Study on Propagation and Diversion Characteristics of Hydraulic Fractures in Vuggy Carbonate Reservoirs

-

摘要:

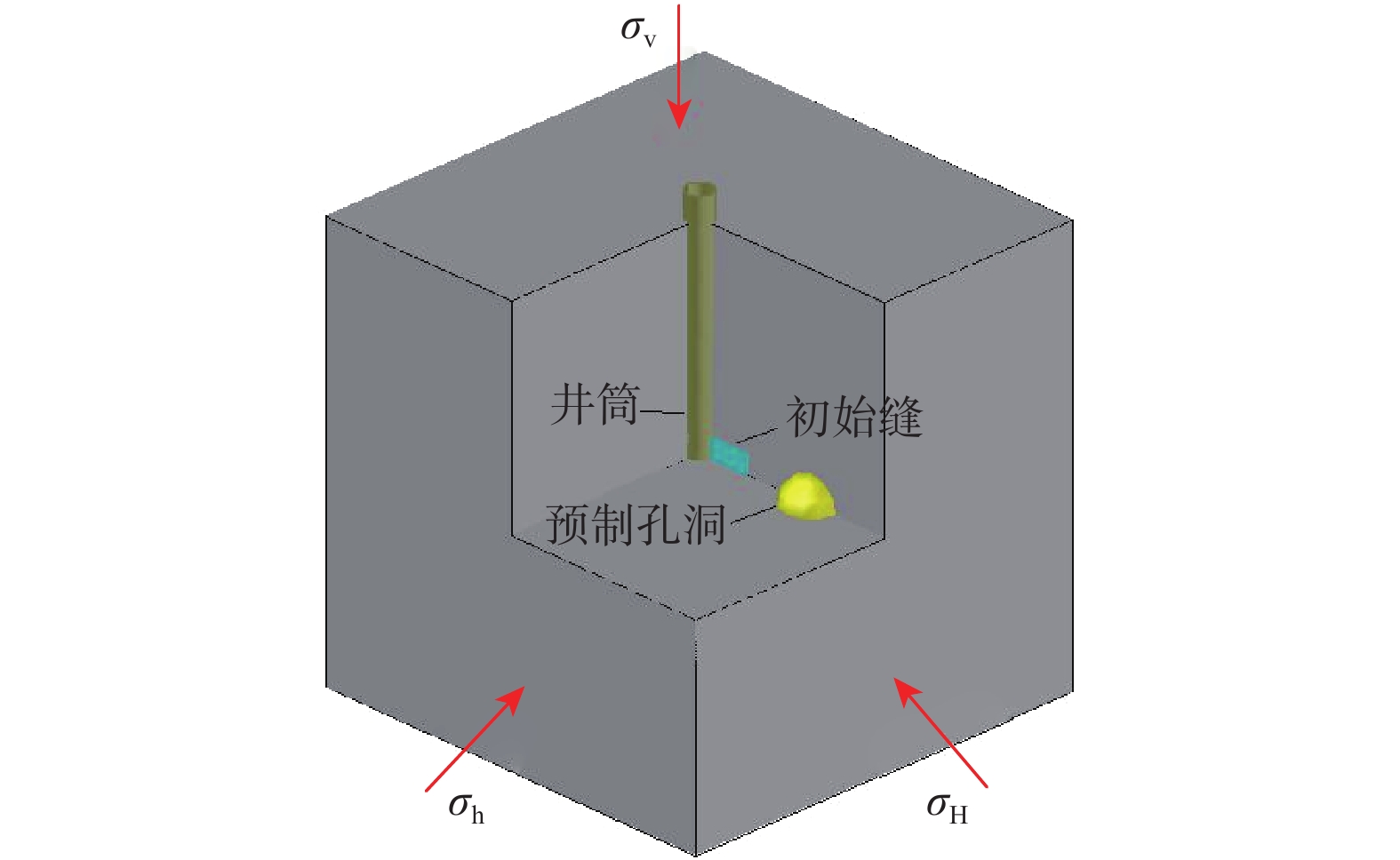

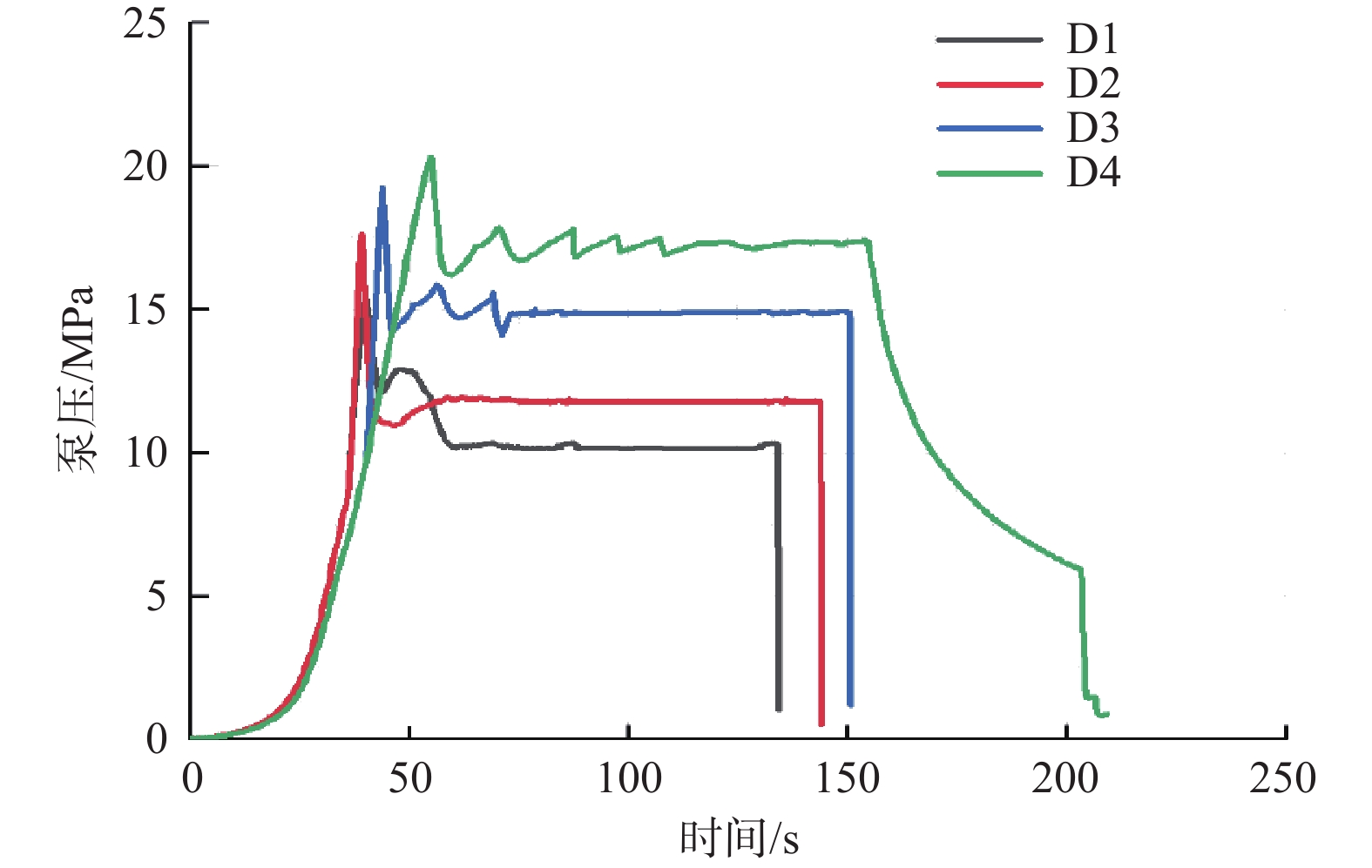

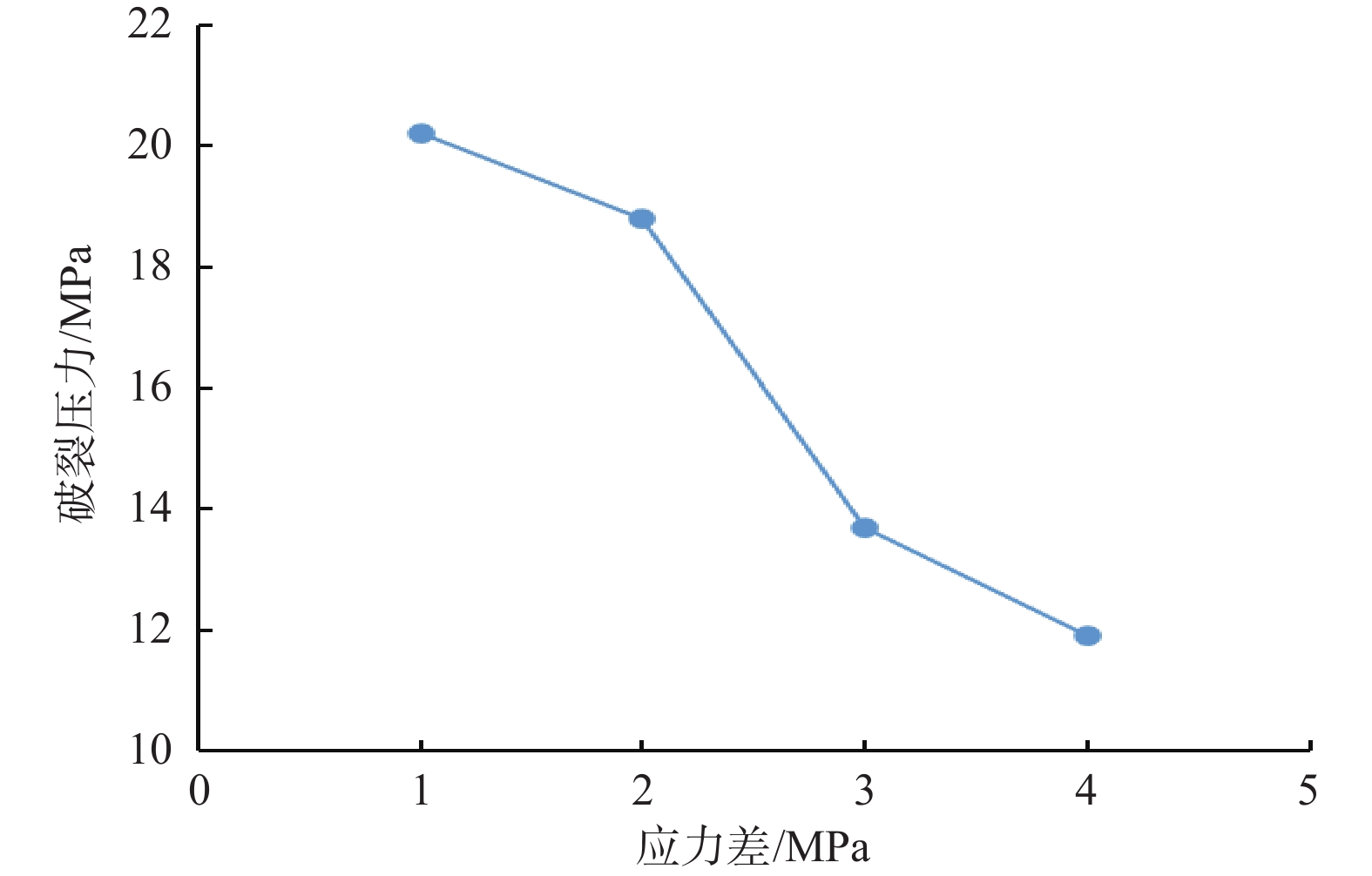

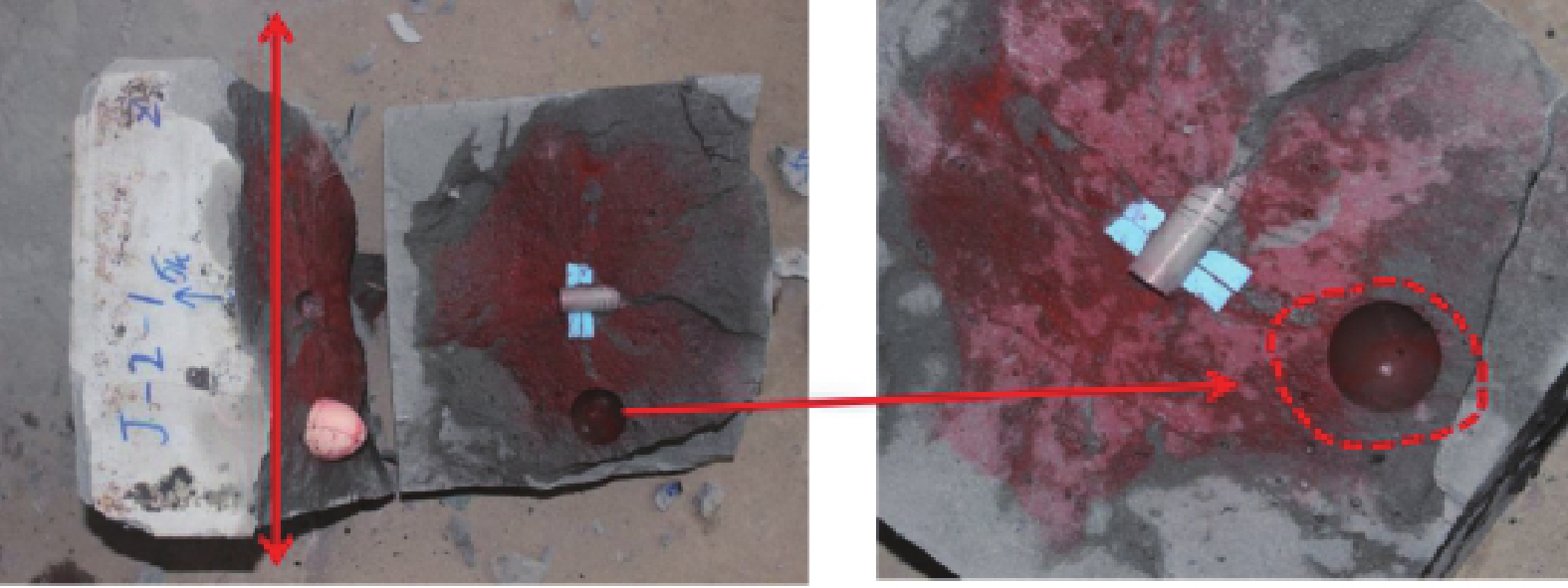

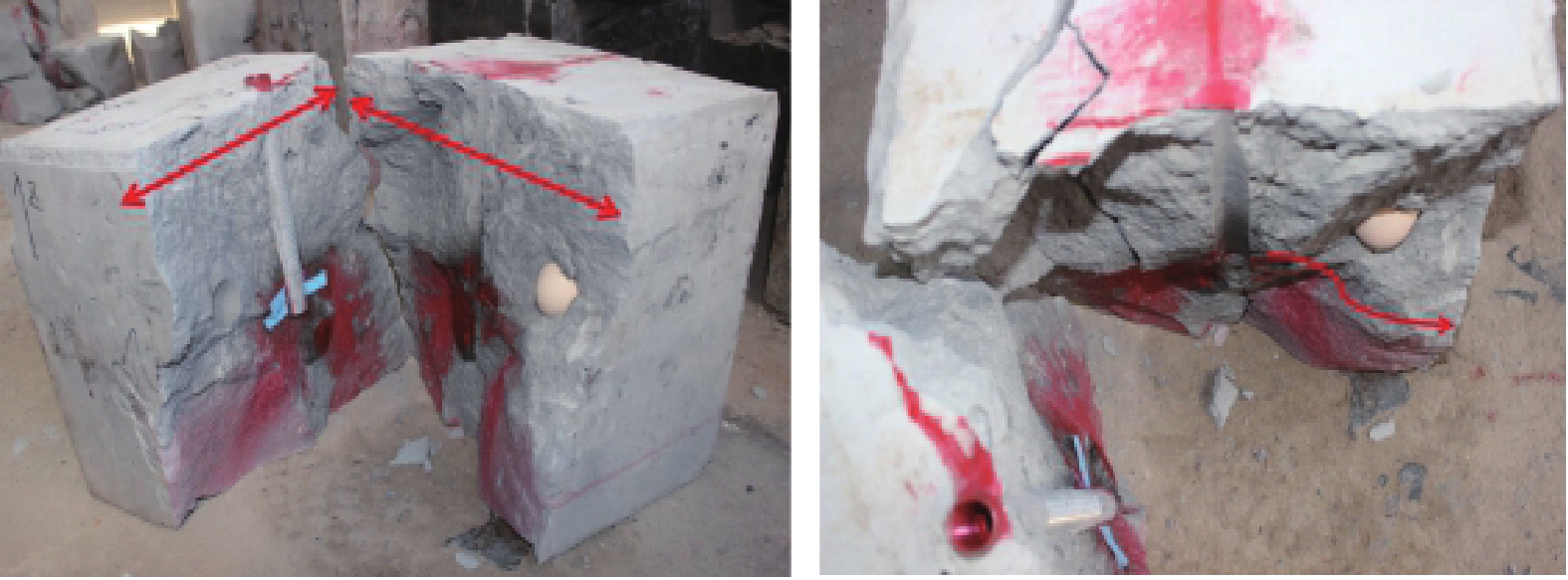

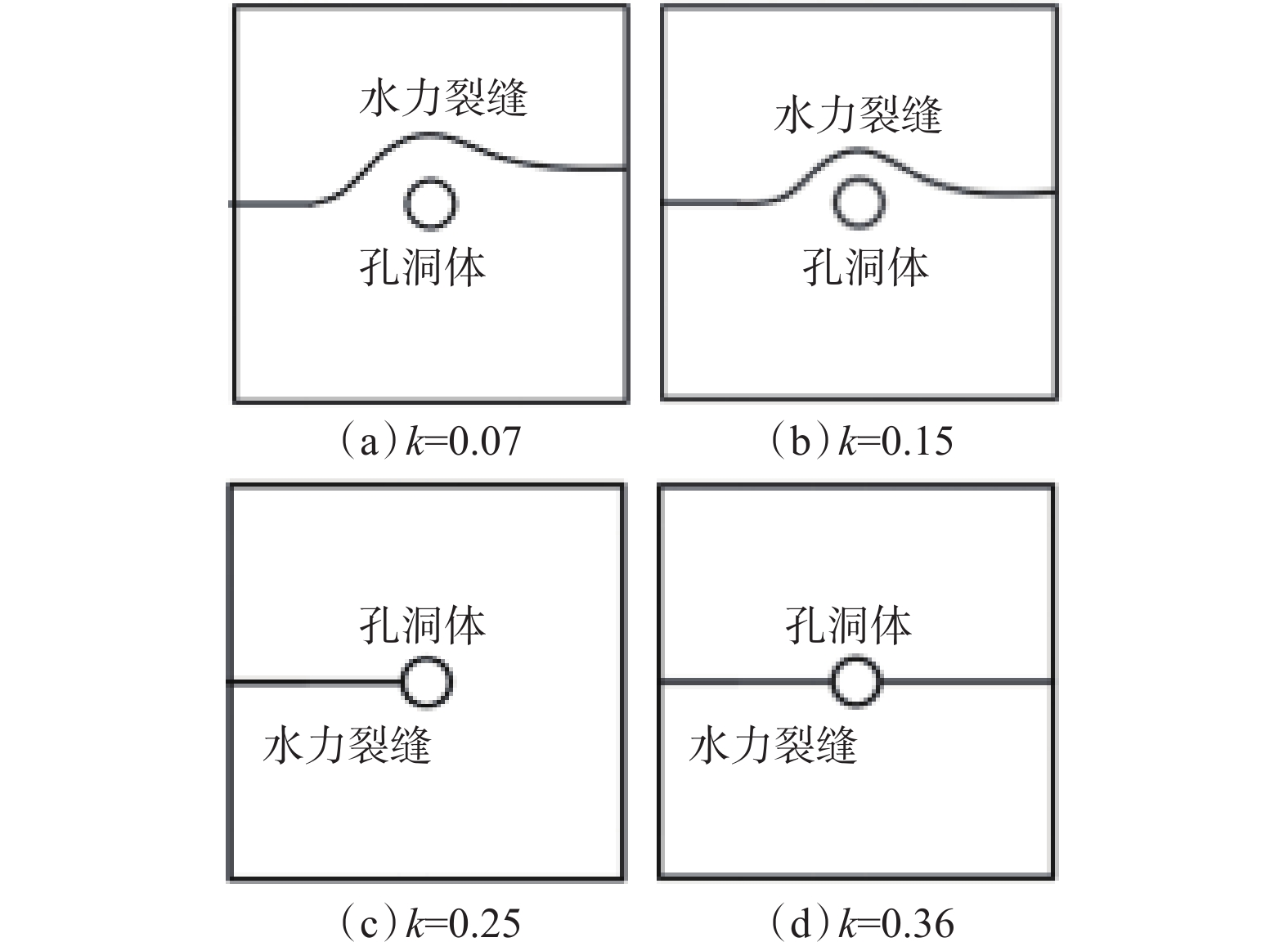

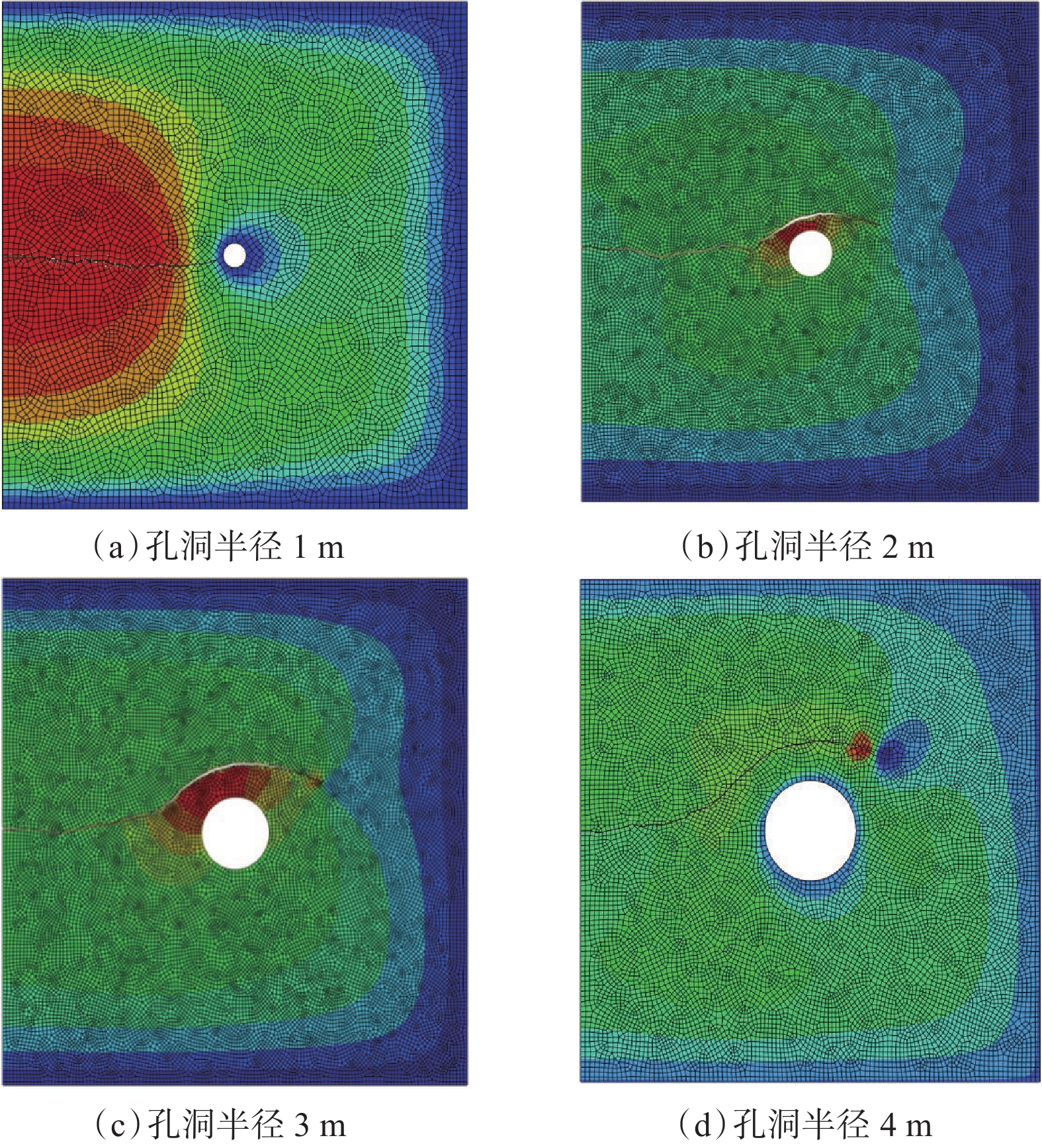

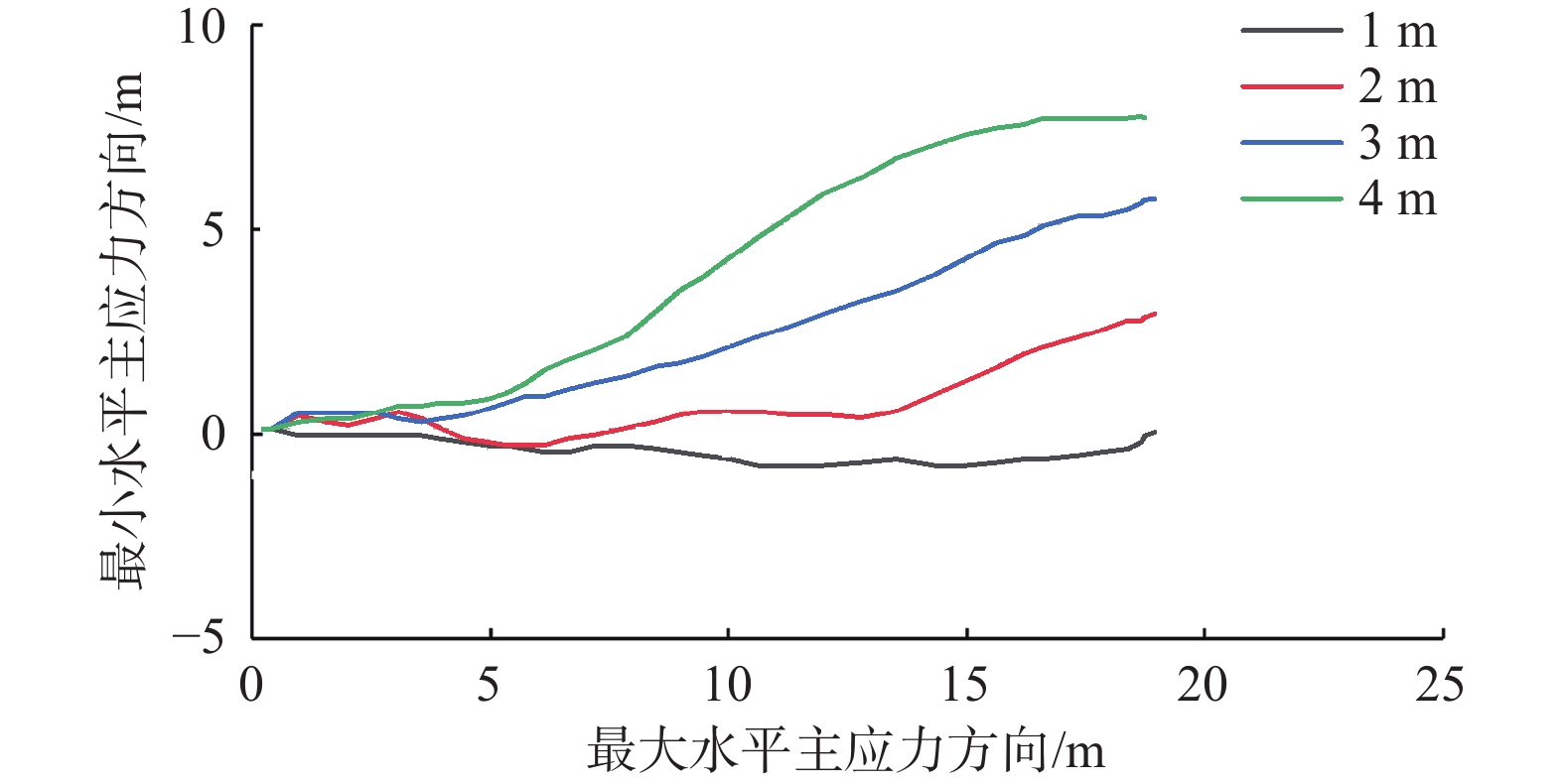

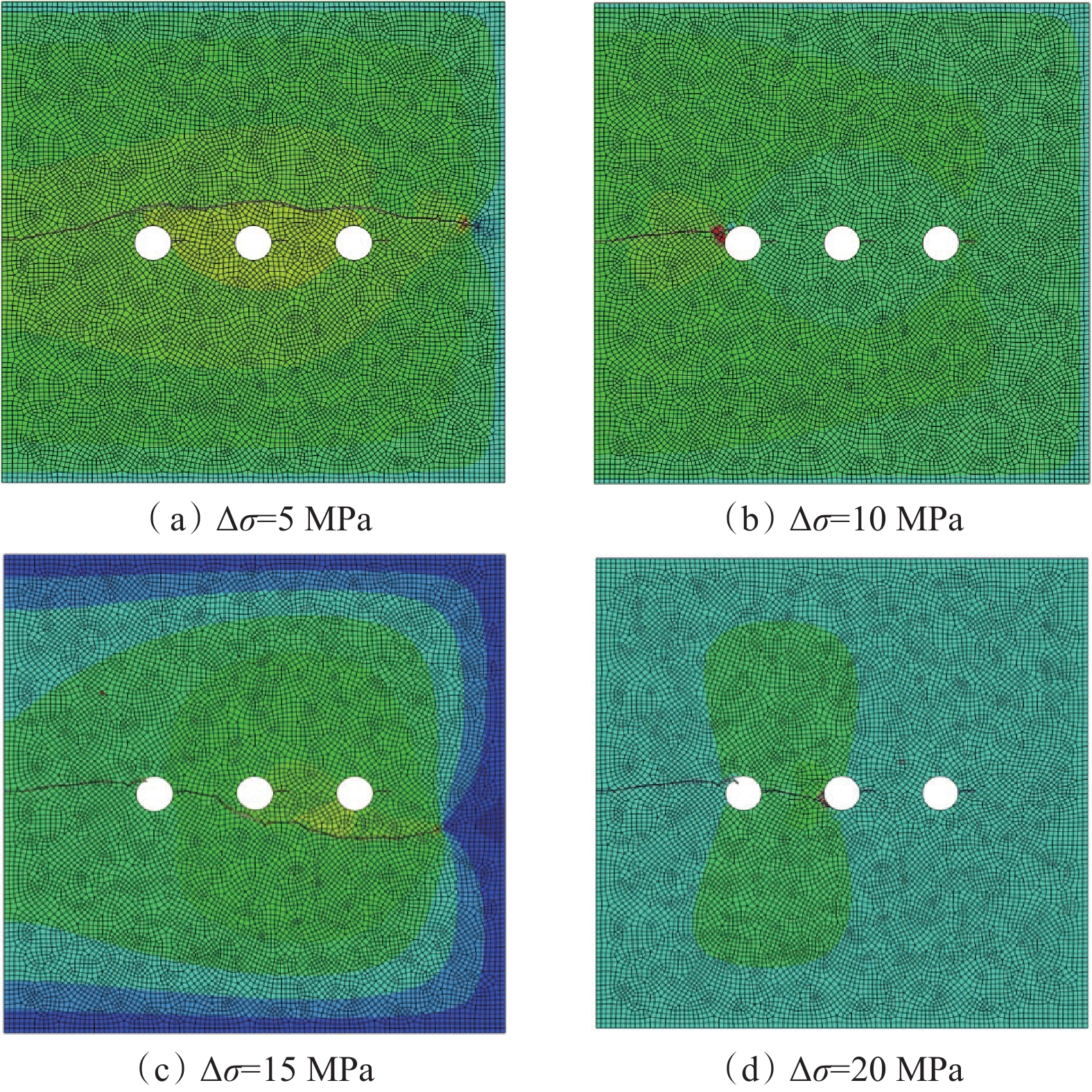

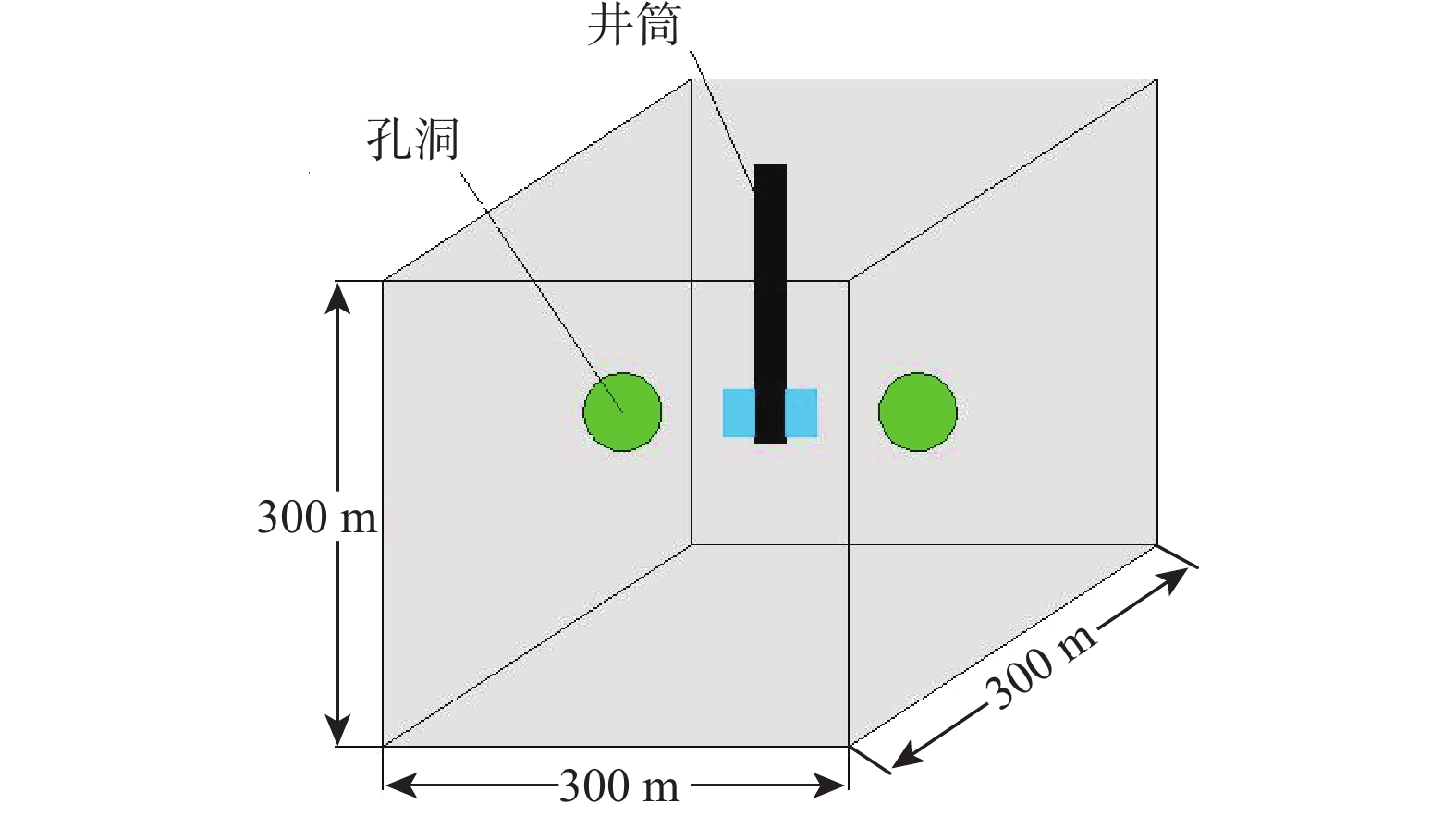

针对孔洞型碳酸盐岩储层改造产生的水力裂缝扩展规律复杂、不一定沿预设路径扩展的问题,基于碳酸盐岩储层孔洞体特征,制备了含孔洞体的碳酸盐岩试样;利用真三轴水力压裂试验结果,分析了不同水平主应力差异下孔洞体对水力裂缝扩展的干扰作用;并利用扩展有限元数值方法,分析了影响孔洞型碳酸盐岩储层水力裂缝扩展及扩展路径的因素。研究结果表明,水平主应力差异系数不大于0.15时,水力裂缝遇到孔洞体后产生非平面扩展,且水平主应力差越小,转向扩展距离越大,裂缝形态越复杂;水平主应力差异系数大于0.15、小于0.36时,水力裂缝会克服孔洞体的应力集中进行平面扩展,但遇到孔洞体后会被孔洞体捕捉,无法穿过孔洞体继续扩展;水平主应力差异系数不小于0.36时,水力裂缝会克服孔洞体的应力集中进行平面扩展,且遇到孔洞体后会直接穿过孔洞体继续扩展;随着水平主应力差增大,破裂压力逐渐降低。研究结果可为孔洞型碳酸盐岩储层压裂设计提供指导。

Abstract:Hydraulic fractures generated in the stimulation of vuggy carbonate reservoirs feature complex propagation as they do not necessarily propagate along the prospected path. In view of this, vuggy carbonate rock samples were prepared based on the analysis of the vuggy characteristics of carbonate reservoirs. With test results of true triaxial hydraulic fracturing, the interference of cavities in the propagation of hydraulic fractures under different horizontal principal stress differences was investigated. Moreover, the extended numerical finite element method was used to analyze the factors affecting the propagation of hydraulic fractures in vuggy carbonate reservoirs and their propagation paths. The results revealed that non-planar propagation would occur when hydraulic fractures encountered cavities when the difference coefficient of the horizontal principal stress was below 0.15, and smaller horizontal principal stress was accompanied by a larger diversion propagation distance and more complex fracture pattern. When the coefficient was between 0.15 and 0.36, hydraulic fractures would overcome the stress concentration of cavities for planar propagation, but they would be captured by cavities encountered along the propagation path. When the coefficient was no less than 0.36, hydraulic fractures would overcome the stress concentration of cavities and penetrate cavities for planar propagation. In addition, the fracturing pressure would decrease as the stress difference increased. The research results can provide a reference for hydraulic fracturing design for vuggy carbonate reservoirs.

-

-

表 1 碳酸盐岩试样压裂试验参数

Table 1 Fracturing test parameters of carbonate rock samples

试样 应力差

异系数k{\sigma_{⃑\text{v}}} /

MPa{\sigma _{\text{H}}} /

MPa{\sigma _{\text{h}}} /

MPaQ/(mL·min−1) D1 0.36 18 15 11 5 D2 0.25 18 15 12 5 D3 0.15 18 15 13 5 D4 0.07 18 15 14 5 表 2 数值模拟地应力参数设置

Table 2 Parameter setting of in-situ stress in numerical simulation

序号 {\sigma _{\text{H}}} /MPa {\sigma _{\text{h}}} / MPa \Dela \sigma / MPa 泊松比 弹性模

量/GPaBiot

系数1 75 70 5 0.19 38.54 0.87 2 65 10 3 60 15 4 55 20 -

[1] 雷群,万玉金,李熙喆,等. 美国致密砂岩气藏开发与启示[J]. 天然气工业,2010,30(1):45–48. doi: 10.3787/j.issn.1000-0976.2010.01.012 LEI Qun, WAN Yujin, LI Xizhe, et al. A study on the development of tight gas reservoirs in the USA[J]. Natural Gas Industry, 2010, 30(1): 45–48. doi: 10.3787/j.issn.1000-0976.2010.01.012

[2] 张倩,李年银,李长燕,等. 中国海相碳酸盐岩储层酸化压裂改造技术现状及发展趋势[J]. 特种油气藏,2020,27(2):1–7. ZHANG Qian, LI Nianyin, LI Changyan, et al. Overview and trend of acid-fracturing technology for marine carbonate reservoirs in China[J]. Special Oil & Gas Reservoirs, 2020, 27(2): 1–7.

[3] 丁士东,赵向阳. 中国石化重点探区钻井完井技术新进展与发展建议[J]. 石油钻探技术,2020,48(4):11–20. DING Shidong, ZHAO Xiangyang. New progress and development suggestions for drilling and completion technologies in Sinopec key exploration areas[J]. Petroleum Drilling Techniques, 2020, 48(4): 11–20.

[4] 贺甲元,程洪,向红,等. 塔河油田碳酸盐岩储层暂堵转向压裂排量优化[J]. 石油钻采工艺,2021,43(2):233–238. HE Jiayuan, CHENG Hong, XIANG Hong, et al. Optimizing the displacement of temporary plugging and diversion fracturing of the carbonate reservoirs in Tahe Oilfield[J]. Oil Drilling & Production Technology, 2021, 43(2): 233–238.

[5] 吴丰,代槿,姚聪,等. 塔河油田奥陶系一间房组与鹰山组断溶体发育模式解剖[J]. 断块油气田,2022,29(1):33–39. WU Feng,DAI Jin,YAO Cong,et al. Developmental mode analysis of the fault-karst reservoir in Yijianfang Formation and Yingshan Formation of Ordovician in Tahe Oilfield[J]. Fault-Block Oil & Gas Field, 2022, 29(1): 33–39.

[6] 赵海洋,刘志远,唐旭海,等. 缝洞型碳酸盐岩储层循缝找洞压裂技术[J]. 石油钻采工艺,2021,43(1):89–96. ZHAO Haiyang, LIU Zhiyuan, TANG Xuhai, et al. Fracturing technology of searching for vugs along fractures in fractured-vuggy carbonate reservoirs[J]. Oil Drilling & Production Technology, 2021, 43(1): 89–96.

[7] 苗娟,何旭晟,王栋,等. 水平井精细分段深度酸化压裂技术研究与应用[J]. 特种油气藏,2022,29(2):141–148. MIAO Juan, HE Xusheng, WANG Dong, et al. Study and application of fine segmented deep acid fracturing technology for horizontal wells[J]. Special Oil & Gas Reserviors, 2022, 29(2): 141–148.

[8] 钟小军,张锐,吴刚,等. 复杂非均质碳酸盐岩储层酸岩反应动力学特征及酸压对策研究[J]. 钻井液与完井液,2020,37(6):798–802. ZHONG Xiaojun, ZHANG Rui, WU Gang, et al. Study on dynamic characteristics of acid rock reaction and acid fracturing countermeasures in complex heterogeneous carbonate reservoirs[J]. Drilling Fluid & Completion Fluid, 2020, 37(6): 798–802.

[9] 郭印同,杨春和,贾长贵,等. 页岩水力压裂物理模拟与裂缝表征方法研究[J]. 岩石力学与工程学报,2014,33(1):52–59. doi: 10.13722/j.cnki.jrme.2014.01.006 GUO Yintong, YANG Chunhe, JIA Changgui, et al. Research on hydraulic fracturing physical simulation of shale and fracture characterization methods[J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(1): 52–59. doi: 10.13722/j.cnki.jrme.2014.01.006

[10] 衡帅,杨春和,郭印同,等. 层理对页岩水力裂缝扩展的影响研究[J]. 岩石力学与工程学报,2015,34(2):228–237. doi: 10.13722/j.cnki.jrme.2015.02.002 HENG Shuai, YANG Chunhe, GUO Yintong, et al. Influence of bedding planes on hydraulic fracture propagation in shale formations[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(2): 228–237. doi: 10.13722/j.cnki.jrme.2015.02.002

[11] GUO Yintong, DENG Peng, YANG Chunhe, et al. Experimental investigation on hydraulic fracture propagation of carbonate rocks under different fracturing fluids[J]. Energies, 2018, 11(12): 1–15.

[12] GUO Yintong, HOU Longfei, YAO Yiming, et al. Experimental study on influencing factors of fracture propagation in fractured carbonate rocks[J]. Journal of Structural Geology, 2020, 131: 103955. doi: 10.1016/j.jsg.2019.103955

[13] 周大伟. 缝洞型岩石体积压裂试验模拟研究[D]. 北京: 中国石油大学(北京), 2016. ZHOU Dawei. Experimental investigation on fracture-vug rock of SRV fracturing[D]. Beijing: China University of Petroleum(Beijing), 2016.

[14] 李林地,张士诚,张劲,等. 缝洞型碳酸盐岩储层水力裂缝扩展机理[J]. 石油学报,2009,30(4):570–573. doi: 10.3321/j.issn:0253-2697.2009.04.016 LI Lindi, ZHANG Shicheng, ZHANG Jin, et al. Mechanism of hydraulic fracture propagation in fracture-cavity carbonate reser-voirs[J]. Acta Petrolei Sinica, 2009, 30(4): 570–573. doi: 10.3321/j.issn:0253-2697.2009.04.016

[15] HUNSWECK M J, SHEN Yongxing, LEW A J. A finite element approach to the simulation of hydraulic fractures with lag[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2013, 37(9): 993–1015. doi: 10.1002/nag.1131

[16] 彪仿俊,刘合,张士诚,等. 水力压裂水平裂缝影响参数的数值模拟研究[J]. 工程力学,2011,28(10):228–235. BIAO Fangjun, LIU He, ZHANG Shicheng, et al. A numerical study of parameter influences on horizontal hydraulic fracture[J]. Engineering Mechanics, 2011, 28(10): 228–235.

[17] 张广明,刘合,张劲,等. 水平井水力压裂的三维有限元数值模拟研究[J]. 工程力学,2011,28(2):101–106. ZHANG Guangming, LIU He, ZHANG Jin, et al. Three-dimensional finite element numerical simulation of horizontal well hydraulic fracturing[J]. Engineering Mechanics, 2011, 28(2): 101–106.

[18] 侯龙飞. 缝洞型碳酸盐岩定向压裂模拟试验研究[D]. 重庆: 重庆大学, 2020. HOU Longfei. Fracture-cavity carbonate directional fracturing simulation test research[D]. Chongqing: Chongqing University, 2020.

[19] 孟勇,贾庆升,张潦源,等. 东营凹陷页岩油储层层间干扰及裂缝扩展规律研究[J]. 石油钻探技术,2021,49(4):130–138. MENG Yong, JIA Qingsheng, ZHANG Liaoyuan, et al. Research on interlayer interference and the fracture propagation law of shale oil reservoirs in the Dongying Sag [J]. Petroleum Drilling Techniques, 2021, 49(4): 130–138.

[20] 崔壮,侯冰,付世豪,等. 页岩油致密储层一体化压裂裂缝穿层扩展特征[J]. 断块油气田,2022,29(1):111–117. CUI Zhuang, HOU Bing, FU Shihao, et al. Fractures cross-layer propagation characteristics of integrated fracturing in shale oil tight reservoir[J]. Fault-Block Oil & Gas Field, 2022, 29(1): 111–117.

[21] 李新勇,耿宇迪,刘志远,等. 缝洞型碳酸盐岩储层压裂效果评价方法试验研究[J]. 石油钻探技术,2020,48(6):88–93. LI Xinyong, GENG Yudi, LIU Zhiyuan, et al. An experimental study on evaluation methods for fracturing effect of fractured-vuggy carbonate reservoir[J]. Petroleum Drilling Techniques, 2020, 48(6): 88–93.

[22] MOËS N, DOLBOW J, BELYTSCHKO T. A finite element method for crack growth without remeshing[J]. International Journal for Numerical Methods in Engineering., 1999, 46: 131–150. doi: 10.1002/(SICI)1097-0207(19990910)46:1<131::AID-NME726>3.0.CO;2-J

-

期刊类型引用(37)

1. 申军武. 井下扭矩保持器设计及实验研究. 中国石油和化工标准与质量. 2025(01): 144-146 .  百度学术

百度学术

2. 刘永升,豆子钧,张金成,高德利. 基于地质-工程一体化的纠偏轨道优化设计及产能评价. 中国石油大学学报(自然科学版). 2025(02): 142-150 .  百度学术

百度学术

3. 许佳鑫,宋明阶,赵红燕,侯亮,李胜楠. 涪陵页岩气田加密井防碰关键技术. 江汉石油职工大学学报. 2024(02): 38-41 .  百度学术

百度学术

4. 尹虎,范涛,江星宏. 页岩气丛式水平井上部井段防碰关键参数设计. 科学技术与工程. 2024(22): 9342-9349 .  百度学术

百度学术

5. 史配铭,贺会锋,朱明明,孟凡金,屈艳平,王玉鹏. 苏里格南部气田Φ152.4 mm小井眼大斜度井快速钻井关键技术. 石油工业技术监督. 2024(09): 51-56 .  百度学术

百度学术

6. 王胜建,迟焕鹏,庞飞,王都乐,周志,李龙,姜鹍鹏. 黔北正安地区页岩气钻探工程难点与对策研究. 地质与勘探. 2023(01): 162-169 .  百度学术

百度学术

7. 张淑侠,王振华,郭锦涛,秦芳玲,何焕杰,吕宁超. 除硼树脂在压裂返排液回用中的应用. 水处理技术. 2023(06): 123-127 .  百度学术

百度学术

8. 邱艳华,吴宇,温庆,林宇,杨建英,何焱,汪刚,文崭,罗彦力. 页岩气平台中压工艺流程的现场应用与评价. 天然气与石油. 2023(03): 27-35 .  百度学术

百度学术

9. 凡广荣. 页岩气水平井强化钻压提速技术研究. 中国石油和化工标准与质量. 2023(15): 193-195 .  百度学术

百度学术

10. 黄晶,赵昆,夏绪波,毛庆春. 压裂工程“井工厂”压裂模式提速提效分析. 江汉石油职工大学学报. 2023(04): 15-17 .  百度学术

百度学术

11. 李阳,赵清民,薛兆杰. 新一代油气开发技术体系构建与创新实践. 中国石油大学学报(自然科学版). 2023(05): 45-54 .  百度学术

百度学术

12. 姚红生,房启龙,袁明进,张壮. 渝东南常压页岩气工程工艺技术进展及下一步攻关方向. 石油实验地质. 2023(06): 1132-1142 .  百度学术

百度学术

13. 刘召友,孙永强,郭百利. 苏里格气田?165.1mm小井眼二开一趟钻优快钻井关键技术. 西部探矿工程. 2023(12): 26-30 .  百度学术

百度学术

14. 张金成. 第一性原理思维法在页岩气革命中的实践与启示. 钻探工程. 2022(02): 1-8 .  百度学术

百度学术

15. 张东清. 涡轮式水力振荡器在涪陵页岩气水平井中的应用. 科技和产业. 2022(05): 283-287 .  百度学术

百度学术

16. 石芳,熊青山,李微,王柯,刘恒. 涪陵页岩气田井场规划技术研究. 能源与环保. 2022(06): 104-113 .  百度学术

百度学术

17. 刘伟,朱礼平,潘登雷,周楚坤,梁霄,刘小斌. WR气田深层页岩气钻井提速提效实践与认识. 天然气技术与经济. 2022(03): 44-50 .  百度学术

百度学术

18. 郑德帅. 可旋转钻柱定向钻进工具设计及测试. 石油钻探技术. 2021(06): 81-85 .  本站查看

本站查看

19. 陈亚联. 新型压裂技术应用分析. 化工技术与开发. 2020(01): 38-41 .  百度学术

百度学术

20. 周亚光. 青海省都兰县八宝山页岩气3井钻探施工技术研究. 能源与环保. 2020(02): 44-46+50 .  百度学术

百度学术

21. 张辉. 大牛地气田丛式小井眼集约化钻井技术. 天然气技术与经济. 2020(02): 28-33 .  百度学术

百度学术

22. 周昊. 全自动液体添加剂橇装置的研制. 化学工程与装备. 2020(10): 169+89 .  百度学术

百度学术

23. 葛明娜,庞飞,包书景. 贵州遵义五峰组—龙马溪组页岩微观孔隙特征及其对含气性控制——以安页1井为例. 石油实验地质. 2019(01): 23-30 .  百度学术

百度学术

24. 仝少凯,高德利. 水力压裂基础研究进展及发展建议. 石油钻采工艺. 2019(01): 101-115 .  百度学术

百度学术

25. 樊好福. 页岩气钻完井配套技术集成研究与应用. 探矿工程(岩土钻掘工程). 2019(08): 15-22 .  百度学术

百度学术

26. 董成林,涂玉林,殷子横,张金成,周号博. 涪陵页岩气田钻井提速集成技术应用研究. 西部探矿工程. 2019(12): 47-50 .  百度学术

百度学术

27. 孔华,兰凯,刘香峰,刘明国,晁文学,郗刘明. 基于振动实测的非均质地层钻头失效分析与对策. 天然气工业. 2019(12): 110-115 .  百度学术

百度学术

28. 刘伟,何龙,胡大梁,李文生,焦少卿. 川南海相深层页岩气钻井关键技术. 石油钻探技术. 2019(06): 9-14 .  本站查看

本站查看

29. 肖佳林,李奎东,高东伟,包汉勇. 涪陵焦石坝区块水平井组拉链压裂实践与认识. 中国石油勘探. 2018(02): 51-58 .  百度学术

百度学术

30. 王光磊,张金成,赵明琨. 涪陵页岩气田井筒完整性实践与认识. 石油机械. 2018(05): 30-34+59 .  百度学术

百度学术

31. 臧艳彬. 川东南地区深层页岩气钻井关键技术. 石油钻探技术. 2018(03): 7-12 .  本站查看

本站查看

32. 路保平,丁士东. 中国石化页岩气工程技术新进展与发展展望. 石油钻探技术. 2018(01): 1-9 .  本站查看

本站查看

33. 刘小伟. 在涪陵页岩气开发中自动化钻机的现状和发展——“十三五”国家科技重大专项深层页岩气开发关键装备及工具研制. 化工管理. 2017(27): 70 .  百度学术

百度学术

34. 梅绪东,金吉中,王朝强,何勇,王丹,张春. 涪陵页岩气田绿色开发的实践与探索. 西南石油大学学报(社会科学版). 2017(06): 9-14 .  百度学术

百度学术

35. 曹明. 页岩气压裂试气工程技术进展. 中国矿业. 2017(S2): 359-362 .  百度学术

百度学术

36. 李彬,付建红,秦富兵,唐一元. 威远区块页岩气“井工厂”钻井技术. 石油钻探技术. 2017(05): 13-18 .  本站查看

本站查看

37. 臧艳彬,张金成,赵明琨,宋争,罗锐. 涪陵页岩气田“井工厂”技术经济性评价. 石油钻探技术. 2016(06): 30-35 .  本站查看

本站查看

其他类型引用(16)

下载:

下载: