Dynamic Fatigue Failure Characteristics and Parameter Optimization ofDrill Strings in Ultra-Deep Wells

-

摘要:

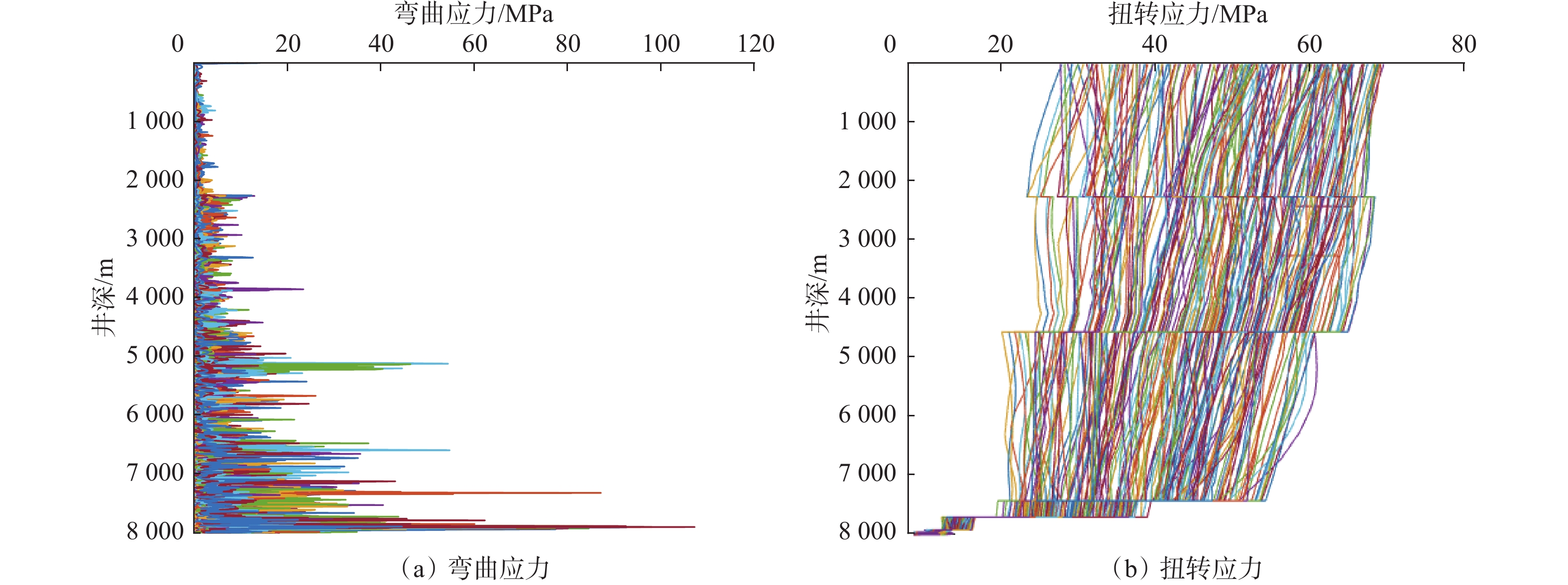

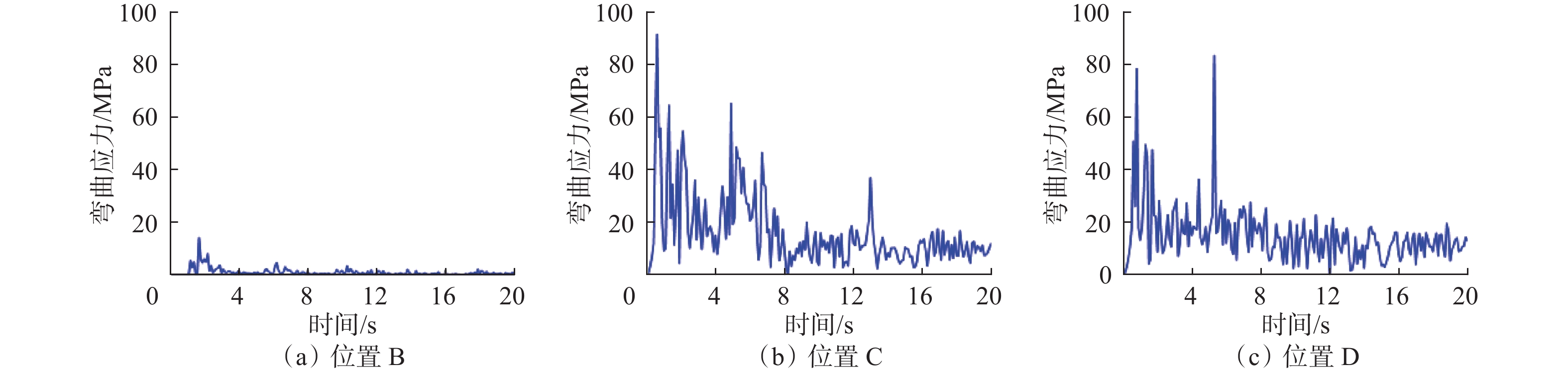

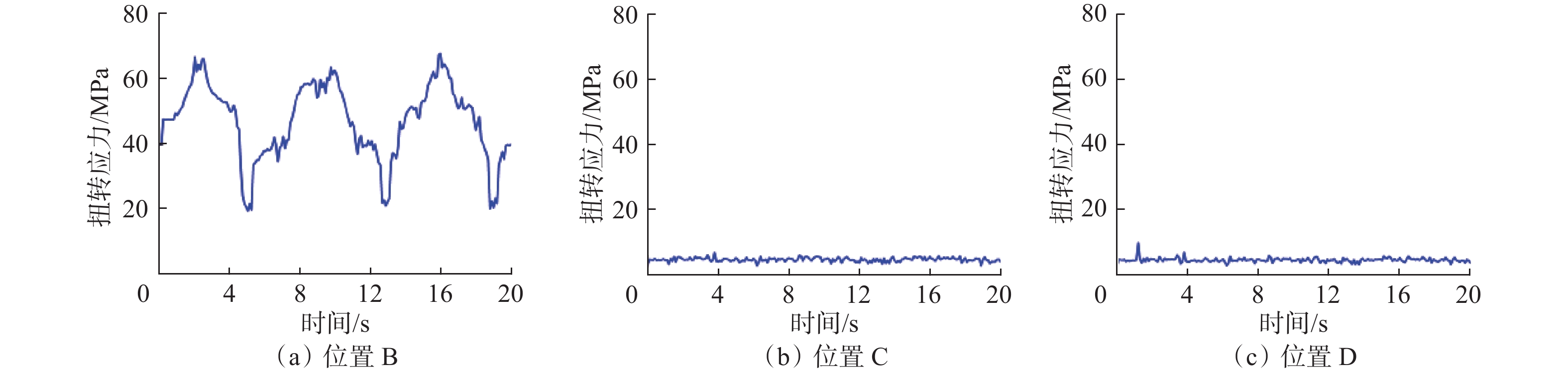

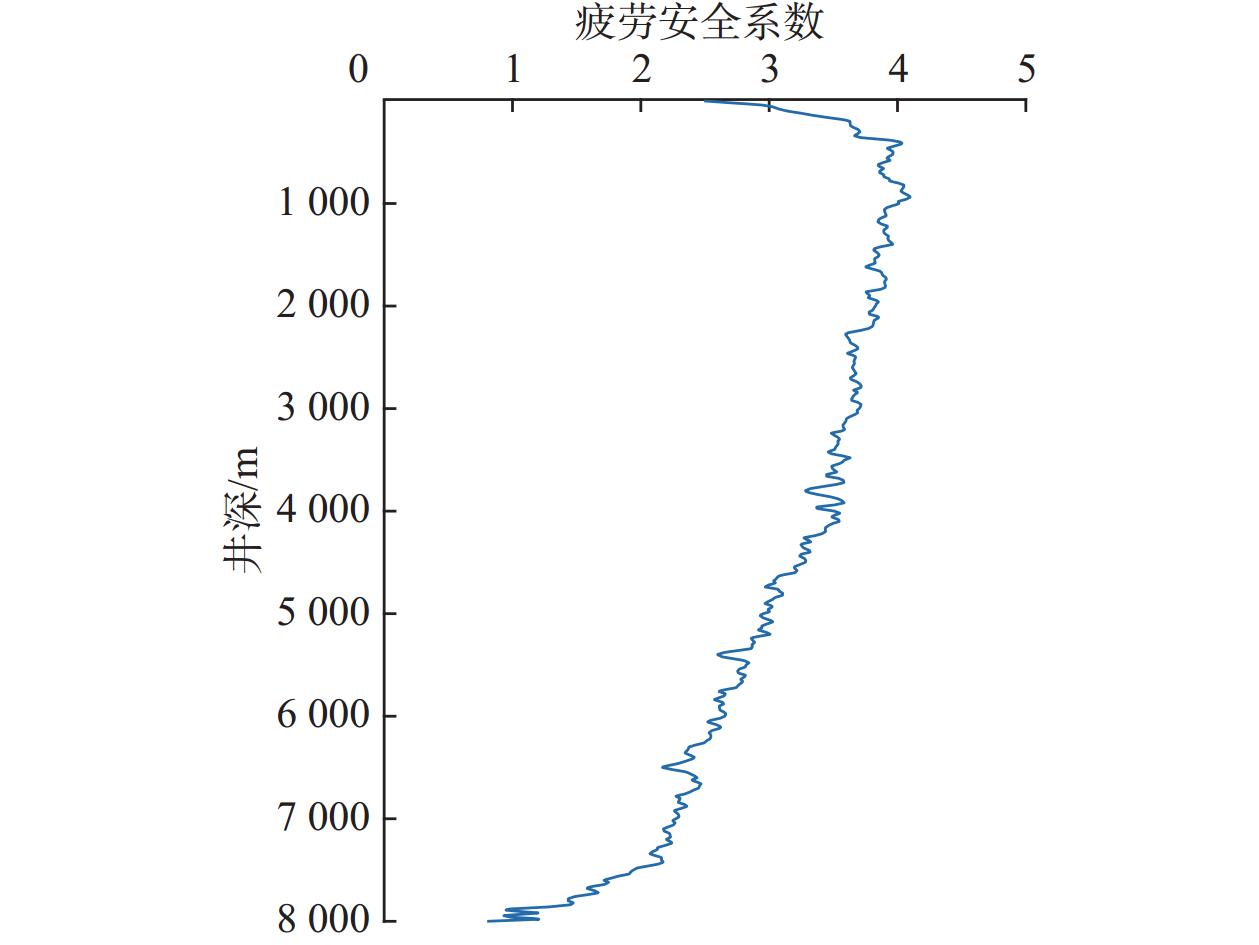

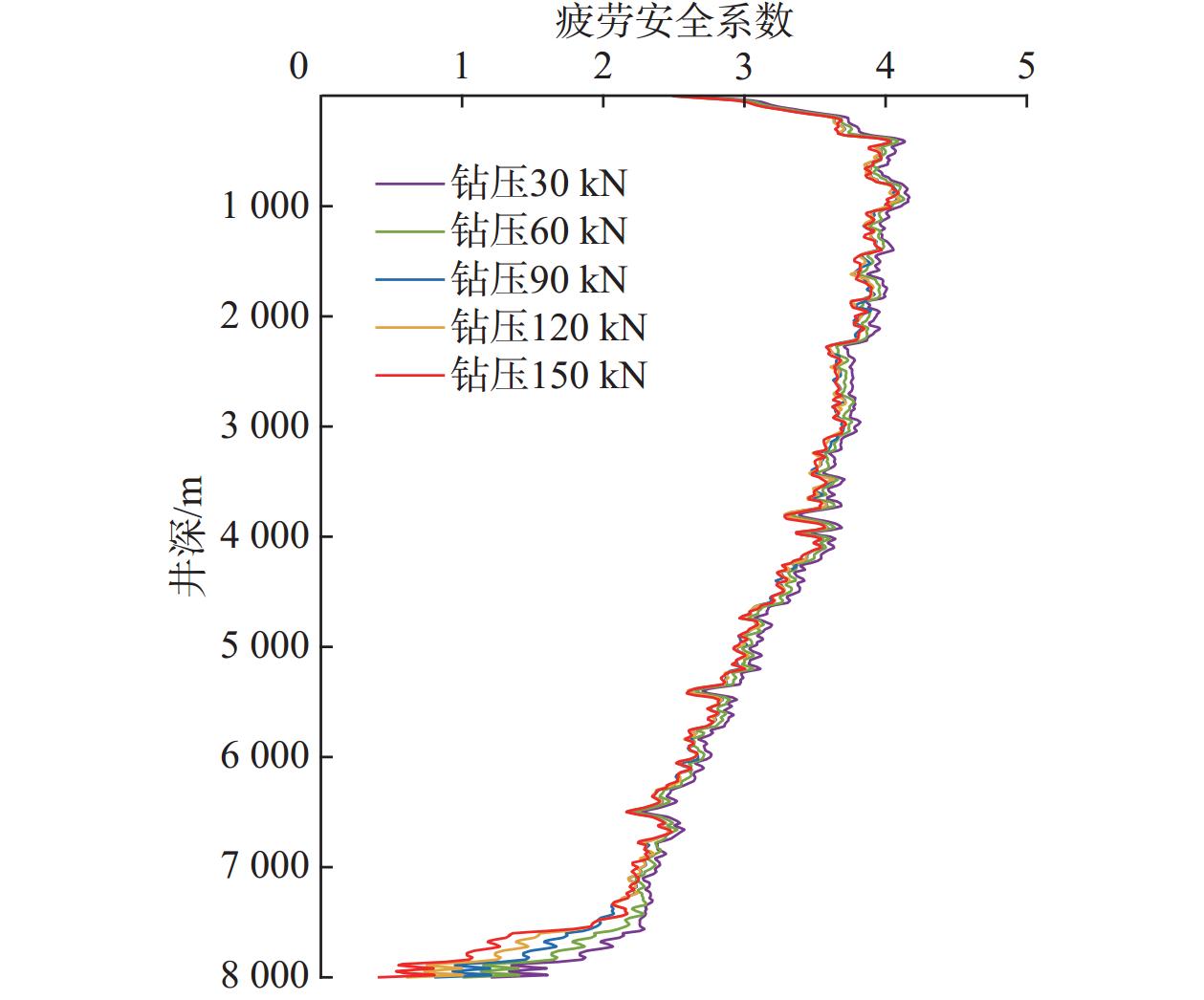

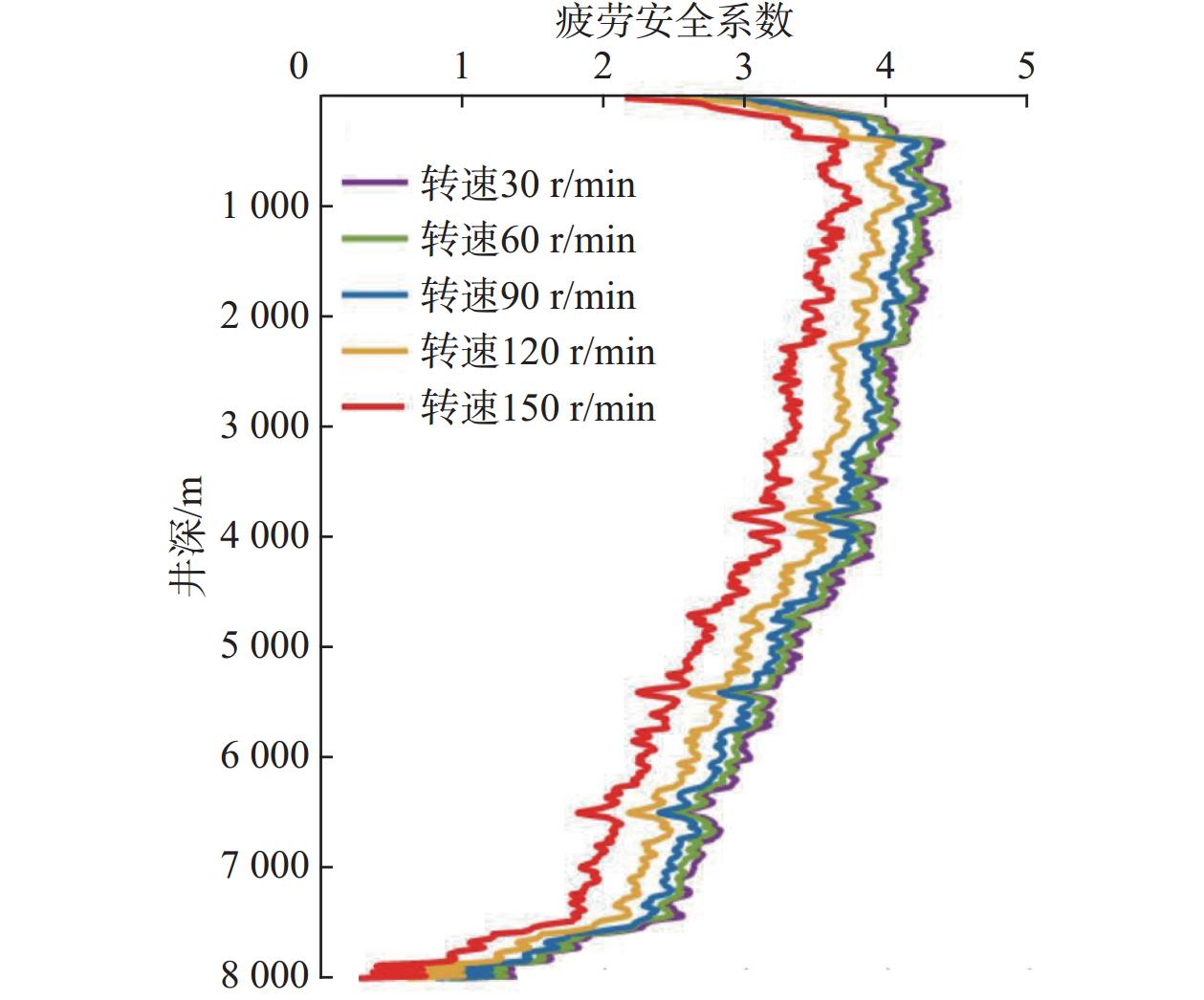

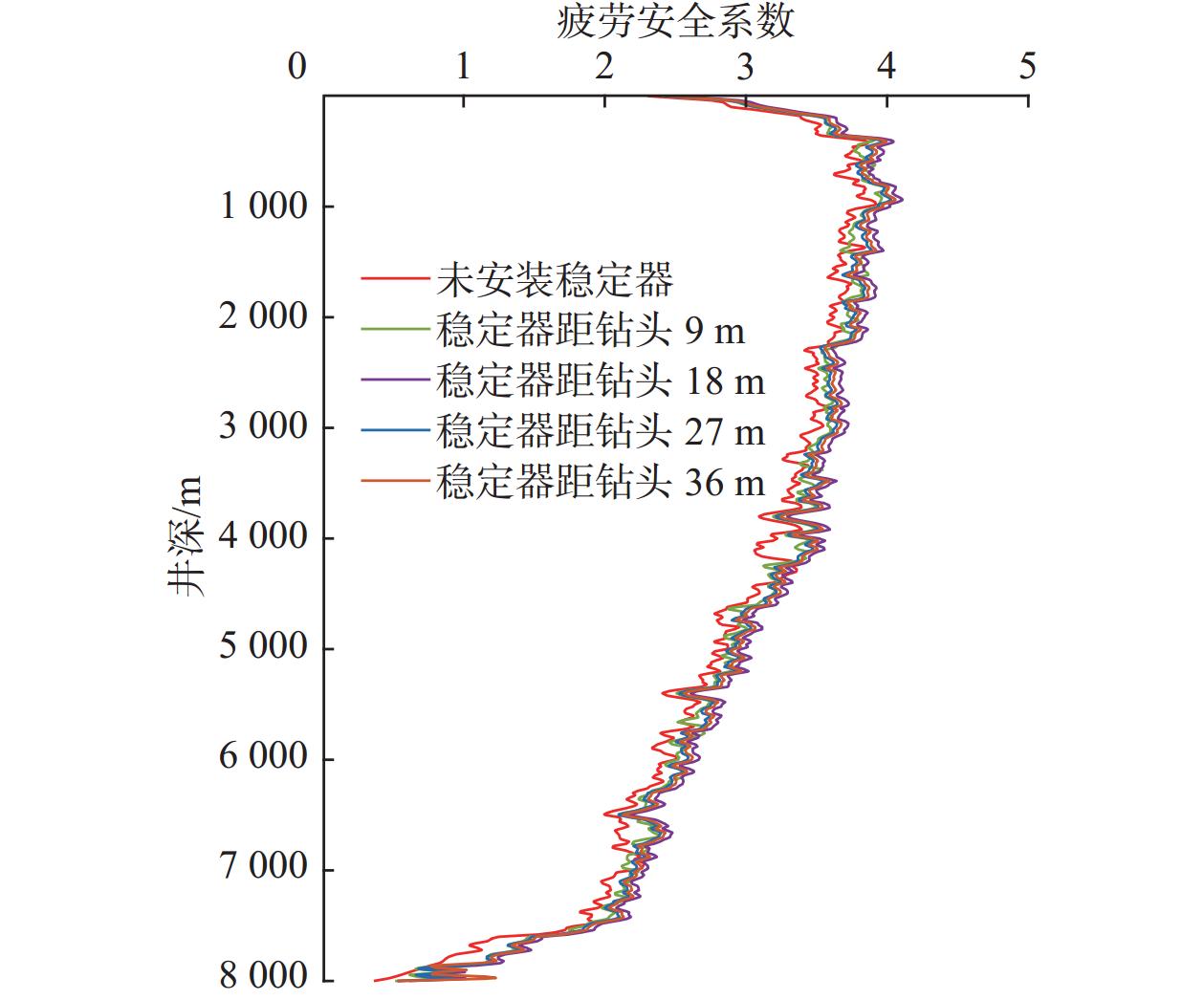

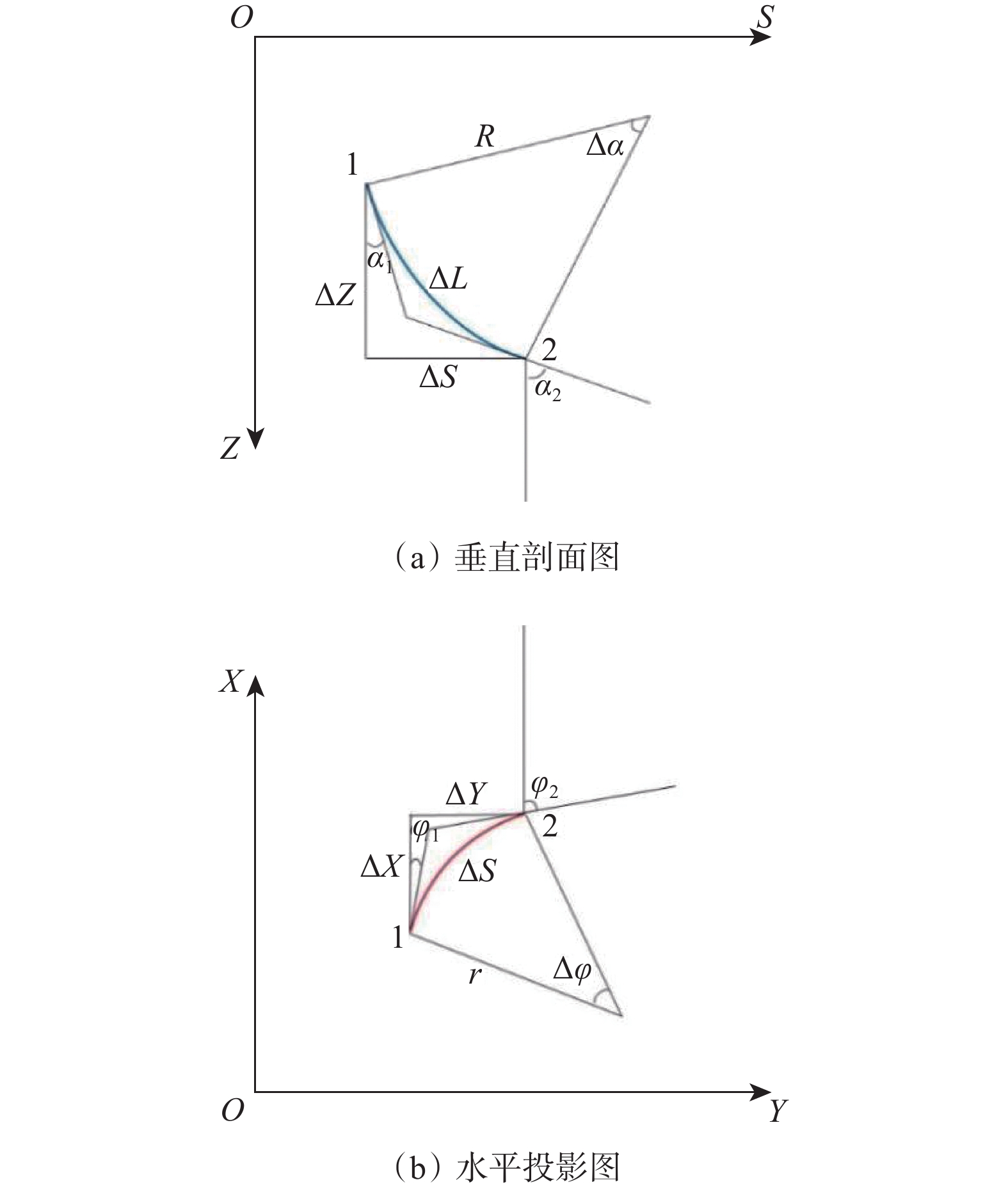

随着油气勘探深度不断增大,超深井钻柱井下振动更加复杂,应力状态随时间变化显著,为保障超深井钻柱的安全性,开展了受空间挠曲井筒约束超细长钻柱的动态疲劳失效特征研究,并进行钻柱结构及工作参数优选。基于实际井眼轨迹,考虑钻柱与井壁的碰撞特征,通过有限元仿真分析,得到全井钻柱动力学特性;根据疲劳损伤累积理论,研究了超深井全井钻柱在非对称循环变幅应力状态下的疲劳强度;结合现场实例,研究了超深井钻柱的危险截面,分析了钻柱疲劳强度随转速、钻压和稳定器安装位置的变化规律。研究表明:钻压和高转速对钻柱疲劳强度的影响较大,低转速对钻柱疲劳强度的影响较小;稳定器可以大幅降低底部钻具组合疲劳失效的概率,而且稳定器安装位置对钻柱疲劳强度的影响较为显著。研究结果为超深井钻柱组合结构参数和钻井参数优选提供了理论依据。

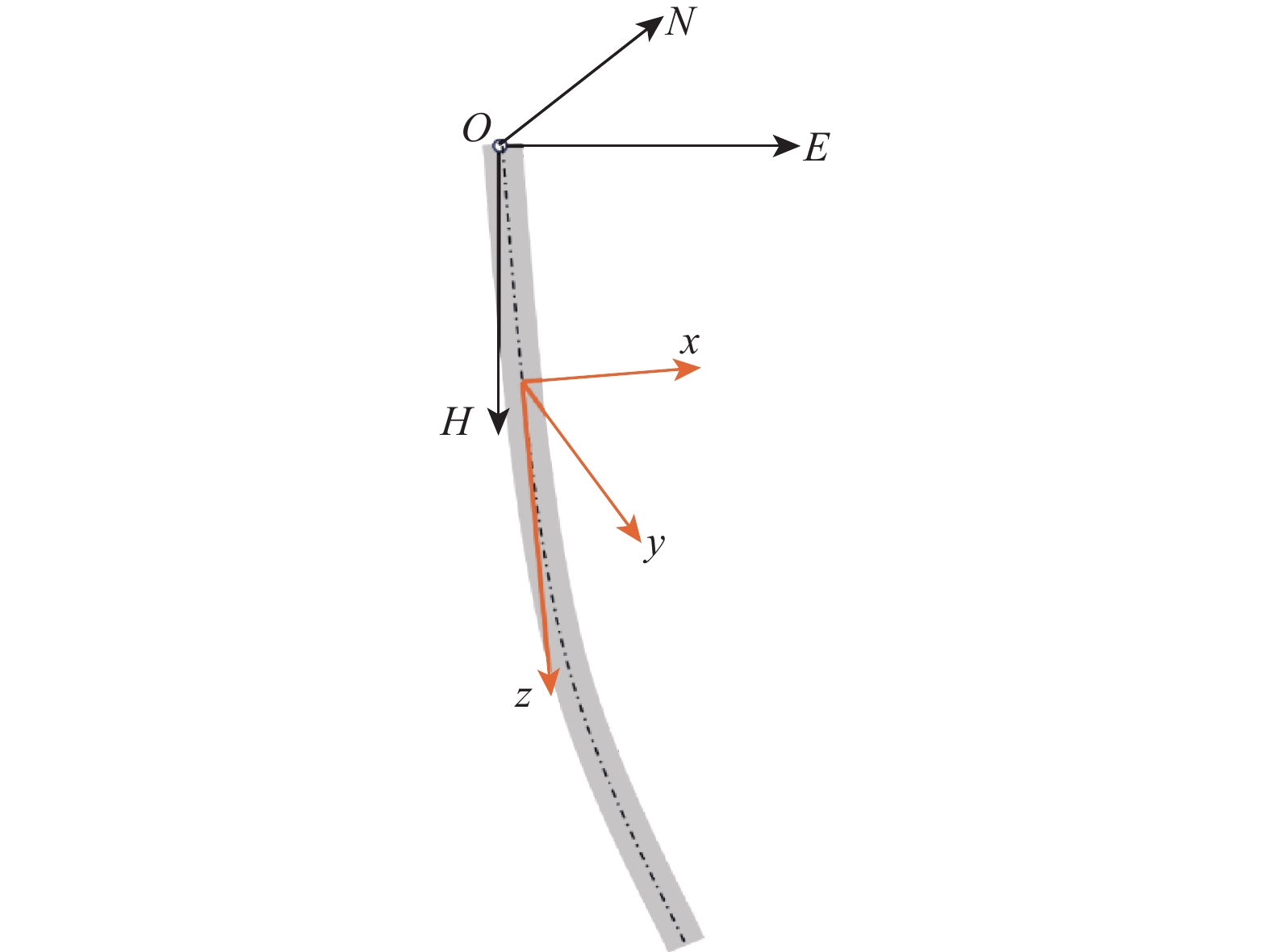

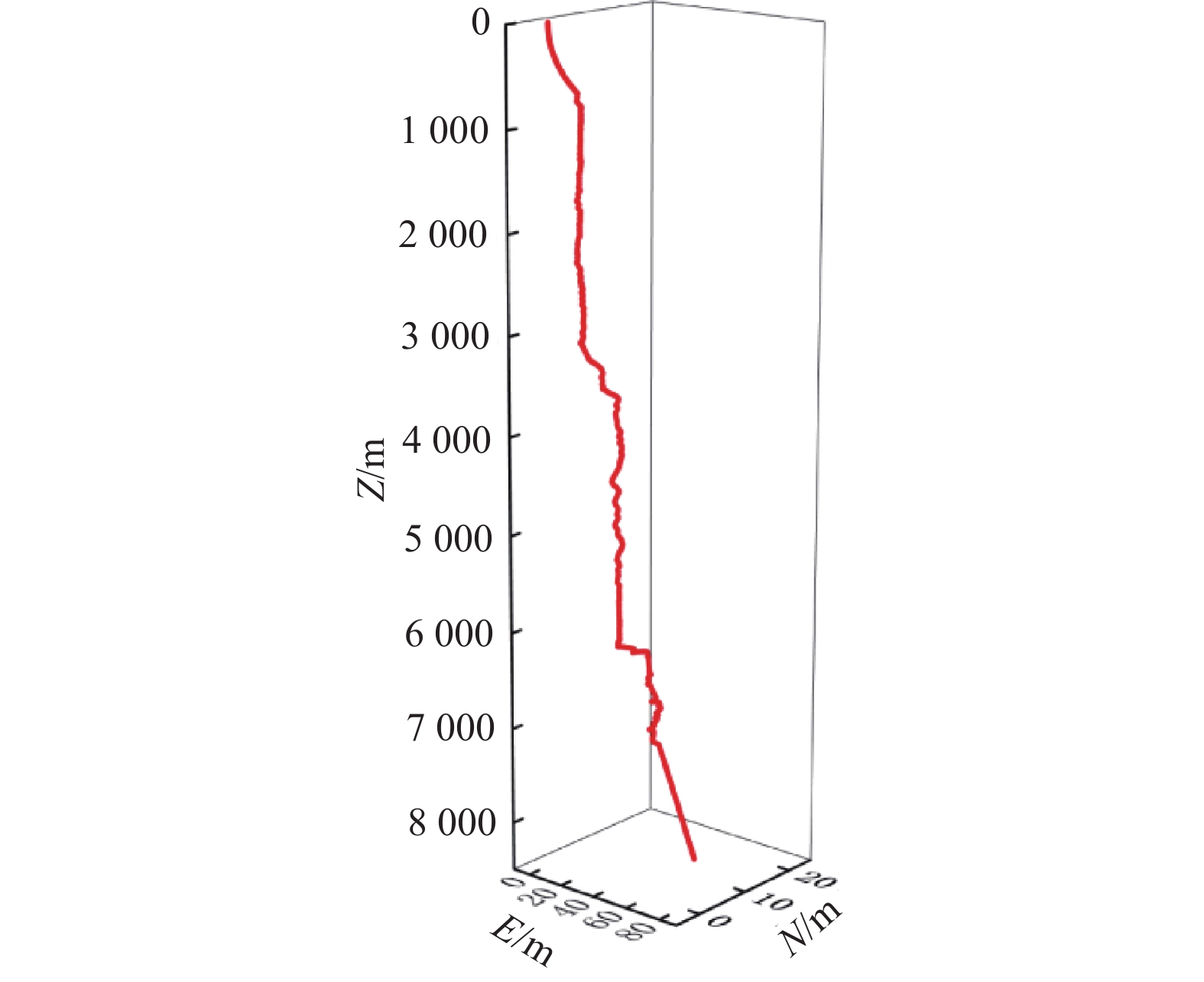

Abstract:With the increasing depth in oil and gas drilling, the downhole vibration of drill strings in ultra-deep wells is very complex and the stress state changes significantly with time. In order to ensure the safety of drill strings in ultra-deep wells, the dynamic fatigue failure characteristics of ultra-thin and ultra-long drill strings constrained by spatially deflected wellbores were studied, and the structure and working parameters of drill strings were optimized. Based on the actual wellbore trajectory, the collision characteristics of the drill string with the borehole wall were considered, and the dynamic characteristics of the drill string were obtained through finite element simulation analysis. The fatigue strength of the drill string in ultra-deep wells under the variable asymmetric cyclic stress state was studied according to the accumulated fatigue damage theory. According to actual field case, the dangerous cross-section of the drill string in ultra-deep wells was analyzed, and the variation law of fatigue strength of the drill string with rotation speed, weight on bit (WOB), and stabilizer position was studied. The research demonstrated that WOB and high rotation speed have a great effect on the fatigue strength of the drill string, and low rotation speed slightly affects the fatigue strength of the drill string. After the stabilizer is installed, the probability of fatigue failure of the bottom hole assembly (BHA) can be greatly reduced, and the stabilizer position has a significant effect on the fatigue strength of the drill string. The research results provide a theoretical basis for the optimization of the structure and drilling parameters of drill strings in ultra-deep wells.

-

Keywords:

- ultra-deep well /

- drill string /

- dynamic stress /

- collision contact /

- fatigue strength /

- parameter optimization

-

-

-

[1] 胡以宝,狄勤丰,王文昌,等. 石油钻柱的动态安全评价分析方法[J]. 工程力学,2012,29(11):375–380. HU Yibao, DI Qinfeng, WANG Wenchang, et al. Dynamic safety evaluation and analysis on oilwell drillstring[J]. Engineering Mechanics, 2012, 29(11): 375–380.

[2] 庞德新,艾白布•阿不力米提,焦文夫,等. 超深气井连续油管多径组合管柱作业新工艺[J]. 天然气工业,2021,41(3):112–118. PANG Dexin, AIBAIBU Abulimiti, JIAO Wenfu, et al. A new technology for the multi-diameter combination operation of coiled tubing in ultra-deep gas wells[J]. Natural Gas Industry, 2021, 41(3): 112–118.

[3] 祝效华,李柯,李文哲,等. 万米深井上部大尺寸井眼钻柱动力学特性研究[J]. 天然气工业,2024,44(1):49–57. ZHU Xiaohua, LI Ke, LI Wenzhe, et al. Drill string mechanical behaviors of large-size borehole in the upper section of a 10000 m deep well[J]. Natural Gas Industry, 2024, 44(1): 49–57.

[4] 谢士远,赵朝阳,关志刚,等. 多轴交变载荷下套管长圆螺纹疲劳失效分析及寿命预测[J]. 特种油气藏,2021,28(3):168–174. XIE Shiyuan, ZHAO Chaoyang, GUAN Zhigang, et al. Fatigue failure analysis and fatigue life prediction of the long round thread of the casing under multi-axial alternate load[J]. Special Oil & Gas Reservoirs, 2021, 28(3): 168–174.

[5] 钟文建,李双贵,熊宇楼,等. 超深水平井钻柱动力学研究及强度校核[J]. 西南石油大学学报(自然科学版),2020,42(4):135–143. ZHONG Wenjian, LI Shuanggui, XIONG Yulou, et al. The dynamics characteristics and strength check of drilling string in ultra-deep horizontal well[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2020, 42(4): 135–143.

[6] 谢涛,邓建明,张磊,等. 渤中19-6构造下部钻具组合动力学特性[J]. 石油钻采工艺,2018,40(增刊1):109–111. XIE Tao, DENG Jianming, ZHANG Lei, et al. Dynamic characteristics of bottom hole assembly in Bozhong 19-6 structure[J]. Oil Drilling & Production Technology, 2018, 40(supplement 1): 109–111.

[7] 邹阿七,王明杰,罗勇,等. BA6S井钻杆失效机理[J]. 断块油气田,2014,21(2):245–248. ZOU Aqi, WANG Mingjie, LUO Yong, et al. Failure mechanism of drillpipe in Well BA6S[J]. Fault-Block Oil & Gas Field, 2014, 21(2): 245–248.

[8] WU Jiang. Drill-pipe bending and fatigue in rotary drilling of horizontal wells[R]. SPE 37353, 1996.

[9] 李文飞,管志川. 深井钻柱疲劳强度计算与分析[J]. 石油机械,2007,35(4):25–27. LI Wenfei, GUAN Zhichuan. Calculation and analysis of fatigue strength of drill string in deep well[J]. China Petroleum Machinery, 2007, 35(4): 25–27.

[10] DI Qinfeng, WANG Mingjie, ZHANG He, et al. Dynamic valuation methodology for fatigue failure of drill string[R]. SPE 180636, 2016.

[11] HAAGENSEN P J, GRØTTUM T I. Fatigue assessment of drill pipes[C]//ASME 2017 36th International Conference on Ocean, Offshore and Arctic Engineering. New York: American Society of Mechanical Engineers, 2017: V004T03A019.

[12] OZGUC O. Analysis of fatigue behaviour of drill pipe on pin-box connection[J]. Proceedings of the Institution of Mechanical Engineers, part M: Journal of Engineering for the Maritime Environment, 2021, 235(1): 68-80.

[13] 耿亚楠,陈孝亮,杨进,等. 基于初始缺陷的钻柱疲劳寿命预测方法[J]. 石油钻采工艺,2016,38(6):817–822. GENG Yanan, CHEN Xiaoliang, YANG Jin, et al. Prediction method on fatigue life of string based on initial imperfection[J]. Oil Drilling & Production Technology, 2016, 38(6): 817–822.

[14] 毛良杰,甘伦科,幸雪松,等. 基于钻柱动力学的底部钻具组合疲劳寿命研究[J]. 石油机械,2022,50(9):1–9. MAO Liangjie, GAN Lunke, XING Xuesong, et al. Study on fatigue life of BHA based on drill string dynamics[J]. China Petroleum Machinery, 2022, 50(9): 1–9.

[15] 廖茂林,周英操,苏义脑,等. 深水钻井管柱系统动力学分析与设计方法研究[J]. 石油钻探技术,2019,47(2):56–62. LIAO Maolin, ZHOU Yingcao, SU Yinao, et al. A study of the dynamic analysis and design method of deepwater drilling string systems[J]. Petroleum Drilling Techniques, 2019, 47(2): 56–62.

[16] GULYAEV V I, GAIDAICHUK V V, SOLOV’EV I L, et al. Computer simulation of resistance forces acting upon curvilinear drill strings[J]. Strength of Materials, 2007, 39(5): 492–501. doi: 10.1007/s11223-007-0055-8

[17] 狄勤丰,陈锋,王文昌,等. 双台肩钻杆接头三维力学分析[J]. 石油学报,2012,33(5):871–877. DI Qinfeng, CHEN Feng, WANG Wenchang, et al. Three-dimensional mechanical analysis of the double-shouldered tool joint[J]. Acta Petrolei Sinica, 2012, 33(5): 871–877.

[18] 狄勤丰,骆大坤,周星,等. 横向主动控斜力作用下底部钻具组合动力学特征[J]. 石油学报,2023,44(9):1552–1561. DI Qinfeng, LUO Dakun, ZHOU Xing, et al. Analysis of dynamic characteristics of bottom hole assembly under transverse active deviation control force[J]. Acta Petrolei Sinica, 2023, 44(9): 1552–1561.

[19] BU Changgen, XIAO Jing, HE Shengyu, et al. Theoretical study on fatigue damage of sonic standing wave resonant drill-string[J]. Journal of Petroleum Science and Engineering, 2023, 220(part A): 111160.

[20] 赵增新,高德利. 套管钻井中变应力幅载荷下管柱疲劳强度的评估[J]. 石油钻探技术,2007,35(5):14–17. doi: 10.3969/j.issn.1001-0890.2007.05.004 ZHAO Zengxin, GAO Deli. Evaluation of casing string fatigue strength under alternating stress amplitude in casing drilling[J]. Petroleum Drilling Techniques, 2007, 35(5): 14–17. doi: 10.3969/j.issn.1001-0890.2007.05.004

[21] 徐灏. 机械强度设计中的安全系数和许用应力[J]. 机械强度,1981(2):39–45. XU Hao. Safety coefficient and allowable stress in the design of mechanical strength[J]. Journal of Mechanical Strength, 1981(2): 39–45.

-

期刊类型引用(1)

1. 刘献博,薛亮,刘敏,王智明,张峥,邵天宇. 连续波钻井液脉冲发生器压力波波形优化研究. 石油机械. 2020(12): 44-51 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: