Study on Enhanced Oil Recovery Method in Deep-Water Turbidite Reservoirs—A Case Study of X Reservoir in Angola

-

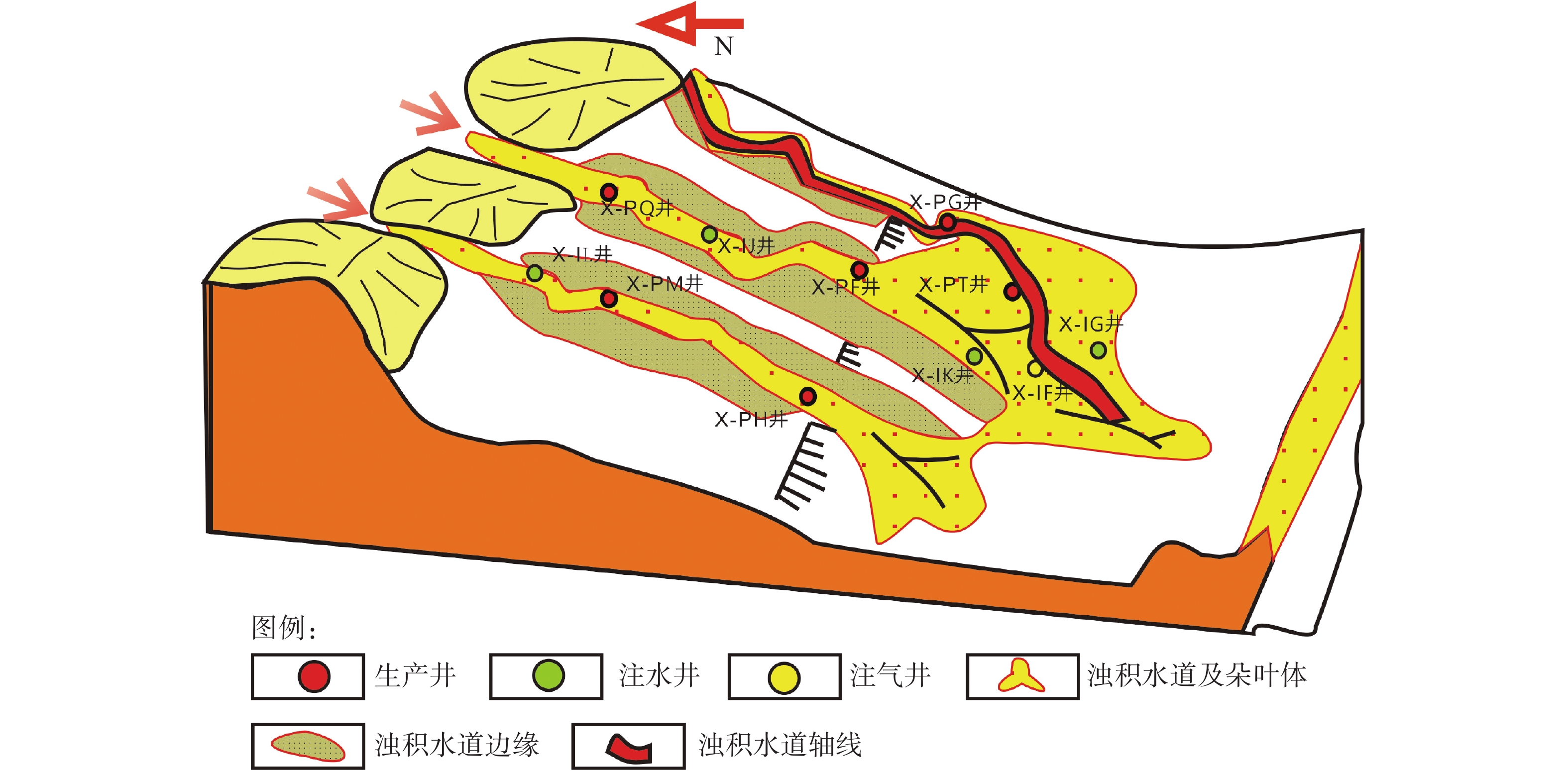

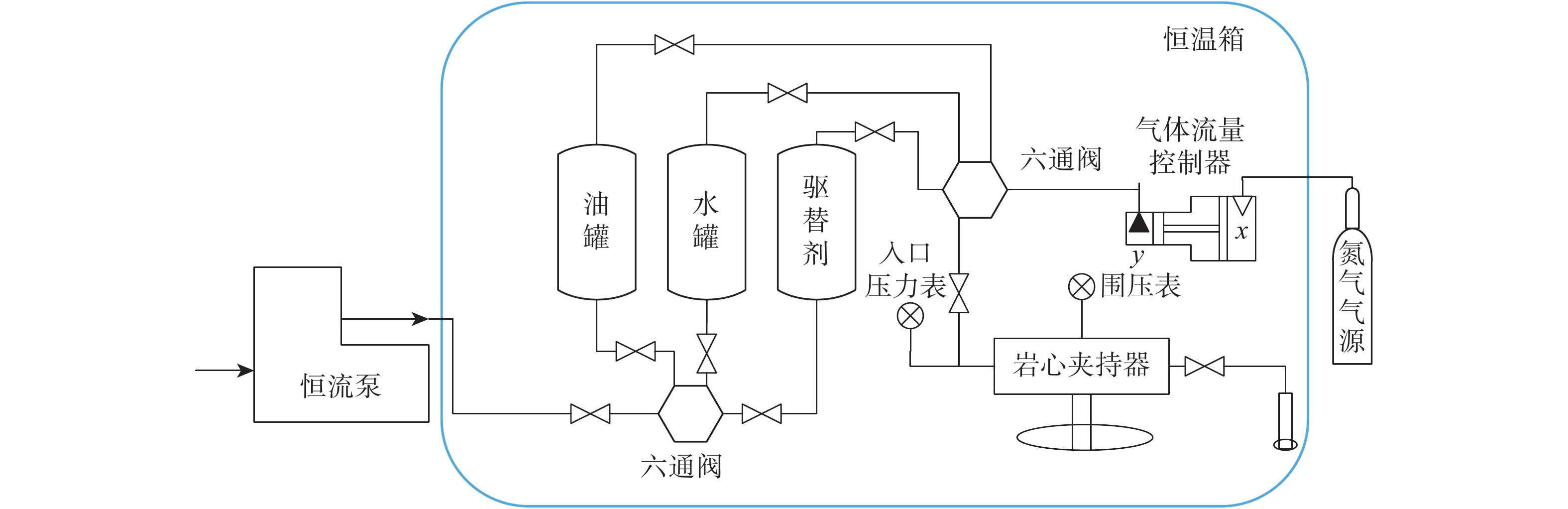

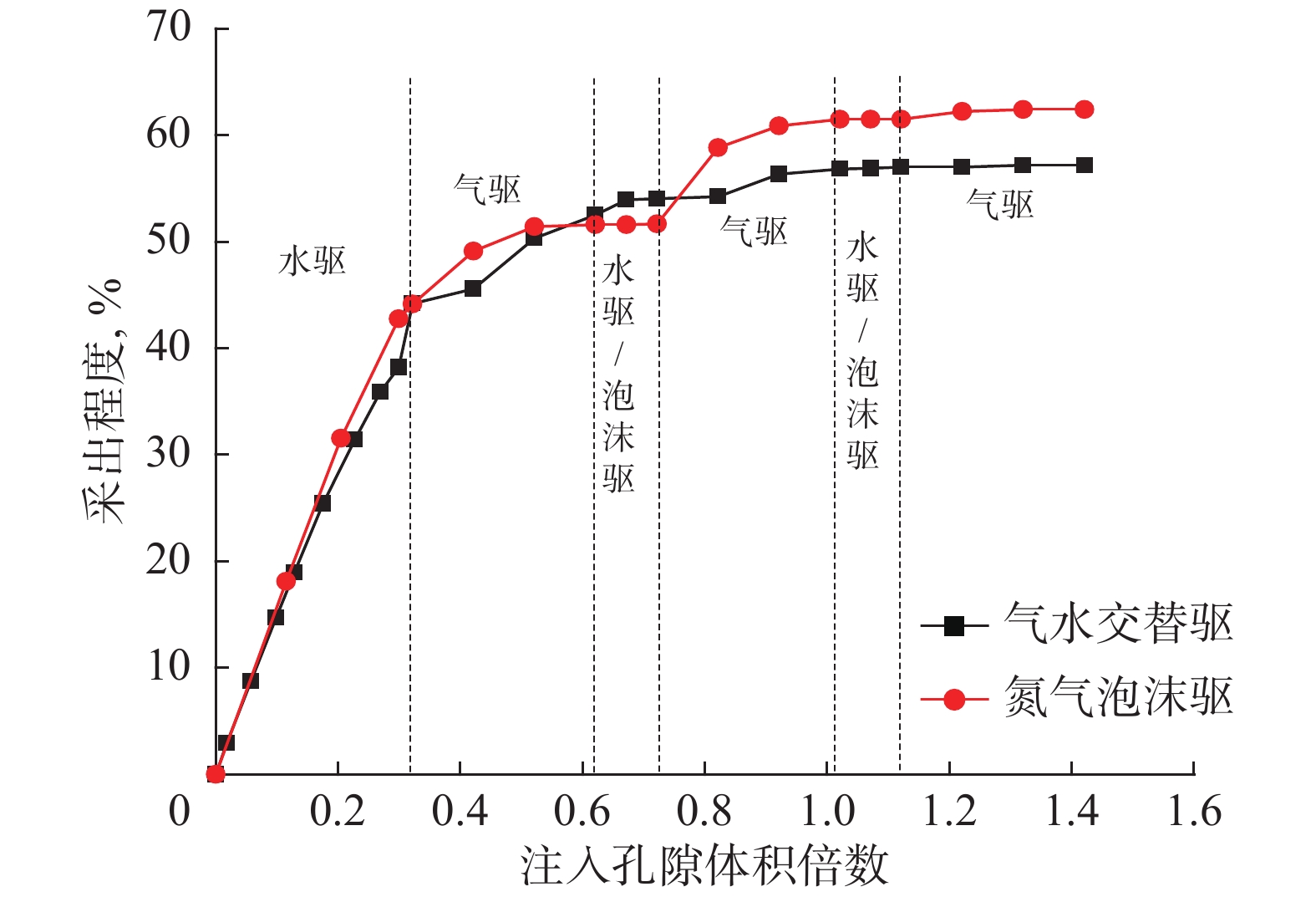

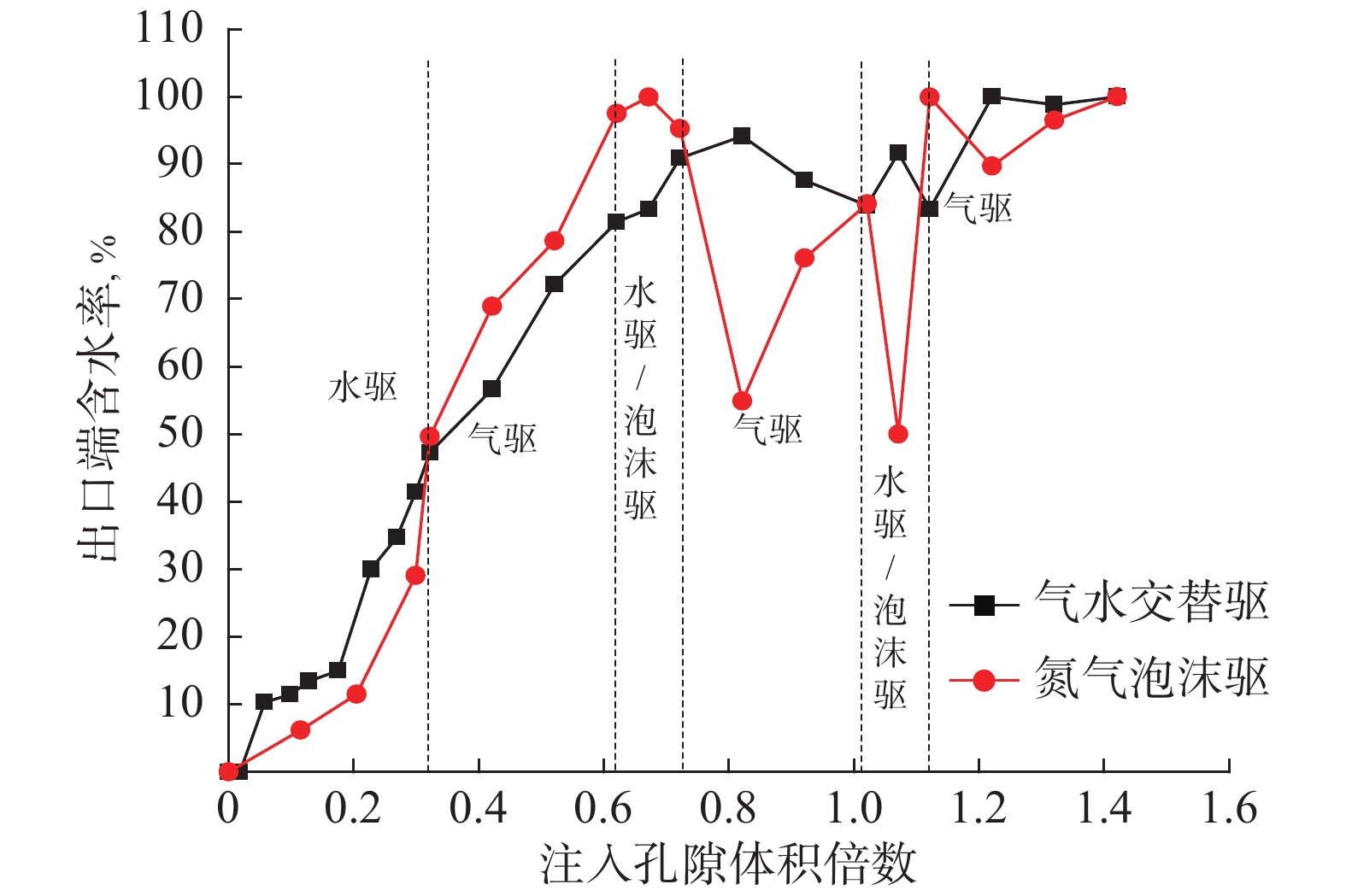

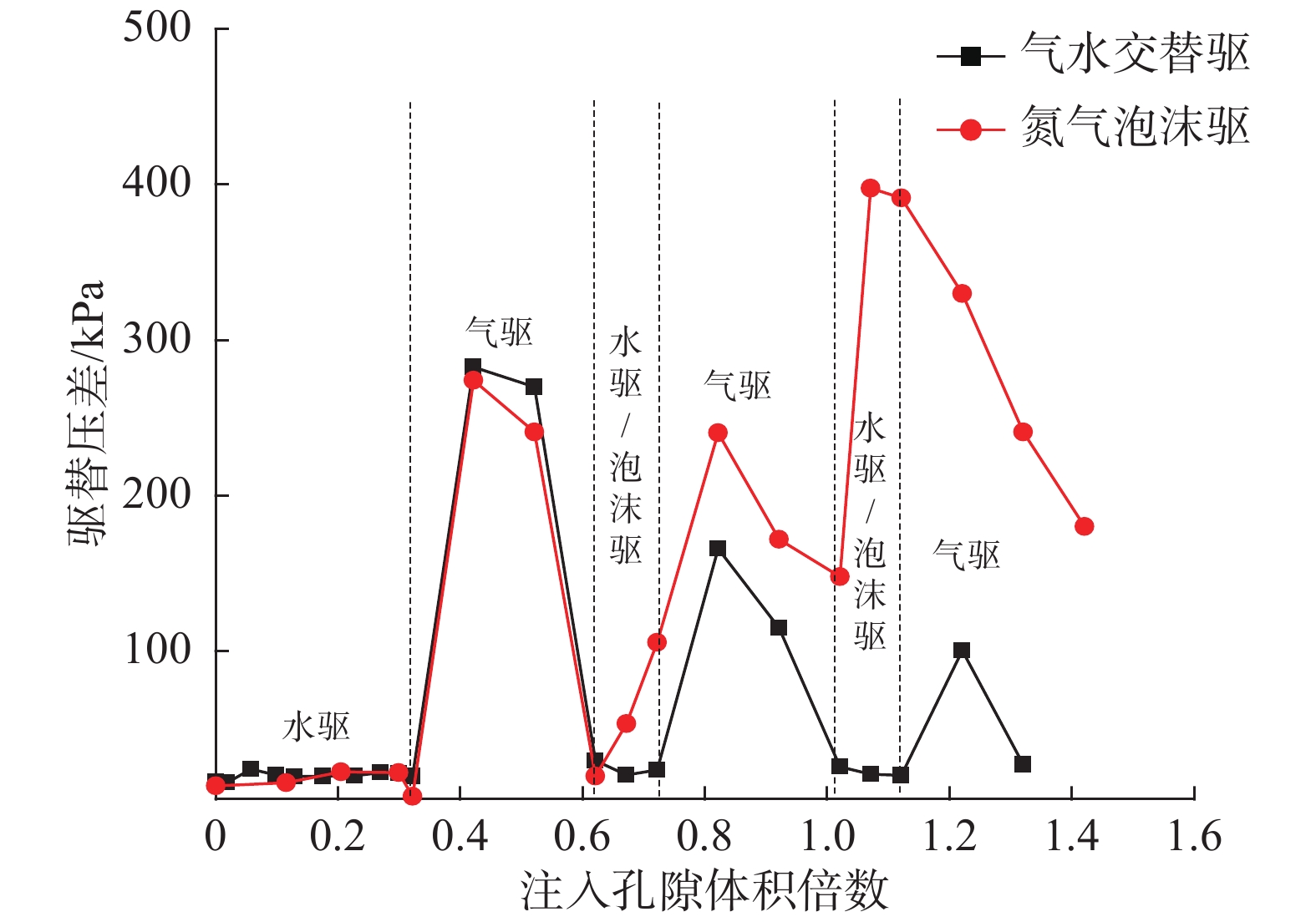

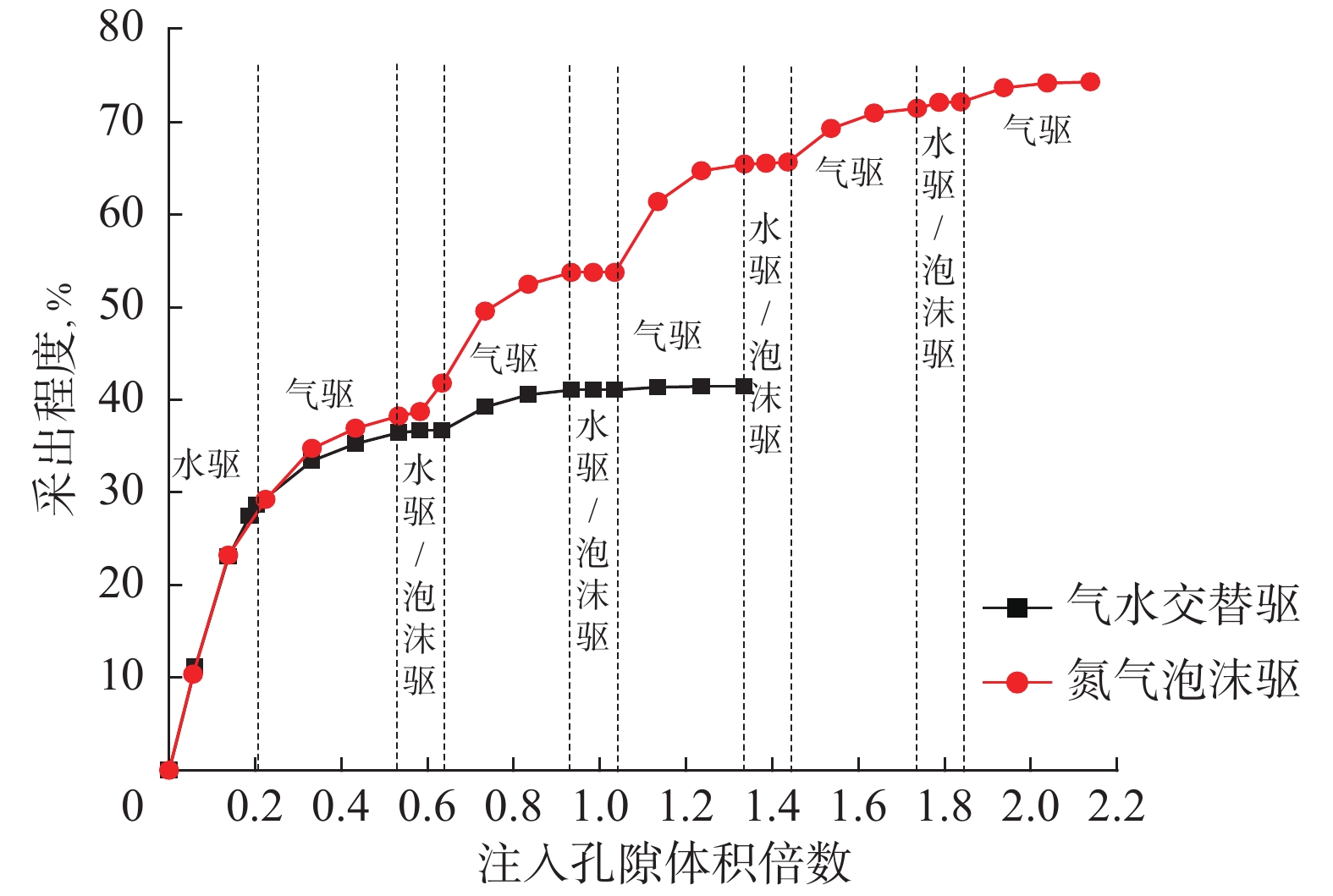

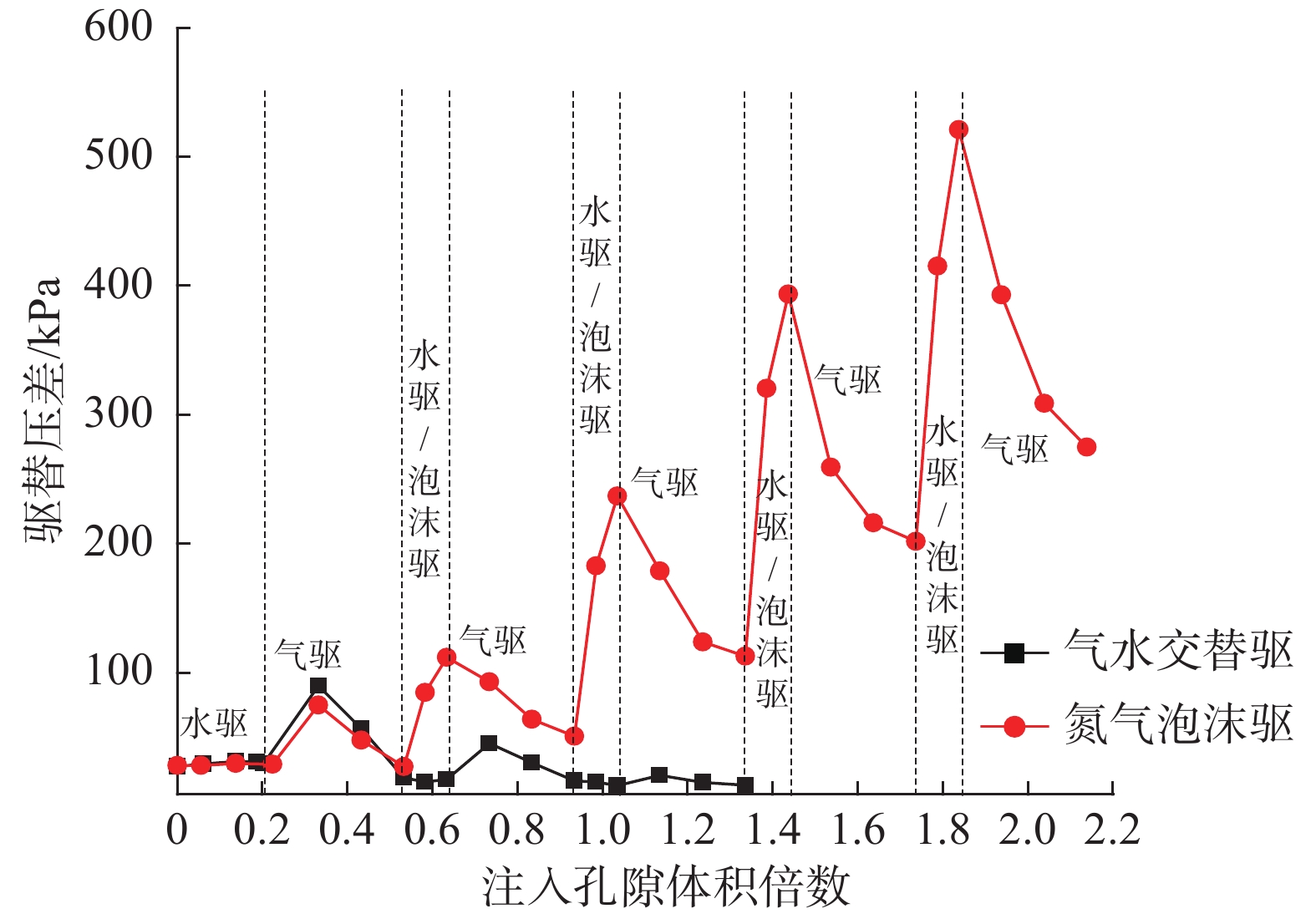

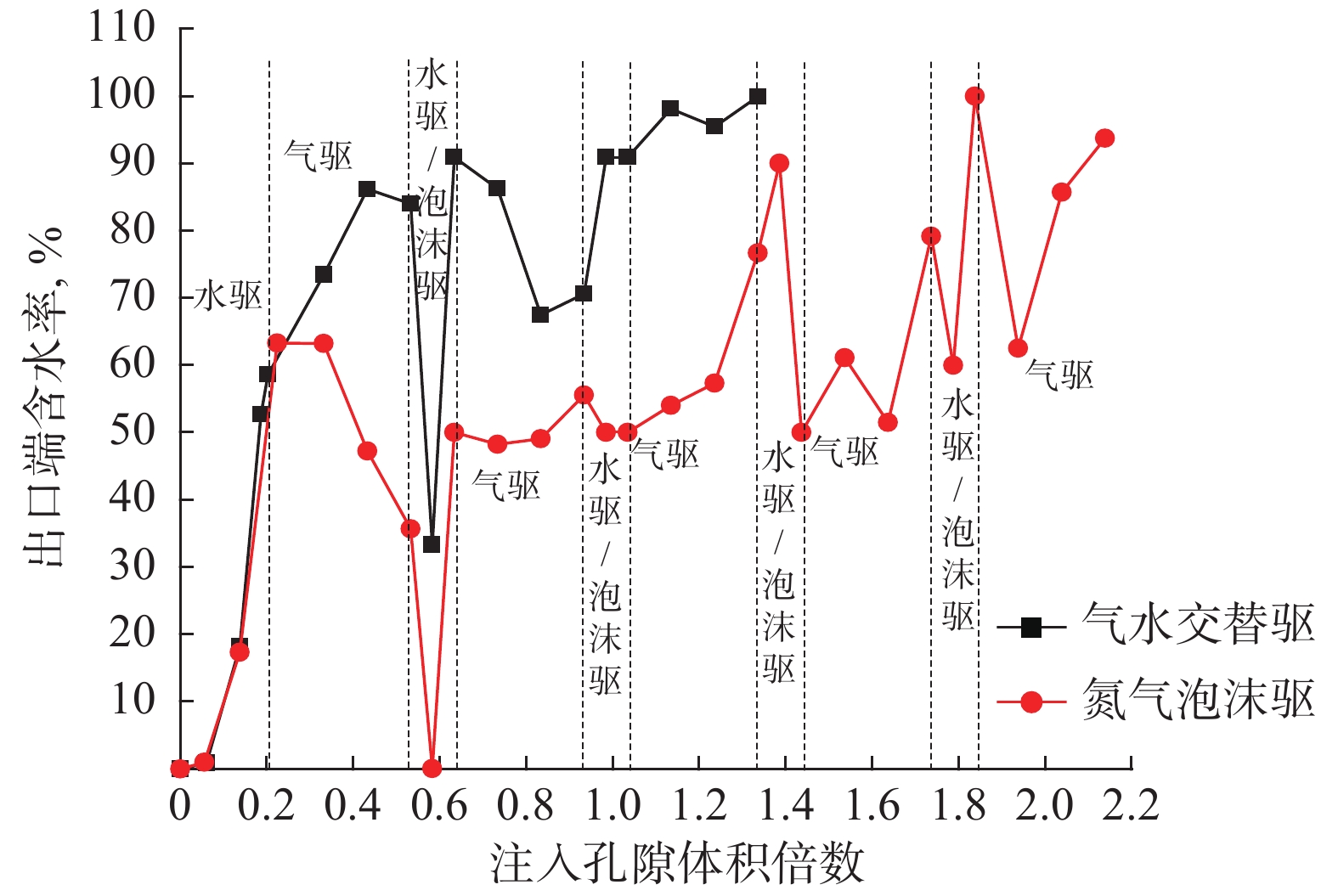

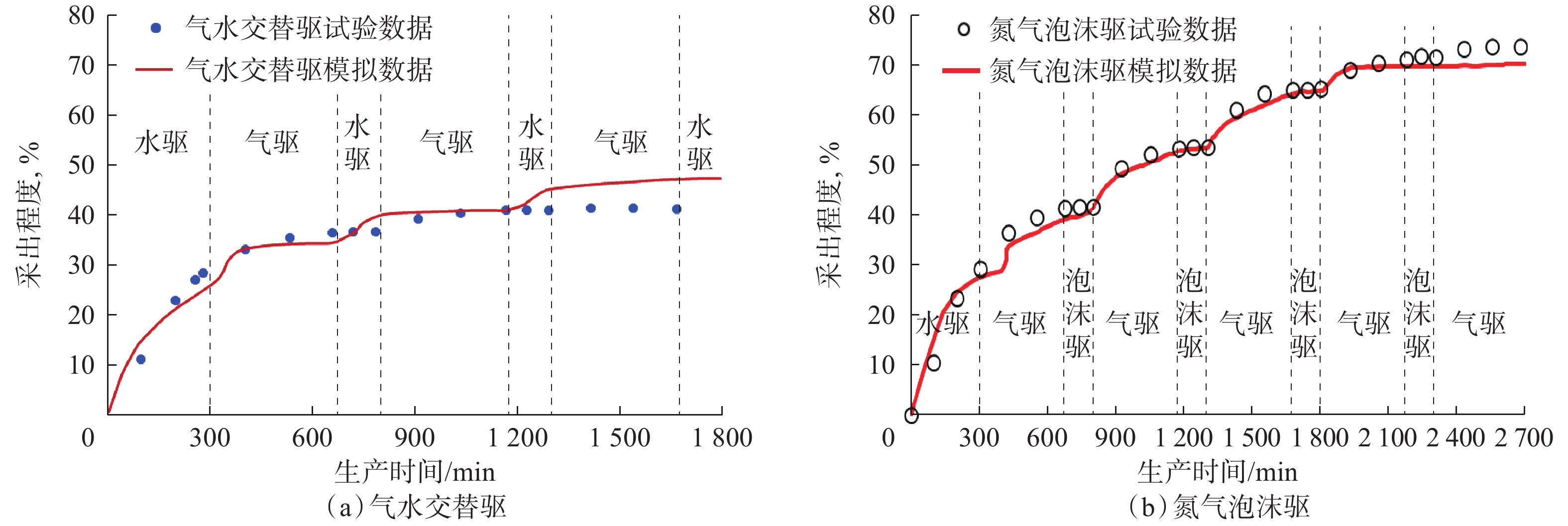

摘要: 深水浊积岩油藏储层非均质性强,平面矛盾突出,注水开发过程中易出现油水前缘不稳定,形成窜流。气为明确气水交替驱与氮气泡沫驱在平面非均质油藏的适用性及其提高采收率机制,结合油藏地质资料,设计制作了不同渗透率级差的岩心模型,开展了气水交替驱和氮气泡沫驱试验,分析了2种提高采收率方法的驱油效果,结合数值模拟研究,探索了驱替过程中不同渗透率条带的流体波及规律。研究结果表明,当岩心模型渗透率级差较小时,气水交替驱可表现出良好的提高波及系数及降低出口端含水率的能力,但当岩心模型渗透率级差较大时,该方法控制气体流度能力降低,提高采收率效果变差。氮气泡沫驱在岩心模型渗透率级差较大时,仍可发挥泡沫堵大不堵小、堵水不堵油以及表面活性剂洗油的多重特性,有效抑制高渗条带中的流体窜逸,使氮气泡沫在低渗条带呈现活塞式驱替,从而实现深部调驱、大幅度提高采收率的目的。因此,氮气泡沫驱可有效提高深水浊积岩油藏采收率,为该类油藏的经济高效开发提供技术支持。Abstract: Due to severe planar-heterogeneity, water-displacing-oil front in deep-water turbidite reservoirs is unstable and may cause water channeling during water flooding. In order to investigate the feasibility and enhanced oil recovery mechanisms of water and gas alternating flooding and nitrogen foam flooding in planar-heterogeneous reservoirs, artificial core samples with different permeability contrasts were designed according to the geological data in core flooding experiments. Based on the history matching of experimental data via numerical simulation, fluid flow behavior was discussed in the heterogeneous core samples. The results showed that water and gas alternating flooding presented good ability in improving sweep efficiency and reducing water cut when the permeability contrast was small; however, its ability in controlling gas mobility was depressed and the enhanced oil recovery effect was decreased when the permeability contrast was large. Due to the selective plugging of nitrogen foam and the surfactant’s improving displacement efficiency, nitrogen foam flooding could still delay fluid channeling in high-permeability streaks of severe planar-heterogeneous core samples while presented the piston-like displacement in low-permeability streaks so as to achieve in-depth profile control and oil recovery improvement. Thus, nitrogen foam flooding could effectively enhance oil recovery in deep-water turbidite reservoirs and provide technical support for the economical and efficient development of such reservoirs.

-

地热是一种无污染、可再生的清洁能源,与传统化石能源相比,具有储量大、分布广和能源利用率高等优势,越来越受到重视[1-4]。但地热资源过度开采或养护不当会造成资源枯竭,为确保地热资源的可持续发展,同时避免环境污染,最有效的技术措施就是地热回灌技术[5-7]。回灌是把经过利用的地热水,通过地热回灌井重新注回热储层段的方法,回灌不仅可以解决地热废水问题,还可以改善或恢复地热储层的产热能力,保持地热储层的流体压力,维持地热田的持续开采和循环利用, 使地热能成为一种可持续的清洁能源[8-10]。回灌过程中,由水中悬浮物、气泡、化学沉淀等导致的回灌井堵塞是造成回灌量有限的主要原因,尤其是孔隙性砂岩热储回灌井堵塞问题一直没有解决,是地热可持续开发利用中公认的技术难题。地热水回灌系统中,回灌井的钻井完井工艺是回灌能否实现的重要技术环节,回灌井井深多为2 000~3 000 m[11]。

目前,东营地区回灌井钻井完井过程中存在一系列问题,如现有回灌井部分井段未固井、钻井液体系不合适等导致井壁不稳定和回灌率偏低,已经成为制约该地区地热产业规模扩大的瓶颈,严重阻碍了地热能的可持续开发利用[12-14]。因此,笔者在现有工艺基础上,将油田油气井的钻井和射孔完井工艺应用到地热回灌井中,形成了地热储层钻井完井技术,现场试验取得了较好的效果,提高了单井回灌量,同时全井段固井延长了地热井的使用寿命,具有较好的推广应用价值,保障了该地区地热能产业的快速发展。

1. 地热储层岩性特征及开发现状

东营地区在大地构造单元上隶属华北坳陷的次级构造单元济阳坳陷的东部,地层自下而上包括太古界泰山岩群,古生界寒武系、奥陶系、石炭系和二叠系,中生界侏罗系、白垩系,新生界新近—古近系、第四系。

该地区自中生代以来,受燕山期地壳运动的影响,区域断裂构造发育,形成了区域温度或热流值普遍升高的背景,区内地温梯度均大于3.0 ℃/100m,开发利用的主要热储层为古近系东营组热储和新近系馆陶组热储,温度一般为65~72 ℃,单井出水量70~120 m3/h。目前,东营地区的地热资源开发利用已初具规模,主要用于原油集输加热、洗浴、渔业养殖及居民清洁能源供暖等,热储层位主要是馆陶组和东营组,开采馆陶组热储的地热井主要在沾化凹陷内,取水段一般为1 500~1 950 m井段,地层岩性为灰白色砾状砂岩、细砂岩和灰绿色细砂岩与棕色泥岩互层,底部为含石英、黑色燧石的砾状砂岩、砂砾岩;开采东营组热储的地热井主要在东营凹陷内,取水段一般为1 400~1 900 m井段,地层岩性为灰绿、灰白色砂岩、细砂岩及泥岩互层,以砂岩为主,中部为棕红色泥岩、细砾岩为主,底部为灰绿、灰白色细砾岩、细砂岩及泥岩。

该地区现有回灌井通常采用二开井身结构,一开表层泵室段全部用水泥封固,二开完钻后采用悬挂器悬挂套管和筛管完井,筛管以上部分用膨胀橡胶止水器止水,环空未用水泥封固(见图1)。

现有筛管完井工艺存在以下问题:1)回灌过程中砂泥岩互层在大液量冲刷下,其中的细粉砂容易随着地热水进入地层中,堵塞孔喉,降低回灌量,且泥岩段垮塌后会堵塞回灌井段,进一步降低回灌能力;2)采用膨胀橡胶止水器封隔筛管上部井段,由于橡胶止水器工艺简单,材质易受腐蚀,缩短地热井后期使用寿命;3)钻井过程中钻井液不合适,固相含量过高,密度过大,易使钻井液通过孔隙渗入地层,并在井壁形成滤饼,堵塞渗流通道,导致地层孔隙度和渗透率降低。回灌层段一般选择渗透性比较好的含水层,而这正是钻井液影响最大的层位,钻井液造成水层渗透率降低,进而影响回灌效果。

2. 钻井完井关键技术

针对以上问题,从钻具组合、钻井液和完井方式等方面进行了关键技术研究,以最大程度地降低对热储储层渗透率的伤害,增大地热水的回灌量。

2.1 优选钻具组合

东营地区馆陶组、东营组砂泥岩互层明显,泥岩占较大比例,由于牙轮钻头破岩方式以研磨为主,吃入地层有限,导致钻头破岩效率低,严重制约机械钻速。另外,该地区地层存在一定倾角,大钻压钻进时易发生井斜,因此选用“PDC钻头+1.25°单弯螺杆+钻铤+钻杆”钻具组合。该钻具组合能够有效控制井眼轨迹,防斜打直,使井眼轨迹平滑[15-16]。同时,PDC钻头适应高转速、低钻压的工作环境,螺杆的转速可以保持在200~260 r/min,钻压控制在30~50 kN,PDC钻头在此工作条件下能保持较高的破岩效率,机械钻速高,二开钻进“一趟钻”即可完成进尺,大大缩短了热储层钻井液浸泡时间,最大程度地降低了钻井液对储层的影响,降低了对储层的伤害。

2.2 钻井液体系优选

东营地区钻遇地层主要为平原组、明化镇组、馆陶组和东营组,地层成岩性差,泥岩较软易水化分散,胶结疏松易垮塌,钻井过程中井眼失稳问题严重,钻井液主要以抑制地层造浆、防止泥岩缩径、护壁和保护储层为目标[17-19],同时全井段禁止使用会堵塞储层孔隙和渗流通道的重晶石、沥青类材料和磺化类材料等。

一开钻遇地层为平原组棕黄色黏土及松散砂层,井眼尺寸较大,环空上返速度低,钻屑携带困难,不利于井眼的清洁,因此采用预水化膨润土钻井液体系,以确保具有足够的携带和悬浮能力。钻井液配方为:清水+5.0%~6.0%膨润土+0.1%~0.2%Na2CO3+0.3%HV-CMC。

二开钻遇地层为明化镇组、馆陶组和东营组,砂泥岩互层,采用护壁性、抑制性和携砂性强的聚合物钻井液体系,其配方为清水+5.0%~6.0%膨润土+0.2%~0.5% Na2CO3+1.0%~2.0% CaCl2+1.0%~2.0%铵盐+1.0%降滤失剂+2.0%~3.0%润滑剂。钻井过程中适时补充0.3%~1.0%的聚合物胶液,聚合物胶液以大分子聚合物为主,以维持钻井液性能稳定,并根据钻井液黏切和滤失量变化情况,用不同加量的小分子或大分子胶液处理。

钻进热储层前,为防止钻井液发生固相侵污,应使用好固控设备,配合高分子聚合物包被剂及时清除固相,严格控制滤失量不大于5 mL,以防止钻井液滤液进入热储层,造成热储层污染。

2.3 完井工艺

油井最常用的完井工艺是水泥固井射孔 ,环空采用水泥封固 ,可以最大限度地保证井壁稳定。钻井过程中热储层常被钻井液污染,一般认为距井壁300~400 mm地带的伤害最严重,射孔孔道长度一般为几厘米至几十厘米,孔道直径一般为几毫米至十几毫米,射孔时可以完全射穿钻井液严重伤害带,使不受污染的产层和井筒连通,可以提高储层渗透率。

该工艺需要根据测井曲线解释结果分析热储层的渗透率、孔隙度、含水层厚度及井温等参数,确定射孔枪和射孔弹的型号和孔密。测井项目包括井径、井温、井斜角、2.5及4.0 m电阻率、自然电位、自然伽马、声幅、声波、双侧向、微电极和微梯度,选择射开渗透率高、孔隙度大的层段,建立渗流通道成井,增大泄流面积,提高回灌能力。

相对于其他完井方式,该完井工艺有以下特点:1)固井防止泥岩垮塌,封堵细粉砂地层,减少细小颗粒堵塞孔喉;2)射孔形成的渗流通道长、渗透率高,可以最大程度地减少近井壁地带钻井液产生的污染;3)优选大段回灌层,避免层间干扰;4)纵向上增大了透水面积,提高了回灌能力。

2.4 洗井工艺

射孔作业结束后,采用联合方法进行洗井,确保将井筒内残留的钻井液及井壁附着的滤饼清洗干净,抽水试验前达到水清砂净,流体中悬浮物含量小于0.005%。 具体洗井工艺如下:

1)首先用清水置换井筒内钻井液,使用旋转喷射洗井工具,水嘴压降不低于2 MPa,从井底向上清洗井壁,利用工具产生的清水扰动作用,清除在井壁上黏附的滤饼;主要含水层井段要增加喷射洗井次数,洗井次数不少于3次。

2)喷射洗井结束后,使用压风机进行气举洗井,直接注入高压气体,实现限气量或者限压力可控井喷,对水层瞬时减压,不断进行减压然后恢复压力,实现地层吞吐清洗效果,进一步疏通地层通道,提高回灌能力。

3. 现场试验

探灌1井位于山东省东营市河口区三义和小区,构造上属于渤海湾盆地济阳坳陷车镇凹陷南部斜坡带的中段,完钻井深2 000 m,完钻层位为古近系东营组,热储层段1 700~1 950 m。

该井一开采用ϕ444.5 mm 钻头钻至井深350 m,ϕ339.7 mm表层套管下至井深349 m,以满足封隔表层松散地层和下入水泵的要求,水泥返至地面;二开采用ϕ311.1 mm钻头钻至井深2 000 m,ϕ244.5 mm套管下至井深1 999 m,水泥返至表层套管鞋,采用射孔完井,射孔井段厚101 m。探灌 1 井的 井身结构如图2所示。

根据测井解释成果,选取1 724~1 739,1 765~1 785,1 795~1 830和1 890~1 921 m作为射孔层段(见表1),合计长度101 m,选取127型射孔枪和127型射孔弹,射孔密度20孔/m。

表 1 测井解释结果Table 1. Logging interpretation results井段/m 厚度/m 孔隙度,% 渗透率/mD 泥质含量,% 结论 1 724~1 739 15 28.91 723.41 19.21 水层 1 765~1 785 20 31.23 695.43 18.31 水层 1 795~1 830 35 27.69 645.31 20.52 水层 1 890~1 921 31 26.45 598.34 19.56 水层 该井于2019 年1月17日完井试水,试水温度68 ℃,试水水量90~105 m3/h。1 月19日开始投产回灌,历经2个采暖季(2019—2020和2020—2021年),回灌量90~105 m3/h,平均回灌量95 m3/h 左右,液位稳定在−20 m左右;且经过2个采暖季的运行,回灌率没有衰减,能满足持续回灌要求。

4. 结论与建议

1)探灌1井将油气井的钻井完井技术应用到地热回灌井中,形成了该地区回灌井钻井完井的特色技术,现场应用效果良好,为进一步探索砂岩地层回灌奠定了坚实基础。

2)射孔完井工艺在地热开发回灌井中已得到成功应用,与传统地热回灌井钻井完井工艺相比,射孔完井工艺对地层的扰动更小,可以精确打开热储层,在后期的地热资源开发利用中,建议进一步研究该完井工艺是否可以应用于地热开发采水井。

3)为了最大程度地保护热储层,建议今后在回灌井施工过程中尝试应用空气钻井技术或欠平衡钻井技术,使井底处于欠平衡状态,井内压力低于储层压力,钻井流体无法进入储层,从而消除钻井流体对储层造成的伤害,提高单井回灌能力,同时进一步提高机械钻速。

-

表 1 不同注入方式X-1型岩心提高采出程度结果

Table 1 Oil recovery percent from different injection methods of X-1 core

岩心

编号初始含油饱和度,

%采出程度,% 注入方式 前期水驱 最终 X-1-1 59.65 45.75 57.20 气水交替驱 X-1-2 59.40 44.16 62.42 氮气泡沫驱 表 2 不同注入方式下X-2型岩心提高采出程度结果

Table 2 Oil recovery percentage from different injection methods of X-2 core

岩心

编号初始含油饱和度,

%采出程度,% 注入方式 前期水驱 最终 X-2-1 52.91 28.66 41.46 气水交替驱 X-2-2 53.27 29.25 74.33 氮气泡沫驱 -

[1] 陈全红,李文厚,郭艳琴,等. 鄂尔多斯盆地南部延长组浊积岩体系及油气勘探意义[J]. 地质学报,2006,80(5):656–663. CHEN Quanhong, LI Wenhou, GUO Yanqin, et al. Turbidite systems and the significance of petroleum exploration of Yanchang Formation in the Southern Ordos Basin[J]. Acta Geologica Sinica, 2006, 80(5): 656–663.

[2] 王金铎,韩文功,于建国,等. 东营凹陷沙三段浊积岩体系及其油气勘探意义[J]. 石油学报,2003,24(6):24–29. WANG Jinduo, HAN Wengong, YU Jianguo, et al. Turbidity system in the third section of Shahejie Formation of Dongying Sag and its implications on petroleum prospecting[J]. Acta Petrolei Sinica, 2003, 24(6): 24–29.

[3] WYNN R B, WEAVER P P E, MASSON D G, et al. Turbidite depositional architecture across three inter-connected deep-water basins on the Northwest African Margin[J]. Sedimentology, 2002, 49(4): 669–695. doi: 10.1046/j.1365-3091.2002.00471.x

[4] 肖玲,田景春,魏钦廉,等. 鄂尔多斯盆地油坊庄油田长2油层组储层宏观非均质性研究[J]. 沉积与特提斯地质,2006,26(2):59–62. XIAO Ling, TIAN Jingchun, WEI Qinlian, et al. Inhomogeneity of the Chang-2 pay sets of the Youfangzhuang Oilfield in the Ordos Basin[J]. Sedimentary Geology and Tethyan Geology, 2006, 26(2): 59–62.

[5] QIU Zhongyan, HAN Xiqiu, WANG Yejian. Turbidite events recorded in deep-sea core IR-GC1 off Western Sumatra: evidence from grain-size distribution[J]. Acta Geologica Sinica(English Edition), 2017, 91(4): 1448–1456. doi: 10.1111/1755-6724.13372

[6] 赵卫平. 井震联合属性分析技术在深水浊积岩储层预测中的应用[J]. 工程地球物理学报,2016,13(2):213–220. doi: 10.3969/j.issn.1672-7940.2016.02.014 ZHAO Weiping. The application of well-seismic joint attribute analysis technique to the prediction of deep-water turbidite sand reservoir[J]. Chinese Journal of Engineering Geophysics, 2016, 13(2): 213–220. doi: 10.3969/j.issn.1672-7940.2016.02.014

[7] HAUGHTON D W, BARKER S P, MCCAFFREY W D. ‘Linked’ debrites in sand-rich turbidite systems—origin and significance[J]. Sedimentology, 2003, 50(3): 459–482. doi: 10.1046/j.1365-3091.2003.00560.x

[8] LI Zhaomin, ZHANG Chao, LI Songyan, et al. Experiment research of CO2 foam alternating CO2 displacement EOR technology in heterogeneous reservoir[J]. Journal of Petrochemical Universities, 2011, 24(6): 1–5.

[9] 刘中云,赵海洋,王建海,等. 塔河油田溶洞型碳酸盐岩油藏注入氮气垂向分异速度及横向波及范围研究[J]. 石油钻探技术,2019,47(4):75–82. LIU Zhongyun, ZHAO Haiyang, WANG Jianhai, et al. Study on vertical differential velocity and transverse scope of nitrogen injection in carbonate reservoirs with fractures and vugs in the Tahe Oilfield[J]. Petroleum Drilling Techniques, 2019, 47(4): 75–82.

[10] 汤瑞佳,王贺谊,余华贵,等. 水气交替注入对CO2驱油效果的影响[J]. 断块油气田,2016,23(3):358–362. TANG Ruijia, WANG Heyi, YU Huagui, et al. Effect of water and gas alternate injection on CO2 flooding[J]. Fault-Block Oil & Gas Field, 2016, 23(3): 358–362.

[11] 李二党,韩作为,高祥瑞,等. 不同注气介质驱替致密油藏微观孔隙动用特征研究[J]. 石油钻探技术,2020,48(5):85–91. LI Erdang, HAN Zuowei, GAO Xiangrui, et al. Research on the microscopic pore producing characteristics of tight reservoirs displaced by different gas injection media[J]. Petroleum Drilling Techniques, 2020, 48(5): 85–91.

[12] 郝宏达,侯吉瑞,赵凤兰,等. 低渗透非均质油藏二氧化碳非混相驱窜逸控制实验[J]. 油气地质与采收率,2016,23(3):95–100. doi: 10.3969/j.issn.1009-9603.2016.03.017 HAO Hongda, HOU Jirui, ZHAO Fenglan, et al. Experiments of gas channeling control during CO2 immiscible flooding in low permeability reservoirs with heterogeneity[J]. Petroleum Geology and Recovery Efficiency, 2016, 23(3): 95–100. doi: 10.3969/j.issn.1009-9603.2016.03.017

[13] SUICMEZ V. S, PIRI M, BLUNT M J. Pore-scale simulation of water alternate gas injection[J]. Transport in Porous Media, 2007, 66(3): 259–286. doi: 10.1007/s11242-006-0017-9

[14] 廖辉,孔超杰,邓猛,等. 氮气泡沫驱提高采收率机理及影响因素研究进展[J]. 当代化工,2019,48(1):122–126. LIAO Hui, KONG Chaojie, DENG Meng, et al. Research progress of influence factors and mechanism of nitrogen foam flooding[J]. Contemporary Chemical Industry, 2019, 48(1): 122–126.

[15] 李文静,林吉生,徐国瑞,等. 绥中36-1油田氮气泡沫逐级调驱实验研究[J]. 科学技术与工程,2016,16(9):177–181. doi: 10.3969/j.issn.1671-1815.2016.09.030 LI Wenjing, LIN Jisheng, XU Guorui, et al. A laboratory research on nitrogen foam flooding step by step in SZ36-1 Oilfield[J]. Science Technology and Engineering, 2016, 16(9): 177–181. doi: 10.3969/j.issn.1671-1815.2016.09.030

[16] 屈鸣,侯吉瑞,闻宇晨,等. 缝洞型油藏裂缝中泡沫辅助气驱运移特征[J]. 石油科学通报,2019,4(3):300–309. QU Ming, HOU Jirui, WEN Yuchen, et al. Migration features of foam-assisted gas drive in fractures of fracture-vuggy reservoirs[J]. Petroleum Science Bulletin, 2019, 4(3): 300–309.

[17] 屈鸣,侯吉瑞,马仕希,等. 缝洞型油藏溶洞储集体氮气泡沫驱注入参数及机理研究[J]. 石油科学通报,2018,3(1):57–66. QU Ming, HOU Jirui, MA Shixi, et al. Mechanism and parameters of nitrogen foam flooding in cave reservoir bodies of fractured-cavity reservoirs[J]. Petroleum Science Bulletin, 2018, 3(1): 57–66.

[18] 阳晓燕. 非均质油藏水驱开发效果研究[J]. 特种油气藏,2019,26(2):152–156. YANG Xiaoyan. Waterflood development effect study of heterogeneous reservoir[J]. Special Oil & Gas Reservoirs, 2019, 26(2): 152–156.

[19] 姚传进,雷光伦,高雪梅,等. 非均质条件下孔喉尺度弹性微球深部调驱研究[J]. 油气地质与采收率,2012,19(5):61–64. doi: 10.3969/j.issn.1009-9603.2012.05.016 YAO Chuanjin, LEI Guanglun, GAO Xuemei, et al. Study on indepth profile control and flooding of pore-scale elastic microspheres under heterogeneous condition[J]. Petroleum Geology and Recovery Efficiency, 2012, 19(5): 61–64. doi: 10.3969/j.issn.1009-9603.2012.05.016

[20] 张莉,岳湘安,王友启. 基于非均质大模型的特高含水油藏提高采收率方法研究[J]. 石油钻探技术,2018,46(5):83–89. ZHANG Li, YUE Xiang’an, WANG Youqi. Research on large scale heterogeneous model based EOR methods for ultra-high water cut reservoirs[J]. Petroleum Drilling Techniques, 2018, 46(5): 83–89.

[21] 刘泉海,罗福全,黄海龙,等. 边底水油藏化学驱提高采收率实验研究[J]. 特种油气藏,2017,24(6):143–147. doi: 10.3969/j.issn.1006-6535.2017.06.028 LIU Quanhai, LUO Fuquan, HUANG Hailong, et al. Experimental study on enhanced oil recovery by chemical flooding in reservoir with edge and bottom water[J]. Special Oil & Gas Reservoirs, 2017, 24(6): 143–147. doi: 10.3969/j.issn.1006-6535.2017.06.028

[22] 韦琦,侯吉瑞,郝宏达,等. 特低渗油藏CO2驱气窜规律研究[J]. 石油科学通报,2019,4(2):145–153. WEI Qi, HOU Jirui, HAO Hongda, et al. Laboratory study of CO2 channeling characteristics in ultra-low-permeability oil reservoirs[J]. Petroleum Science Bulletin, 2019, 4(2): 145–153.

[23] 屈鸣,侯吉瑞,李军,等. 缝洞型油藏三维可视化模型底水驱油水界面特征研究[J]. 石油科学通报,2018,3(4):422–433. QU Ming, HOU Jirui, LI Jun, et al. Research into characteristics of the oil-water interface during bottom water flooding in a fractured-vuggy reservoir by a 3-D visual model[J]. Petroleum Science Bulletin, 2018, 3(4): 422–433.

[24] 白玉杰,曹广胜,侯玉花,等. 超临界二氧化碳+水交替驱注入井极限关井时间计算[J]. 特种油气藏,2020,27(1):162–168. BAI Yujie, CAO Guangsheng, HOU Yuhua, et al. Limit shut-in period calculation of CO2 + water alternating injection well[J]. Special Oil & Gas Reserviors, 2020, 27(1): 162–168.

[25] 周涌沂,汪勇,田同辉,等. 改善平面非均质油藏水驱效果方法研究[J]. 西南石油大学学报,2007,29(4):82–85. ZHOU Yongyi, WANG Yong, TIAN Tonghui, et al. Research on the method of improving water-flooding effect for the reservoirs with plane heterogeneity[J]. Journal of Southwest Petroleum University, 2007, 29(4): 82–85.

[26] 张立娟,岳湘安,杨志国,等. 非均质高温油藏非混相水气交替实验研究[J]. 断块油气田,2015,22(6):776–780. ZHANG Lijuan, YUE Xiang,an, YANG Zhiguo, et al. Immiscible water-alternating-gas experiments in high-temperature heterogeneous reservoir[J]. Fault-Block Oil & Gas Field, 2015, 22(6): 776–780.

[27] SALEHI M M, SAFARZADEH M A, SAHRAEI E, et al. Comparison of oil removal in surfactant alternating gas with water alternating gas, water flooding and gas flooding in secondary oil recovery process[J]. Journal of Petroleum Science and Engineering, 2014, 120: 86–93. doi: 10.1016/j.petrol.2014.05.017

[28] 元福卿,李冉,李兆敏,等. 低张力泡沫驱提高采收率的三维物理模拟研究[J]. 油田化学,2015,32(1):72–77. YUAN Fuqing, LI Ran, LI Zhaomin, et al. Three-dimensional physical simulation research of enhanced oil recovery in low tension foam flooding[J]. Oilfield Chemistry, 2015, 32(1): 72–77.

[29] 李松泉,程林松,李秀生,等. 特低渗透油藏非线性渗流模型[J]. 石油勘探与开发,2008,35(5):606–612. LI Songquan, CHENG Linsong, LI Xiusheng, et al. Nonlinear seepage flow of ultralow permeability reservoirs[J]. Petroleum Exploration and Development, 2008, 35(5): 606–612.

[30] 董平川, 牛彦良, 李莉. 各向异性油藏渗流的有限元数值模拟[J]. 岩石力学与工程学报, 2007, 26(增刊1): 2633-2633. DONG Pingchuan, NIU Yanliang, LI Li. Finite element numerical simulation of seepage in an anisotropic reservoir[J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(supplement 1): 2633-2633.

[31] 田敏,李楠,吴文瑞,等. 考虑启动压力梯度的油水两相渗流压力分布[J]. 复杂油气藏,2012,5(1):51–554. doi: 10.3969/j.issn.1674-4667.2012.01.014 TIAN Min, LI Nan, WU Wenrui, et al. Pressure distribution of oil-water seepage considering start-up pressure gradient[J]. Complex Hydrocarbon Reservoirs, 2012, 5(1): 51–554. doi: 10.3969/j.issn.1674-4667.2012.01.014

[32] 胡渤. 不同渗透率和孔喉条件下泡沫流体的特性及调驱机理[J]. 油气地质与采收率,2016,23(4):70–75. doi: 10.3969/j.issn.1009-9603.2016.04.011 HU Bo. Property of foam fluid and its mechanism of profile control and displacement in the reservoirs with different permeabilities and pore-throats[J]. Petroleum Geology and Recovery Efficiency, 2016, 23(4): 70–75. doi: 10.3969/j.issn.1009-9603.2016.04.011

[33] 张云宝,徐国瑞,邹剑,等. 三相泡沫体系堵水效果及影响因素实验研究[J]. 油气藏评价与开发,2019,9(2):44–49,82. ZHANG Yunbao, XU Guorui, ZOU Jian, et al. Experimental study on water plugging effect and influence factors of three phase foam system[J]. Reservoir Evaluation and Development, 2019, 9(2): 44–49,82.

-

期刊类型引用(4)

1. 王学民,常彬,桑士震,周波波,魏仁远. 半圈闭深循环基岩热储开采扰动分析及回灌方案研究. 上海国土资源. 2024(01): 126-134+142 .  百度学术

百度学术

2. 赵侃,沈健,蔡芸,赵苏民. 砂岩热储回灌难点识别与应对措施探讨. 地学前缘. 2024(06): 196-203 .  百度学术

百度学术

3. 白良杰,周岩,张昊,邢韦亮,冯烨. 冀东油田地热井降本优化设计与现场应用. 油气藏评价与开发. 2024(06): 872-877 .  百度学术

百度学术

4. 刘邹炜,杨明合,黄琳,廖开瑞,张俊. 废弃井地热能开发工艺与数值模拟研究进展. 太阳能学报. 2023(03): 311-318 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: