Research on Crude Oil Thickening Mechanisms during Nitrogen Injection in Fracture-Cavity Carbonate Reservoirs

-

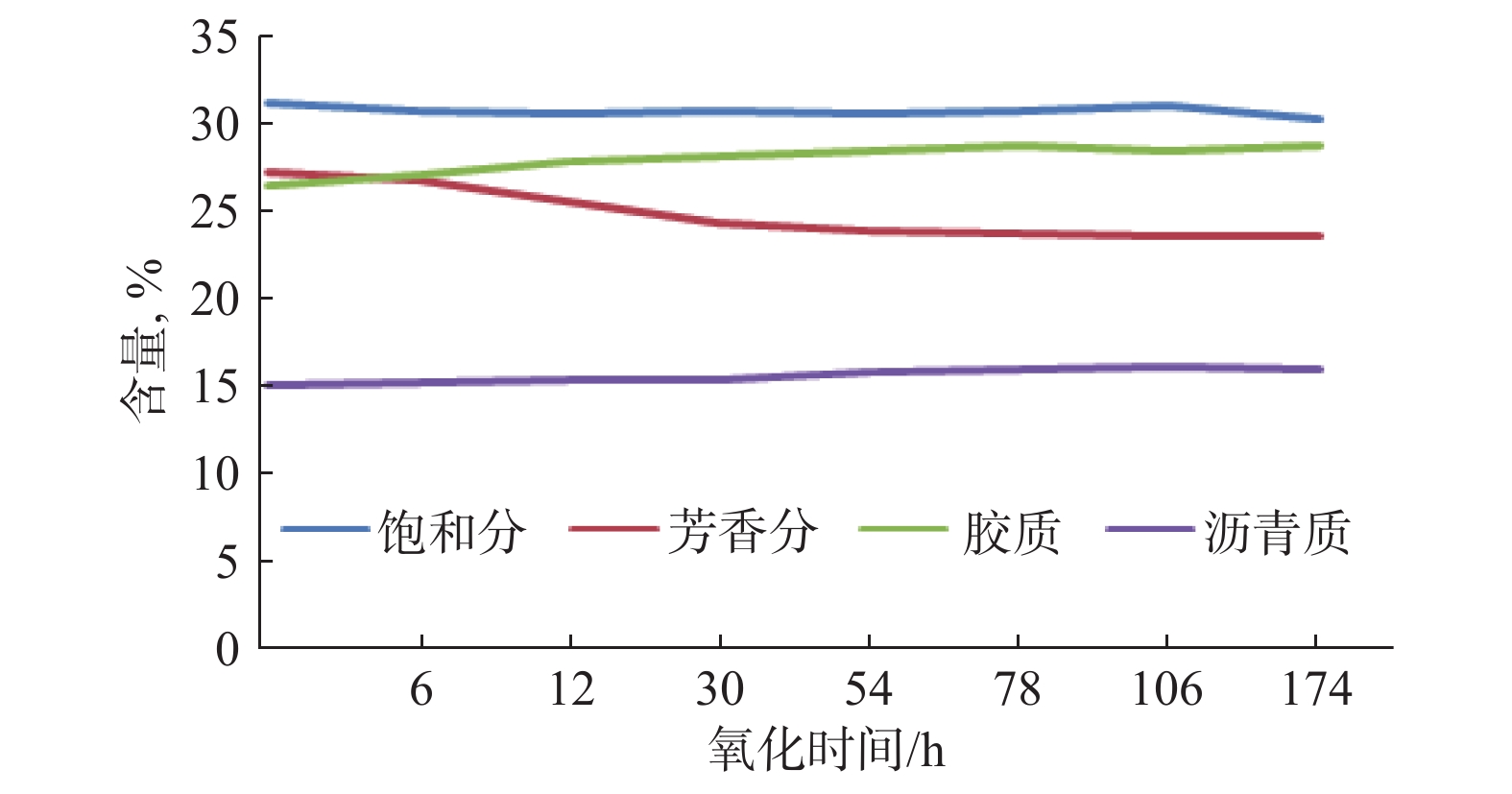

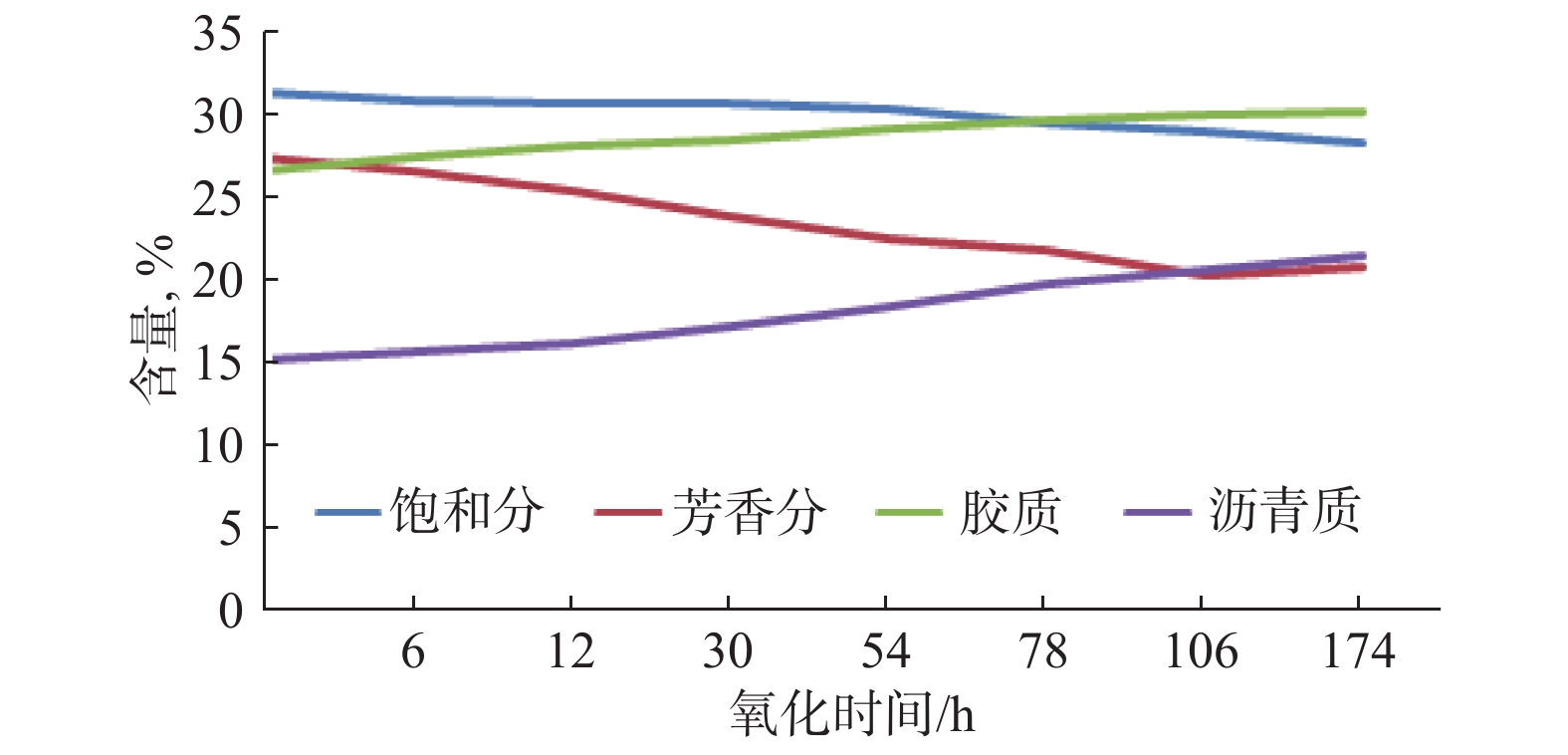

摘要: 为了明确缝洞型碳酸盐岩油藏注氮气原油变稠的机理并制定相应的开发对策,提高注氮气的采收率,开展了缝洞型油藏注氮气致稠机理研究。该研究通过注氮气模拟试验,分析了氮气抽提作用、氮气含氧量和伴注水对原油黏度的影响。结果表明,氮气含氧是引起原油黏度增大的主导因素,含氧量为1%时,仅需2 d多即可将氧气耗尽,黏度达到18 000 mPa·s,为初始黏度的6倍;含氧量为5%时,在7 d多时间内黏度持续升高达到1 122 000 mPa·s,为初始黏度的366倍。乳化含水和抽提对原油黏度的影响相当,黏度升高1~3倍。研究表明,提高注入氮气的纯度是防止塔河油田缝洞型油藏注氮气致稠的最有效方法,研究结果为解决缝洞型碳酸盐岩油藏注氮气原油致稠问题提供了理论依据。Abstract: Research was conducted on the thickening mechanism of crude oil during nitrogen injection in fracture-cavity reservoirs to clarify the thickening mechanism and take corresponding countermeasures, thereby enhancing the oil recovery of nitrogen injection. In this study, simulation experiments of nitrogen injection were performed to analyze the influence on crude oil brought by nitrogen extraction, oxygen content in nitrogen, and mixed water. The experiments showed that the oxygen content in nitrogen was the major influential factor. When the oxygen content was 1%, it took only more than 2 days to exhaust the oxygen, and the viscosity reached 18 000 mPa·s, which was 6 times the initial viscosity. When the oxygen content increased to 5%, the viscosity continued to grow to 1 122 000 mPa·s within more than 7 days, which was 366 times the initial viscosity. Emulsification with water and nitrogen extraction resulted in the same effect on viscosity: the viscosity increased 1–3 times. The results demonstrate improving the purity of injected nitrogen is the most effective way to prevent crude oil thickening of fracture-cavity reservoirs during nitrogen injection in Tahe Oilfield. It has provided a theoretical basis for solving the problem of crude oil thickening brought by nitrogen injection in fracture-cavity carbonate reservoirs.

-

与钻井液钻井相比,气体钻井具有机械钻速高、钻头寿命长、储层保护和防漏失效果好等优点[1-3]。但是,气体钻井存在2个瓶颈问题:直井易斜和下套管困难[4-6]。气体钻井中井斜控制难度大,与地层不均质、底部钻具组合(BHA)振动剧烈和井下情况复杂(如地层出水)等因素有关[7-11]。对此,目前公认的比较有效的方法是用空气锤进行钻进,不但机械钻速快,而且在砂岩、泥页岩和碳酸盐岩地层中均有很好的井斜控制效果。但在塔里木油田山前巨厚砾石层中采用空气锤钻进,不但井斜控制难度很大,后续下套管作业也十分困难,主要表现为井筒规则性很差。

现场实践表明,采用带预弯结构的钟摆BHA控斜效果较好,套管下入也很顺利[12-13]。目前,基于预弯钟摆BHA的控斜方法已在塔里木油田应用6口井,均取得了成功。但现有BHA受力模型都假设井筒光滑,没有考虑井筒的不规则性[14-17],因此不适合用其分析巨厚砾石层气体钻井井斜机理。为此,笔者从BHA与不规则井筒相互作用的角度出发,建立了有限元力学模型,分析了井筒不规则性对井斜的影响,并以塔里木油田山前地区钻遇巨厚砾石层的某气体钻井为例进行了实例分析,验证了相关结论的可靠性和准确性。

1. BHA与井筒相互作用模型

1.1 BHA与不规则井筒相互作用物理模型

图1(a)所示为塔里木油田山前地区巨厚砾石层采用空气锤钻井的一口典型井的实际井筒特征。可以看出,其井筒存在严重的不规则、不光滑现象。据此,建立了BHA与不规则井筒相互作用的物理模型,如图1(b)所示。

由图1可知,BHA会受到不规则井筒的作用。在规则井筒中,BHA受重力作用的同时得到下井壁的“连续”支撑作用,可认为“BHA躺在下井壁上”;但在不规则井筒中,下井壁的不规则“凸起”会形成附加支点,改变BHA的受力特征,减小钻头上的降斜力,甚至可能在钻头上形成增斜力。

1.2 钻柱井壁摩擦接触模型

在BHA与不规则井筒相互作用模型的基础上,建立了如图2所示的钻柱井壁摩擦接触模型。设该模型中:采用笛卡尔直角坐标系

O−x−y−z ,z轴与井眼轴线重合,在井眼中心建立局部柱坐标系o−t−n−z ;Ω1代表钻柱,Ω2代表井壁,S(m) 代表力学边界(m =1,2分别表示2个接触体);l表示接触体增量步起始时刻的间隙大小,l为负表示过盈。采用罚函数法计算分析摩擦接触问题。在每一个时间步检查各从节点是否穿透主面,如有穿透,则在该从节点与被穿透主面间引入界面接触力,其大小与穿透深度、主面的刚度成正比。用

pc={pT,pN}T 表示接触面上的力,用o−t−n−z 表示接触面的局部坐标系,则接触状态的分离、粘结和滑动3类特征依次表示如下[18]:u(1)N−u(2)N+l>0pN=pT=0 (1) {u(1)N−u(2)N+l=0|u(1)T−u(2)T|=0pN=−αN(u(2)N−u(1)N−l)pT=−αT(u(2)T−u(1)T) (2) {u(1)N−u(2)N+l=0|u(1)T−u(2)T|>0pN=−αN(u(2)N−u(1)N−l)pT=−μf|pN|sign(u(2)T−u(1)T) (3) 式中:

u(m)N ,u(m)T 分别为接触点法向增量位移和切向增量位移,m;pN, pT分别为接触面上的法向力(以压为正)和切向力,N;μf为滑动摩擦系数;αN,αT分别为法向罚参数和切向罚参数。1.3 BHA与井筒相互作用有限元计算模型

以单稳定器钟摆钻具组合为例,确定了4种工况:工况1,井筒规则,不弯曲;工况2,井筒有一定程度的弯曲,钻铤在特定位置与井筒相接触(即形成附加支点),但钻铤未发生变形;工况3,井筒有较大程度的弯曲,钻铤在特定位置与井筒相接触,且由于附加支点的作用钻铤发生了弯曲变形;工况4,井筒的不规则性比工况3更为严重。取钻头(空气锤钎头)外径为431.8 mm,钻铤外径为228.6 mm,钻铤内径为71.4 mm,扶正器外径为428.0 mm,扶正器距钻头27 m,井眼直径为431.8 mm,井斜角为5°,并假定BHA与井筒的摩擦系数为0.2,建立了BHA与井筒相互作用有限元计算模型,如图3所示。

2. 井筒不规则程度对钻头侧向力的影响

采用显式算法模拟BHA与井筒间的相互作用机制,计算分析了井筒不同规则程度对钻头侧向力的影响。该分析包括2个计算分析步:1)对BHA施加重力作用;2)在钻头处施加钻压。

在管柱自重和50 kN钻压作用下(空气密度为1.29 kg/m3),工况1—4下钻头对井筒的作用力见表1(负为降斜力,正为增斜力)。

表 1 钻头对井筒的作用力Table 1. Force of the bit on the wellbore工况 x方向作用力/N y方向作用力/N z方向作用力/N 1 –1 708.50 –17.80 –150.50 2 –998.30 –3.30 –87.70 3 –0.10 0.01 0.01 4 7 435.70 56.30 595.50 由表1可知,主要的作用力为x向作用力,即侧向力。对比发现:工况1条件下,由于钟摆效应,钻头降斜力较大,此时钻具组合具有较好的降斜效果;工况2条件下,井筒的不规则性使得其在特定位置形成附加支点,减小了钟摆的摆距,使钻头处的降斜力大幅减小;工况3条件下,不规则井筒使钻柱发生一定变形,进一步减小了BHA的降斜能力;工况4条件下,严重不规则的井筒使钻柱发生较大变形,使钻头处产生较大的增斜力。由此可知,井筒越不规则,钟摆BHA降斜能力越弱,甚至可能变为增斜钻具组合。

图4所示为用矢量图表示的不同工况条件下钻头处的侧向力特征。

由图4可知,井筒的规则程度对钻头侧向力影响很大,在严重不规则井筒中,钻头处会产生增斜力,不利于控制井斜。因此,采用气体钻井钻进含砾岩层等复杂地层时,应尽可能提高井筒的规则性,以更好地控制井斜。

3. 实例分析

以塔里木油田山前地区钻遇巨厚砾石层的某井为例,其三开2 505.00~2 926.00 m井段采用空气锤钻井,井斜角从0.71º 增至4.48º,增幅很大;起钻通井后,2 926.00~3 502.00 m井段采用带预弯结构的钟摆BHA控斜,纯钻时间120.42 h,钻压小于20 kN,转速60 r/min,平均扭矩约4.5 kN·m,且波动幅度很小,井斜角由最大5.20°减至0.63°(3 404.00 m处),取得了很好的降斜效果。该井上述井段在钻进中的井斜角随井深的变化情况如图5所示[12]。

为分析巨厚砾石层气体钻井的井筒特征,利用测井仪器对井径进行了测量。利用三次样条函数对所测井径数据进行处理,可得如图6所示的重构井筒[13]。图6(a)所示为2 700.00~2 760.00 m井段的井筒特征,该井段采用空气锤钻进,所用空气锤钻头直径为431.8 mm。由图6(a)可知,该井段的井筒特征随井深的变化情况非常复杂,除椭圆形状十分明显外(长轴的长度508.0 mm,短轴的长度431.8 mm),其上、下截面形状之间的变化差异也很大,存在严重的不规则和不光滑现象。图6(b)所示为3 140.00~3 200.00 m井段的井筒特征,该井段采用预弯钟摆BHA控斜钻进。由图6(b)可知,该井段的井筒特征相对规则,椭圆度较小。结合图5中井斜数据可知,该井段的井斜角从3.29º减小至1.79º,控制效果显著。

由以上分析可知,空气锤钻进井段控斜效果不好,而预弯钟摆BHA钻进井段井斜角减小幅度大,控斜效果显著。这与本文模型分析所得结论相一致:井筒的不规则性增加了井斜控制难度,选择控斜方法时必须考虑井筒规则性对井斜控制效果的影响,并设法提高井筒的规则性。实践表明,预弯钟摆BHA控斜效果好,其中一个重要原因是其可以在一定程度上改变井眼形状,提高井壁的光滑度。

本文BHA受力分析结果与塔里木油田多口井的现场实测数据都能很好地吻合,证明建立的巨厚砾石层气体钻井条件下的BHA与井筒相互作用有限元模型可靠、准确。

4. 结 论

1)不规则井筒易形成附加支点,缩短钟摆钻具组合的摆距,减小钻头上的降斜力。严重不规则井筒可使BHA发生弯曲变形,改变BHA的受力特征,大幅度减小钻头上的降斜力甚至使钻头侧向力成为增斜力。

2)井筒规则程度对BHA的三维受力特征有较大影响,BHA力学分析应考虑井筒不规则性的影响。在含砾岩层等易形成不规则井筒的气体钻井中,选择钻井工具时应充分考虑所钻井筒的规则性。

3)塔里木油田山前地区巨厚砾石层气体钻井实践表明,预弯钟摆BHA可有效改善井眼截面形状,提高井筒的规则性,有利于控制井斜。

-

表 1 试验用原油初始黏度

Table 1 Initial viscosity of crude oil in the experiment

油样 组分含量,% 重均相对

分子质量黏度/(mPa·s) 饱和 芳香 胶质 沥青质 50 ℃ 130 ℃ 油样A 27.35 32.28 24.10 16.28 1 081 4 570 68.6 油样B 29.13 31.18 27.75 11.94 1 081 3 540 62.5 油样C 30.81 31.22 17.38 20.59 1 064 370 20.4 油样D 32.31 31.13 18.58 18.01 1 087 961 37.1 表 2 不同油样对抽提效果的影响

Table 2 Influence of different oil samples on extraction

油样 质量/

g注入速度/

(L·min–1)注入量/

L抽提量/

g质量占比,% 油样A 72.70 2.96 221.74 0.12 0.17 油样B 75.70 3.00 230.88 0.12 0.16 油样C 109.10 2.97 332.76 0.12 0.11 油样D 83.19 2.99 253.73 0.07 0.08 表 3 氮气注入倍数对油样A抽提效果的影响

Table 3 Influence of nitrogen injection multiples on extraction in Sample A

油样质

量/g注入速度/

(L·min–1)注入倍数 抽提量/

g质量

比,%50 ℃黏度/

(mPa·s)增黏

倍数72.95 2.90 3 0.05 0.07 5 026 1.10 99.63 2.98 5 0.11 0.11 5 519 1.21 72.70 2.96 10 0.12 0.17 6 701 1.47 63.35 2.97 30 0.27 0.43 14 933 3.27 表 4 注入速度对原油抽提效果的影响

Table 4 Influence of nitrogen injection rates on extraction

油样质量/g 注入速度/(L·min−1) 注入量/L 抽提量/g 63.35 2.97 579.65 0.27 63.35 3.49 579.65 0.25 63.35 4.07 579.65 0.24 表 5 油样E在不同含氧量氮气中氧化不同时间后的黏度

Table 5 Viscosity of Sample E after oxidization for different time in nitrogen with different oxygen contents

含氧量,% 油样E氧化不同时间后的黏度/(mPa·s) 6 h 12 h 30 h 54 h 78 h 126 h 174 h 1 10 020 12 600 15 480 17 750 18 200 18 300 18 000 5 12 500 35 330 62 000 98 400 228 000 453 000 1 122 000 15 55 630 384 000 9 360 000 32 750 000 表 6 油样E经不同含氧量氮气氧化前后C,H 和 N 元素含量的变化

Table 6 Change of contents of Element C, H and N in Sample E before and after oxidization by nitrogen with different oxygen contents

油样 H,% C,% N,% S,% O,% 油样E 11.95 85.13 0.51 1.80 0.61 含氧量1%氮气抽提3次 11.80 84.99 0.51 1.84 0.86 含氧量1%氮气抽提7次 11.78 84.94 0.51 1.86 0.91 含氧量5%氮气抽提3次 11.66 84.71 0.51 1.89 1.23 含氧量5%氮气抽提7次 11.49 84.36 0.49 1.86 1.85 表 7 TK1原油乳化含水样品黏度

Table 7 Viscosity of emulsified water-bearing samples from Well TK1

原油乳化含水率,% 真实含水率,% 50 ℃原油黏度/(mPa·s) 原始样 5.51 385 10 9.82 575 20 14.35 1 420 30 27.41 4 337 45 44.38 22 590 60 56.06 273 000 70 62.55 449 000 75 67.34 212 000 表 8 TK2原油乳化含水样品黏度

Table 8 Viscosity of emulsified water-bearing samples from Well TK2

原油乳化含水率,% 真实含水率,% 50 ℃原油黏度/(mPa·s) 原始样 4.65 1 880 10 9.16 2 480 20 20.8 7 500 30 33.45 13 200 40 40.1 22 800 55 53.0 44 000 65 63.5 109 000 70 67.2 78 800 -

[1] 杨景斌,侯吉瑞. 缝洞型碳酸盐岩油藏岩溶储集体注氮气提高采收率实验[J]. 油气地质与采收率,2019,26(6):107–114. YANG Jingbin, HOU Jirui. Experiments on enhancing oil recovery by nitrogen injection in fracture-vuggy carbonate reservoirs[J]. Petroleum Geology and Recovery Efficiency, 2019, 26(6): 107–114.

[2] 关华,郭平,赵春兰,等. 渤海湾盆地永安油田永66区块氮气驱油机理[J]. 岩性油气藏,2020,32(2):149–160. GUAN Hua, GUO Ping, ZHAO Chunlan, et al. Nitrogen flooding mechanism in Yong66 Block of Yong’an Oilfield, Bohai Bay Basin[J]. Lithologic Reservoirs, 2020, 32(2): 149–160.

[3] 姜海涛. 救援井与事故井连通技术研究[D]. 北京: 中国石油大学(北京), 2014. JIANG Haitao. Study on the Technology of Intercommunicating the relief well and the accident well[D].Beijing: China University of Petroleum(Beijing), 2014

[4] WANG Leizheng, YU Wei. Gas huff and puff process in Eagle Ford Shale: recovery mechanism study and optimization[R]. SPE 195185, 2019.

[5] 刘中云,赵海洋,王建海,等. 塔河油田溶洞型碳酸盐岩油藏注入氮气垂向分异速度及横向波及范围研究[J]. 石油钻探技术,2019,47(4):75–82. doi: 10.11911/syztjs.2019092 LIU Zhongyun, ZHAO Haiyang, WANG Jianhai, et al. Study on vertical differential velocity and transverse scope of nitrogen injection in carbonate reservoirs with fractures and vugs in the Tahe Oilfield[J]. Petroleum Drilling Techniques, 2019, 47(4): 75–82. doi: 10.11911/syztjs.2019092

[6] 刘笑春,黎晓茸,杨飞涛,等. 长庆姬塬油田黄3区CO2驱对采出原油物性影响[J]. 油气藏评价与开发,2019,9(3):36–40. doi: 10.3969/j.issn.2095-1426.2019.03.007 LIU Xiaochun, LI Xiaoxiang, YANG Feitao, et al. Effect of CO2 flooding on physical properties of produced crude oil in Huang 3 Block of Jiyuan Oilfield, Changqing[J]. Oil and Gas Reservoir Evaluation and Development, 2019, 9(3): 36–40. doi: 10.3969/j.issn.2095-1426.2019.03.007

[7] YU Wei, LASHGARI H R, SEPEHRNOORI K. Simulation study of CO2 huff-n-puff process in Bakken tight oil reservoirs[R]. SPE 169575, 2014.

[8] 唐人选,梁珀,吴公益,等. 苏北复杂断块油藏二氧化碳驱油效果影响因素分析及认识[J]. 石油钻探技术,2020,48(1):98–103. doi: 10.11911/syztjs.2019125 TANG Renxuan, LIANG Po, WU Gongyi, et al. Analyzing and understanding the influencing factors of CO2 flooding in the Subei complex fault block reservoirs[J]. Petroleum Drilling Techniques, 2020, 48(1): 98–103. doi: 10.11911/syztjs.2019125

[9] 侯剑锋,刘鹏刚,曹廷义. 轻质原油注空气热特征及氧化动力学研究[J]. 油气藏评价与开发,2020,10(4):113–118. HOU Jianfeng, LIU Penggang, CAO Tingyi. Study on thermal characteristics and oxidation kinetics of light crude oil by air injec-tion[J]. Oil and Gas Reservoir Evaluation and Development, 2020, 10(4): 113–118.

[10] 龙安林,张茂林,宋惠馨,等. 减氧空气驱低温氧化反应机理研究:以尕斯库勒油田E31油藏为例[J]. 能源与环保,2020,42(4):105–109. LONG Anlin, ZHANG Maolin, SONG Huixin, et al. Study on mechanism of low temperature oxidation reaction of deoxidized air drive: taking E31 reservoir of Gaskule Oilfield as an example[J]. Energy and Environmental Protection, 2020, 42(4): 105–109.

[11] 廖广志,王红庄,王正茂,等. 注空气全温度域原油氧化反应特征及开发方式[J]. 石油勘探与开发,2020,47(2):334–340. LIAO Guangzhi, WANG Hongzhuang, WANG Zhengmao, et al. Characteristics and development methods of crude oil oxidation reaction in the whole temperature range of air injection[J]. Petroleum Exploration and Development, 2020, 47(2): 334–340.

[12] 张地平. 地下电磁定位测距方法研究[D]. 成都: 电子科技大学, 2018. ZHANG Diping. Research on location method of underground electromagnetic positioning[D]. Chengdu: University of Electronic Science and Technology of China, 2018

[13] MONTES A R, GUTIERREZ D, MOORE R G, et al. Is high pressure air injection (HPAI) simply a flue-gas flood?[R]. SPE 133206, 2010.

[14] REN S R, GREAVES M, RATHBONE R R. Air injection LTO process: an IOR technique for light-oil reservoirs[J]. Society of Petroleum Engineers Journal, 2002, 7(1): 90–99.

[15] CLARA C, DURANDEAU M, QUENAULT G, et al. Laboratory studies for light oil air injection projects: potential application in Handil Field[J]. SPE Reservoir Evaluation&Engineering, 2000, 3(3): 239–248.

[16] 王伟伟. 压力对轻质原油氧化动力学参数的影响[J]. 断块油气田,2020,27(1):109–112. WANG Weiwei. Influence of pressure on oxidation kinetic parameters of light crude oil[J]. Fault-Block Oil & Gas Field, 2020, 27(1): 109–112.

[17] 李一波,蒲万芬,王爱香,等. 轻质油藏注空气低温高压氧化实验研究[J]. 石油钻采工艺,2012,34(6):90–92. doi: 10.3969/j.issn.1000-7393.2012.06.026 LI Yibo, PU Wanfen, WANG Aixiang, et al. Experimental study on low temperature high pressure oxidation in air injection in light oil reservoir[J]. Oil Drilling & Production Technology, 2012, 34(6): 90–92. doi: 10.3969/j.issn.1000-7393.2012.06.026

[18] 文江波,罗海军,柯兰茜,等. 流动剪切对原油乳化含水率的影响及基于焓的定量表征[J]. 科学技术与工程,2019,19(11):104–107. WEN Jiangbo, LUO Haijun, KE Lanxi, et al. Effect of flow shear on water content of crude oil emulsion and quantitative characterization based on enthalpy[J]. Science Technology and Engineering, 2019, 19(11): 104–107.

[19] 黄咏梅,赵宏伟,盖云飞. 薄层低渗透断块稠油氮气分散降黏增产技术研究与应用[J]. 长江大学学报(自然科学版),2020,17(2):71–77. HUANG Yongmei, ZHAO Hongwei, GAI Yunfei. Research and application of technology of reducing viscosity and increasing production of heavy oil by nitrogen dispersion in the fault block reservoir with thin layer and low permeability[J]. Journal of Yangtze University (Natural Science Edition), 2020, 17(2): 71–77.

[20] ZHANG Lijun, CHENG Shiqiang, YU Haili. Analysis of pressure transient for fractured-vuggy reservoirs with coupling of pipe flow and seepage[C]. International Symposium on Multi-Field Coupling Theory of Rock and Soil Media and Its Applications, 2010: 313–317.

[21] 张晓,李小波,荣元帅,等. 缝洞型碳酸盐岩油藏周期注水驱油机理[J]. 复杂油气藏,2017,10(2):38–42. ZHANG Xiao, LI Xiaobo, RONG Yuanshuai, et al. Mechanism of cyclic water flooding in fiactured-vuggy type carbonate reservoir[J]. Complex Hydrocarbon Reservoirs, 2017, 10(2): 38–42.

-

期刊类型引用(0)

其他类型引用(2)

下载:

下载: