The Evaluation and Application of Lost Circulation Control by Elastic Mesh Materials

-

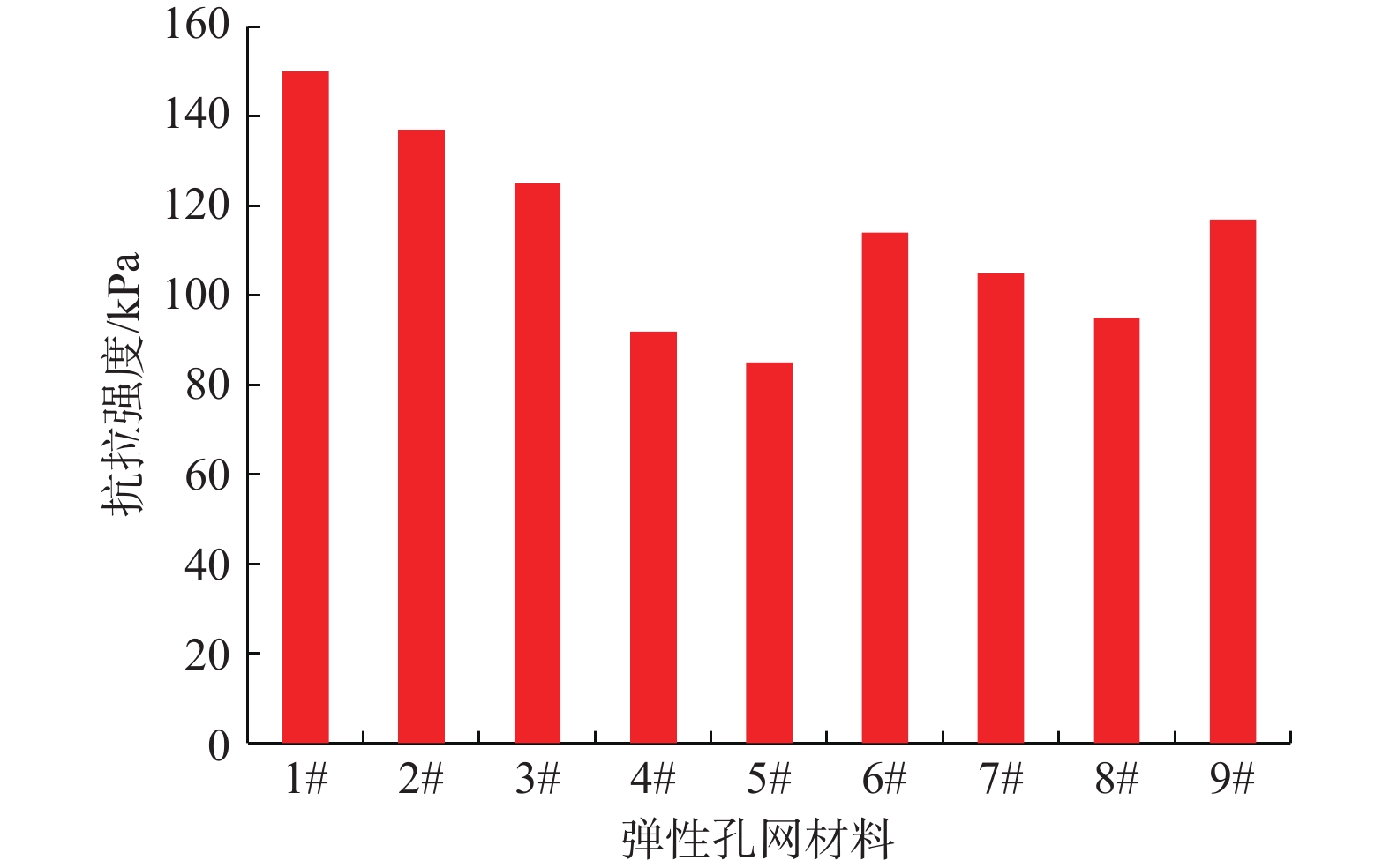

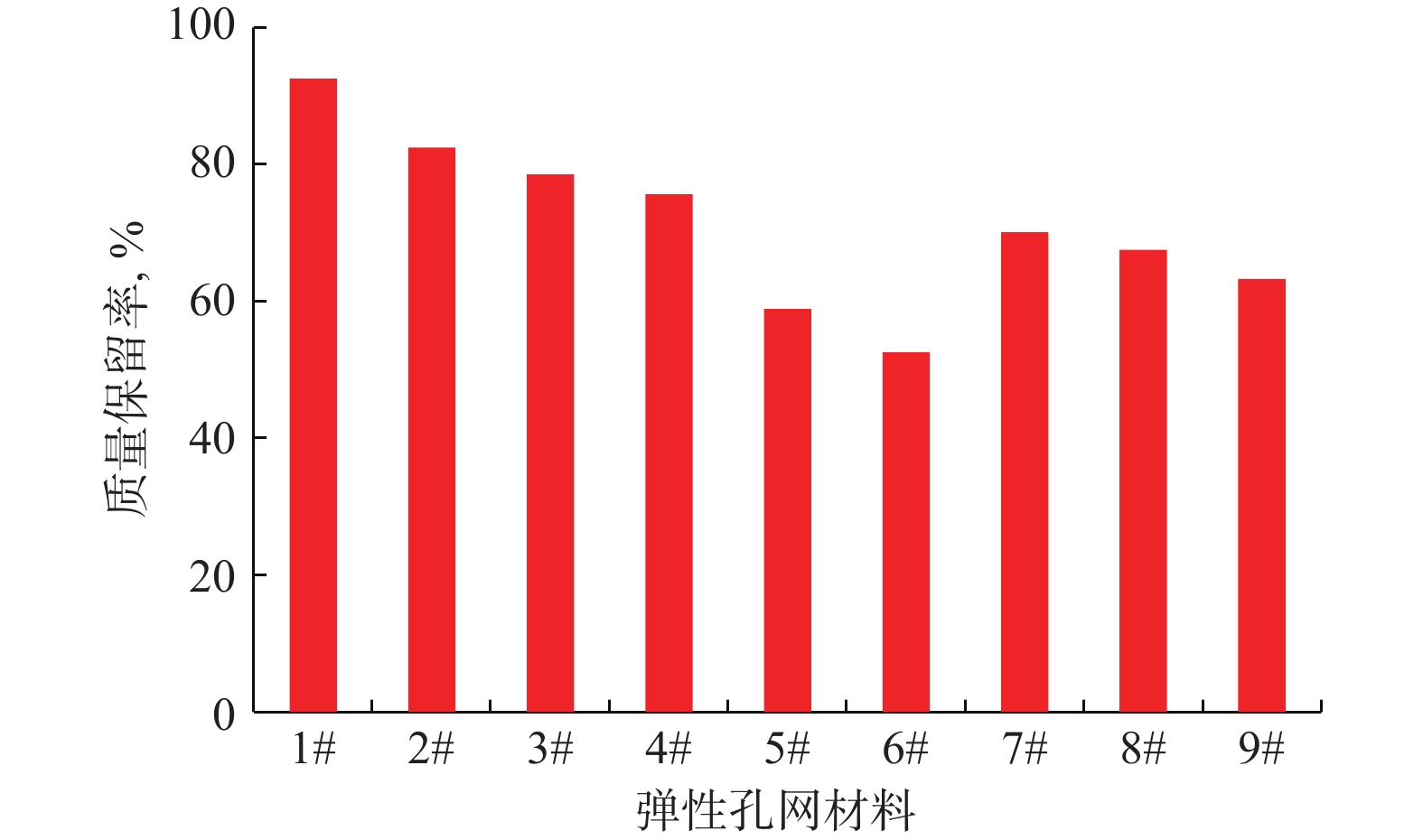

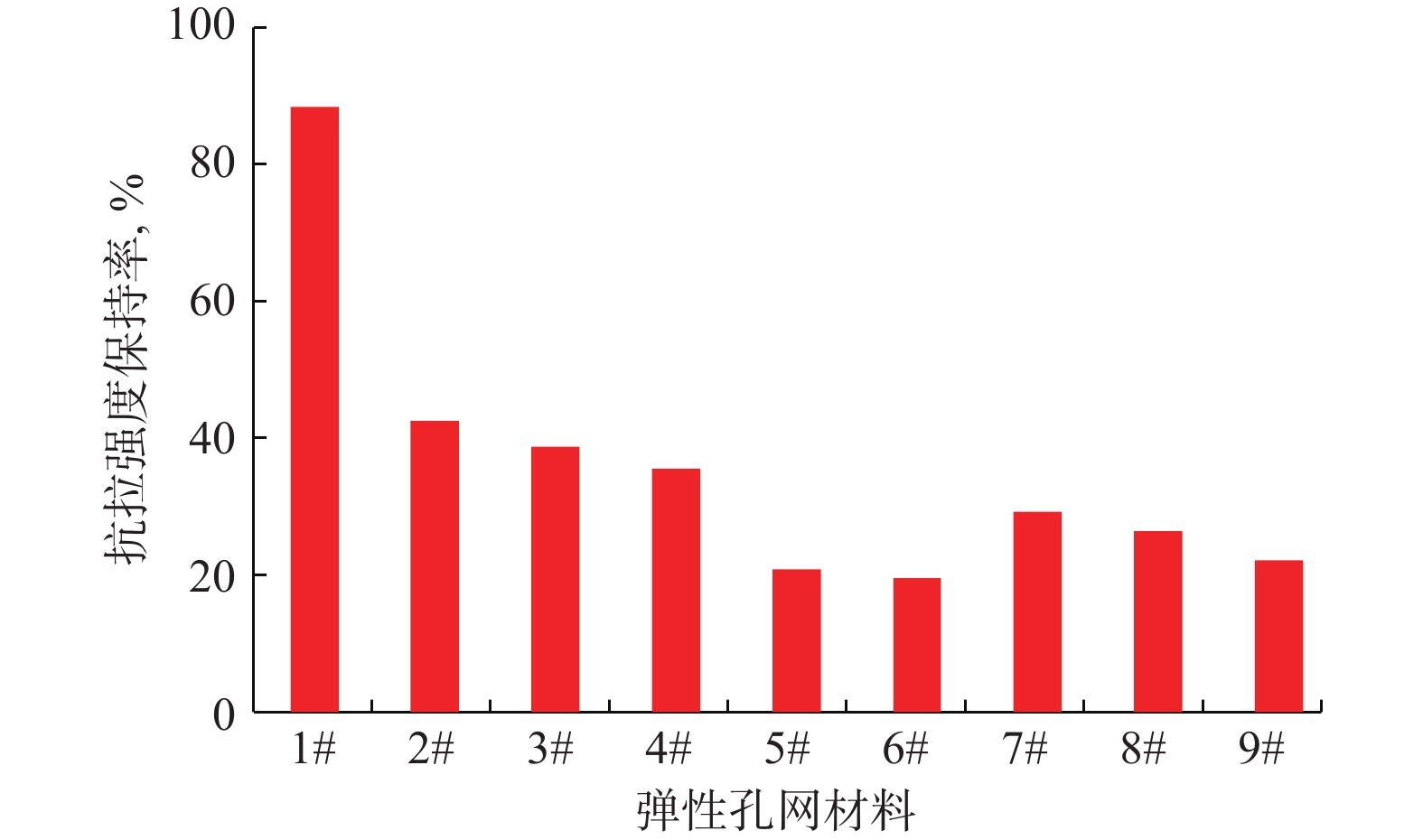

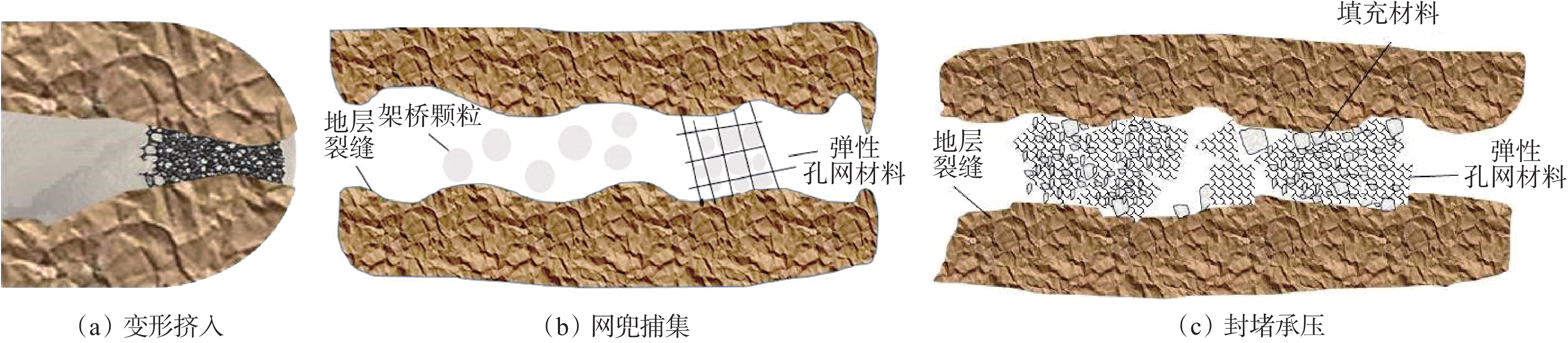

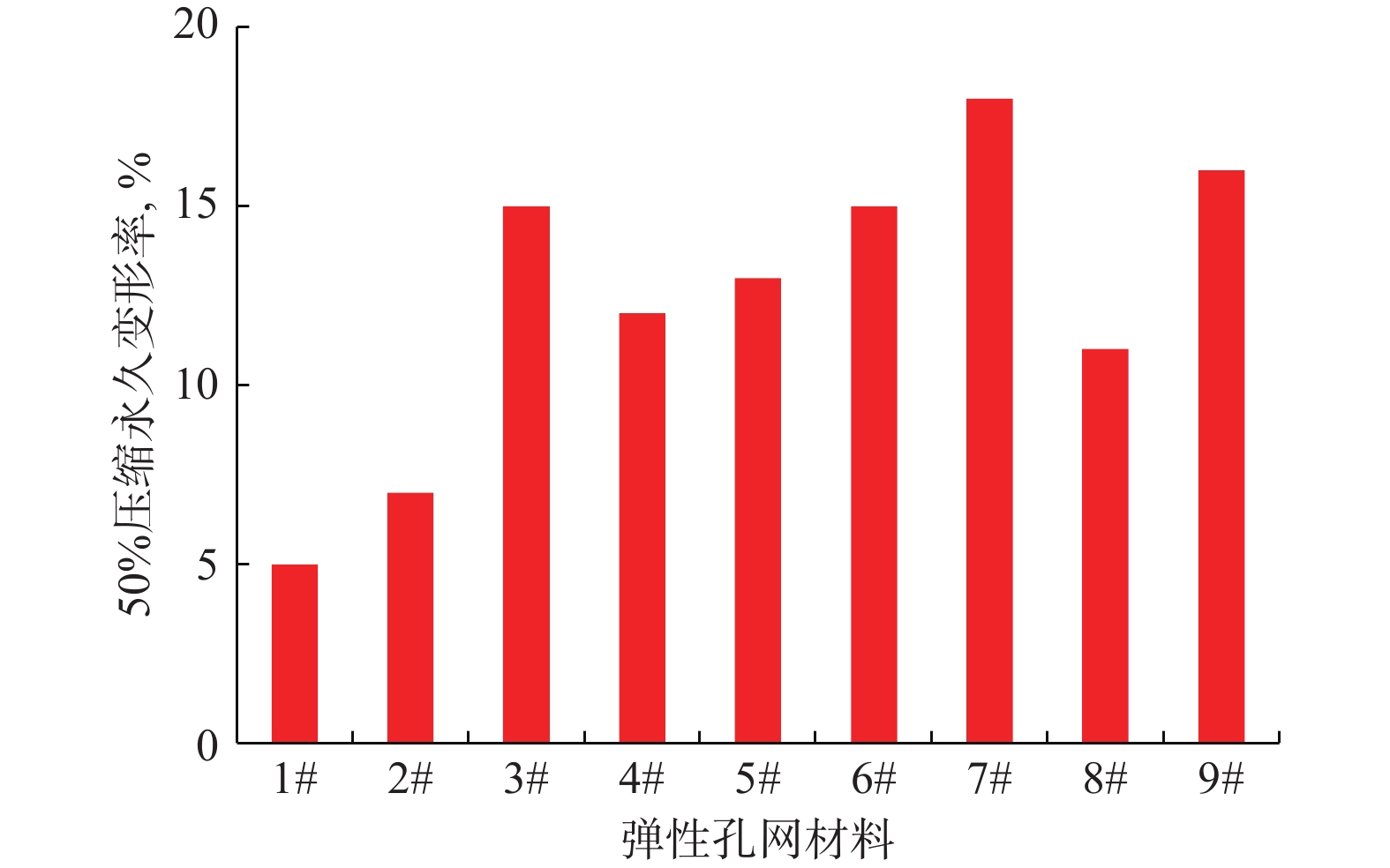

摘要: 现有常规桥浆堵漏材料存在裂缝适应性不强、封堵层浅和堵漏成功率较低等问题。为此,优选了不同规格弹性孔网材料,进行了压缩回弹性、抗拉强度和抗温性等性能评价试验,优选了综合性能最佳的弹性孔网材料,并考察了弹性孔网材料尺寸、形状和加量对堵漏效果的影响。试验结果表明,1#弹性孔网材料的50%压缩永久变形率低于10%,抗拉强度为150 kPa,抗温能力达150 ℃,适合用作堵漏材料;正方体形弹性孔网材料可滞留在裂缝内,堵漏效果较好,尺寸为5.0 mm×5.0 mm×5.0 mm的弹性孔网材料对尺寸为5.0 mm×4.0 mm的楔形缝封堵效果最优;弹性孔网材料加量为0.08%时的堵漏效果最好。弹性孔网材料在多口井进行了现场堵漏,一次堵漏成功率达86.7%。研究表明,弹性孔网材料对裂缝性地层具有较好的适应性和堵漏效果,能够解决地层漏失问题。Abstract: The existing conventional bridge slurry plugging materials have problems such as weak fracture adaptability, shallow plugging layer and low plugging success rate. For this reason, different specifications of elastic mesh materials were selected for evaluation tests of compressive resilience, tensile strength and temperature resistance, and the one with the optimal performance was identified. In addition, we investigated the influence of sizes, shapes and concentrations of the elastic mesh material on plugging efficacy. Experimental results indicate that elastic mesh material marked No.1 is suitable for plugging, due to its low permanent compressive rate of 10% at 50% of its compressive strength, high tensile strength of 150 kPa and high temperature resistance of 150 °C. The cubic elastic mesh material can remain in fractures, and thus presents excellent performance in plugging. The elastic mesh material in the size of 5.0 mm×5.0 mm×5.0 mm has the best plugging performance in wedge-shaped fracture in the size of 5.0 mm × 4.0 mm. In addition, the optimal concentration of the elastic mesh material is 0.08%, and the success rate of one-time plugging has reached 86.7% after the elastic mesh material has been applied in multiple wells. The research demonstrated that the elastic mesh material has good adaptability and plugging effect for fractured formations, and can solve the problem of lost circulation.

-

-

表 1 不同类型弹性孔网材料的泡孔规格

Table 1 Specifications of different elastic mesh materials

编号 弹性孔网类型 泡孔规格/目 1# 阻燃型 12 2# 阻燃型 6 3# 阻燃型 4 4# 阻燃型 2 5# 过滤型 8 6# 过滤型 6 7# 过滤型 2 8# 过滤型 10 9# 过滤型 4 表 2 不同形状弹性孔网材料楔形长裂缝封堵试验结果

Table 2 Long wedge-shaped fractures plugged with elastic mesh materials in different shapes

堵漏浆配方 漏失速率/(L·s–1) 封堵情况 堵漏基浆 0.50 堵漏基浆+0.08%正方体形弹性孔网材料 0.06 滞留在裂缝中 堵漏基浆+0.08%长方体形弹性孔网材料 0.40 随堵漏浆漏失 堵漏基浆+0.08%三棱柱形弹性孔网材料 0.20 少量滞留在裂缝中 表 3 不同尺寸弹性孔网材料封堵楔形长裂缝试验结果

Table 3 Long wedge-shaped fractures plugged with elastic mesh materials in different sizes

堵漏浆配方 漏失速率/(L·s–1) 封堵情况 堵漏基浆 0.50 堵漏基浆+0.08% 弹性孔网

材料(15.0 mm×15.0 mm×15.0 mm)0.40 封堵缝口 堵漏基浆+0.08% 弹性孔网

材料(10.0 mm×10.0 mm×10.0 mm)0.10 进入裂缝浅 堵漏基浆+0.08%弹性孔网

材料(5.0 mm×5.0 mm×5.0 mm)0.06 进入裂缝深 表 4 不同加量弹性孔网材料的长裂缝封堵试验结果

Table 4 Long fractures plugged with elastic mesh materials in different concentrations

堵漏浆配方 漏失速率/(L·s–1) 封堵情况 堵漏基浆 0.50 堵漏基浆+0.04% 弹性孔网材料 0.30 进入裂缝中 堵漏基浆+0.08% 弹性孔网材料 0.06 进入裂缝中 堵漏基浆+0.12% 弹性孔网材料 0.20 封堵缝口 -

[1] 陈晓华,王翔,冯永超,等. 泾河油田裂缝性致密油藏防漏堵漏技术[J]. 断块油气田,2017,24(2):297–300. CHEN Xiaohua, WANG Xiang, FENG Yongchao, et al. Loss prevention and control technology for fractured reservoirs in Jinghe Oilfield[J]. Fault-Block Oil & Gas Field, 2017, 24(2): 297–300.

[2] 梁文利. 深层页岩气油基钻井液承压堵漏技术[J]. 钻井液与完井液,2018,35(3):37–41. LIANG Wenli. Enhancing pressure bearing capacity of formation to control mud losses in deep shale gas drilling with oil base drilling fluids[J]. Drilling Fluid & Completion Fluid, 2018, 35(3): 37–41.

[3] 张杜杰,金军斌,陈瑜,等. 深部裂缝性致密储层随钻堵漏材料补充时机研究[J]. 特种油气藏,2020,27(6):158–164. ZHANG Dujie, JIN Junbin, CHEN Yu, et al. Study on the supplement timing of leakage stoppage materials while drilling for deep fractured tight reservoirs[J]. Special Oil & Gas Reservoirs, 2020, 27(6): 158–164.

[4] 何选蓬,程天辉,周健,等. 秋里塔格构造带风险探井中秋1井安全钻井关键技术[J]. 石油钻采工艺,2019,41(1):1–7. HE Xuanpeng, CHENG Tianhui, ZHOU Jian, et al. Key technologies of safe drilling in Zhongqiu 1 Well, a risk exploration well in Qiulitag Tectonic Belt[J]. Oil Drilling & Production Technology, 2019, 41(1): 1–7.

[5] 王建龙,徐旺,郭耀,等. 苏里格气田苏25区块水平井钻井关键技术[J]. 长江大学学报(自然科学版),2019,16(7):26–30. WANG Jianlong, XU Wang, GUO Yao, et al. Key technology of horizontal well drilling in Block Su25 of Sulige Gas Field[J]. Journal of Yangtze University(Natural Science Edition), 2019, 16(7): 26–30.

[6] 韩成,罗鸣,杨玉豪,等. 莺琼盆地高温高压窄安全密度窗口钻井关键技术[J]. 石油钻采工艺,2019,41(5):568–572. HAN Cheng, LUO Ming, YANG Yuhao, et al. Key drilling technologies for HTHP wells with narrow safety density window in the Yingqiong Basin[J]. Oil Drilling & Production Technology, 2019, 41(5): 568–572.

[7] 颜帮川,蒋官澄,胡文军,等. 高温延迟交联聚丙烯酰胺凝胶堵漏剂的研究[J]. 钻井液与完井液,2019,36(6):679–682. YAN Bangchuan, JIANG Guancheng, HU Wenjun, et al. Study on high temperature delayed crosslinking PAM gel LCM[J]. Drilling Fluid & Completion Fluid, 2019, 36(6): 679–682.

[8] 刘金华,刘四海,龙大清,等. 明1井交联成膜与化学固结承压堵漏技术[J]. 石油钻探技术,2017,45(2):54–60. LIU Jinhua, LIU Sihai, LONG Daqing, et al. Strengthening plugging operations by combining cross-linked film and chemical consolidation in Well Ming-1[J]. Petroleum Drilling Techniques, 2017, 45(2): 54–60.

[9] 王刚,刘晨超,冯杰,等. 新型高强度承压堵漏吸水膨胀树脂研发与应用[J]. 特种油气藏,2019,26(2):147–151. doi: 10.3969/j.issn.1006-6535.2019.02.027 WANG Gang, LIU Chenchao, FENG Jie, et al. R&D and application of a new high-Strength pressure-sealing water-swelling resin[J]. Special Oil & Gas Reservoirs, 2019, 26(2): 147–151. doi: 10.3969/j.issn.1006-6535.2019.02.027

[10] 王波,孙金声,李伟,等. 陕北西部地区裂缝性地层堵漏技术研究与实践[J]. 钻井液与完井液,2020,37(1):9–14. WANG Bo, SUN Jinsheng, LI Wei, et al. Study on and practice of lost circulation control technology in drilling fractured formations in west Shaanbei[J]. Drilling Fluid & Completion Fluid, 2020, 37(1): 9–14.

[11] 何新星,李皋,段慕白,等. 地层裂缝动态变形对堵漏效果的影响研究[J]. 石油钻探技术,2018,46(4):35–39. HE Xinxing, LI Gao, DUAN Mubai, ea al. The influence of dynamic deformation of formation fractures on the plugging effect[J]. Petroleum Drilling Techniques, 2018, 46(4): 35–39.

[12] 李辉,刘华康,何仲,等. 塔河油田碳酸盐岩储层恶性漏失空间堵漏凝胶技术[J]. 钻井液与完井液,2019,36(1):25–28. doi: 10.3969/j.issn.1001-5620.2019.01.005 LI Hui, LIU Huakang, HE Zhong, et al. Use gel to control severe mud losses in carbonate reservoir formations in Tahe Oilfield[J]. Drilling Fluid & Completion Fluid, 2019, 36(1): 25–28. doi: 10.3969/j.issn.1001-5620.2019.01.005

[13] 韩成,黄凯文,罗鸣,等. 南海莺琼盆地高温高压井堵漏技术[J]. 石油钻探技术,2019,47(6):15–20. doi: 10.11911/syztjs.2019081 HAN Cheng, HUANG Kaiwen, LUO Ming, et al. Plugging technology for HTHP wells in the Yingqiong Basin of the South China Sea[J]. Petroleum Drilling Techniques, 2019, 47(6): 15–20. doi: 10.11911/syztjs.2019081

[14] GB/T 6669—2008 软质泡沫聚合材料: 压缩永久变形的测定[S]. GB/T 6669—2008 Flexible cellular polymeric materials: determination of compression set[S].

[15] GB/T 6344—2008 软质泡沫聚合材料: 拉伸强度和断裂伸长率的测定[S]. GB/T 6344—2008 Flexible cellular polymeric materials: determination of tensile strength and elongation at break[S].

[16] 陈曾伟. 基于神经网络算法的井下裂缝诊断与堵漏技术[J]. 钻井液与完井液,2019,36(1):20–24. doi: 10.3969/j.issn.1001-5620.2019.01.004 CHEN Zengwei. Downhole fracture diagnosis and mud loss control technologies bases on neural network algorithm[J]. Drilling Fluid & Completion Fluid, 2019, 36(1): 20–24. doi: 10.3969/j.issn.1001-5620.2019.01.004

[17] 康毅力,张敬逸,许成元,等. 刚性堵漏材料几何形态对其在裂缝中滞留行为的影响[J]. 石油钻探技术,2018,46(5):26–34. KANG Yili, ZHANG Jingyi, XU Chengyuan, et al. The effect of geometrical morphology of rigid lost circulation material on its retention behavior in fractures[J]. Petroleum Drilling Techniques, 2018, 46(5): 26–34.

[18] 王贵,蒲晓林. 提高地层承压能力的钻井液堵漏作用机理[J]. 石油学报,2010,31(6):1009–1012. doi: 10.7623/syxb201006024 WANG Gui, PU Xiaolin. Plugging mechanism of drilling fluid by enhancing wellbore pressure[J]. Acta Petrolei Sinica, 2010, 31(6): 1009–1012. doi: 10.7623/syxb201006024

-

期刊类型引用(10)

1. 栾凯伦,高斐,楼一珊,黄梦婷. 基于BP神经网络的井壁坍塌预测. 矿产勘查. 2025(02): 371-379 .  百度学术

百度学术

2. 傅玉,蒲杨. 长裸眼水平段超深井完井液密度对井壁稳定的重要性剖析. 天然气技术与经济. 2024(06): 15-19+63 .  百度学术

百度学术

3. 王磊. 基于瞬态热流固耦合的钻井井壁稳定性分析. 断块油气田. 2023(02): 331-336 .  百度学术

百度学术

4. 张文,刘向君,梁利喜,熊健. 致密砂岩地层气体钻井井眼稳定性试验研究. 石油钻探技术. 2023(02): 37-45 .  本站查看

本站查看

5. 王丽君. 苏里格气田苏53区块防塌钻井液技术研究. 辽宁化工. 2022(09): 1264-1266+1298 .  百度学术

百度学术

6. 何立成,唐波. 准噶尔盆地超深井钻井技术现状与发展建议. 石油钻探技术. 2022(05): 1-8 .  本站查看

本站查看

7. 刘厚彬,崔帅,孟英峰,周彦行,罗益. 深层脆性页岩水平井井壁崩落失稳研究. 断块油气田. 2021(03): 323-328 .  百度学术

百度学术

8. 邓媛,何世明,邓祥华,彭远春,何世云,汤明. 力化耦合作用下的层理性页岩气水平井井壁失稳研究. 石油钻探技术. 2020(01): 26-33 .  本站查看

本站查看

9. 张磊,许杰,刘海龙,谢涛,韩耀图. 层理性地层井壁坍塌失稳规律研究. 石油机械. 2019(02): 24-32 .  百度学术

百度学术

10. 向朝纲,陈俊斌,杨刚. 钻井液浸泡作用下脆性页岩强度特征实验. 断块油气田. 2018(06): 803-806 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: