Performance Test and Numerical Simulation Research on Vacuum Insulated Casings for Permafrost Protection

-

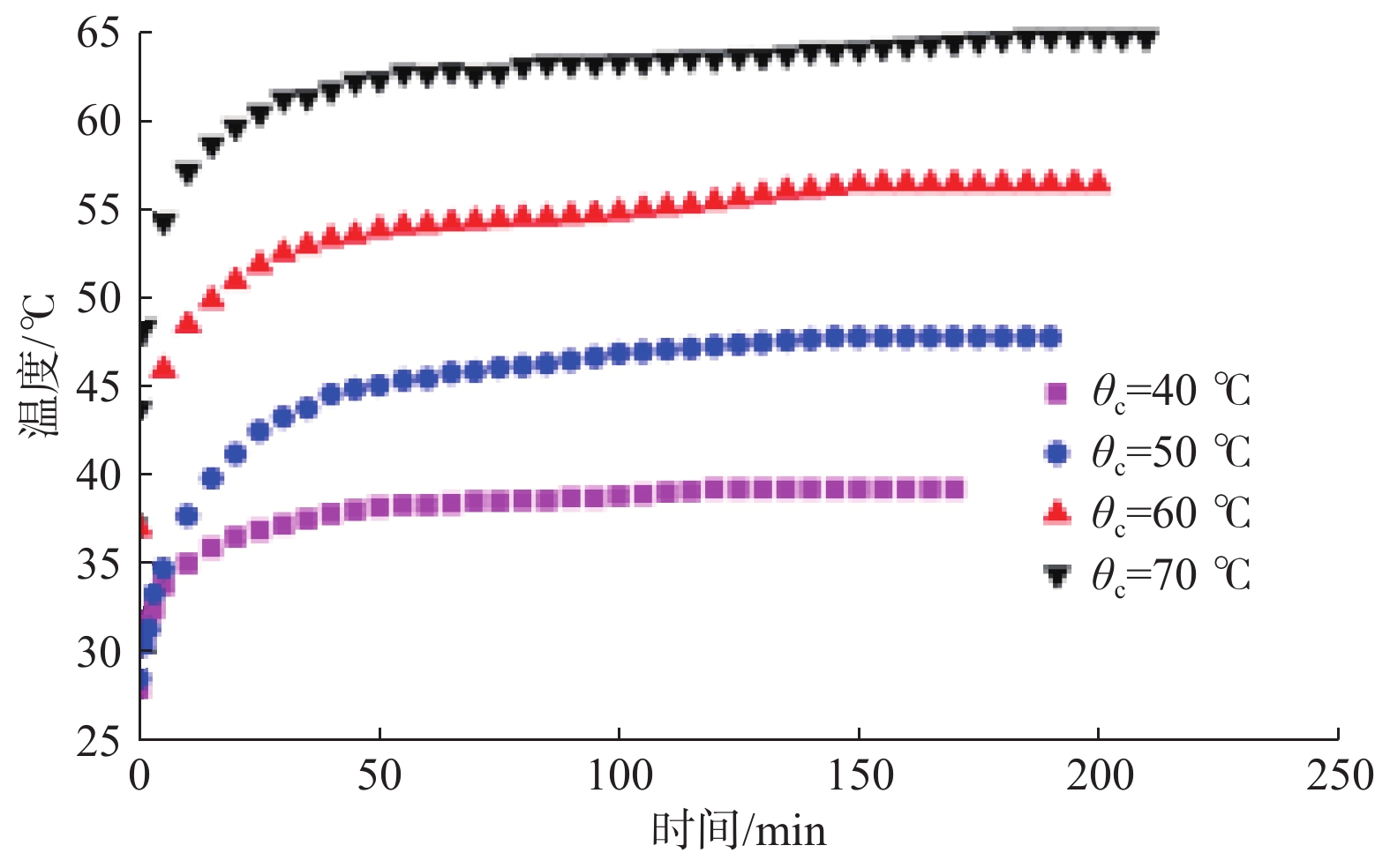

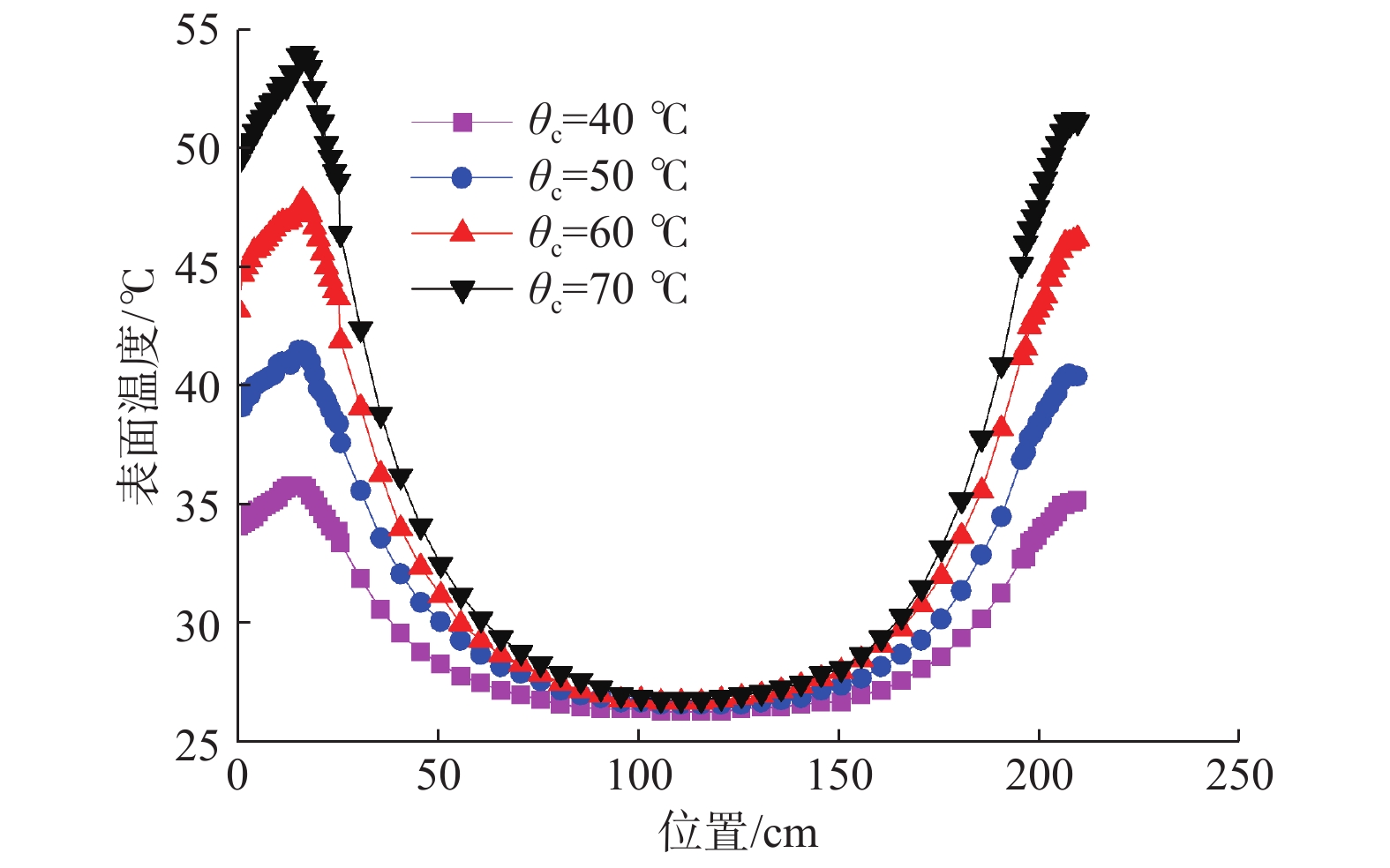

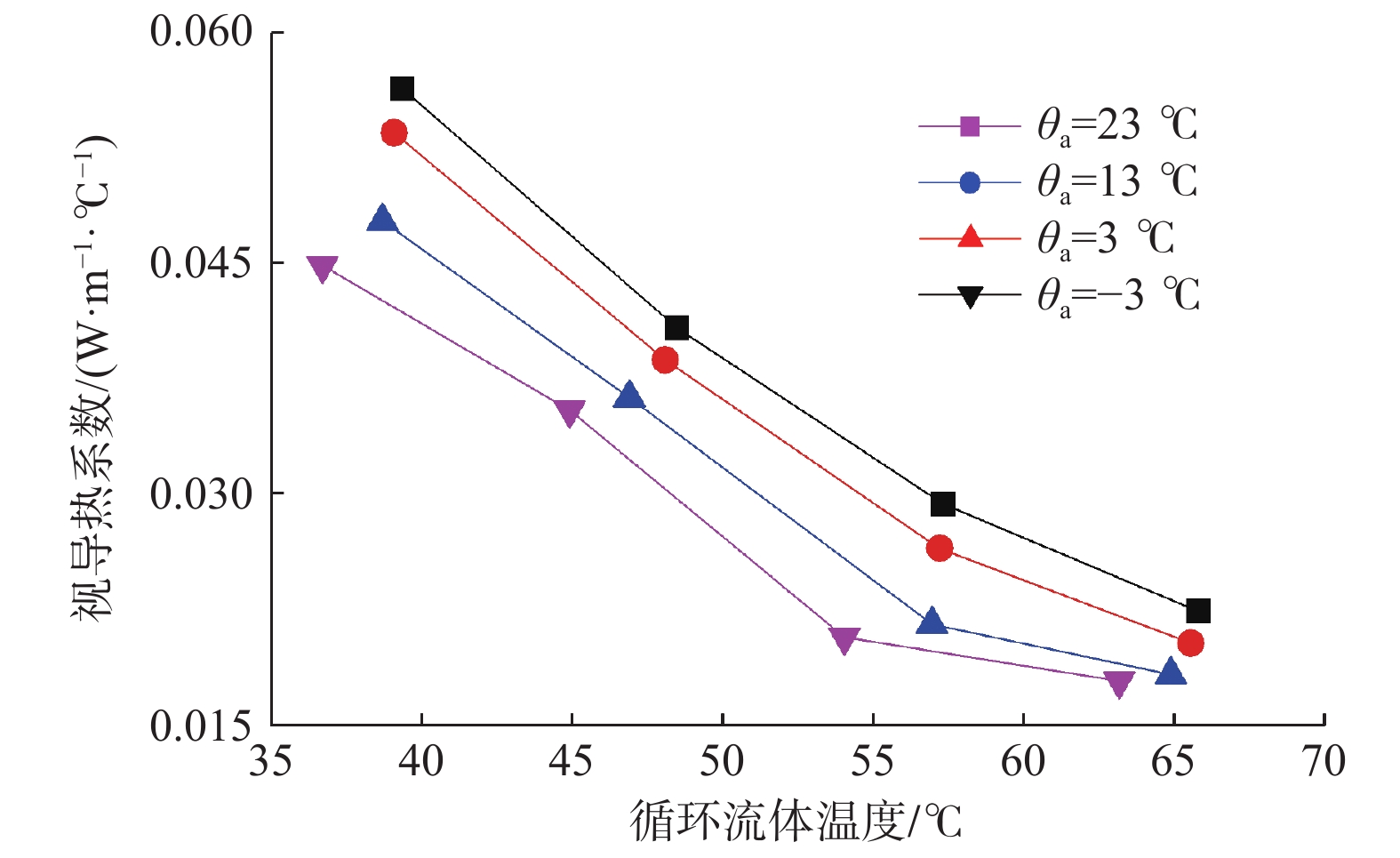

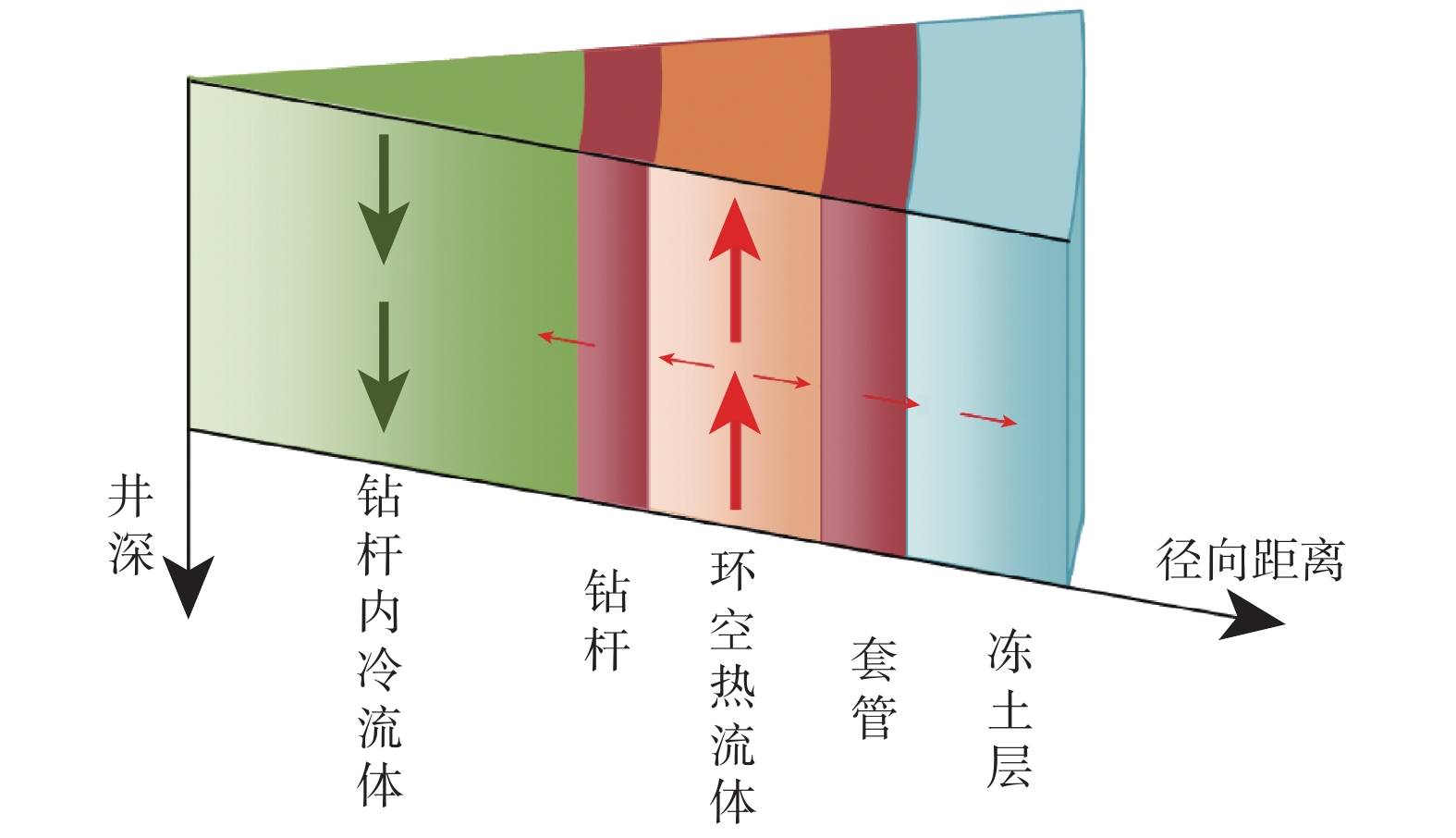

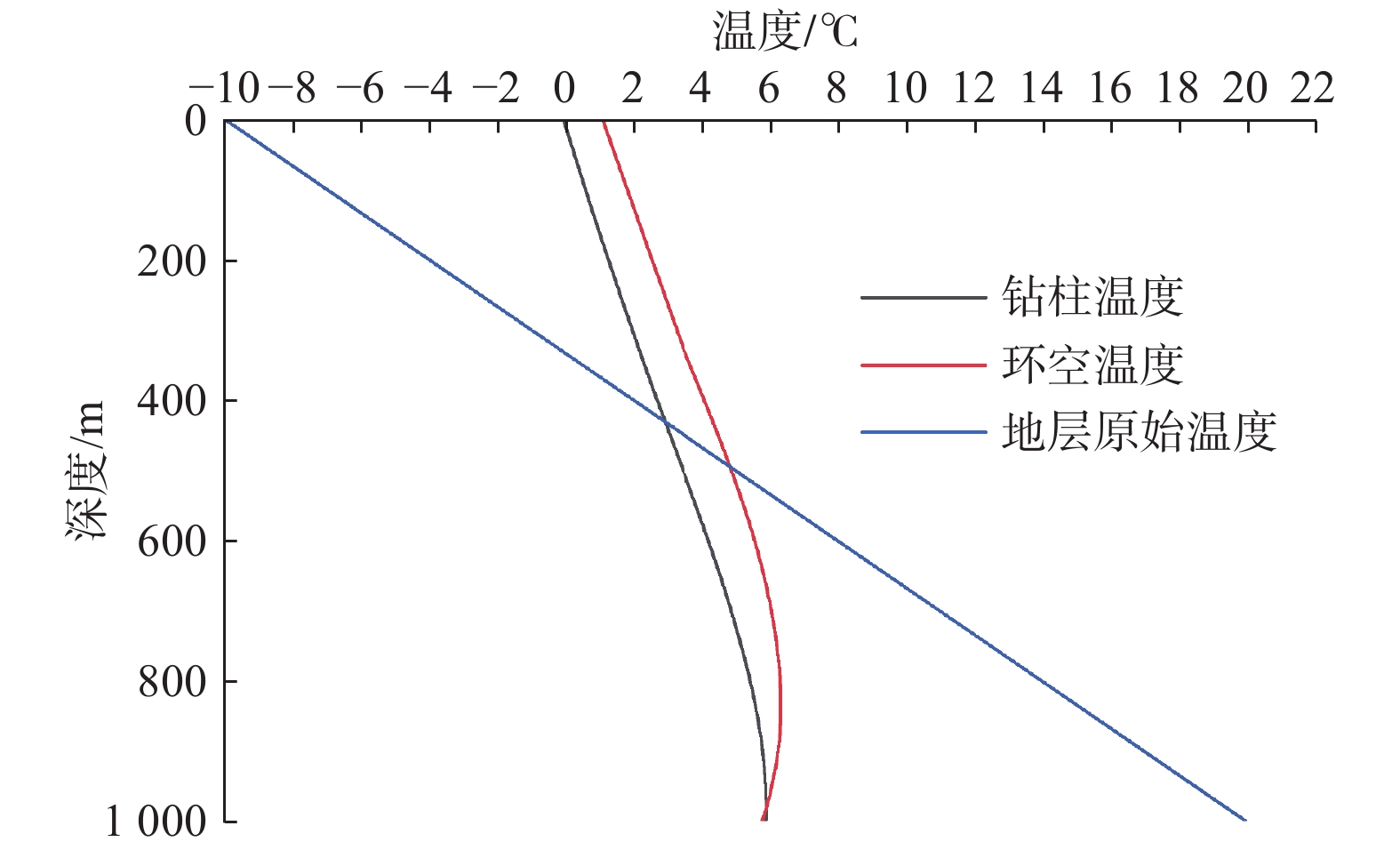

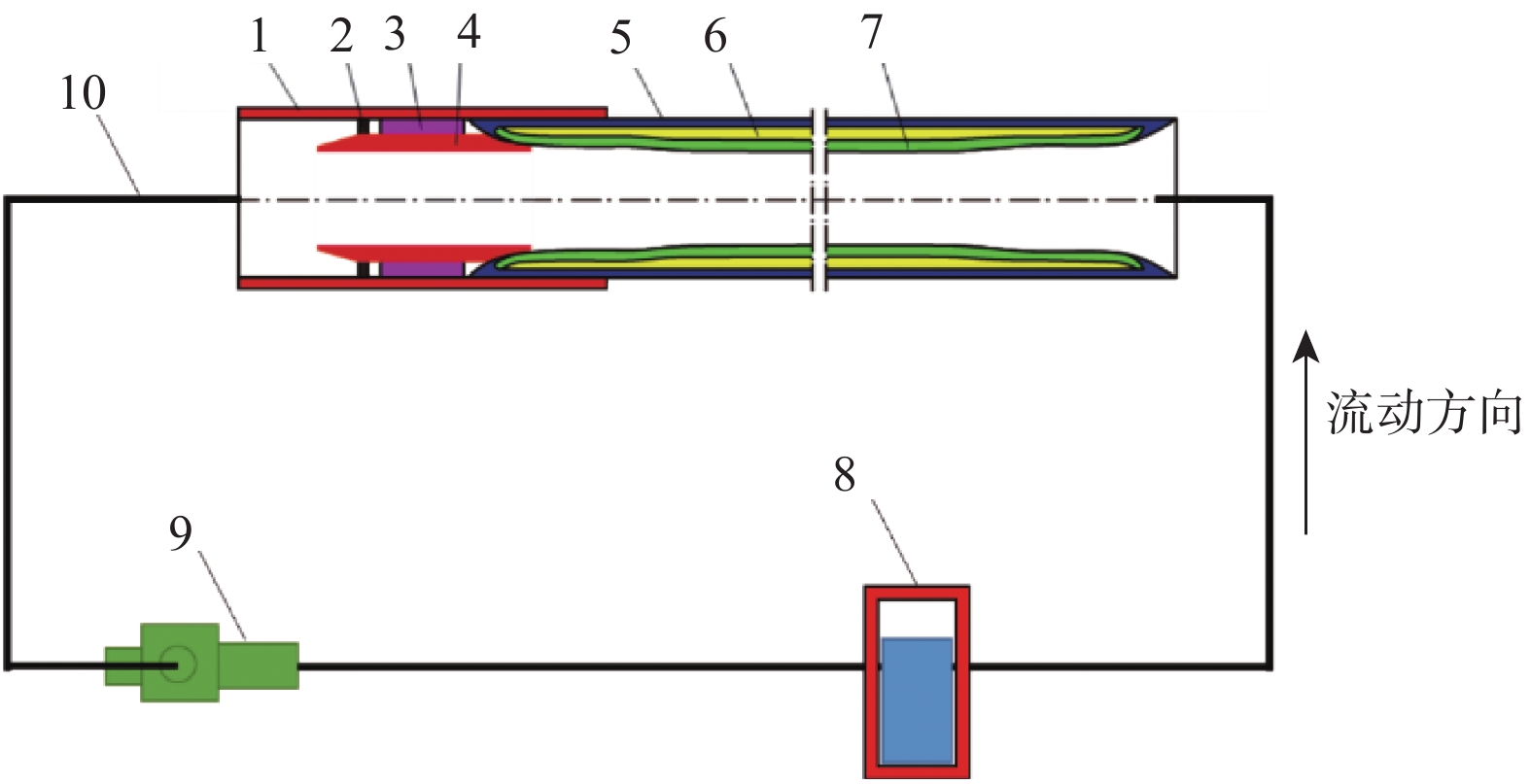

摘要: 针对冻土层钻井过程中可能引发的冻土融沉和井口下沉等问题,研究采用真空隔热套管保护冻土层,并采用试验和数值模拟方法研究了真空隔热套管的保温性能。试验结果显示:真空隔热套管能在限制径向传热的同时限制表面的轴向传热,减小套管表面的升温幅度和升温范围;其视导热系数远小于传统套管,在不同环境温度和钻井液温度下都具有保温性能;降低真空度可以提高其保温性能,强化其对冻土层的保护。数值模拟结果表明,真空隔热套管可以减小冻土层融化区域,降低冻土融沉和井口下沉的可能性。在此基础上,提出了降低真空度、加大套管总成内的隔热套管段长度和接箍处包裹隔热泡沫等提高真空隔热套管保温性能的工程措施。研究结果验证了真空隔热套管对冻土层保护的有效性和稳定性,对开发极地油气资源具有一定的指导作用。Abstract: Because permafrost settles as it thaws, there is a risk that the wellhead will sink while drilling, and therefore, vacuum insulated casings were introduced to protect the permafrost, and their thermal insulation performance was analyzed through experiments and numerical simulations. The field test results showed that the vacuum insulated casings could limit both the radial and the axial heat transfer on the surface simultaneously, which restricts the range and magnitude of temperature increase on the casing surface. Because the vacuum insulated casings have much lower apparent thermal conductivity than that of traditional casings, their thermal insulation performance can be maintained at various ambient temperatures and drilling fluid temperatures. In addition, decreasing the vacuum degree can improve their thermal insulation performance and strengthen their protection of the permafrost. The numerical simulation results indicated that the vacuum insulated casings could greatly reduce the permafrost thaw zone and lower the possibility of settling and wellhead sinking due to permafrost thaw. Furthermore, the following measures were adopted to enhance the thermal insulation performance of the vacuum insulated casings, including vacuum degree reduction, insulated casings length increase in the casing assembly, and insulation foam wrapping at the coupling. The research results have verified the effectiveness and stability of vacuum insulated casings in protecting the permafrost, so as to guide the development of oil and gas resources in the Arctic region.

-

-

-

[1] BLAAUW R J. Oil and gas development and opportunities in the Arctic Ocean// Environmental security in the Arctic Ocean[M]. Netherlands: Springer, 2013: 175–184.

[2] BERKMAN P A, YOUNG O R. Governance and environmental change in the Arctic Ocean[J]. Science, 2009, 324(5925): 339–340. doi: 10.1126/science.1173200

[3] 马巍,王大雁. 中国冻土力学研究50a回顾与展望[J]. 岩土工程学报,2012,34(4):625–640. MA Wei, WANG Dayan. Studies on frozen soil mechanics in China in past 50 years and their prospect[J]. Chinese Journal of Geotechnical Engineering, 2012, 34(4): 625–640.

[4] VERNIKOVSKY V A, DOBRETSOV N L, METELKIN D V, et al. Concerning tectonics and the tectonic evolution of the Arctic[J]. Russian Geology and Geophysics, 2013, 54(8): 838–858. doi: 10.1016/j.rgg.2013.07.006

[5] SEKRETOV S B. Northwestern margin of the East Siberian Sea, Russian Arctic: seismic stratigraphy, structure of the sedimentary cover and some remarks on the tectonic history[J]. Tectonophysics, 2001, 339(3/4): 353–371.

[6] 王淑玲,姜重昕,金玺. 北极的战略意义及油气资源开发[J]. 中国矿业,2018,27(1):20–26, 39. WANG Shuling, JIANG Chongxin, JIN Xi. The strategic significance of the Arctic and the development of oil and gas resources[J]. China Mining Magazine, 2018, 27(1): 20–26, 39.

[7] 杨进,路保平. 极地冷海钻井技术挑战及关键技术[J]. 石油钻探技术,2017,45(5):1–7. YANG Jin, LU Baoping. The challenges and key technologies of drilling in the cold water area of the Arctic[J]. Petroleum Drilling Techniques, 2017, 45(5): 1–7.

[8] 李文龙,高德利,杨进,等. 深水超深井钻井井筒温度剖面预测[J]. 石油钻采工艺,2020,42(5):558–563. LI Wenlong, GAO Deli, YANG Jin, et al. Prediction of the borehole temperature profile in ultradeep drilling under ocean deepwater conditions[J]. Oil Drilling & Production Technology, 2020, 42(5): 558–563.

[9] 李德旗,张华,郭玉超,等. 气井生产期间井筒内温度变化对水泥环密封完整性影响的研究及应用[J]. 钻采工艺,2020,43(1):24–26. LI Deqi, ZHANG Hua, GUO Yuchao, et al. Study on effects of wellbore temperature variation on cement sheath integrity during gas well production[J]. Drilling & Production Technology, 2020, 43(1): 24–26.

[10] VRIELINK H J, BRADFORD J S, BASARAB L, et al. Successful application of casing-while-drilling technology in a Canadian arctic permafrost application[R]. SPE 111806, 2008.

[11] 朱广海,刘章聪,熊旭东,等. 电加热稠油热采井筒温度场数值计算方法[J]. 石油钻探技术,2019,47(5):110–115. ZHU Guanghai, LIU Zhangcong, XIONG Xudong, et al. Numerical calculation method of the wellbore temperature field for electric heating heavy oil thermal recovery[J]. Petroleum Drilling Techniques, 2019, 47(5): 110–115.

[12] 付亚荣,李琳,杨中峰,等. 隔热保温防磨油管下入深度确定方法[J]. 石油机械,2019,47(7):128–132. FU Yarong, LI Lin, YANG Zhongfeng, et al. Method for depth determining of thermal insulation anti-wear tubing[J]. China Petroleum Machinery, 2019, 47(7): 128–132.

[13] 张伟,刘志龙,万芬,等. 渤海稠油热采隔热管优选和注氮工艺优化[J]. 海洋石油,2020,40(4):25–30. ZHANG Wei, LIU Zhilong, WAN Fen, et al. Optimization of heat-insulating pipes for thermal recovery of heavy oil in Bohai Sea and optimization of nitrogen injection technology[J]. Offshore Oil, 2020, 40(4): 25–30.

[14] 魏纳,孙万通,孟英峰,等. 海洋天然气水合物藏钻探环空相态特性[J]. 石油学报,2017,38(6):710–720. WEI Na, SUN Wantong, MENG Yingfeng, et al. Annular phase behavior analysis during marine natural gas hydrate reservoir drilling[J]. Acta Petrolei Sinica, 2017, 38(6): 710–720.

[15] 凯斯 W M, 克拉福德 M E, 威甘德 B. 对流传热与传质[M]. 4版. 赵镇南, 译. 北京: 高等教育出版社, 2007: 69–70. KAYS W M, CRAWFORD M E, WEIGAND B. Convective heat and mass transfer[M]. 4th ed. ZHAO Zhennan, translated. Beijing: Higher Education Press, 2007: 69–70.

[16] DOKHANI V, MA Yue, YU Mengjiao. Determination of equivalent circulating density of drilling fluids in deepwater drilling[J]. Journal of Natural Gas Science and Engineering, 2016, 34: 1096–1105. doi: 10.1016/j.jngse.2016.08.009

[17] ZHANG Zheng, XIONG Youming, GAO Yun, et al. Wellbore temperature distribution during circulation stage when well-kick occurs in a continuous formation from the bottom-hole[J]. Energy, 2018, 164: 964–977. doi: 10.1016/j.energy.2018.09.048

[18] 张健, 卢运虎.超深井筒温度分布及其对围岩力学性质的影响研究[J].岩石力学与工程学报, 2019, 38(增刊1): 2831–2839. ZHANG Jian, LU Yunhu. Study on temperature distribution of ultra-deep wellbore and its effect on mechanical properties of surrounding rock[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(supplement 1): 2831–2839.

[19] 李亚涛. 冻土层钻井井口稳定性研究[D]. 北京: 中国石油大学(北京), 2018. LI Yatao. Study on the stability of wellhead during drilling in permafrost zone[D]. Beijing: China University of Petroleum(Beijing), 2018.

下载:

下载: