Research and Development Suggestions on Theory and Techniques in Ultra-Deep Well Engineering

-

摘要:

超深井工程受到高温高压、复杂地层、超长井眼和腐蚀介质等多重因素约束,其安全高效作业面临全方位的技术挑战。为此,针对超深井工程的安全高效设计控制问题,介绍了该工程的发展概况与技术特点;选取井眼轨迹预测与防斜打快、钻柱振动特性分析与减振控制、钻井延伸极限预测与设计控制,以及套管失效风险评估与安全控制等几个重要理论与技术问题,介绍了国内外的相关研究进展及笔者团队的最新研究成果;然后,针对超深井工程提出了若干创新发展建议。研究结果表明,超深井工程理论与技术的发展整体呈现出体系化、科学化、多学科交叉、地质与工程一体化等基本特点。建议在基础理论问题、关键核心技术、技术协同关系、技术迭代模式和多学科交叉融合等方面加强创新研究,以持续推进超深井工程基础理论与关键技术创新发展。

Abstract:Ultra-deep well engineering is constrained by multiple factors such as high temperature and high pressure, complicated formations, ultra-long wellbores, and corrosive medium, resulting in all-around technical challenges for safe and efficient operations. Therefore, In view of the safe and efficient design control problems in ultra-deep well engineering was studied, the development overview and technical characteristics of ultra-deep well engineering were summarized.Several important theoretical and technical issues were introduced, including well trajectory prediction and fast drilling with deviation prevention, characteristic analysis and control technology of downhole drilling string vibration, prediction and design control techniques of drilling extension limit, and casing failure risk assessment and safety control, etc. In addition, research progress in China and abroad, and the latest research results of the authors’ team were introduced. Finally, some suggestions were put forward on innovative development for ultra-deep well engineering. The results suggest that the overall development of theory and techniques in ultra-deep well engineering have the typical characteristics of systematic, scientific, interdisciplinary and geology-engineering integration. Strengthening the innovative research on fundamental theoretical issues is recommended, along with key and core techniques, technological collaboration relationships, technological iteration modes, and interdisciplinary integration, so as to promote the continuous innovative development of basic theory and key techniques in ultra-deep well engineering.

-

-

-

[1] 李阳,薛兆杰,程喆,等. 中国深层油气勘探开发进展与发展方向[J]. 中国石油勘探,2020,25(1):45–57. LI Yang, XUE Zhaojie, CHENG Zhe, et al. Progress and development directions of deep oil and gas exploration and development in China[J]. China Petroleum Exploration, 2020, 25(1): 45–57.

[2] 高德利. 油气钻采科技创新:驱动复杂油气田勘探开发事业高效绿色发展[J]. 前瞻科技,2023,2(2):5–10. GAO Deli. Technological innovations in drilling and production drive efficient & green exploration and development of the complicated oil & gas fields[J]. Science and Technology Foresight, 2023, 2(2): 5–10.

[3] 曾义金,金衍,周英操,等. 深层油气钻采技术进展与展望[J]. 前瞻科技,2023,2(2):32–46. ZENG Yijin, JIN Yan, ZHOU Yingcao, et al. Progress and prospect of deep oil & gas drilling and production technologies[J]. Science and Technology Foresight, 2023, 2(2): 32–46.

[4] 高德利,黄文君. 深层、超深层定向钻井中若干基础研究进展与展望[J]. 天然气工业,2024,44(1):1–12. GAO Deli, HUANG Wenjun. Basic research progress and prospect in deep and ultra-deep directional drilling[J]. Natural Gas Industry, 2024, 44(1): 1–12.

[5] 苏义脑,路保平,刘岩生,等. 中国陆上深井超深井钻完井技术现状及攻关建议[J]. 石油钻采工艺,2020,42(5):527–542. SU Yinao, LU Baoping, LIU Yansheng, et al. Status and research suggestions on the drilling and completion technologies for onshore deep and ultra deep wells in China[J]. Oil Drilling & Production Technology, 2020, 42(5): 527–542.

[6] 高德利. 复杂地质条件下深井超深井钻井技术[M]. 北京:石油工业出版社,2004:10-15. GAO Deli. Deep and ultra-deep well drilling technology under complex geological conditions[M]. Beijing: Petroleum Industry Press, 2004: 10-15.

[7] 汪海阁,黄洪春,毕文欣,等. 深井超深井油气钻井技术进展与展望[J]. 天然气工业,2021,41(8):163–177. WANG Haige, HUANG Hongchun, BI Wenxin, et al. Deep and ultra-deep oil/gas well drilling technologies: progress and prospect[J]. Natural Gas Industry, 2021, 41(8): 163–177.

[8] 何立成,唐波. 准噶尔盆地超深井钻井技术现状与发展建议[J]. 石油钻探技术,2022,50(5):1–8. HE Licheng, TANG Bo. The up to date technologies of ultra-deep well drilling in Junggar Basin and suggestions for further improvements[J]. Petroleum Drilling Techniques, 2022, 50(5): 1–8.

[9] 高德利,黄文君,刁斌斌,等. 复杂结构井定向钻井技术现状及展望[J]. 前瞻科技,2023,2(2):11–21. GAO Deli, HUANG Wenjun, DIAO Binbin, et al. Current status and prospect of directional drilling technologies for complex wells[J]. Science and Technology Foresight, 2023, 2(2): 11–21.

[10] 高德利. 易斜地层防斜打快钻井理论与技术探讨[J]. 石油钻探技术,2005,33(5):16–19. GAO Deli. Discussions on theories and techniques about rapid drilling while preventing deviating in formations tending to deflecting[J]. Petroleum Drilling Techniques, 2005, 33(5): 16–19.

[11] LUBINSKI A. A study of the buckling of rotary drilling string[J]. Drilling and Production Practice, 1950, 50: 178–214.

[12] LUBINSKI A, WOODS H B. Factors affecting the angle of inclination and dog-legging in rotary bore holes[J]. Drilling and Production Practice, 1953: 222-250.

[13] MILLHEIM K, JORDAN S, RITTER C J. Bottom-hole assembly analysis using the finite-element method[J]. Journal of Petroleum Technology, 1978, 30(2): 265–274. doi: 10.2118/6057-PA

[14] HO H S. General formulation of drillstring under large deformation and its use in BHA analysis[R]. SPE 15562, 1986.

[15] HO H S. Prediction of drilling trajectory in directional wells via a new rock-bit interaction model[R]. SPE 16658, 1987.

[16] 白家祉,苏义脑. 井斜控制理论与实践[M]. 北京:石油工业出版社,1990:66-128. BAI Jiazhi, SU Yinao. Theory and practice of well deviation control[M]. Beijing: Petroleum Industry Press, 1990: 66-128.

[17] 高德利,刘希圣,徐秉业. 井眼轨迹控制[M]. 东营:石油大学出版社,1994:34-152. GAO Deli, LIU Xisheng, XU Bingye. Prediction and control of wellbore trajectory[M]. Dongying: Petroleum University Press, 1994: 34-152.

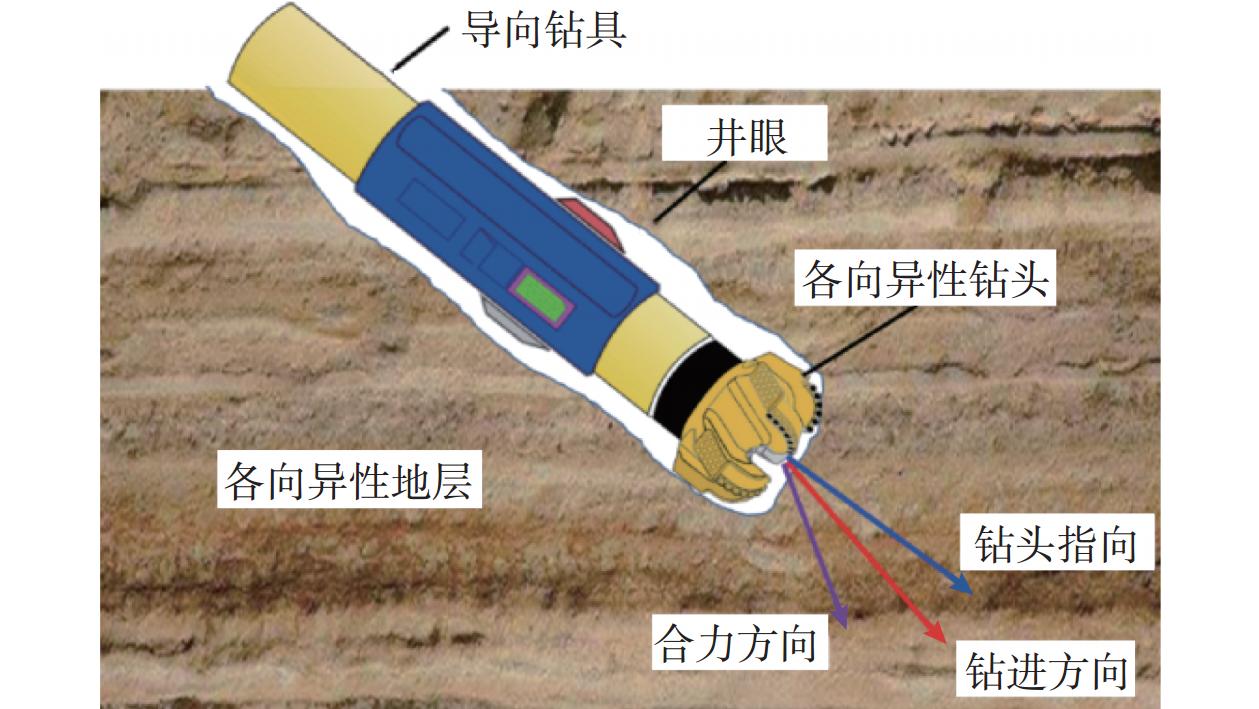

[18] 狄勤丰,芮子翔,周星,等. 带旋转导向工具的底部钻具组合横向振动特性研究[J]. 石油钻探技术,2021,49(6):8–16. DI Qinfeng, RUI Zixiang, ZHOU Xing, et al. Research on lateral vibration characteristics of bottom hole assembly with rotary steerable tool[J]. Petroleum Drilling Techniques, 2021, 49(6): 8–16.

[19] 张伟,马登宝,杨洪,等. 新型钟摆钻具组合防斜打快技术及在风城011井的应用[J]. 石油天然气学报,2009,31(5):321–323. ZHANG Wei, MA Dengbao, YANG Hong, et al. New anti-deviation and fast drilling technology of pendulum assembly and its application in Fengcheng 011 Well[J]. Journal of Oil and Gas Technology, 2009, 31(5): 321–323.

[20] 胡修俊,祝效华,贾彦杰,等. 刚性满眼钻具组合模态分析研究[J]. 石油机械,2009,37(11):36–38. HU Xiujun, ZHU Xiaohua, JIA Yanjie, et al. The modal analysis and research on the rigid packed hole assembly[J]. China Petroleum Machinery, 2009, 37(11): 36–38.

[21] 狄勤丰,沈双平. 防斜打快技术的研究与发展[J]. 自然杂志,2004,26(2):111–115. DI Qinfeng, SHEN Shuangping. Research and development of the vertical and fast drilling technology[J]. Chinese Journal of Nature, 2004, 26(2): 111–115.

[22] 高德利,高宝奎,谢金稳,等. 钻压防斜技术的实践与理论探讨[J]. 石油钻采工艺,1995,17(6):1–6. GAO Deli, GAO Baokui, XIE Jinwen, et al. Researching and practice of deviation control by increasing WOB[J]. Oil Drilling & Production Technology, 1995, 17(6): 1–6.

[23] 周俊昌,余雄鹰,罗勇,等. 复合钻井防斜打快技术研究与应用[J]. 中国海上油气,2007,19(3):188–191. ZHOU Junchang, YU Xiongying, LUO Yong, et al. The research and application of the coupled driven drilling technology[J]. China Offshore Oil and Gas, 2007, 19(3): 188–191.

[24] 柴麟,张凯,刘宝林,等. 自动垂直钻井工具分类及发展现状[J]. 石油机械,2020,48(1):1–11. CHAI Lin, ZHANG Kai, LIU Baolin, et al. Classification and development status of automatic vertical drilling tools[J]. China Petroleum Machinery, 2020, 48(1): 1–11.

[25] 高德利,刘希圣. 钻头与地层相互作用的新模型[J]. 石油钻采工艺,1989,11(5):23–28. GAO Deli, LIU Xisheng. A new model of drill to formation interaction[J]. Oil Drilling & Production Technology, 1989, 11(5): 23–28.

[26] 黄文君,王舸,高德利. 推靠式旋转导向工具造斜率预测方法[J]. 天然气工业,2021,41(7):101–106. HUANG Wenjun, WANG Ge, GAO Deli. A method for predicting the build-up rate of “push-the-bit” rotary steering Tool[J]. Natural Gas Industry, 2021, 41(7): 101–106.

[27] 王舸,黄文君,高德利. 滑动钻进造斜率预测与分析[J]. 石油钻采工艺,2022,44(2):139–144. WANG Ge, HUANG Wenjun, GAO Deli. Prediction and analysis of build-up rate during sliding drilling[J]. Oil Drilling & Production Technology, 2022, 44(2): 139–144.

[28] WANG Ge, HUANG Wenjun, GAO Deli. Real-time control algorithm of well trajectory for push-the-bit rotary steering drilling system[J]. SPE Journal, 2023, 28(5): 2148–2164. doi: 10.2118/214703-PA

[29] 高德利,黄文君,刘永升,等. 钻柱力学与套管磨损预测若干研究进展[J]. 石油管材与仪器,2020,6(4):1–9. GAO Deli, HUANG Wenjun, LIU Yongsheng, et al. Some research advances in drill string mechanics and casing wear prediction for well engineering[J]. Petroleum Tubular Goods & Instruments, 2020, 6(4): 1–9.

[30] FINNIE I, BAILEY J J. An experimental study of drill-string vibration[J]. Journal of Engineering for Industry, 1960, 82(2): 129–135. doi: 10.1115/1.3663020

[31] DUNAYEVSKY V A, ABBASSIAN F, JUDZIS A. Dynamic stability of drillstrings under fluctuating weight on bit[J]. SPE Drilling & Completion, 1993, 8(2): 84–92.

[32] JANSEN J D. Nonlinear dynamics of oilwell drillstrings[D]. Delft: Delft University of Technology, 1993.

[33] MILLHEIM K K, APOSTAL M C. The effect of bottomhole assembly dynamics on the trajectory of a bit[J]. Journal of Petroleum Technology, 1981, 33(12): 2323–2338. doi: 10.2118/9222-PA

[34] ALDRED W D, SHEPPARD M C. Drillstring vibrations: A new generation mechanism and control strategies[R]. SPE 24582, 1992.

[35] CLAYER F, VANDIVER J K, LEE H Y. The effect of surface and downhole boundary conditions on the vibration of drillstrings[R]. SPE 20447, 1990.

[36] BAUMGARTNER T, VAN OORT E. Pure and coupled drill string vibration pattern recognition in high frequency downhole data[R]. SPE 170955, 2014.

[37] LI Yafeng, XUE Qilong, WANG Jin, et al. Pattern recognition of stick-slip vibration in combined signals of drillstring vibration[J]. Measurement, 2022, 204: 112034. doi: 10.1016/j.measurement.2022.112034

[38] OKOLI P, CRUZ VEGA J, SHOR R. Estimating downhole vibration via machine learning techniques using only surface drilling parameters[R]. SPE 195334, 2019.

[39] ALSAIHATI A, ALOTAIBI B. Determining severity of lateral and torsional downhole vibrations while drilling surface holes using three machine learning techniques[J]. SPE Journal, 2022, 27(3): 1493–1503. doi: 10.2118/209575-PA

[40] HEGDE C, MILLWATER H, GRAY K. Classification of drilling stick slip severity using machine learning[J]. Journal of Petroleum Science and Engineering, 2019, 179: 1023–1036. doi: 10.1016/j.petrol.2019.05.021

[41] 章扬烈,萧载阳. 液压减振器功能的探讨[J]. 石油矿场机械,1997,26(3):21–24. ZHANG Yanglie, XIAO Zaiyang. Discussion on the function of hydraulic shock absorber[J]. Oil Field Equipment, 1997, 26(3): 21–24.

[42] 兰志钢. 双向液压减振器的失效机理及改进建议[J]. 石油钻探技术,2012,40(2):104–108. LAN Zhigang. Failure mechanism of two-way hydraulic shock absorbers and improvement measures[J]. Petroleum Drilling Techniques, 2012, 40(2): 104–108.

[43] 管志川,刘永旺,魏文忠,等. 井下钻柱减振增压装置工作原理及提速效果分析[J]. 石油钻探技术,2012,40(2):8–13. doi: 10.3969/j.issn.1001-0890.2012.02.002 GUAN Zhichuan, LIU Yongwang, WEI Wenzhong, et al. Downhole drill string absorption & hydraulic supercharging device’ working principle and analysis of speed-increasing effect[J]. Petroleum Drilling Techniques, 2012, 40(2): 8–13. doi: 10.3969/j.issn.1001-0890.2012.02.002

[44] JANSEN J D, VAN DEN STEEN L. Active damping of self-excited torsional vibrations in oil well drillstrings[J]. Journal of Sound and Vibration, 1995, 179(4): 647–668. doi: 10.1006/jsvi.1995.0042

[45] TUCKER W R, WANG C. On the effective control of torsional vibrations in drilling systems[J]. Journal of Sound and Vibration, 1999, 224(1): 101–122. doi: 10.1006/jsvi.1999.2172

[46] NAVARRO-LÓPEZ E M, CORTÉS D. Avoiding harmful oscillations in a drillstring through dynamical analysis[J]. Journal of Sound and Vibration, 2007, 307(1/2): 152–171.

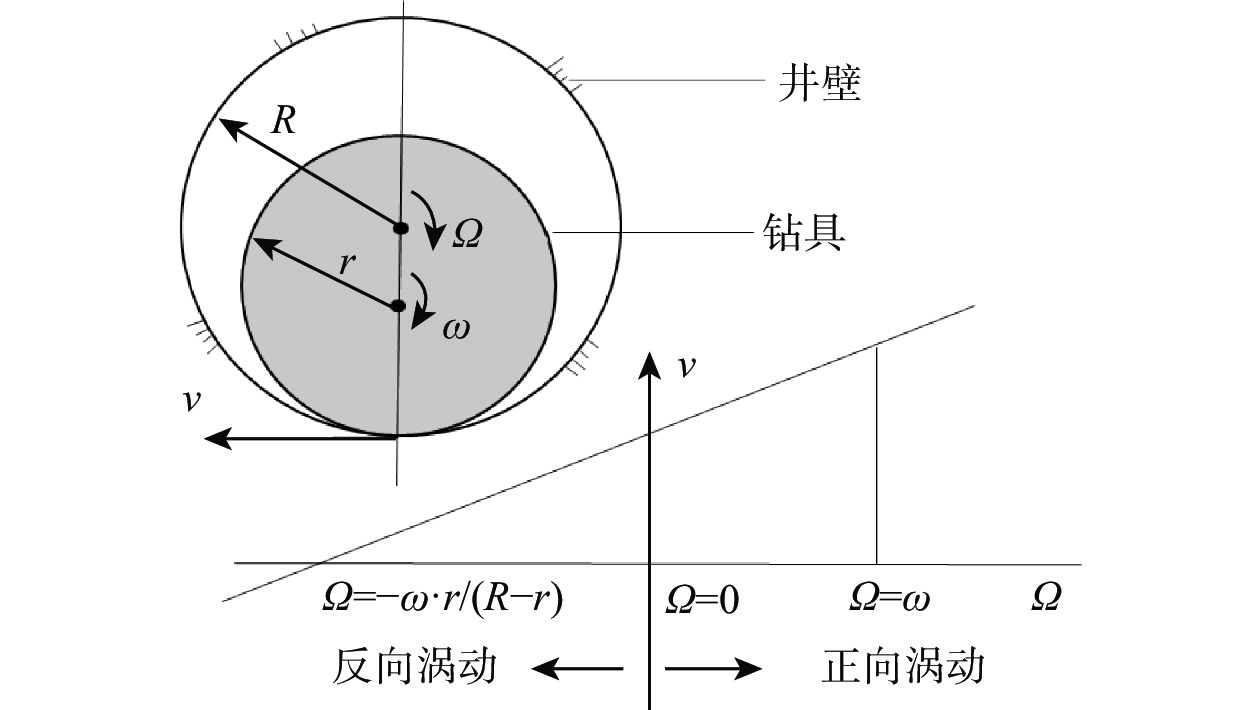

[47] 高德利,高宝奎,耿瑞平. 钻柱涡动特性分析[J]. 石油钻采工艺,1996,18(6):9–13. GAO Deli, GAO Baokui, GENG Ruiping. Analysis of drillstring whirling[J]. Oil Drilling & Production Technology, 1996, 18(6): 9–13.

[48] LIU Yongsheng, GAO Deli. A nonlinear dynamic model for characterizing downhole motions of drill-string in a deviated well[J]. Journal of Natural Gas Science and Engineering, 2017, 38: 466–474. doi: 10.1016/j.jngse.2017.01.006

[49] 黄文君,石小磊,高德利. 水平钻井振动减阻器参数优化设计[J]. 天然气工业,2023,43(8):108–115. HUANG Wenjun, SHI Xiaolei, GAO Deli. Optimal design method of vibration drag reduction parameters in horizontal well drilling[J]. Natural Gas Industry, 2023, 43(8): 108–115.

[50] SHI Xiaolei, HUANG Wenjun, GAO Deli, et al. Extension limit analysis of drillstring with drag reduction oscillators in horizontal drilling[J]. Geoenergy Science and Engineering, 2023, 228: 211996. doi: 10.1016/j.geoen.2023.211996

[51] SHI Xiaolei, HUANG Wenjun, GAO Deli. Mechanical models of drillstrings with drag reduction oscillators and optimal design methods of vibration parameters in horizontal drilling[J]. Geoenergy Science and Engineering, 2023, 224: 211585. doi: 10.1016/j.geoen.2023.211585

[52] 高德利,黄文君. 井下管柱力学与控制方法若干研究进展[J]. 力学进展,2021,51(3):620–647. doi: 10.6052/1000-0992-21-028 GAO Deli, HUANG Wenjun. Some research advances in downhole tubular mechanics and control methods[J]. Advances in Mechanics, 2021, 51(3): 620–647. doi: 10.6052/1000-0992-21-028

[53] MEERTENS R, VAN DER HARST T, KLOSS P. Drilling to the limit/long reach oil strike extended reach appraisal/development well tern TA-05[R]. SPE 28833, 1994.

[54] ALFSEN T E, HEGGEN S, BLIKRA H, et al. Pushing the limits for extended reach drilling: new world record from platform Statfjord C, Well C2[J]. SPE Drilling & Completion, 1995, 10(2): 71–76.

[55] RODMAN D W, SWIETLIK G. Extended reach drilling limitations: A shared solution[R]. SPE 38466, 1997.

[56] MEADER T, ALLEN F, RILEY G. To the limit and beyond-the secret of world-class extended-reach drilling performance at Wytch Farm[R]. SPE 59204, 2000.

[57] GAO Deli, TAN Chengjin, TANG Haixiong. Limit analysis of extended reach drilling in South China Sea[J]. Petroleum Science, 2009, 6(2): 166–171. doi: 10.1007/s12182-009-0026-8

[58] 汪志明,郭晓乐. 大位移井水力延伸极限研究[J]. 钻采工艺,2008,31(4):1–3. doi: 10.3969/j.issn.1006-768X.2008.04.001 WANG Zhiming, GUO Xiaole. Hydraulic extended limitation of extended-reach well[J]. Drilling & Production Technology, 2008, 31(4): 1–3. doi: 10.3969/j.issn.1006-768X.2008.04.001

[59] 闫铁,张凤民,刘维凯,等. 大位移井钻井极限延伸能力的研究[J]. 钻采工艺,2010,33(1):4–7. doi: 10.3969/j.issn.1006-768X.2010.01.002 YAN Tie, ZHANG Fengmin, LIU Weikai, et al. Mechanical analysis on the limit extended capacity for an extended reach well[J]. Drilling & Production Technology, 2010, 33(1): 4–7. doi: 10.3969/j.issn.1006-768X.2010.01.002

[60] LONG T P, MCCORMICK J E, FRILOT M A. Inaccessible drilling targets and completions operation made possible by the alleviation of excessive torque and drag[R]. SPE 125991, 2009.

[61] SCHAMP J H, ESTES B L, KELLER S R. Torque reduction techniques in ERD wells[R]. SPE 98969, 2006.

[62] NEWMAN K, BURNETT T, PURSELL J, et al. Modeling the affect of a downhole vibrator[R]. SPE 121752, 2009.

[63] SOLA K I, LUND B. New downhole tool for coiled tubing extended reach[R]. SPE 60701, 2000.

[64] 张辉,于文涛,陈忠帅,等. 水力脉冲轴向振荡减阻工具研制[J]. 石油矿场机械,2014,43(7):73–76. ZHANG Hui, YU Wentao, CHEN Zhongshuai, et al. Development of hydropulse axial-oscillation friction-reduce Tool[J]. Oil Field Equipment, 2014, 43(7): 73–76.

[65] 王杰,夏成宇,冯定,等. 新型涡轮驱动水力振荡器设计与实验研究[J]. 工程设计学报,2016,23(4):391–395. doi: 10.3785/j.issn.1006-754X.2016.04.015 WANG Jie, XIA Chengyu, FENG Ding, et al. Design and experimental study on a new type of turbine driven hydraulic oscillator[J]. Journal of Engineering Design, 2016, 23(4): 391–395. doi: 10.3785/j.issn.1006-754X.2016.04.015

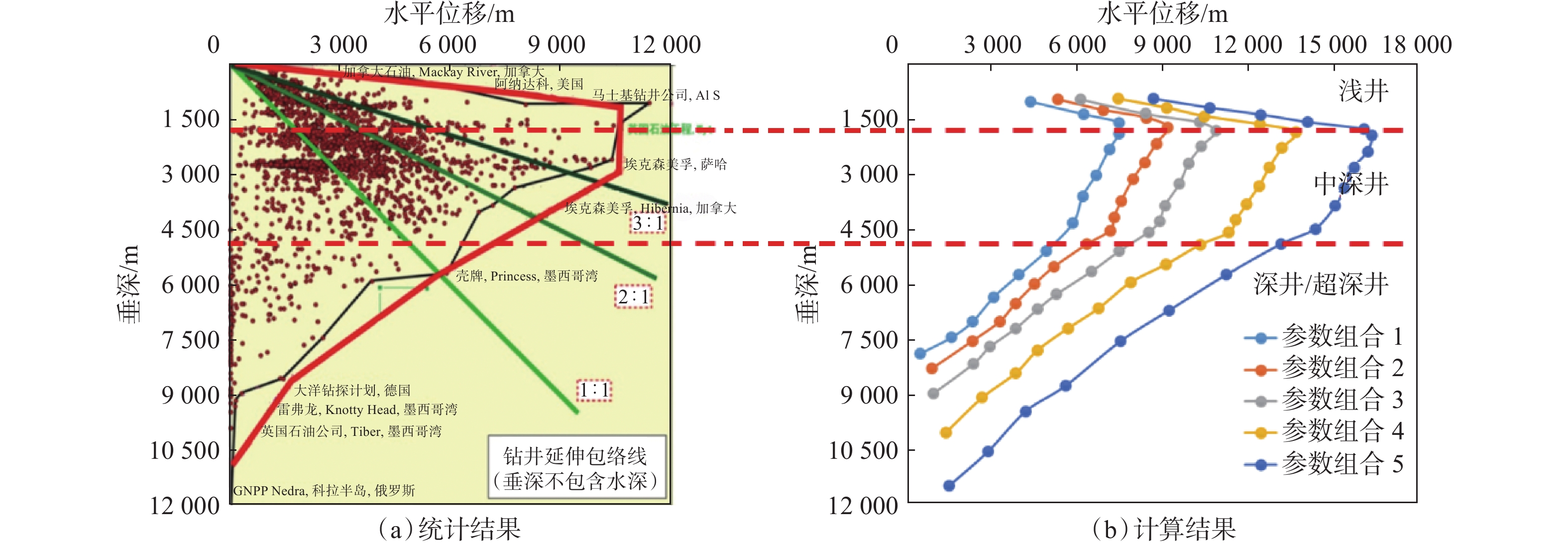

[66] 高德利,黄文君,李鑫. 大位移井钻井延伸极限研究与工程设计方法[J]. 石油钻探技术,2019,47(3):1–8. doi: 10.11911/syztjs.2019069 GAO Deli, HUANG Wenjun, LI Xin. Research on extension limits and engineering design methods for extended reach drilling[J]. Petroleum Drilling Techniques, 2019, 47(3): 1–8. doi: 10.11911/syztjs.2019069

[67] HUANG Wenjun, GAO Deli, LIU Yinghua. A study of mechanical extending limits for three-section directional wells[J]. Journal of Natural Gas Science and Engineering, 2018, 54: 163–174. doi: 10.1016/j.jngse.2018.03.031

[68] ZHAO Jun, HUANG Wenjun, GAO Deli. Research on dynamic prediction of tubular extension limit and operation risk in extended-reach drilling[J]. Journal of Natural Gas Science and Engineering, 2022, 107: 104542. doi: 10.1016/j.jngse.2022.104542

[69] HUANG Wenjun, GAO Deli. Analysis of drilling difficulty of extended-reach wells based on drilling limit theory[J]. Petroleum Science, 2022, 19(3): 1099–1109. doi: 10.1016/j.petsci.2021.12.030

[70] 高德利. 油气井管柱力学与工程[M]. 东营:中国石油大学出版社,2006:121-181. GAO Deli. Down-hole tubular mechanics and its applications[M]. Dongying: China University of Petroleum Press, 2006: 121-181.

[71] CHEN Zhanfeng, ZHU Weiping, DI Qinfeng, et al. Numerical and theoretical analysis of burst pressures for casings with eccentric wear[J]. Journal of Petroleum Science and Engineering, 2016, 145: 585–591. doi: 10.1016/j.petrol.2016.05.024

[72] 刘奎,高德利,王宴滨,等. 局部载荷对页岩气井套管变形的影响[J]. 天然气工业,2016,36(11):76–82. doi: 10.3787/j.issn.1000-0976.2016.11.010 LIU Kui, GAO Deli, WANG Yanbin, et al. Effects of local load on shale gas well casing deformation[J]. Natural Gas Industry, 2016, 36(11): 76–82. doi: 10.3787/j.issn.1000-0976.2016.11.010

[73] LIN Tiejun, ZHANG Qiang, LIAN Zhanghua, et al. Evaluation of casing integrity defects considering wear and corrosion: application to casing design[J]. Journal of Natural Gas Science and Engineering, 2016, 29: 440–452. doi: 10.1016/j.jngse.2016.01.029

[74] GAO Deli, SUN Lianzhong, LIAN Jihong. Prediction of casing wear in extended-reach drilling[J]. Petroleum Science, 2010, 7(4): 494–501. doi: 10.1007/s12182-001-0098-6

[75] WU J, ZHANG M G. Casing burst strength after casing wear[R]. SPE 94304, 2005.

[76] SONG J S, BOWEN J, KLEMENTICH F. The internal pressure capacity of crescent-shaped wear casing[R]. SPE 23902, 1992.

[77] 王小增,窦益华,杨久红. 偏心磨损套管应力分布的双极坐标解答[J]. 石油钻探技术,2006,34(2):18–21. doi: 10.3969/j.issn.1001-0890.2006.02.005 WANG Xiaozeng, DOU Yihua, YANG Jiuhong. An analysis for the stress of eccentric worn casing with bipolar coordinates[J]. Petroleum Drilling Techniques, 2006, 34(2): 18–21. doi: 10.3969/j.issn.1001-0890.2006.02.005

[78] 王建军,赵楠,张赟新,等. 井下油套管管柱修复技术研究[J]. 石油管材与仪器,2022,8(6):15–20. WANG Jianjun, ZHAO Nan, ZHANG Yunxin, et al. Comparison of repairing technologies for tubing and casing strings in oil and gas well[J]. Petroleum Tubular Goods & Instruments, 2022, 8(6): 15–20.

[79] 田启忠,温盛魁,伊伟锴,等. 长井段套管破损补贴修复技术研究与应用[J]. 石油机械,2015,43(11):88–91. TIAN Qizhong, WEN Shengkui, YI Weikai, et al. Patching techniques for reparation of damaged casing in long well interval[J]. China Petroleum Machinery, 2015, 43(11): 88–91.

[80] 徐太保. 机械切割在南海西部气田修井作业中的应用[J]. 石油管材与仪器,2020,6(6):83–85. XU Taibao. Application of mechanical cutting in workover operation in western gas field of South China Sea[J]. Petroleum Tubular Goods & Instruments, 2020, 6(6): 83–85.

[81] 潘一,温峥,杨双春,等. 国内外堵漏剂的研究进展[J]. 油田化学,2015,32(4):628–632. PAN Yi, WEN Zheng, YANG Shuangchun, et al. Research progress of plugging agent at domestic and foreign[J]. Oilfield Chemistry, 2015, 32(4): 628–632.

[82] HUANG Wenjun, GAO Deli, LIU Yinghua. Short-term and long-term mechanical models of wellbores considering cement consolidation and formation creep[J]. SPE Journal, 2019, 24(5): 2064–2082. doi: 10.2118/195573-PA

[83] HUANG Wenjun, GAO Deli. A theoretical study of the critical external pressure for casing collapse[J]. Journal of Natural Gas Science and Engineering, 2015, 27(Part 1): 290–297.

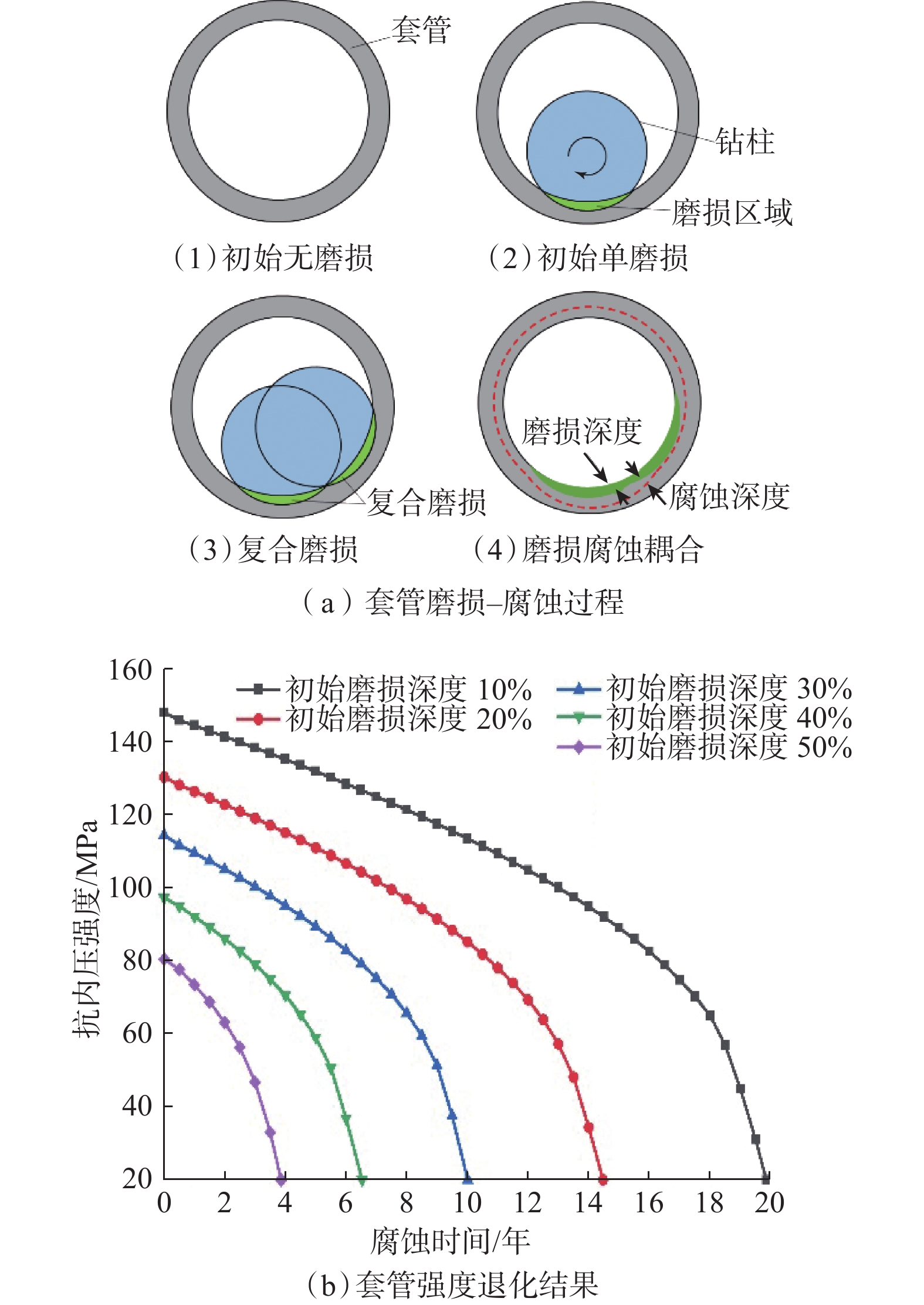

[84] 黄文君,张星坤,高德利. 复合磨损模式下的套管失效风险预测方法:以ϕ193.68 mm×12.7 mm 套管为例[J]. 天然气工业,2022,42(7):85–94. HUANG Wenjun, ZHANG Xingkun, GAO Deli. Prediction method of casing failure risk under compound wear mode: a case study on ϕ193.68 mm×12.7 mm casing[J]. Natural Gas Industry, 2022, 42(7): 85–94.

[85] 黄文君,张星坤,高德利,等. 复合模式下套管磨损形状与深度计算模型[J]. 石油学报,2021,42(10):1373–1381. doi: 10.7623/syxb202110011 HUANG Wenjun, ZHANG Xingkun, GAO Deli, et al. Casing wear shape and depth calculation model in a compound mode[J]. Acta Petrolei Sinica, 2021, 42(10): 1373–1381. doi: 10.7623/syxb202110011

[86] ZHANG Xingkun, HUANG Wenjun, GAO Deli. Prediction model of casing wear shape and residual strength under compound modes[J]. SPE Journal, 2022, 27(4): 2183–2207. doi: 10.2118/209612-PA

[87] WANG Jieli, HUANG Wenjun, GAO Deli. Prediction models of burst strength degradation for casing with considerations of both wear and corrosion[J]. Petroleum Science, 2024, 21(1): 458–474. doi: 10.1016/j.petsci.2023.08.014

[88] 黄文君,王捷力,高德利. 磨损–腐蚀耦合效应下超深井套管失效机理与剩余强度预测[C]//中国深层超深层油气勘探开发关键技术与装备交流研讨会论文集. 北京:中国石化出版社,2023:481-486. HUANG Wenjun, WANG Jieli, GAO Deli. Failure mechanism and residual strength prediction of casing in ultra-deep wells under the coupling effect of wear and corrosion[C]//Proceedings of the Symposium on Key Technologies and Equipment Exchange for Deep and Ultra-deep Oil and Gas Exploration and Development in China. Beijing: China Petrochemical Press, 2023: 481-486.

-

期刊类型引用(2)

1. 史配铭,倪华峰,贺会锋,石崇东,李录科,张延兵. 鄂尔多斯盆地深层煤岩气水平井水平段安全钻井关键技术. 石油钻探技术. 2025(01): 17-23 .  本站查看

本站查看

2. 胡勇,惠栋,杜强,蒋德生,李滔,刘其松,闫静,陈颖莉,李隆新,刘微. 四川盆地中坝气田雷三气藏高效开发及其对中国高含硫气藏开采的意义. 天然气工业. 2024(11): 24-36 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: