周秋媚,何建华,邓乃尔,钟治奇,蒋柯,曹茜,武瑾. 含油气盆地中有机成因天然氢气形成初探. 成都理工大学学报(自然科学版). 2025(02): 330-343 .  百度学术

百度学术

2. 史配铭,倪华峰,贺会锋,石崇东,李录科,张延兵. 鄂尔多斯盆地深层煤岩气水平井水平段安全钻井关键技术. 石油钻探技术. 2025(01): 17-23 .  本站查看

本站查看

3. 陈波,谭枭麒. MO-DRILL油基钻井液体系在东海油气田的优化与应用. 山东化工. 2024(23): 198-200 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: