Hardening Properties and Enhancement Mechanisms of Modified Alumina Cement at Minus Temperature

-

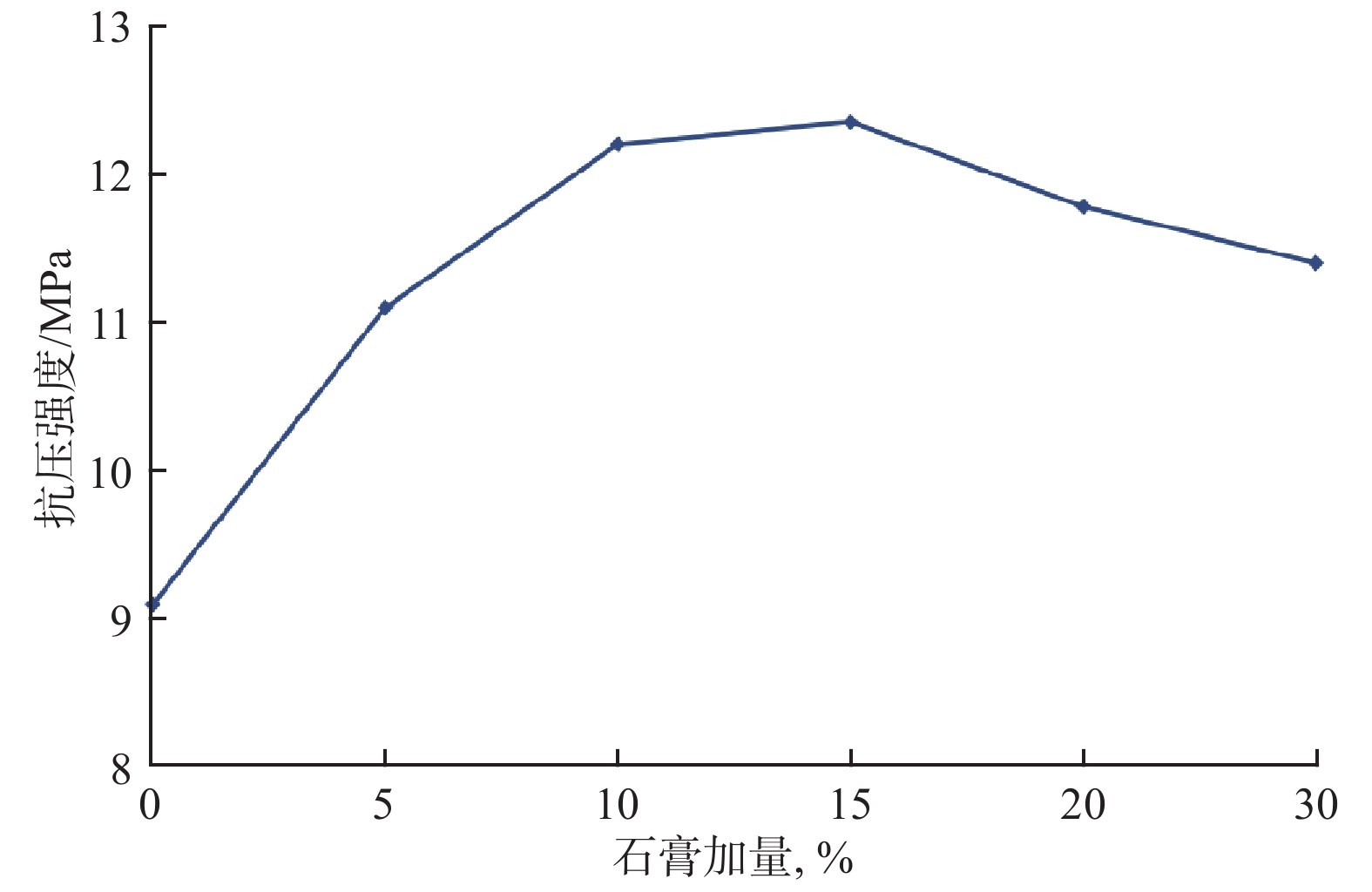

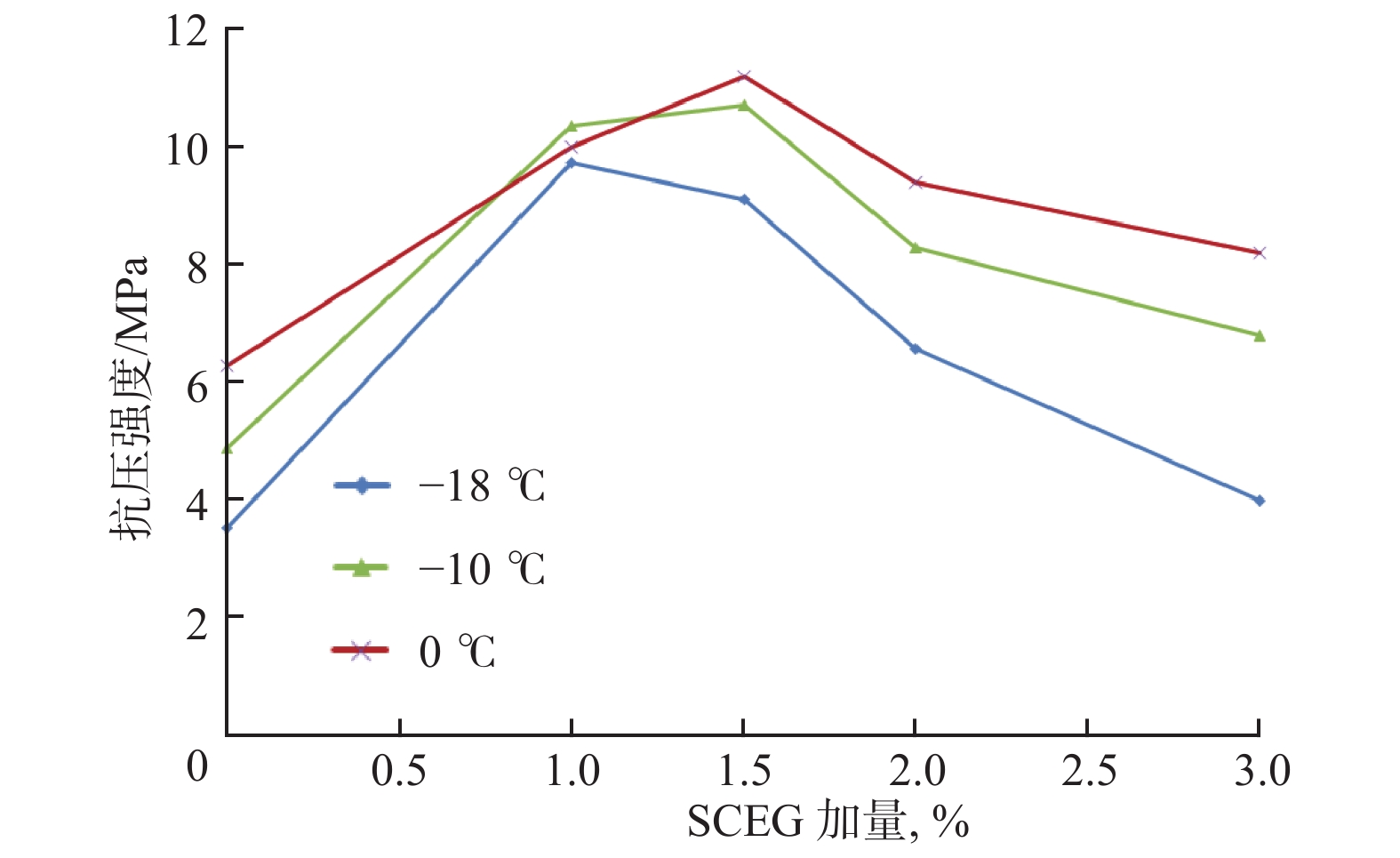

摘要: 针对负温环境下固井水泥浆水化反应减缓甚至停滞,导致固井施工难以进行的问题,开展了改性高铝水泥浆的硬化特性优化和早期强度的增强机制研究。在0,–10和–18 ℃温度下,进行了改性高铝水泥浆的凝结时间、流动度及抗压强度等性能对比试验,研究了负温环境下水泥浆关键性能的变化规律及与凝结时间调节剂SCEG之间的关系;在分析水化产物物相组成和微观结构的基础上,研究了水泥浆负温硬化机制,并通过添加石膏促进AFt生成来提高水泥石的抗压强度。试验表明:–18~0 ℃温度下,改性高铝水泥浆中添加占水泥质量0~3%的SCEG,该水泥浆可在0.3~6.0 h内硬化;该水泥浆24 h抗压强度达9.7~11.2 MPa,添加占水泥质量10%~15%的石膏后,水泥石抗压强度可提高30%左右。XRD测试发现,负温环境下水泥水化矿物主要为铝酸盐熟料而非硅酸盐熟料,产物主要为Ca2Al(Al,Si)2O7、AFm、AFt及少量硅酸盐水化产物C–S–H,且AFt含量越高,水泥石抗压强度越高。研究表明,改性高铝水泥具有良好的负温硬化能力,添加适量的石膏可提高水泥水化产物中AFt的含量,有助于提高水泥石的抗压强度。Abstract: Because the hydration reaction of cement is unable to proceed below the freezing point and hinders cementing, a research on the hardening properties optimization and enhancement mechanism for early strength of modified alumina cement was conducted. Changes in setting time, fluidity and compressive strength of cement at different temperatures of 0, −10, and −18 °C were compared, and the relationship between these changes at different temperatures and the setting time modifier SCEG was studied. Based on the analysis of phase compositions and microstructures of hydration products, the mechanism of hardening of cement at minus temperature was studied, and gypsum was added to promote the formation of AFt so as to enhance the compressive strength of hardened cement paste. The experiment demonstrated that the cement can be hardened within 0.3–6.0 hour when SCEG about 0–3% cement mass is added to the modified alumina cement from 0 °C to −18 °C. In that case, its compressive strength can reach 9.7–11.2 MPa within 24 hours and even rise 30% after gypsum about 10%–15% cement mass is added. X-ray diffraction (XRD) analysis indicates that the main hydrated mineral in the cement is aluminate clinker instead of silicate clinker at minus temperature, with Ca2Al(Al,Si)2O7, AFm, AFt, and a few C-S-H as the main products. To be specific, a higher content of AFt can bring higher compressive strength of hardened cement paste. The results show that modified alumina cement possesses optimized hardening properties at minus temperatures, and appropriate amount of gypsum can increase the content of AFt in hydration products, improving the compressive strength of hardened cement paste.

-

Keywords:

- minus temperature /

- cementing /

- modified alumina cement /

- hydration /

- ettringite /

- early strength

-

-

表 1 改性高铝水泥浆负温凝结时间试验结果

Table 1 Setting time of modified alumina cement at minus temperature

试验温度/℃ SCEG加量,% 初凝时间/min 终凝时间/ min 0 0 20 35 3.0 85 204 9.0 205 258 15.0 275 453 25.0 — — –10 0 23 87 3.0 130 245 6.0 279 497 10.0 507 1400 15.0 — — –18 0 26 46 1.0 107 162 1.5 141 235 2.0 265 547 3.0 397 719 注:基浆为220 mL SCLC-1溶液+2.5 g TEL+500 g改性高铝水泥,其中SCLC-1溶液中溶质含量为20%,下同;如未特殊说明,本文所有外加剂加量均为与水泥的质量比;“—”表示未测出,即7 d未凝。 表 2 改性高铝水泥浆负温流动度试验结果

Table 2 Fluidity of modified alumina cement at minus temperatures

试验温度/℃ SCEG加量,% 流动度/cm 0 0 13 1.0 14 1.5 16 2.0 16 3.0 17 3.5 18 –10 0 16 1.0 16 1.5 17 2.0 17 3.0 18 3.5 18 –18 0 16 1.0 17 1.5 16 2.0 17 3.0 18 3.5 19 表 3 石膏加量对改性高铝水泥浆性能的影响(–18 ℃)

Table 3 Influence of amount of gypsum on modified alumina cement performance (–18 ℃)

试验编号 石膏加量,% 流动度/cm 凝结时间/min 初凝 终凝 1 0 16 141 235 2 5 17 170 253 3 10 17 182 265 4 15 18 175 242 5 20 16 142 230 6 30 14 113 210 表 4 光标处水泥水化产物能谱分析结果

Table 4 EDX analysis result on the cursor of hydration products of modified alumina cement

原子序数 元素符号 原子个数比,% 质量比,% 8 O 75.81 59.01 20 Ca 12.52 24.42 14 Si 7.90 10.80 17 Cl 2.00 3.45 13 Al 1.77 2.32 -

[1] 杨进,路保平. 极地冷海钻井技术挑战及关键技术[J]. 石油钻探技术,2017,45(1):1–7. YANG Jin, LU Baoping. The challenges and key technologies of drilling in the cold water area of the Arctic[J]. Petroleum Drilling Techniques, 2017, 45(1): 1–7.

[2] HAMILTON J M. The challenges of deep-water Arctic development[J]. International Journal of Offshore and Polar Engineering, 2011, 21(4): 241–247.

[3] 邱礼泉,刘东明,孔广胜,等. 温度测井在东北冻土区天然气水合物勘查中的应用[J]. 物探与化探,2017,41(6):1215–1219. QIU Liquan, LIU Dongming, KONG Guangsheng, et al. The application of temperature logging to the gas hydrate resource exploration in permafrost areas of Northeast China[J]. Geophysical and Geochemical Exploration, 2017, 41(6): 1215–1219.

[4] 王成文,王瑞和,陈二丁,等. 锂盐早强剂改善油井水泥的低温性能及其作用机理[J]. 石油学报,2011,32(1):140–144. doi: 10.7623/syxb201101023 WANG Chengwen, WANG Ruihe, CHEN Erding, et al. Performance and mechanism of the lithium-salt accelerator in improving properties of the oil-well cement under low temperature[J]. Acta Petrolei Sinica, 2011, 32(1): 140–144. doi: 10.7623/syxb201101023

[5] 赵琥,邱超,宋茂林,等. 深水固井低温水泥外加剂的开发及应用[J]. 石油钻探技术,2012,40(4):72–75. ZHAO Hu, QIU Chao, SONG Maolin, et al. Development and application of additive in deepwater cementing[J]. Petroleum Drilling Techniques, 2012, 40(4): 72–75.

[6] KIM S W, PARK W S, EOM N Y, et al. Influence of curing temperature on the compressive strength of high performance concrete[J]. Applied Mechanics and Materials, 2014, 597: 316–319.

[7] 杨进,路保平. 极地冷海钻井技术挑战及关键技术[J]. 石油钻探技术,2017,45(5):1–7. YANG Jin, LU Baoping. The challenges and key technologies of drilling in the cold water area of the Arctic[J]. Petroleum Drilling Techniques, 2017, 45(5): 1–7.

[8] GRIFFITH J E, TOTTEN P L, KING B L, et al. Well cementing methods and compositions for use in cold environments: US5571318[P]. 1996-11-05.

[9] 刘浩亚,赵卫,李燕,等. 负温早强水泥浆体系的室内实验[J]. 石油钻采工艺,2019,41(3):294–300. LIU Haoya, ZHAO Wei, LI Yan, et al. Laboratory experiments on the egative-temperature, early-strength slurry system[J]. Oil Drilling & Production Technology, 2019, 41(3): 294–300.

[10] 徐梓竣,张邀丹,李志军,等. 冰单轴压缩强度试验的方法与设备[J]. 水利科学与寒区工程,2018,1(5):27–34. doi: 10.3969/j.issn.1002-3305.2018.05.007 XU Zijun, ZHANG Yaodan, LI Zhijun, et al. Method and equipment for uniaxial compresstive strength test of ice[J]. Hydro Science and Cold Zone Engineering, 2018, 1(5): 27–34. doi: 10.3969/j.issn.1002-3305.2018.05.007

[11] 刘浩亚,鲍洪志,赵卫. –18 ℃下冻土区负温水泥浆水化微观过程研究[J]. 钻井液与完井液,2019,36(1):77–81. doi: 10.3969/j.issn.1001-5620.2019.01.015 LIU Haoya, BAO Hongzhi, ZHAO Wei. Study on microscopic hydration process of a cold temperature cement slurry used in frozen areas at –18 ℃[J]. Drilling Fluid & Completion Fluid, 2019, 36(1): 77–81. doi: 10.3969/j.issn.1001-5620.2019.01.015

[12] 钱觉时,余金城,孙化强,等. 钙矾石的形成与作用[J]. 硅酸盐学报,2017,45(11):1569. QIAN Jueshi, YU Jincheng, SUN Huaqiang, et al. Formation and function of ettringite in cement hydrates[J]. Journal of the Chinese Ceramic Society, 2017, 45(11): 1569.

[13] 徐玲琳,李楠,王培铭,等. 温度对铝酸盐水泥基三元体系早期水化的影响[J]. 硅酸盐学报,2016,44(11):1552–1557. XU Linglin, LI Nan, WANG Peiming, et al. Temperature effect on early hydration of calcium aluminate cement based ternary blends[J]. Journal of the Chinese Ceramic Society, 2016, 44(11): 1552–1557.

[14] 张金山,姚燕,叶家元,等. 外加剂对钙矾石形貌的影响[J]. 硅酸盐学报,2019,47(5):602–609. ZHANG Jinshan, YAO Yan, YE Jiayuan, et al. Influence of chemical admixtures on morphology of ettringite[J]. Journal of the Chinese Ceramic Society, 2019, 47(5): 602–609.

[15] 程小伟,刘开强,李早元,等. 油井水泥浆液–固态演变的结构与性能[J]. 石油学报,2016,37(10):1287–1292. doi: 10.7623/syxb201610009 CHENG Xiaowei, LIU Kaiqiang, LI Zaooyuan, et al. Structure and properties of oil well cement slurry during liquid-solid transition[J]. Acta Petrolei Sinica, 2016, 37(10): 1287–1292. doi: 10.7623/syxb201610009

[16] 胡晨光,王娟,白瑞英,等. 氯离子环境下钙矾石和水化硅酸钙体系铝配位分布[J]. 功能材料,2018,49(2):2146–2151. HU Chenguang, WANG Juan, BAI Ruiying, et al. Distribution of aluminum coordination in ettringite and C–S–H gels system under chloride ions environment[J]. Journal of Functional Materials, 2018, 49(2): 2146–2151.

[17] 郝璟珂,宋远明,王志娟,等. AFm 阴离子类型对硫铝酸盐水泥水化产物钙矾石稳定性的影响[J]. 硅酸盐学报,2019,47(11):1554–1558. HAO Jingke, SONG Yuanming, WANG Zhijuan, et al. Effect of AFm anion type on stability of ettringite generated from calcium sulphoaluminate cement hydration[J]. Journal of the Chinese Ceramic Society, 2019, 47(11): 1554–1558.

[18] 孙正宁,周健,慕儒,等. 新型超硫酸盐水泥水化硬化机理[J]. 硅酸盐通报,2019,38(8):2362–2368. SUN Zhengning, ZHOU Jian, MU Ru, et al. Hydration and hardening mechanisms of newly developed supersulfated cement[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(8): 2362–2368.

下载:

下载: