Analysis of Gas Phase Fluctuation Pressure in Oil Pipes During Production and Shutdown Operations of Gas Storage

-

摘要:

为优化储气库采–关作业,降低油管气相波动压力,减少冲击载荷导致的阀芯和油管疲劳失效,考虑气相压缩性、流动速度、压力波速等因素,基于质量及动量守恒方程,建立了储气库采–关作业油管气相波动压力数学模型,并采用特征线法编程求解。以呼图壁储气库H2井为例,分析了储气井日产气量、油管深度、油管内径、关阀时间和气体流量等因素对油管波动压力的影响。随着阀门关闭时间延长,波动压力峰值减小,达到峰值的时间增长;随着油管内径减小、日产气量增大、关阀时间缩短,波动压力呈增大趋势。日产气量从50×104 m3/d增至600×104 m3/d,井口波动压力最大峰值减小10.05 MPa,井底波动压力最大峰值减小4.01 MPa。研究表明,油管气相波动压力数学模型具有较高精度,可以为储气库采–关作业提供指导。

Abstract:To optimize the production and shutdown operations of gas storage, reduce the gas phase fluctuation pressure of oil pipes and avoid fatigue failure of valve cores and oil pipes caused by impact loads, a mathematical model of gas phase fluctuation pressure in the oil pipes for production and shutdown operations of gas storage was established by considering the gas phase compressibility, flow velocity, pressure wave velocity, and other factors. The model was established based on the conservation equation of mass and momentum, and the model was solved by the method of characteristics programming. With Well H2 of Hutubi gas storage as an example, the effects of factors such as daily gas production, depth and inner diameter of oil pipe, shutdown time, and gas volume of gas storage well on the fluctuation pressure of oil pipe were analyzed. As the shutdown time prolonged, the peak fluctuation pressure decreased, and the time to reach the peak increased. As the inner diameter of the oil pipe decreased, the daily production increased, and the shutdown time decreased. The fluctuation pressure showed an increasing trend. Compared with a daily production of 50×104 m3/d and 600×104 m3/d, the maximum peak fluctuation pressure at the wellhead decreased by 10.05 MPa, and the maximum fluctuation pressure at the bottom of the well decreased by 4.01 MPa. The research shows that the mathematical model for the gas phase fluctuation pressure of the oil pipe has high accuracy, it can provide assistance for the production and shutdown operations of gas storage.

-

Keywords:

- gas storage /

- production and shutdown conversion /

- fluctuation pressure /

- oil pipe /

- peak pressure

-

目前,全球已建成715座储气库。中国地下储气库建设起步于20世纪70年代,至今已建成25座储气库[1-2],其中呼图壁储气库是目前国内规模最大的储气库,总库容达107×108 m3。随着储气库日采气量增大,储气库调峰周期性的采–关(阀门由采气状态向关井状态调整)过程中会产生较大的波动压力[3-6],导致发生阀芯刺漏、油管柱密封失效等问题,会造成天然气窜漏或泄漏,可能引发火灾、爆炸等重大事故。挪威科技工业研究也证实,储气库采–关气井的泄漏情况是一般生产井的2~3倍[7-10]。

国内外研究者已开展了储气库储层应力敏感、气体速敏等实验,揭示了储气库注气压力动态变化诱发的储层微粒运移规律[11]。同时,采用数值模拟、有限元方法等方法,揭示了储气库井筒内的动力特性和频域变化特征,探究了储气库注采过程管柱非线性振动特性[12-13]。目前,大量相关研究集中在数值模拟分析方面,基于储气库采–关作业转换过程的波动压力变化规律尚不明确,且少有系统开展阀门、油管系统以及储气库采–关作业油管气相波动压力计算分析的研究[14-18]。为此,笔者考虑气相压缩性、气相压力波速[19]、开关阀门速度等因素,建立了呼图壁储气库采–关作业油管气相波动压力数学模型,提出了具体特征线计算方法,以呼图壁储气库H2井为例,分析了储气井日产气量、油管深度、油管内径、关阀时间、气体流量等因素对波动压力的影响规律,以期为现场阀门调节提供理论指导。

1. 波动压力数学模型的建立

1.1 运动方程

根据动量守恒方程,建立油管气相波动压力运动方程:

pA+ρg(A+∂A∂sds2)dssinβ+(p+∂p∂sds2)∂A∂sds−[pA+∂(pA)∂sds]−τ0Xds=ρ(A+∂A∂sds2)dsdvdt (1) 式中:p为压力,MPa;A为油管内横截面积,m2;ρ为液相密度,kg/L;g为重力加速度,m/s2;s为管柱长度,m;β为油管与地平面夹角,(°);τ0为湿相周切向力,N/m2;X为管柱周长,m;v为气相流动速度,m/s;t为时间,s。

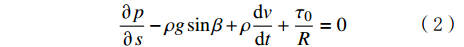

通过化简式(1),约去微元项ds及A等参数,得到:

∂p∂s−ρgsinβ+ρdvdt+τ0R=0 (2) 考虑水力半径、油管深度、摩擦阻力等参数,根据连续守恒方程得到:

∂z∂s+1ρg∂p∂s+1g(∂v∂t+v∂v∂s)+fv|v|8Rg=0 (3) 式中:R 为油管水力半径,m;f为油管摩阻系数。

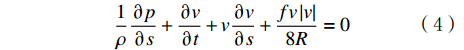

油管气相波动压力运动方程为:

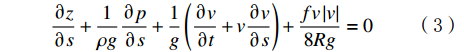

1ρ∂p∂s+∂v∂t+v∂v∂s+fv|v|8R=0 (4) 1.2 连续方程

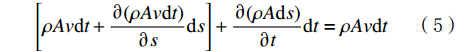

根据质量守恒方程,可得到油管气相波动压力连续方程:

[ρAvdt+∂(ρAvdt)∂sds]+∂(ρAds)∂tdt=ρAvdt (5) 整理式(5),得到:

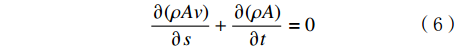

∂(ρAv)∂s+∂(ρA)∂t=0 (6) 将式(6)变形,可得:

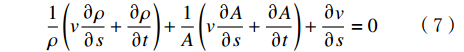

1ρ(v∂ρ∂s+∂ρ∂t)+1A(v∂A∂s+∂A∂t)+∂v∂s=0 (7) 化简式(7),可得:

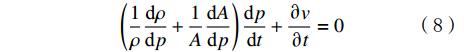

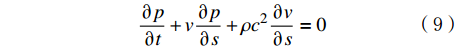

(1ρdρdp+1AdAdp)dpdt+∂v∂t=0 (8) 油管气相波动压力连续方程为:

∂p∂t+v∂p∂s+ρc2∂v∂s=0 (9) 式中:c为压力波速,m/s。

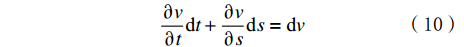

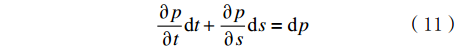

式(5)、式(6)的微分变量需满足:

∂v∂tdt+∂v∂sds=dv (10) ∂p∂tdt+∂p∂sds=dp (11) 1.3 模型求解

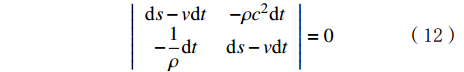

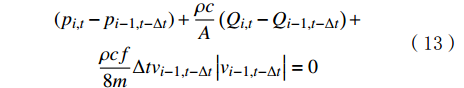

根据特征线法求解原理,考虑式(10)与式(11)唯一解条件,得到如下行列式:

|ds−vdt−ρc2dt−1ρdtds−vdt|=0 (12) 对气相波动压力特征线第1族函数差分,可得:

(pi,t−pi−1,t−Δt)+ρcA(Qi,t−Qi−1,t−Δt)+ρcf8mΔtvi−1,t−Δt|vi−1,t−Δt|=0 (13) 对气相波动压力特征线第2族函数差分,可得:

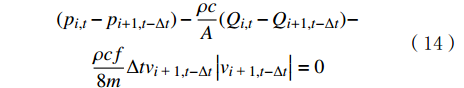

(pi,t−pi+1,t−Δt)−ρcA(Qi,t−Qi+1,t−Δt)−ρcf8mΔtvi + 1,t−Δt|vi + 1,t−Δt|=0 (14) 式中:

pi,t 为i节点在t时刻的压力,MPa;Qi,t 为i节点在t时刻的流量,m3/s;Δt 为时间间隔,s;i为网格节点。储气库采–关工况条件下,油管气相波动压力求解步骤如下:

1)将油管深度划分 n 个单元网格,当 t =0 时,波动压力为初始时间,此时井筒流体处于稳定流动状态,作为网格求解初始条件。波动压力传播过程中,将第 i 个( t 时刻)油管网格深度的气相波速、密度、黏度和压力视为恒定常数(网格内长度波动压力数值不发生变化),滑移计算不同网格的波动压力,得到沿着井筒不同网格变化的波动压力。

2)确定每个网格初始稳态气相偏差因子、气体密度、气体黏度、油管压力和温度等物性参数,可通过气体状态方程等方法求取稳态油管气相压力。

3)结合每个网格初始稳态气相物性参数,采用双流体数学模型,求解油管气相压力波速。

4)输入t=0时刻(第1个网格)气相密度、温度、井口压力、气相黏度、油管内径等参数,迭代计算t时刻(第i个网格)的气相波动压力。

2. 模型验证

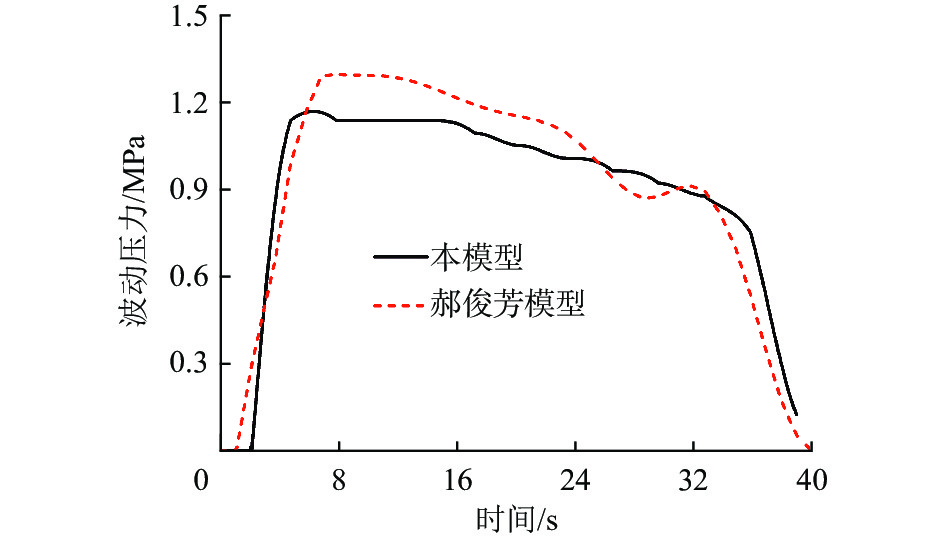

实测波动压力数据与所建模型计算波动压力数据对比结果如图1所示。采用井筒波动压力测试结果[20],数学模型输入数据与测试条件一致。采用ϕ215.9 mm内径管体,测试井深3273.75 m、流体平均密度0.87 kg/L,流性指数0.725、测试时间40 s、井口压力0.101 MPa等关键参数,按照波动压力模型求解方法计算波动压力。与实测数据对比,最大误差≤5%,由于采–关作业油管与实验井筒所采用的波动压力模型及求解方法相同,因此采用实验井实测数据验证模型准确性具有一定可靠性。

3. 波动压力影响因素分析

3.1 实例基础参数及阀门阻力系数设置

3.1.1 基础参数

呼图壁储气库H2井井深为3191 m,日产气量为5×104m3/d,油管内径为88.9 mm,气体成分为甲烷,阀门关阀方式为线性,井口温度为25 ℃,关阀时间为50 s,井口气相动力黏度为10.318 μPa·s,井口气相密度为1.138 kg/m3,采用的是储气井ϕ50.8 mm阀门,电压频率为50 Hz,现场调阀模式采用无模型触探式的关阀方式,即直接通过远程控制,一次性线性全关至0%。

3.1.2 阀门阻力系数

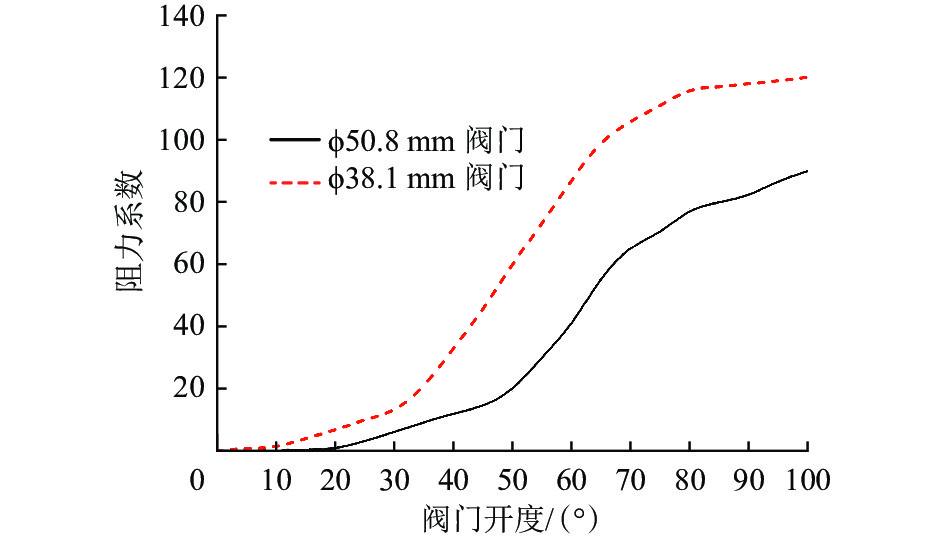

阀门阻力系数曲线由厂家交付阀门时提供,储气库采–关常用ϕ50.8 mm和ϕ 38.1 mm阀门,采用三次样条插值方法,将阀门阻力系数离散点平滑成曲线,计算波动压力模型时,首先计算相应开度下的阀门阻力系数,作为模型求解的基础条件;呼图壁储气库井区气井阀门的有效阻力系数区间约为20~80,当阀门开度在有效阻流区间内时,适当延长阀门调节时间,达到减小波动压力峰值的目的;当阀门开度在无效阻流区间内时,通过减少调阀时间,提高调阀效率,结果如图2所示。随着井深及日产气量的增大,油管内气相压力波速增大,井底压力响应时间缩短。

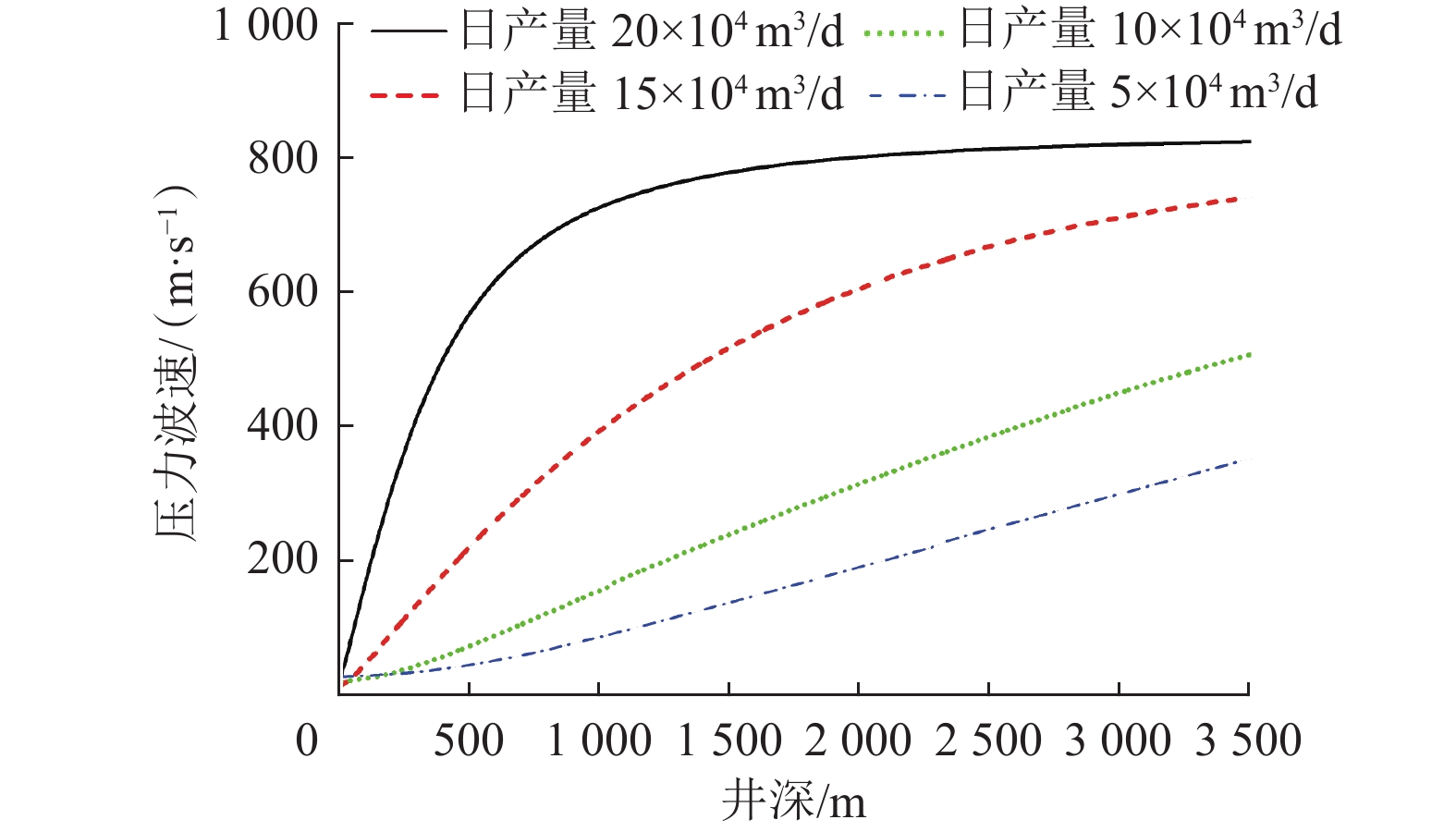

3.2 储气井日产气量对油管压力波速的影响

不同日产气量条件下的井深与油管内气相压力波速关系如图3所示。井深不大于500 m时,随着井深增大,日产气量为5×104 m3/d的压力波速趋于恒定,而日产气量为20×104 m3/d的压力波速急剧增大。井深大于500 m时,随着井深增大,压力波速增大趋势显著。压力波速受气体可压缩性的影响较大,井深为1 000 m时,日产气量从5×104 m3/d变化至20×104 m3/d,压力波速从88.95 m/s增至729.81 m/s,增大720.5%。准确求解油管气相的压力波速,不仅能提高波动压力求解精度,还可以指导阀门调节时间间隔的制定。

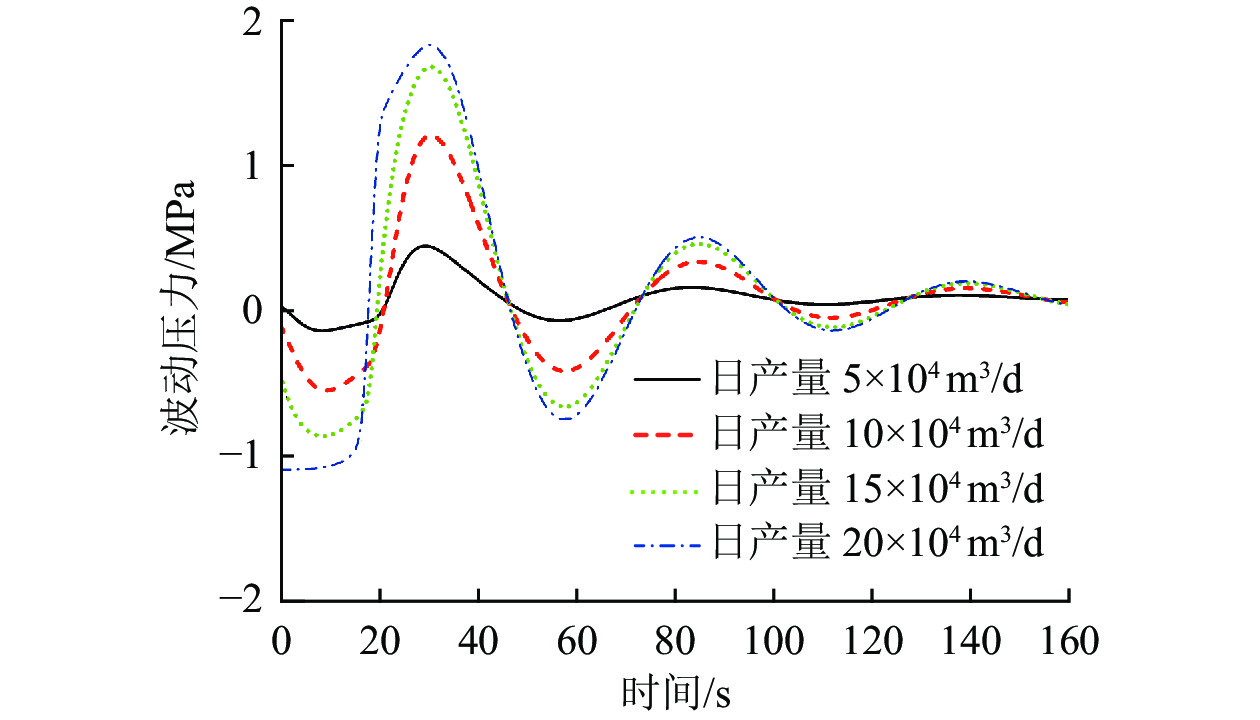

3.3 储气井日产气量对油管波动压力的影响

日产气量对井口波动压力的影响如图4所示。随着日产气量增大,油管内气体动能增大,波动压力呈现增大趋势。由于摩擦阻力消耗了波动压力传播能量,井底波动压力同井口比较,井底波动压力同时受气体流速和油管沿程摩擦阻力的影响,因此井口比井底受波动压力的影响更大,更易发生油管疲劳损坏,过大的井口波动压力会缩短阀芯的使用寿命。

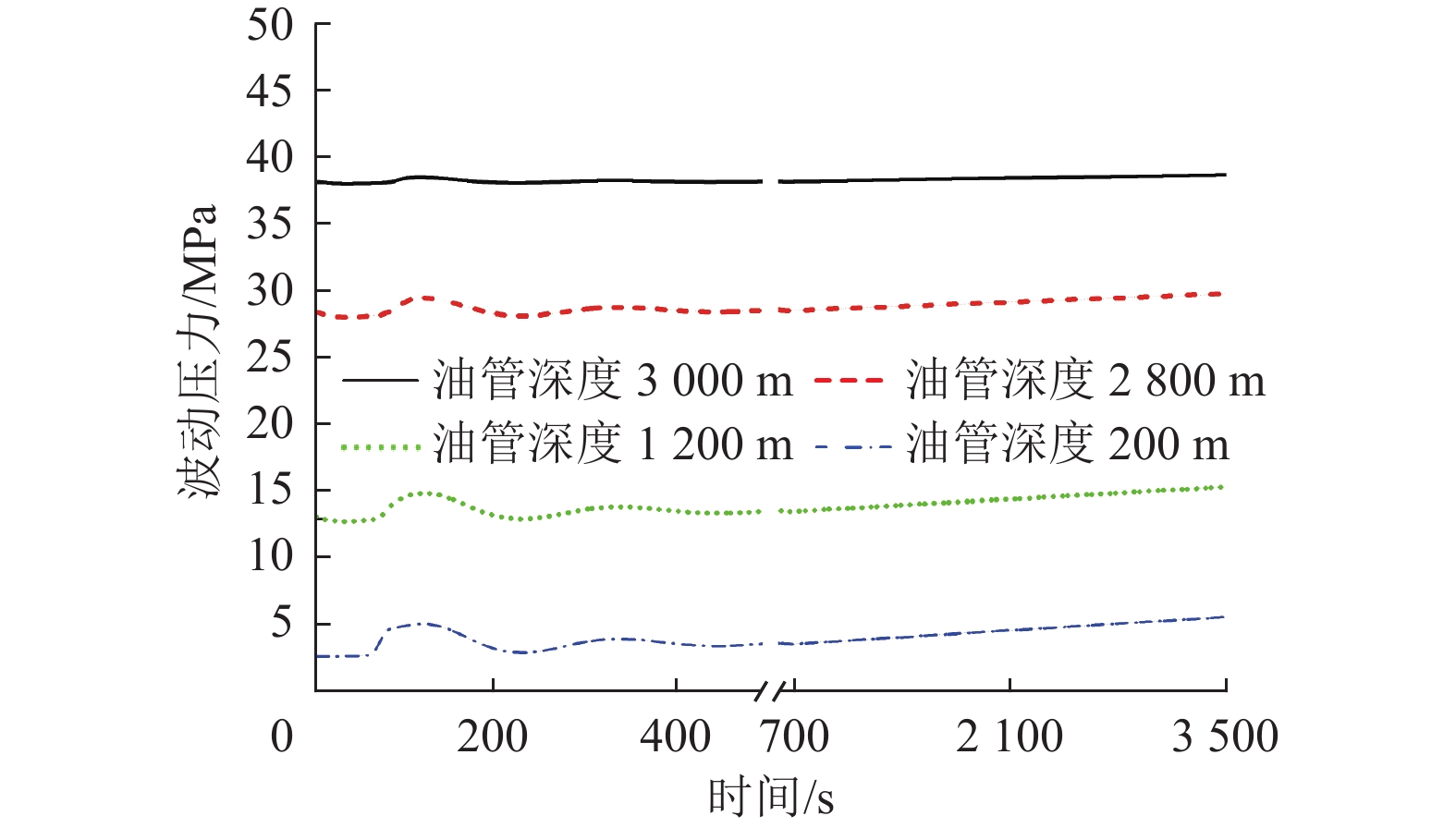

3.4 油管深度对油管波动压力的影响

油管深度对油管气相有效压力的影响如图5所示,油管内气相有效压力为波动压力与稳态压力代数和,井底的波动压力相比井底初始稳态压力较小,井底波动压力对有效压力影响不显著。当波动压力从井口向井底传播时,波动压力受油管内壁摩擦阻力影响,井口波源处的波动压力远大于井底波动压力,距井口距离越小,油管柱受波动压力冲击载荷影响越大。

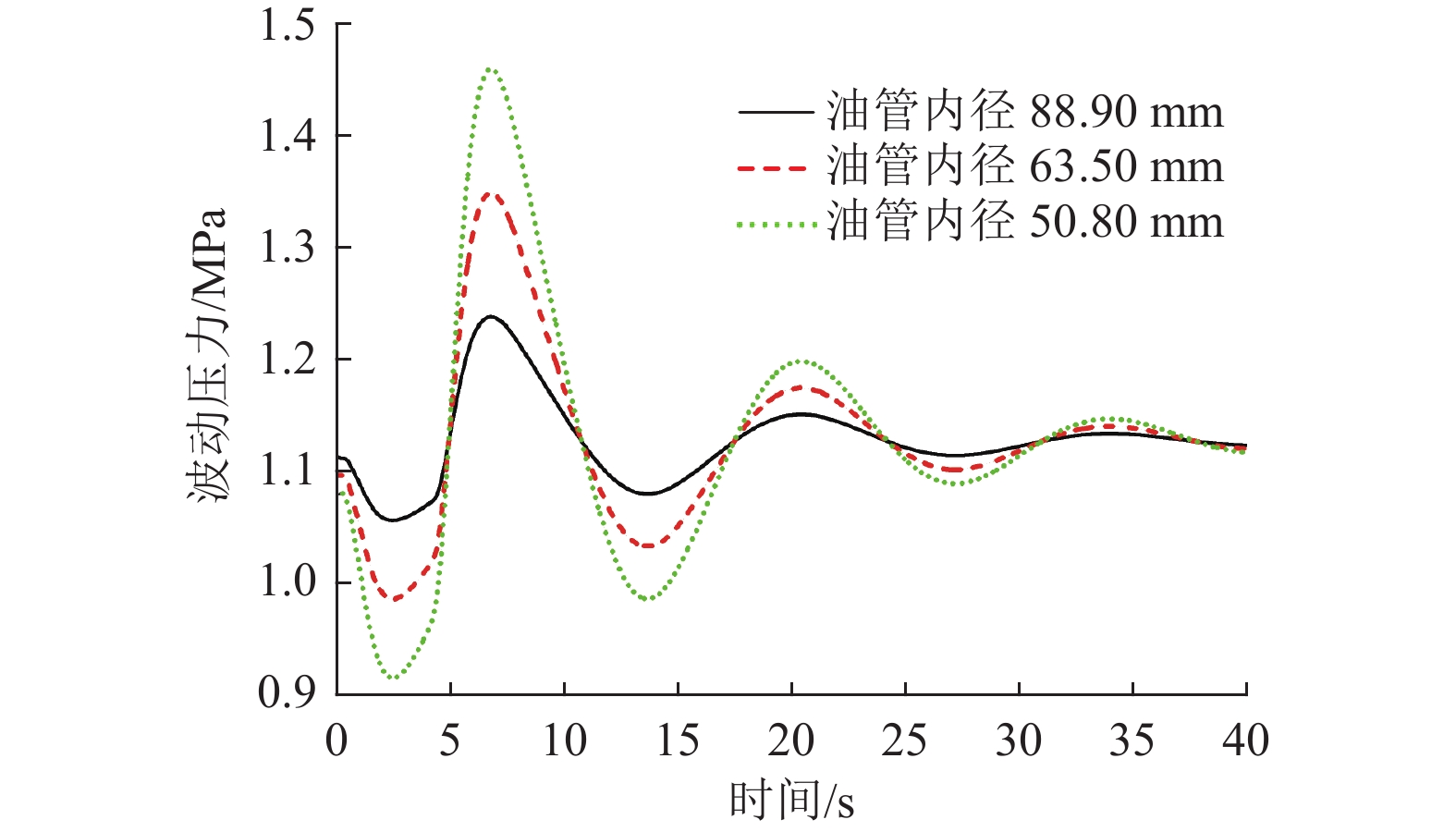

3.5 油管内径对井口波动压力的影响

油管内径对井口油管气相波动压力的影响如图6所示。油管内径减小使相同流量的气体流动速度增大,单位时间内转换的气体动能增大,从而使油管气相波动压力呈现增大趋势。当油管内径从88.9 mm变化至50.8 mm,油管内气相波动压力峰值从1.22 MPa增大至1.43 MPa,油管内气相波动压力峰值增大了17.21%,油管内径的变化对波动压力影响不大,可以将其作为次要因素考虑。

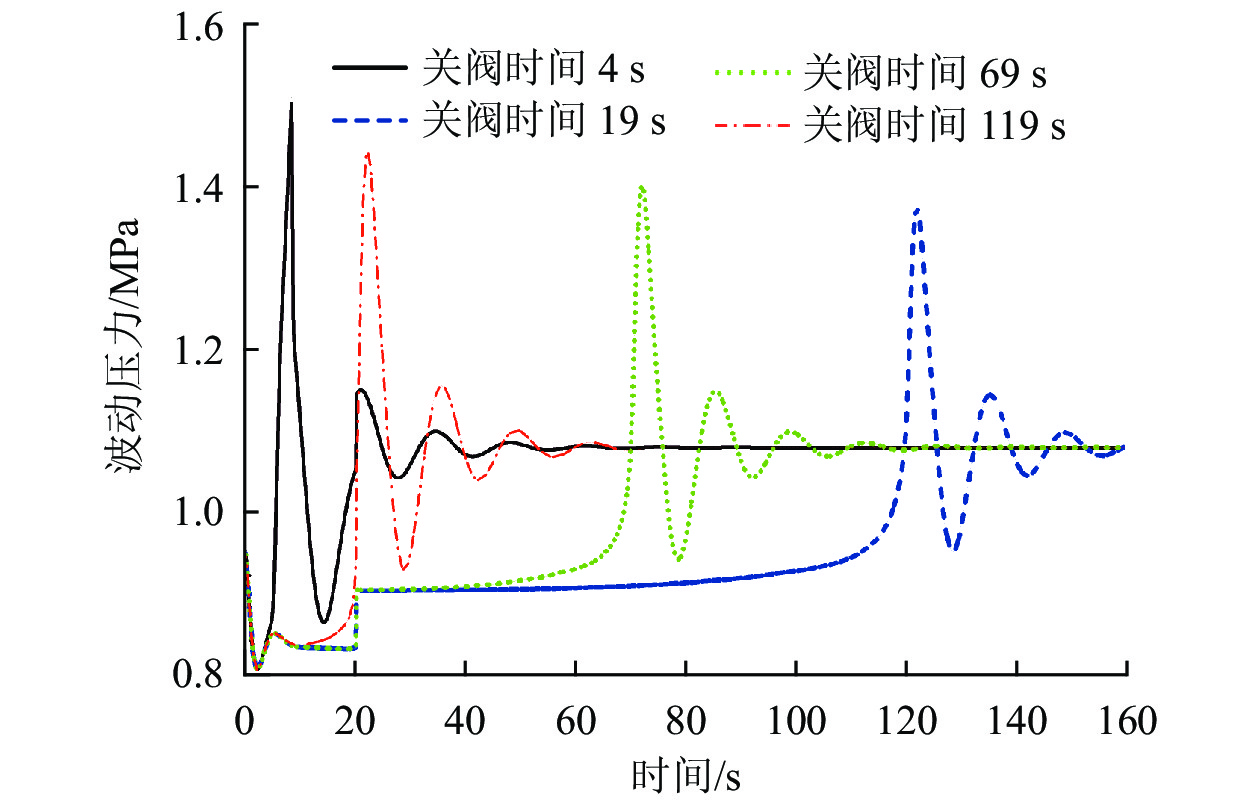

3.6 关阀时间对油管波动压力的影响

随着阀门关闭时间延长,波动压力峰值减小,且达到峰值的时间增长(见图7)。相比于液相,气相可压缩性大,更易使波动压力能量耗散,波动压力周期峰值衰减更快。关阀时间为4 s时,气相波动压力峰值在第3个周期(60 s)时衰减至0,波动压力对油管影响消失。当关阀时间从4 s变化至119 s时,油管气相波动压力峰值从1.58 MPa降至1.31 MPa,油管气相波动压力峰值降低了17.1%,关阀时间对波动压力影响显著,延长关阀时间可减小波动压力峰值。在日产气量较大的情况下,适当延长调阀时间,有利于减小阀芯的疲劳损坏程度。

3.7 高产气量注–采转换井口压力分析

呼图壁储气库H2 水平井高产气量采–关转换过程中井口压力数据见表1。油管内气相波动压力受气体流量和关阀时间影响较大,采用15 s线性关阀方案,日产气量从50×104 m3/d增至600×104 m3/d,井口波动压力从9.21 MPa增大至19.26 MPa,井底最大波动压力峰值从0.61 MPa增大至4.62 MPa。结合阀门型号、油管承压能力、阀门阻流系数、井身结构等基础参数,利用油管气相波动压力数学模型,按照阀门开度区间绘制阀门开度曲线,可得到适用于现场的最优阀门控制方法。

表 1 高产气量注–采转换井口压力分析Table 1. Analysis of wellhead pressure for injection and production conversion for high gas production气体流量/

(104m3·d−1)井口波动

压力/MPa井口初始

稳压值/MPa有效井口

压力/MPa井底波动

压力/MPa井底初始

稳压值/MPa有效井底

压力/MPa50 1.21 8.00 9.21 0.61 21.55 22.16 150 1.66 8.00 9.66 0.83 21.55 22.38 250 4.93 8.00 12.93 2.37 21.55 23.92 350 7.25 8.00 15.25 3.26 21.55 24.81 600 11.26 8.00 19.26 4.62 21.55 26.17 4. 结 论

1)针对储气库采–关作业工况,建立了油管气相波动压力数学模型,该模型精度高,可适用于关–采、关–注以及注–关等注采转换过程中的波动压力计算。

2)相比于低产气井,波动压力冲击载荷对高产气井影响更为显著,需要适当延长调阀时间。随着油管深度增大,井底波动压力呈现减小趋势,浅井井底波动压力冲击载荷相比于深井更大。

3)现场储气库采–关作业时,可根据阀门阻流区间确定阀门调节速度。储气库阀门开度在有效阻流区间内时,可适当延长阀门调节时间减小波动压力峰值;阀门开度在无效阻流区间内时,可通过减少调阀时间提高调阀效率。

-

表 1 高产气量注–采转换井口压力分析

Table 1 Analysis of wellhead pressure for injection and production conversion for high gas production

气体流量/

(104m3·d−1)井口波动

压力/MPa井口初始

稳压值/MPa有效井口

压力/MPa井底波动

压力/MPa井底初始

稳压值/MPa有效井底

压力/MPa50 1.21 8.00 9.21 0.61 21.55 22.16 150 1.66 8.00 9.66 0.83 21.55 22.38 250 4.93 8.00 12.93 2.37 21.55 23.92 350 7.25 8.00 15.25 3.26 21.55 24.81 600 11.26 8.00 19.26 4.62 21.55 26.17 -

[1] FOROUZANFAR F, REYNOLDS A C, LI Gaoming. Optimization of the well locations and completions for vertical and horizontal wells using a derivative-free optimization algorithm[J]. Journal of Petroleum Science and Engineering, 2012, 86/87: 272–288. doi: 10.1016/j.petrol.2012.03.014

[2] 王泉,陈超,李道清,等. 基于有效渗透率的单井增产潜力定量评价:以新疆H储气库为例[J]. 新疆石油地质,2020,41(4):450–456. WANG Quan, CHEN Chao, LI Daoqing, et al. Quantitative evaluation of well yield-increasing potential based on effective permeability: a case of H gas storage in Xinjiang[J]. Xinjiang Petroleum Geology, 2020, 41(4): 450–456.

[3] 党文辉,刘天恩,袁光杰,等. 呼图壁储气库勺型水平井钻井关键技术[J]. 石油钻采工艺,2021,43(5):593–600. DANG Wenhui, LIU Tianen, YUAN Guangjie, et al. Key drilling technologies of scoop-shape horizontal well in Hutubi Gas Storage[J]. Oil Drilling & Production Technology, 2021, 43(5): 593–600.

[4] FATT I, DAVIS D H. Reduction in permeability with overburden pressure[J]. Journal of Petroleum Technology, 1952, 4(12): 16. doi: 10.2118/952329-G

[5] 吴俊霞,伊伟锴,孙鹏,等. 文23储气库封堵井完整性保障技术[J]. 石油钻探技术,2022,50(5):57–62. doi: 10.11911/syztjs.2022027 WU Junxia, YI Weikai, SUN Peng, et al. Integrity assurance technologies for plugged wells in Wen 23 Gas Storage[J]. Petroleum Drilling Techniques, 2022, 50(5): 57–62. doi: 10.11911/syztjs.2022027

[6] SELVADURAI A P S, GŁOWACKI A. Stress-induced permeability alterations in an argillaceous limestone[J]. Rock Mechanics and Rock Engineering, 2017, 50(5): 1079–1096. doi: 10.1007/s00603-016-1153-3

[7] 刘慧,丁心鲁,张士杰,等. 地下储气库注气过程一体化压力及地层参数计算方法[J]. 石油钻探技术,2022,50(6):64–71. LIU Hui, DING Xinlu, ZHANG Shijie, et al. Integrated calculation method of pressure and formation parameters in gas injection process of underground gas Storage[J]. Petroleum Drilling Techniques, 2022, 50(6): 64–71.

[8] 周军,彭井宏,罗莎,等. 考虑安全稳定运行的大型枯竭气藏储气库注采优化[J]. 特种油气藏,2021,28(6):76–82. ZHOU Jun, PENG Jinghong, LUO Sha, et al. Optimization of gas injection and production in gas storage based on large depleted gas reservoir with consideration of safe and stable operation[J]. Special Oil & Gas Reservoirs, 2021, 28(6): 76–82.

[9] 王容,李隆新,刘晓旭,等. 深层碳酸盐岩气藏改建储气库注采能力预测方法及应用[J]. 特种油气藏,2023,30(1):126–133. doi: 10.3969/j.issn.1006-6535.2023.01.018 WANG Rong, LI Longxin, LIU Xiaoxu, et al. Prediction method and application of injection-production capacity of gas storage converted from deep carbonate gas reservoir[J]. Special Oil & Gas Reservoirs, 2023, 30(1): 126–133. doi: 10.3969/j.issn.1006-6535.2023.01.018

[10] 天工. 呼图壁地下储气库调峰气量再创新高[J]. 天然气工业,2020,40(12):70. TIAN Gong. Peak regulating gas volume of Hutubi underground gas storage reaches a new high[J]. Natural Gas Industry, 2020, 40(12): 70.

[11] 康毅力,邵佳新,游利军,等. 储气库井注气压力剧变诱发微粒运移实验模拟[J]. 石油钻采工艺,2020,42(6):797–803. KANG Yili, SHAO Jiaxin, YOU Lijun, et al. Experimental simulation on the fine migration induced by the violent change of the gas injection pressure of gas storage well[J]. Oil Drilling & Production Technology, 2020, 42(6): 797–803.

[12] 闫行,闫怡飞,闫相祯. 基于小波多尺度变换的储气库井管柱非线性振动特性研究[J]. 振动与冲击,2019,38(20):51–60. YAN Hang, YAN Yifei, YAN Xiangzhen. A study on nonlinear vibration characteristics of gas storage well string based on the wavelet multi-scale transform[J]. Journal of Vibration and Shock, 2019, 38(20): 51–60.

[13] 张刚雄,李彬,郑得文,等. 中国地下储气库业务面临的挑战及对策建议[J]. 天然气工业,2017,37(1):153–159. ZHANG Gangxiong, LI Bin, ZHENG Dewen, et al. Challenges to and proposals for underground gas storage (UGS) business in China[J]. Natural Gas Industry, 2017, 37(1): 153–159.

[14] 孔祥伟,刘祚才,靳彦欣. 川渝裂缝性地层自动压井环空多相压力波速特性研究[J]. 应用数学和力学,2022,43(12):1370–1379. KONG Xiangwei, LIU Zuocai, JIN Yanxin. Study on multiphase pressure wave velocity characteristics of automatic kill annulus in Chuanyu fractured formation[J]. Applied Mathematics and Mechanics, 2022, 43(12): 1370–1379.

[15] 王克良,李胤,李静,等. 储气库管线壁厚设计[J]. 科技广场,2014(2):250–252. doi: 10.3969/j.issn.1671-4792.2014.02.055 WANG Keliang, LI Yin, LI Jing, et al. Design of wall thickness of pipelines in gas storage[J]. Science Mosaic, 2014(2): 250–252. doi: 10.3969/j.issn.1671-4792.2014.02.055

[16] 孔祥伟,林元华,邱伊婕. 微流量控压钻井中节流阀动作对环空压力的影响[J]. 石油钻探技术,2014,42(3):22–26. KONG Xiangwei, LIN Yuanhua, QIU Yijie. Effect of choke valve action on annular pressure with micro-flux control in MPD drilling[J]. Petroleum Drilling Techniques, 2014, 42(3): 22–26.

[17] JELMERT T A, SELSENG H. Permeability function describes core permeability in stress sensitivity rocks[J]. Oil & Gas Journal, 1998, 12(7): 60–63.

[18] 王思凡,张安康,胡东锋. 连续油管打捞砂埋节流器技术研究与现场试验[J]. 石油钻探技术,2021,49(5):108–113. doi: 10.11911/syztjs.2021067 WANG Sifan, ZHANG Ankang, HU Dongfeng. Research and field tests of coiled tubing fishing technology for sand-buried throttles[J]. Petroleum Drilling Techniques, 2021, 49(5): 108–113. doi: 10.11911/syztjs.2021067

[19] 孔祥伟,林元华,何龙,等. 一种考虑虚拟质量力的两相压力波速经验模型[J]. 力学季刊,2015,36(4):611–617. KONG Xiangwei, LIN Yuanhua, HE Long, et al. An empirical pressure wave velocity model for two-phase flow by considering virtual mass force[J]. Chinese Quarterly of Mechanics, 2015, 36(4): 611–617.

[20] 郝俊芳. 平衡钻井与井控[M]. 北京: 石油工业出版社, 1992: 56-59. HAO Junfang. Balanced drilling and well control[M]. Beijing: Petroleum Industry Press, 1992: 56-59.

-

期刊类型引用(1)

1. 郭海伟. 基于增量学习的储气库井底压力快速计算方法. 断块油气田. 2025(02): 292-299 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: