Integrated Completion Technology of Water and Sand Control in Reservoirs with Extra-High Porosity and Permeability in Bohai Oilfield

-

摘要:

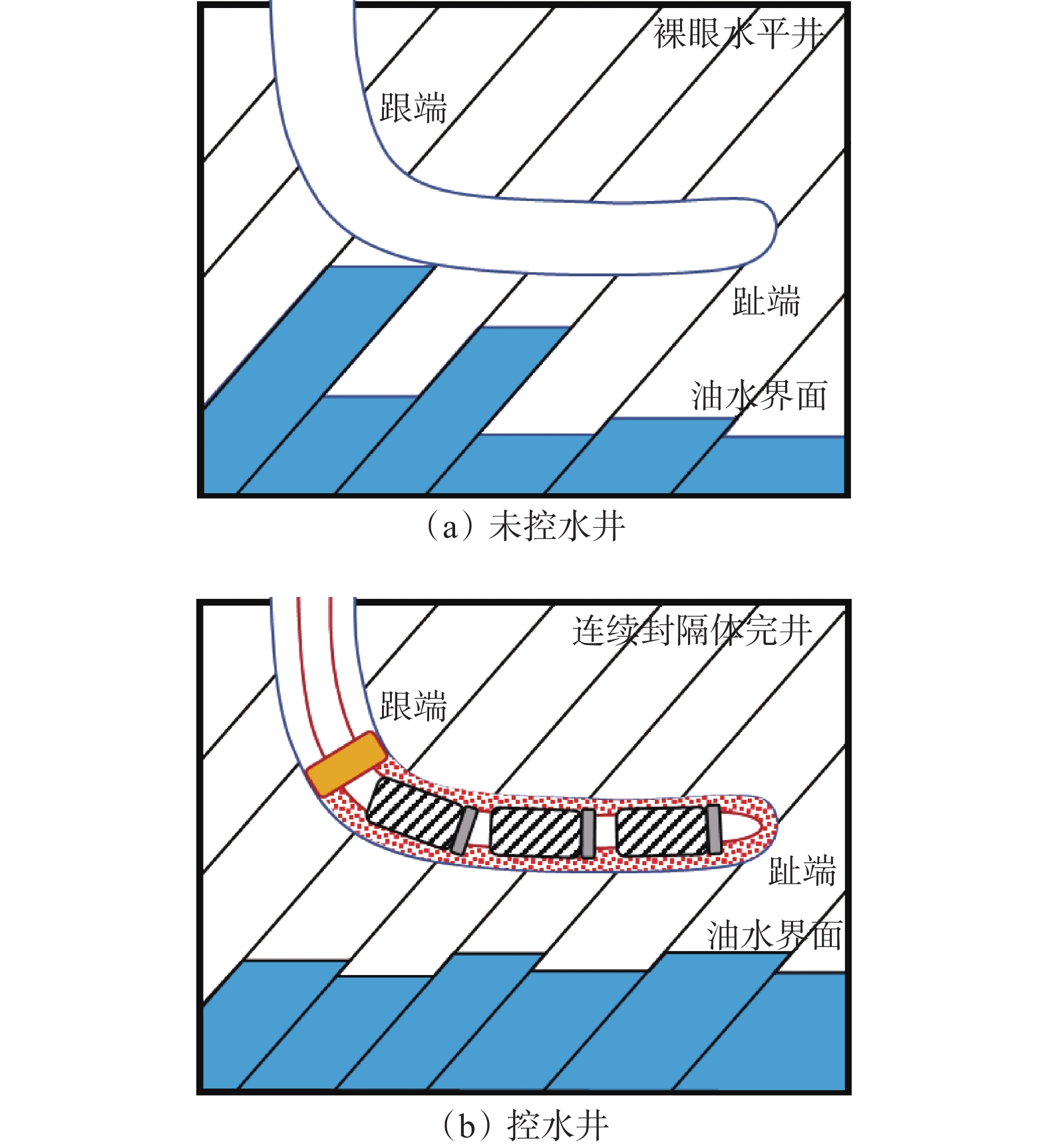

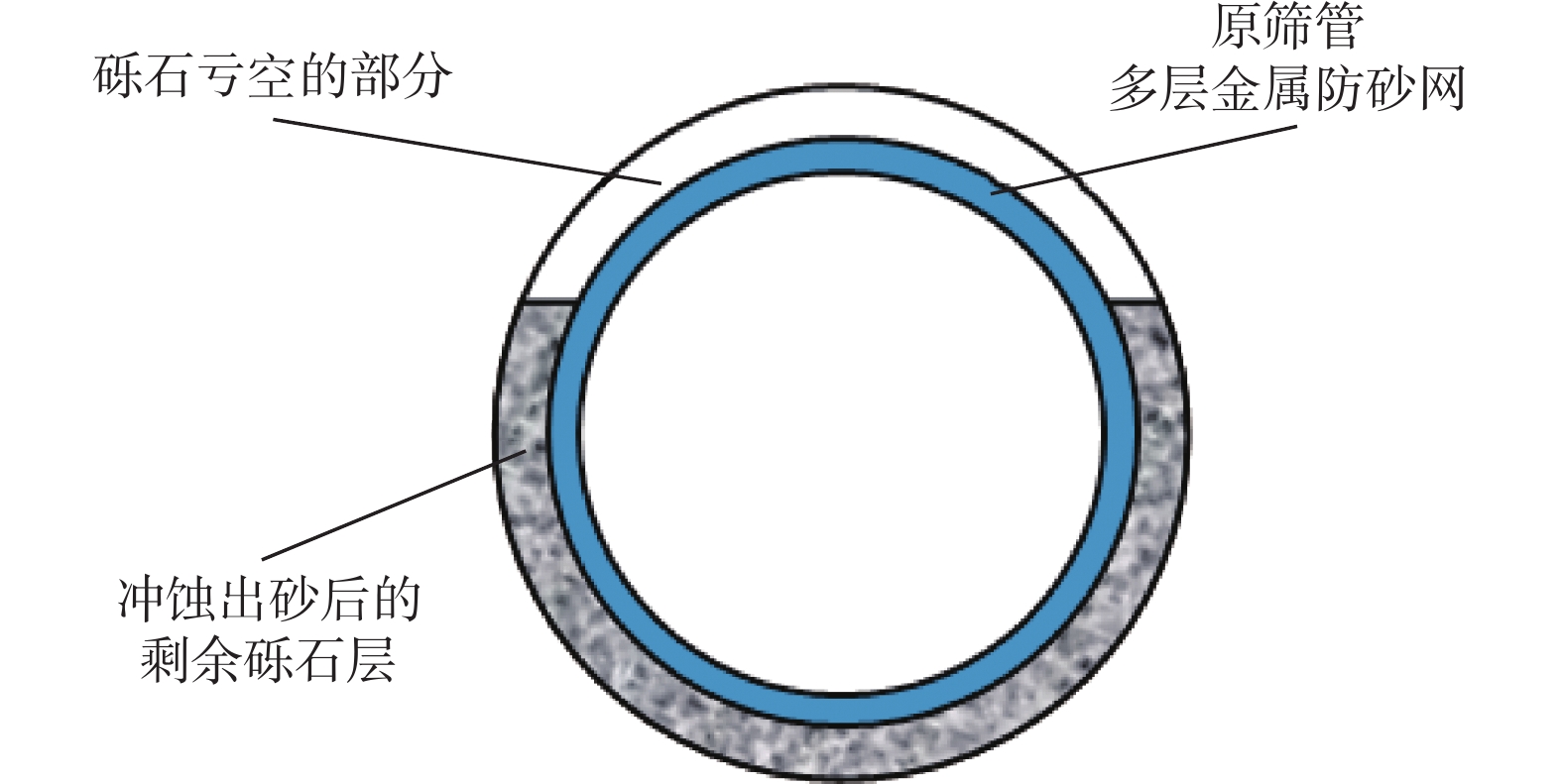

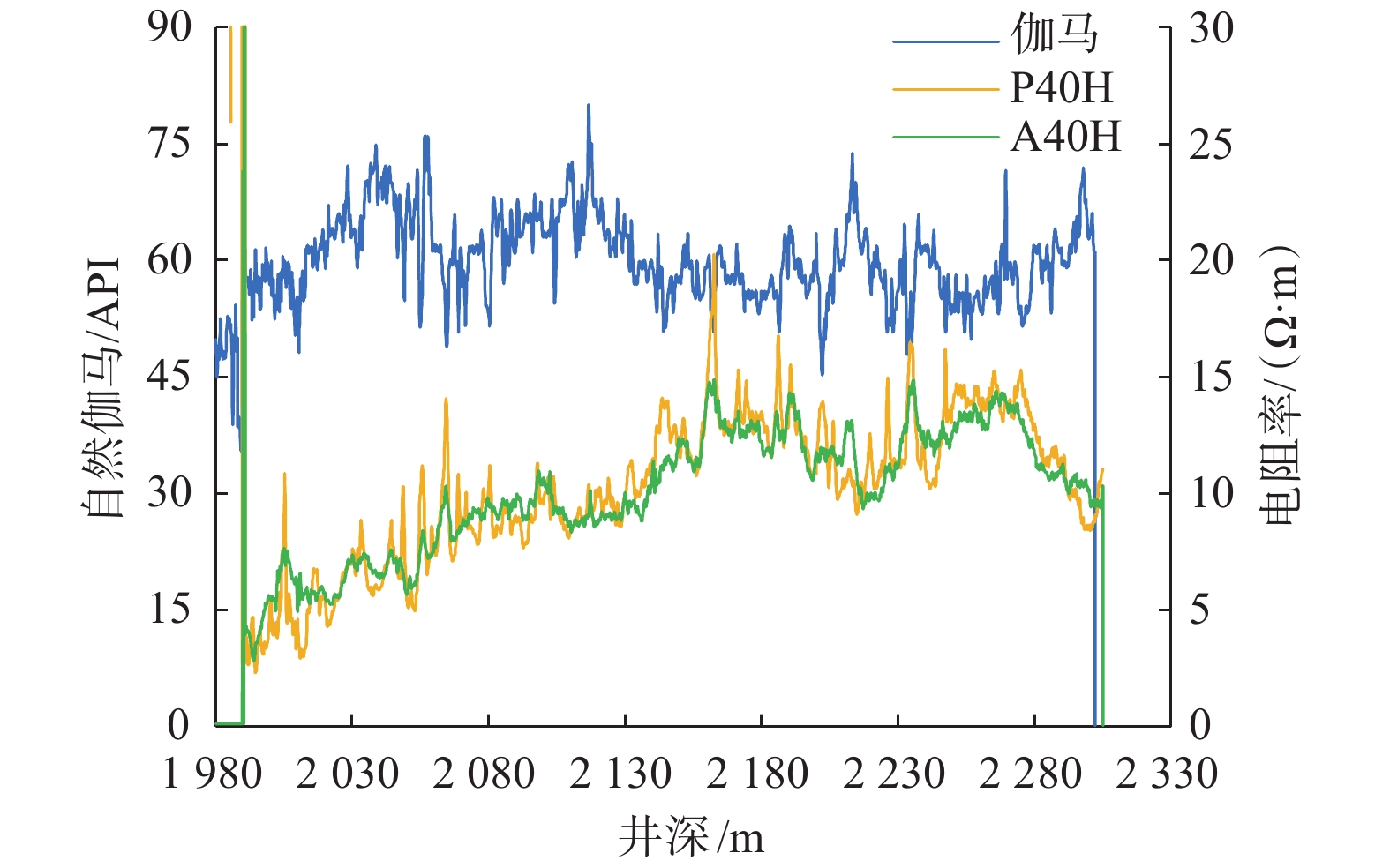

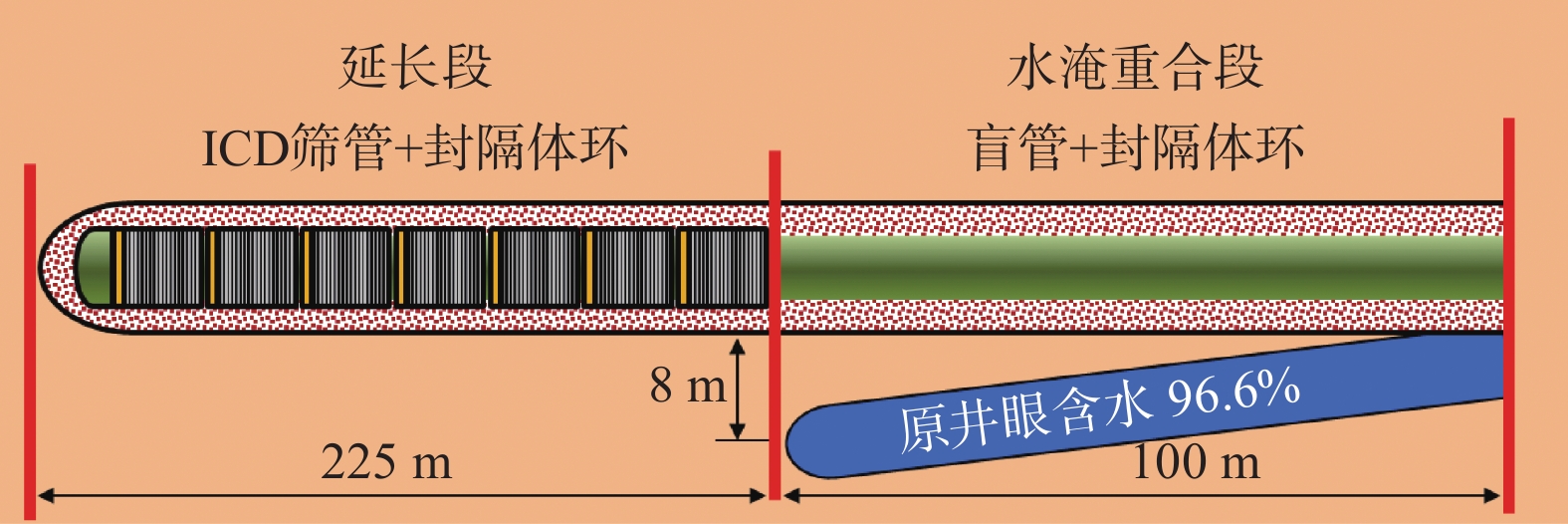

渤海BN油田的特高孔渗疏松砂岩油藏储层非均质性强,生产井出水、出砂问题严重,而现有各自独立设计实施的控水和防砂工艺存在设计实施繁琐、控水防砂效果差等问题。为此,在连续封隔体控水完井技术的基础上,根据地质工程一体化的思路,给出了优选连续封隔体颗粒粒径、设计ICD筛管控流强度及优化配置ICD筛管的方法,形成了适用于渤海特高孔渗储层的防砂控水一体化完井技术。BN油田3口井进行了控水防砂一体化完井技术试验,与邻井相比,单井无水采油期平均延长187 d,初期含水率远低于预期含水率,井口无砂时间明显增长,其中BN-D4H1井井口无砂时间长达889 d。现场试验结果表明,防砂控水一体化完井技术可以满足BN油田控水、防砂的双重需求。

Abstract:The reservoir of Bohai BN Oilfield, dominated by unconsolidated sandstone with ultra-high porosity and permeability, exhibits strong heterogeneity and has serious water and sand production from producing wells. The existing water and sand control measures designed and implemented independently have problems such as cumbersome design and implementation, and poor effect of water and sand control. Therefore, based on the completion technology of continuous packer water control and the idea of geological engineering integration, the methods of optimizing the particle size of the continuous packer, designing the flow control strength of inflow control devices (ICDs), and optimizing the configuration of ICDs were proposed, and the integrated completion technology of water and sand control suitable for the Bohai reservoir with ultra-high porosity and permeability was developed. The integrated completion technology of water and sand control was tested in three wells in BN Oilfield. Compared with the adjacent well, the water-free oil production period of a single well was extended by 187 days on average, the initial water cut was much lower than expected. The wellhead sand-free time was significantly increased, among which the wellhead sand-free time of Well BN-D4H1 was 889 days. Field test results demonstrate that the integrated completion technology of sand and water control can meet the need for water and sand control in BN Oilfield.

-

随着低渗透、非常规油气资源的不断开发,长水平段水平井应用越来越广泛。钻水平井时,通常采用螺杆钻具进行滑动定向钻进,来控制井眼轨迹,但滑动定向钻进时,钻柱摩阻扭矩大,易出现托压现象,导致机械钻速降低[1-3]。通常情况下,滑动钻进时的机械钻速为复合钻进时的1/3~1/2[4]。

为了解决滑动钻进时的托压问题,提高滑动钻进机械钻速,国内外学者研究并提出了各种降阻技术方法,并进行了应用,取得了良好的效果,但同时也具有各自的局限性[5-16]。提高复合钻进比例,降低滑动钻进比例,可大幅度提高钻井速度,但复合钻进时井眼轨迹控制能力降低[5]。目前,水力振荡器应用范围较广,并且取得了一定的效果,但影响范围小、降阻效果不明显,并且水力压耗大[6-8]。旋转导向技术克服了滑动导向技术的不足,机械钻速高,但其使用及维护成本高,不利于降低钻井成本[9-12]。钻柱旋转可大幅度降低轴向摩阻,避免托压现象[13-14]。螺杆钻具已应用成熟且成本低,但进行定向钻进时不能旋转钻柱。为解决使用螺杆钻具定向钻进时不能旋转钻柱的问题,基于钻柱旋转降阻提速原理,笔者设计了可旋转钻柱滑动钻进工具(rotary slide drilling,RSD)。该工具既能保证螺杆钻具滑动定向钻进,又能旋转RSD以上的大部分钻柱。

1. RSD的降阻功能及结构设计

RSD与螺杆钻具配合使用,安放在螺杆钻具和无磁钻铤以上的位置,如图1所示。为在滑动定向钻进时实现旋转钻柱的功能,RSD需要产生可以抵消螺杆钻具反扭矩的扭矩,来保持工具面稳定,实现降低螺杆钻具滑动定向钻进时摩阻的目的。

采用钻具组合ϕ215.9 mm钻头+ϕ165.1 mm螺杆钻具+ϕ165.1 mm无磁钻铤+ϕ127.0 mm钻杆×10根+ϕ171.5 mm RSD+ϕ127.0 mm钻杆,对于相同的井身结构和井眼轨迹,利用Landmark软件计算水平段钻至1 000.00 m长时的摩阻,采用常规螺杆滑动钻进时的摩阻为250 kN,而采用RSD滑动钻进时的摩阻只有22 kN。

根据RSD的功能要求,设计了工具结构,如图2所示。RSD的基本结构由推力轴承和摩擦扭矩部件组成:推力轴承承受工作时的钻压及轴向拉力;摩擦扭矩部件包括弹簧和摩擦部件,可以在旋转时产生一个恒定的摩擦扭矩,利用弹簧的规格和压缩程度调节摩擦扭矩的大小。

RSD的上接头与钻杆连接,下接头与无磁钻铤和螺杆钻具连接。当钻杆顺时针旋转时,RSD就会对螺杆的外壳产生一个顺时针的扭矩,经过调节弹簧和摩擦部件,使RSD产生的扭矩抵消螺杆的反扭矩,从而达到钻柱旋转时稳定工具面的目的。

2. RSD的工作原理

RSD要平衡螺杆钻具反扭矩,就必须能产生大小相等、方向相反的扭矩。螺杆钻具的反扭矩随钻压增大而增大,且呈现振动状态,这就要求在正常钻压范围内,RSD产生的扭矩曲线与螺杆反扭矩曲线存在交点,因此将RSD产生的扭矩设计为一恒定值,不管螺杆反扭矩随着钻压如何变化,都会存在一个交点,最终实现平衡螺杆反扭矩的目标。

综上分析得知,在RSD扭矩

TS 、螺杆钻具反扭矩Tp 及钻柱与井壁摩擦扭矩Tf 的共同作用下,可以使工具面角长时间保持稳定,即:θ(Tp,TS,Tf,t)=C (1) 式中:θ为工具面角,rad;

TS 为RSD扭矩,N·m;Tp 为螺杆钻具反扭矩,N·m;Tf 为钻柱与井壁的摩擦扭矩,N·m;t为时间;C为常数。2.1 BHA井底扭转振动模型

为了分析钻柱在RSD扭矩和螺杆扭矩作用下的动力学特性,将RSD以下的钻具组合简化为一个整体(BHA),首先根据扭矩和转动惯量计算出BHA的角加速度,对其进行积分,可得不同时间下的工具面角:

θ(t)=TS(t)−Tp(t)−Tf(t)2∑miri2t2 (2) 其中,BHA的摩擦扭矩

Tf(t) 为:Tf(t)=mgμRω(t)R√v2p+[ω(t)R]2 (3) 式中:mi为BHA第i个单元的质量,kg;ri为BHA第i个质量单元到转轴的垂直距离,m; m为BHA的质量,kg;g为重力加速度,m/s2;μ为BHA与井壁的摩擦因数,一般取0.3;R为BHA的半径,m;vp为机械钻速,m/s;

ω(t) 为BHA的角速度,rad/s。正常钻进时,由于钻柱的振动及地层的非均质性,钻头的破岩扭矩是剧烈变化的,难以进行理论计算,根据现场使用井下参数记录仪Blackbox测得的井下数据及地面数据,反演螺杆钻具的反扭矩(ϕ215.9 mmPDC钻头)为:

Tp(t)=2858+312sin(25πt)+389sin(103πt) (4) 式(4)是基于ϕ215.9 mmPDC钻头正常钻进(钻压60~80 kN)测得的数据反演出的,揭示了破岩扭矩的平均值、振幅及频率等基本特征,可基本反映破岩扭矩的振动状态,因此可以用其分析RSD正常钻进时的工作原理。式(4)的缺点是无法反映钻压从零加载至正常值过程中扭矩的变化。

2.2 影响因素分析

利用上述BHA井底扭转振动模型,可研究RSD扭矩、BHA长度及规格对工具面角的影响。下面以BHA为ϕ215.9 mm钻头×0.30 m+ϕ165.1 mm螺杆钻具×8.50 m+ϕ165.1 mm无磁钻铤×18.20 m +ϕ171.5 mmRSD×3.00 m为例进行模拟分析。

模拟时输入的参数:机械钻速15 m/h,摩擦因数0.3,BHA长度30 m,BHA的平均外径165.1 mm、平均内径72.0 mm,BHA平均线质量130 kg/m。

模拟了RSD扭矩为2 800,2 858和2 900 N·m时,工具面角20 s内的变化情况,结果见图3。从图3可以看出:当RSD扭矩为2 858 N·m时,工具面角上下波动,但波峰波谷保持不变,因此处于动态平衡状态;当RSD扭矩为2 800 N·m时,工具面角逐渐减小;当RSD扭矩为2 900 N·m时,工具面角逐渐增大。RSD扭矩为2 800和2 900 N·m时都处于不平衡状态,但可以利用不平衡状态调整工具面角。

当RSD扭矩为2 858 N·m时,螺杆钻具处于动态平衡状态,虽然工具面角不发散,但处于左右摇摆状态。BHA中螺杆、无磁钻铤的长度和规格由钻井工艺决定,一般无法改变,但RSD的位置可调。由式(3)可知,对于相同尺寸的钻头、螺杆钻具和钻杆,RSD与螺杆钻具间的距离越大,BHA的转动惯量越大,与井壁的摩擦扭矩越大。

利用上节模型,模拟了RSD与螺杆钻具之间加入不同长度钻杆后工具面角20 s内的变化情况,结果见图4(图4中,钻具组合1为ϕ215.9 mm钻头×0.30 m+ϕ165.1 mm螺杆钻具×8.50 m+ϕ165.1 mm无磁钻铤×18.20 m+ϕ127.0 mm钻杆×108.00 m+ϕ171.5 mm RSD×3.00 m;钻具组合2为ϕ215.9 mm钻头×0.30 m+ϕ165.1 mm螺杆钻具×8.50 m+ϕ165.1 mm无磁钻铤×18.20 m+ϕ127.0 mm钻杆×72.00 m +ϕ171.5 mm RSD×3.00 m;钻具组合3为ϕ215.9 mm钻头×0.30 m+ϕ165.1 mm螺杆钻具×8.50 m+ϕ165.1 mm无磁钻铤×18.20 m+ϕ127.0 mm钻杆×36.00 m+ϕ171.5 mm RSD×3.00 m)。由图4可以看出,当RSD与螺杆钻具间的距离由54.20 m增至126.20 m后,工具面角变化幅度由85°降为12°,表明RSD的安放位置对于工具面角的摆动具有重要影响。

综上分析,RSD要实现旋转钻柱滑动定向钻进,需要满足以下2个条件:

1)RSD输出的扭矩能够使螺杆钻具工具面左右摇摆幅度一致。RSD输出扭矩与螺杆钻具的扭矩振动参数有关,可根据BHA扭转动力学模型计算。

2)RSD安放位置要合理。RSD输出扭矩与破岩时螺杆反扭矩差值一定时,较长的钻具具有较大的转动惯量和摩擦阻力,可有效减小螺杆左右摇摆的幅度。RSD的安放位置应根据BHA扭转动力学模型计算结果来确定。

3. RSD原理样机测试

RSD测试的关键是模拟螺杆钻具反扭矩的振动。图5所示为RSD功能测试装置,其模拟螺杆钻具反扭矩振动的原理是,电动机通过与减速器、磁粉离合器配合,输出变化且可控的转速和扭矩。利用磁粉离合器调节扭矩,首先根据磁粉离合器的性能参数建立扭矩与电流的关系,利用井下实际扭矩的分析结果,在工控机上进行编程,通过控制电流来控制磁粉离合器输出的扭矩。

模拟螺杆反扭矩的波动范围为0~200 N·m,振动频率为1 Hz。RSD原理样机产生75 N·m的扭矩,模拟螺杆反扭矩在70~90和60~90 N·m振动,振动状态为锯齿状。

当螺杆反扭矩在70~90 N·m振动时,其平均值为80 N·m,高于RSD原理样机产生的扭矩(75 N·m),此时RSD原理样机的外壳(相当于实钻过程中的螺杆钻具外壳)出现反转,工具面角随时间增长逐渐减小(如图6(a)所示),工具面角平均值从20°降至–40°左右。

当螺杆反扭矩在60~90 N·m振动时,其平均值为75 N·m,与RSD原理样机产生的扭矩大小相等、方向相反。因此RSD原理样机的外壳出现了左右振动幅度相当的振动,虽然振动很激烈,但工具面角基本在0°~60°范围波动(如图6(b)所示),工具面角随着时间增长保持相对稳定,说明RSD可以保持工具面动态稳定。

4. 现场测试

RSD工程样机在中海石油的试验井进行了测试,测试时长48 h。该试验井井深539.25 m,井斜角28.7°。测试钻具组合按理论分析组装:ϕ215.9 mm钻头+ϕ165.1mm螺杆钻具+ϕ165.1 mm无磁钻铤(MWD)+ϕ127.0 mm钻杆×10根+ϕ171.5 mm RSD+ϕ127.0 mm钻杆。钻井参数:钻压10~80 kN,转速10 r/min,排量15~25 L/s。

测试过程中,RSD的强度满足要求,其润滑系统运转正常。根据MWD的测量结果,绘制了工具面角与钻压的关系曲线,见图7。从图7可以看出:钻压在10~30 kN范围内,随着钻压增大,工具面角增大,说明RSD产生的扭矩高于螺杆反扭矩;钻压在30~60 kN范围内,工具面稳定,说明RSD产生的扭矩与螺杆反扭矩大小近似相等;钻压在70~80 kN范围内,随着钻压增大,工具面角逐渐减小,说明RSD产生的扭矩小于螺杆反扭矩。由此可知,在特定钻压范围内,RSD可实现钻柱旋转、螺杆定向的功能,初步达到了设计目标。

5. 结论与建议

1)定向钻进可旋转钻柱降阻工具利用旋转钻柱减小轴向摩擦力,是一种用于解决钻压传递、提高机械钻速的工具。

2)基于BHA的扭转动力学模型分析得知,RSD实现降阻功能的必要条件为平衡螺杆反扭矩和安放位置合理。

3)室内及现场测试证明,利用RSD可以在旋转钻柱条件下稳定螺杆工具面。

4)定向钻进可旋转钻柱降阻工具目前还处于探索阶段,需要继续对其结构进行优化,以提高其性能、延长其使用寿命。

-

表 1 BN油田连续封隔体控水防砂井实际生产与设计对比

Table 1 Comparison of actual production and design of wells with continuous packer application in BN Oilfield

井号 配产量/

(m3·d−1)初期实际产油量/

(m3·d−1)预期初期

含水率,%实际初期

含水率,%BN-A29H1 50 160 50 4 BN-A36H1 35 175 81 2 BN-D4H1 40 140 75 9 -

[1] 罗杨,徐进杰,王建忠,等. 致密油水平井出砂机理[J]. 大庆石油地质与开发,2018,37(3):168–174. LUO Yang, XU Jinjie, WANG Jianzhong, et al. Sand producing mechanism for the horizontal wells in the tight oil[J]. Petroleum Geology & Oilfield Development in Daqing, 2018, 37(3): 168–174.

[2] 袁光杰,张玉达,董京楠,等. 油气井筒出砂理论技术新进展[J]. 科学技术与工程,2023,23(7):2694–2704. YUAN Guangjie, ZHANG Yuda, DONG Jingnan, et al. New development of sand production theory and technology in oil and gas wellbore[J]. Science Technology and Engineering, 2023, 23(7): 2694–2704.

[3] 黄晓东,董海宽,邓永祥,等. 海上油田高含水油藏水平井堵水实验研究[J]. 科学技术与工程,2014,14(25):202–205. HUANG Xiaodong, DONG Haikuan, DENG Yongxiang, et al. The experimental study for water shut-off on horizontal well of high water cut reservoir in offshore oilfield[J]. Science Technology and Engineering, 2014, 14(25): 202–205.

[4] 宋勇. 胜利油区整装油藏特高含水期水平井提高采收率技术[J]. 油气地质与采收率,2015,22(3):119–123. SONG Yong. EOR technology for the horizontal wells at extra-high water cut stage in integrated oil reservoirs of Shengli Oilfield[J]. Petroleum Geology and Recovery Efficiency, 2015, 22(3): 119–123.

[5] 杨成. 渤中34-1油田NmⅢ油组沉积相分析与砂体预测[D]. 成都:西南石油大学,2018. YANG Cheng. Sedimentary facies analysis and prediction of sand-body in NmⅢ oil group of Bozhong 34-1 Oilfield[D]. Chengdu: Southwest Petroleum University, 2018.

[6] 邢洪宪,李斌,韦龙贵,等. 适度防砂完井技术在渤海油田的应用[J]. 石油钻探技术,2009,37(1):83–86. XING Hongxian, LI Bin, WEI Longgui, et al. Application of proper sand control completion technology in Bohai Oilfield[J]. Petroleum Drilling Techniques, 2009, 37(1): 83–86.

[7] 刘新锋,高斐,赵轩康,等. 渤海湾中部疏松砂岩油藏砾石充填适度防砂适应性评价[J]. 科学技术与工程,2019,19(22):129–135. LIU Xinfeng, GAO Fei, ZHAO Xuankang, et al. Moderate sand control adaptability evaluation of gravel packing in loose sandstone reservoirs in central Bohai Bay[J]. Science Technology and Engineering, 2019, 19(22): 129–135.

[8] 孟文波,刘书杰,黄熠,等. 海上长水平井旁通筛管砾石充填技术及应用[J]. 中国海上油气,2021,33(6):166–173. MENG Wenbo, LIU Shujie, HUANG Yi, et al. Gravel packing technology of bypass screen and its application in offshore long horizontal wells[J]. China Offshore Oil and Gas, 2021, 33(6): 166–173.

[9] 谢金川. 水平井砾石充填防砂工艺技术的研究与应用[J]. 钻采工艺,2019,42(3):38–40. XIE Jinchuan. Research on gravel packing sand control technology and application in horizontal wells[J]. Drilling & Production Technology, 2019, 42(3): 38–40.

[10] 段友智,艾爽,刘欢乐,等. 形状记忆筛管自充填防砂完井技术[J]. 石油钻探技术,2019,47(5):86–90. DUAN Youzhi, AI Shuang, LIU Huanle, et al. Shape memory screen self-packing sand control completion technology[J]. Petroleum Drilling Techniques, 2019, 47(5): 86–90.

[11] 何海峰. 胜利海上疏松砂岩油藏分层防砂分层采油技术[J]. 石油钻探技术,2021,49(6):99–104. HE Haifeng. Separate layer sand control and oil production technology in offshore unconsolidated sandstone reservoirs of Shengli Oilfield[J]. Petroleum Drilling Techniques, 2021, 49(6): 99–104.

[12] 曹砚锋,李汉兴,黄辉,等. 海上油田高效开发钻完井关键技术研究新进展[J]. 中国海上油气,2022,34(6):124–134. CAO Yanfeng, LI Hanxing, HUANG Hui, et al. Research progress on drilling and completion technology for efficient development of offshore oilfields[J]. China Offshore Oil and Gas, 2022, 34(6): 124–134.

[13] 张伟,戴宗,龚斌,等. 裂缝性礁灰岩过饱和充填控水影响因素分析[J]. 特种油气藏,2022, 29(2):164–169. ZHANG Wei, DAI Zong, GONG Bin, et al. Analysis on factors affecting water control by supersaturated filling of fractured reef limestone[J]. Special Oil & Gas Reservoirs, 2022, 29(2): 164–169.

[14] 董长银,陈琛,周博,等. 油气藏型储气库出砂机理及防砂技术现状与发展趋势展望[J]. 石油钻采工艺,2022,44(1):43–55. DONG Changyin, CHEN Chen, ZHOU Bo, et al. Sand production mechanism and sand control technology status and prospect of oil-gas reservoir type gas storage[J]. Oil Drilling & Production Technology, 2022, 44(1): 43–55.

[15] 高晓飞,罗东红,闫正和,等. 一种减缓底水锥进的新方法:中心管技术及其在西江23-1油田水平井开发中的应用[J]. 中国海上油气,2010,22(2):114–118. GAO Xiaofei, LUO Donghong, YAN Zhenghe, et al. A new method for delaying coning in bottom water reservoir: application of stinger technology in horizontal well development of XJ23-1 Oilfield[J]. China Offshore Oil and Gas, 2010, 22(2): 114–118.

[16] 宋显民,兰少坤,王兴,等. 水平井调流控水完井技术及优化设计方法[J]. 西南石油大学学报(自然科学版),2022,44(5):166–174. SONG Xianmin, LAN Shaokun, WANG Xing, et al. Completion technology and optimization design method of self-adaptive flow control in horizontal well[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2022, 44(5): 166–174.

[17] 孙昕迪,白宝君. 国内外水平井控水技术研究现状[J]. 石油勘探与开发,2017,44(6):967–973. SUN Xindi, BAI Baojun. Comprehensive review of water shutoff methods for horizontal wells[J]. Petroleum Exploration and Development, 2017, 44(6): 967–973.

[18] 杨树坤,郭宏峰,郝涛,等. 海上油田电控智能控水采油工具研制及性能评价[J]. 石油钻探技术,2022,50(5):76–81. YANG Shukun, GUO Hongfeng, HAO Tao, et al. Development and performance evaluation of an electrically controlled intelligent water control and oil recovery tool for offshore oilfields[J]. Petroleum Drilling Techniques, 2022, 50(5): 76–81.

[19] 饶志华,薛亮,单彦魁,等. ICD筛管环空连续封隔+裂缝充填双重控水实验:以南海东部X油田裂缝型礁灰岩油藏为例[J]. 大庆石油地质与开发,2023,42(1):83–90. RAO Zhihua, XUE Liang, SHAN Yankui, et al. Experiment of dual water control by ICD screen annular continuous packing + fracture filling: Taking fractured reef limestone reservoir of X Oilfield in east of South China Sea as an example[J]. Petroleum Geology & Oilfield Development in Daqing, 2023, 42(1): 83–90.

[20] 陶彬,袁才,吴湘杰,等. 稀油均质油藏水平井控水的必要性分析[J]. 石化技术,2022,29(9):165–167. TAO Bin, YUAN Cai, WU Xiangjie, et al. Analysis on the necessity of water control for horizontal well in thin oil homogeneous reservoir[J]. Petrochemical Industry Technology, 2022, 29(9): 165–167.

[21] 张俊斌,安永生,汪红霖,等. 水平井连续封隔体ICD完井生产动态数值模拟方法研究[J]. 中国海上油气,2021,33(3):121–125. ZHANG Junbin, AN Yongsheng, WANG Honglin, et al. Study on numerical simulation method for production performance of ICD completion with continuous packer in horizontal wells[J]. China Offshore Oil and Gas, 2021, 33(3): 121–125.

[22] 万小进,吴绍伟,周泓宇,等. 调流控水筛管配合颗粒充填控水技术研究与试验[J]. 钻采工艺,2020,43(5):61–63. WAN Xiaojin, WU Shaowei, ZHOU Hongyu, et al. Research and test on water control technology of flow regulation and water control screen tube with particle filling[J]. Drilling & Production Technology, 2020, 43(5): 61–63.

[23] 周泓宇,万小进,吴绍伟,等. 水平井控水砾石充填防砂技术研究[J]. 石油钻探技术,2021,49(1):101–106. ZHOU Hongyu, WAN Xiaojin, WU Shaowei, et al. Study on the sand control technique for gravel packing with water control for horizontal wells[J]. Petroleum Drilling Techniques, 2021, 49(1): 101–106.

[24] 赵旭,龙武,姚志良,等. 水平井砾石充填调流控水筛管完井技术[J]. 石油钻探技术,2017,45(4):65–70. ZHAO Xu, LONG Wu, YAO Zhiliang, et al. Completion techniques involving gravel-packing inflow-control screens in horizontal wells[J]. Petroleum Drilling Techniques, 2017, 45(4): 65–70.

[25] 谢日彬,李海涛,杨勇,等. 礁灰岩油田水平井微粒充填ICD均衡控水技术[J]. 石油钻采工艺,2019,41(2):160–164. XIE Ribin, LI Haitao, YANG Yong, et al. Particle filling based ICD isostatic water control technology used for horizontal wells in limestone reef oilfields[J]. Oil Drilling & Production Technology, 2019, 41(2): 160–164.

[26] 李锋,李晓平,杨勇,等. 连续封隔体防止泥堵技术的应用及效果分析[J]. 西南石油大学学报(自然科学版),2022,44(1):121–131. LI Feng, LI Xiaoping, YANG Yong, et al. Application of continuous pack-off technology in packing-off mudstone of horizontal well[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2022, 44(1): 121–131.

[27] 杨勇,李锋,张伟,等. 礁灰岩油藏微粒过饱和充填技术机理及创新实践[J]. 西南石油大学学报(自然科学版),2022,44(4):129–138. YANG Yong, LI Feng, ZHANG Wei, et al. The mechanisms and innovative applications of over-saturated particles well completion technique in limestone reservoir[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2022, 44(4): 129–138.

[28] 李中,邱浩,文敏,等. 潜山裂缝气藏连续封隔体复合控水实验评价:以HZ凝析气田为例[J]. 断块油气田,2022,29(6):837–841. LI Zhong,QIU Hao,WEN Min,et al. Experimental evaluation of composite water control for continuous packer in buried hill fractured gas reservoir:A case study of HZ condensate gas field[J]. Fault-Block Oil & Gas Field, 2022, 29(6): 837–841.

[29] 单彦魁,王丙刚,魏裕森,等. 控水防砂一体化工艺技术研究与应用[J]. 中国海上油气,2022,34(3):133–138. SHAN Yankui, WANG Binggang, WEI Yusen, et al. Research and application of integrated water and sand control technology[J]. China Offshore Oil and Gas, 2022, 34(3): 133–138.

[30] 王利华,邓金根,周建良,等. 适度出砂开采标准金属网布优质筛管防砂参数设计实验研究[J]. 中国海上油气,2011,23(2):107–110. WANG Lihua, DENG Jingen, ZHOU Jianliang, et al. Experimental study on premium screen mesh opening design for reasonable sand control[J]. China Offshore Oil and Gas, 2011, 23(2): 107–110.

[31] 张俊斌,张庆华,张译,等. 疏松砂岩油藏水平井防砂筛管优选和防砂精度优化[J]. 石油钻采工艺,2018,40(6):811–817. ZHANG Junbin, ZHANG Qinghua, ZHANG Yi, et al. Selection and sand control precision optimization of sand control screen for horizontal wells in unconsolidated sandstone oil reservoirs[J]. Oil Drilling & Production Technology, 2018, 40(6): 811–817.

[32] 白蓉,唐洪明,孙福街,等. 适度出砂在NB35-2稠油油田应用探索[J]. 西南石油大学学报(自然科学版),2009,31(3):103–106. BAI Rong, TANG Hongming, SUN Fujie, et al. Probe into reasonable sand production applied in NB35-2 heavy oil reservoir[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2009, 31(3): 103–106.

[33] 陈宇,邓金根,何宝生,等. 砾石充填井工业砾石尺寸优选[J]. 石油钻探技术,2011,39(3):92–95. CHEN Yu, DENG Jingen, HE Baosheng, et al. Optimization of industrial gravel size in gravel packed wells[J]. Petroleum Drilling Techniques, 2011, 39(3): 92–95.

[34] SAUCIER R J. Considerations in gravel pack design[J]. Journal of Petroleum Technology, 1974, 26(2): 205–212. doi: 10.2118/4030-PA

-

期刊类型引用(8)

1. 张峰,姬超,刘宇. 长水平段水平井钻井技术难点分析及对策分析. 中国石油和化工标准与质量. 2024(01): 156-158 .  百度学术

百度学术

2. 赵铁桥. 水平井高效钻井技术进展研究. 中国石油和化工标准与质量. 2024(04): 168-170 .  百度学术

百度学术

3. 余文帅,苏强,孟鐾桥,夏连彬,李亚天,谭天一. 天府气田致密气水平井二开一趟钻钻井关键技术. 天然气勘探与开发. 2024(06): 35-44 .  百度学术

百度学术

4. 亢武臣,杨书博,赵琪琪,黄豪彩,丁士东. 基于优化变分模态分解和互相关的钻井液脉冲信号处理方法. 石油钻探技术. 2023(03): 144-151 .  本站查看

本站查看

5. 路保平,陈会年. 《石油钻探技术》50年与未来发展建议. 石油钻探技术. 2023(04): 3-10 .  本站查看

本站查看

6. 甘新星,董仲林,马吉龙,杜晓雨. 南川页岩气田超长水平段水平井高效下套管技术. 断块油气田. 2023(05): 874-878 .  百度学术

百度学术

7. 张辉. 电力通信网络可信安全接入机制研究与设计. 软件. 2023(09): 59-63 .  百度学术

百度学术

8. 黄熠,刘和兴,刘智勤,彭巍,徐超. 南海西部浅层大位移水平井钻井关键技术与实践. 中国海上油气. 2023(06): 115-123 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: