Research Progress and Development Prospect of Intelligent Surface Logging Technology

-

摘要:

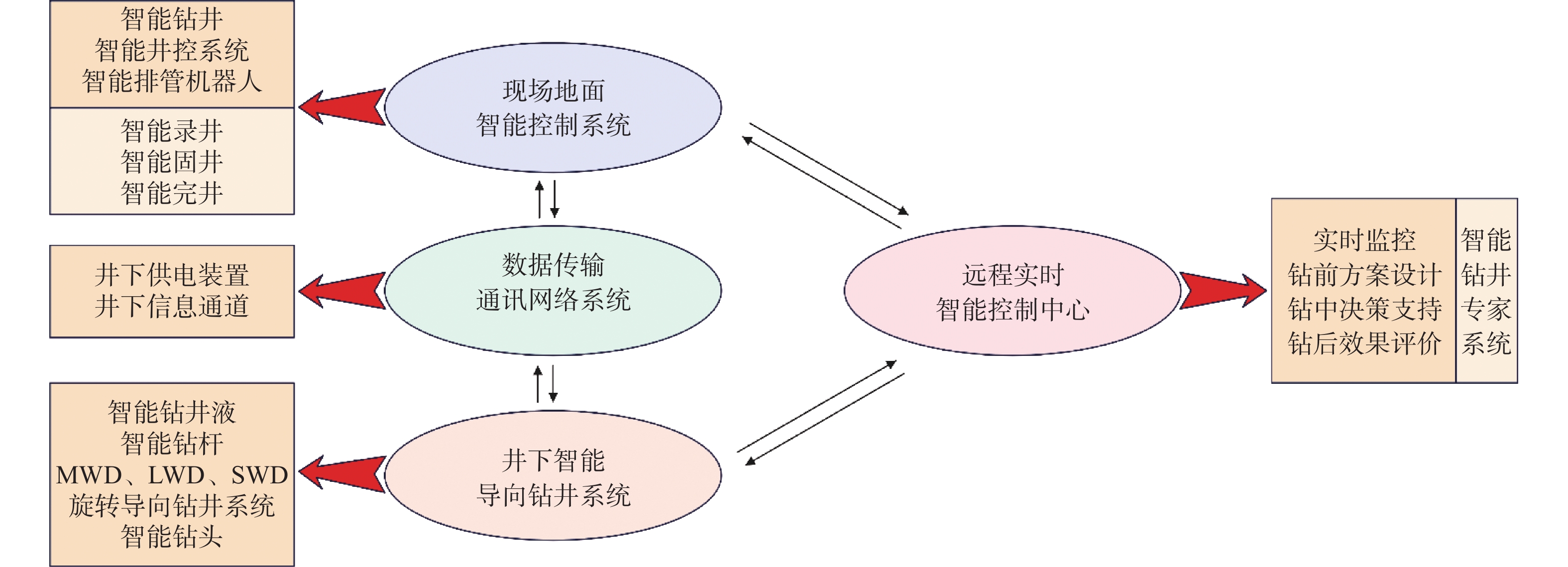

录井具有样品条件及制样工序复杂、采集项目多而离散、人工经验依赖性强且人均产值低等特点,亟需加强智能化转型,但相比于其他石油工程技术,智能录井技术进展缓慢,且局限于应用层面。为此,从智能钻井的进展与成效入手,分析了国内外智能钻井在硬件系统、控制系统、应用系统方面的进展与差距;然后,从地质录井、工程录井、智慧平台3个方面分析了智能录井的主要技术进展,包括“数据+”驱动和视觉驱动的岩性识别、流体识别、井下与地面风险识别及预警等。通过对比智能钻井与智能录井的现状,提出智能录井应强化井下智能录井、智能录井机器人等硬件系统及多场数字孪生、多元采集智能控制、多模态录井大模型、智能解释评价等软件系统的研发。同时强调,既要高度重视,又要理性看待智能录井的发展,要在回顾评价、横向对比的基础上,做好战略定位与研发流程优化,实现进度追赶与作用发挥。这些分析与观点,对推动智能录井实现良性、快速发展具有指导意义。

Abstract:Surface logging has the characteristics of complex sample conditions and sample preparation process, numerous and discrete collection items, strong dependence on hands-on experience, and low per capita output. It is urgent to strengthen intelligentialization transformation. However, compared with other petroleum engineering technologies, intelligent surface logging is making slow advancement and facing application limits. Therefore, the progress and gap of hardware systems, control systems, and application systems of intelligent drilling in China and abroad were analyzed from the progress and achievement of intelligent drilling. Then, the main technical progress of intelligent surface logging was analyzed in terms of geological surface logging, engineering surface logging, and intelligent platform, covering “data +” driven and visually driven lithology identification, fluid identification, and downhole and surface risk identification and early alarming. Based on the comparison between intelligent drilling and intelligent surface logging, it was suggested that the research and development of hardware systems such as downhole intelligent surface logging, and intelligent surface logging robots, as well as software systems such as multi-field digital twins, multi-acquisition intelligent control, multimode large model of surface logging, and intelligent interpretation and evaluation should be strengthened. At the same time, it was emphasized that we should attach great importance to and rationally look at the development of intelligent surface logging and determine strategic positioning and process optimization on the basis of retrospective evaluation and horizontal comparison, so as to catch up with the progress and engagement. These analyses and viewpoints have guiding significance in promoting the benign and rapid development of intelligent surface logging.

-

Keywords:

- Intelligent surface logging /

- intelligent drilling /

- robots /

- digital twin /

- large model /

- intelligent control

-

各向异性是指地层某种物理参数(如声波速度、电导率、渗透率等)沿不同方向测量的结果不一样[1-3]。电阻率的各向异性是指水平方向电阻率(Rh)与垂直方向电阻率(Rv)的差异,通常用

λ=√Rv/Rh 来表征其大小[4]。各向异性是地层的固有属性,成因复杂,矿物组成、孔隙分布、颗粒排列,以及裂缝和层理等,均会使地层表现出电各向异性特征[5]。在大斜度井、水平井中,随钻电磁波电阻率的相位差电阻率曲线和幅度比电阻率曲线受地层各向异性影响呈现明显差异,其差异程度与地层各向异性及井眼–地层夹角相关,利用这种差异能进行各向异性系数提取和电阻率反演校正[6-8]。近年来,学者们进行电磁测井技术模拟,考察各向异性引起仪器测井响应的变化规律,建立了二维、三维快速反演方法[9],这些方法在大斜度井、水平井中应用效果显著,而对于井斜角小于30°的井,各向异性虽对相位电阻率、幅度比电阻率有影响,但电阻率曲线的差异不明显,无法提取地层的各向异性信息。基于此,笔者利用微电阻率成像测井的高分辨率和不同方位电阻率的差异性特征来表征地层的各向异性,与实钻井随钻电阻率计算的各向异性系数的一致性较好,并且微电阻率成像表征的各向异性具有更高的分辨率[10-12],对薄互层、裂缝性地层和非均质地层引起的各向异性有很好的指示作用。

1. 各向异性地层随钻电阻率测井响应特征

以斯伦贝谢公司的ARC675型随钻电阻率测井仪为例,其采用5发2收(T−T−T−R−R−T−T)非对称分布的天线,采用混合补偿的井眼补偿方法,除具有对称补偿仪器的优点外,还采用了2 MHz和400 kHz 2种频率及5种源距,可以测得径向上20条不同探测深度的电阻率曲线,仪器结构如图1所示。

基于ARC675型随钻电阻率测井仪,利用正演模拟[13-15]分析各向异性地层随钻电阻率的测井响应特征。模型参数设置:水平电阻率Rh为20 Ω∙m,各向异性系数

λ 分别为2和3,在无限厚地层条件下,不考虑钻井液侵入和井眼环境的影响,模拟井眼与地层呈不同夹角时随钻电阻率测井的响应特征,结果如图2所示(图2中,蓝色、绿色、红色、青色、粉色线分别代表406.4,558.8,711.2,863.6和1 016.0 mm源距的相位差、幅度比电阻率)。对比图2中仪器的响应特征,可得如下规律性认识:1)井眼与地层的夹角大于30°时,相位差电阻率开始大于幅度比电阻率,且相位差电阻率曲线的差异随夹角增大而变大,显现出典型的各向异性特征;2)井眼与地层的夹角不大于30°时,相位差、幅度比电阻率曲线的差异均不明显,不能判断地层是否存在各向异性;3)各向异性系数和井眼与地层的夹角越大,相位差、幅度比电阻率曲线的差异越大。

国内外学者通常利用这种差异进行地层各向异性识别和电阻率反演[16-18],以获得地层水平电阻率。但是,当井眼与地层的夹角不大于30°时,地层各向异性虽对相位差电阻率、幅度比电阻率有影响,但影响不大,无法利用曲线的差异特征来表征地层的各向异性信息。

2. 微电阻率成像各向异性表征方法

相对于随钻电阻率测井,微电阻率成像测井具有更高的分辨率,可进行井周测量,对地层层理、倾角、裂缝、破碎特征等具有很好的指示性。

以斯伦贝谢公司FMI电成像工具为例,该工具每个井深点周向上有

S(S=192) 个电阻率测量值,分别记为Rtp1 ,Rtp2 ,…,RtpS ;在一定窗长内有M个井深取样点,对应的微电阻率成像有M×S 个电阻率测量值。利用微电阻率成像进行各向异性表征时,首先将窗长内M×S 个测量值按其测量值代表的物理量(电导率)大小划分为N 个区间,每个区间用对应的灰度等级值an(n=1,⋯,N) 代替,形成离散型变量,记为X ,其中:X={x1,x2,⋯,xi,⋯,xM×S}(i=1,2,⋯,M×S) (1) xi 必然有且仅有一个灰度区间an (n 为1~N 中的某一个值)与之对应,设离散型变量X 的分布数列P 可表示为:P{X=xi}|i∈[1,2,⋯,M×S]=P{X=an}=pn(n=1,2,⋯,N) (2) 样本是有限的,结合概率的可列可加性,其分布函数可表示为:

F(x)=P{X⩽ (3) 利用差分代替微分,步长为h,通过近似公式计算离散变量

X 取值在{x}_{\mathrm{i}} 处的概率密度:{q}_{i}=f\left({x}_{i}\right)=F{'}\left({x}_{i}\right)\approx \frac{F\left({x}_{i}+h\right)-F\left({x}_{i}-h\right)}{2h}{|}_{h\to 0} (4) 将电阻率成像图像转换为灰度图像,依据灰度等级值

{a}_{n}\left(n=1,2,\cdots ,N\right) 把窗长内M\times S 个测量值划分为N 个区间,累计落在同一区间的测量点,计算各区间测点数占总测点数的比例{l}_{n}\left(n=1,2,\cdots ,N\right) 。根据测量点的概率密度函数

{q}_{n}\left(n=1,2,\cdots ,N\right) 、区间测点数占总测点数的比例{l}_{\mathrm{n}}\left(n=1,2,\cdots ,N\right) ,对导电介质体积进行加权赋值,计算导电介质的等效体积,加权方法为:E=-{\sum }_{n=1}^{N}{q}_{n}\mathrm{lg}{q}_{n} (5) a =\frac{GR-{GR}_{\mathrm{m}\mathrm{i}\mathrm{n}}}{{GR}_{\mathrm{m}\mathrm{a}\mathrm{x}}-{GR}_{\mathrm{m}\mathrm{i}\mathrm{n}}} (6) {L}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}}={\sum }_{n=1}^{N}{(\delta }_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}} {l}_{n}) (7) {V}_{{\rm{shale}}}=\frac{{2}^{3.7 a}-1}{{2}^{3.7}-1} {\left(\frac{{L}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}}}{{L}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}}+{L}_{\mathrm{s}\mathrm{a}\mathrm{n}\mathrm{d}}} E\right)}^{2} (8) \,其中\qquad\qquad\quad {\delta }_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}}=\left\{\begin{array}{l}1\quad{a}_{i}\in {\{\boldsymbol{V}}_{\mathrm{m}}\}\\ 0\quad{a}_{i}\in \left\{{\boldsymbol{V}}_{\mathrm{s}}\right\}\end{array}\right.\qquad (9) 式中:

{q}_{n} 为图像第n级灰度值的概率密度;N 为图像的总灰度级;E 为所有灰度等级区域的熵增系数;GR 为测量点的自然伽马值,API;{GR}_{\mathrm{m}\mathrm{a}\mathrm{x}},{GR}_{\mathrm{m}\mathrm{i}\mathrm{n}} 分别为自然伽马的最大值和最小值,API;a为泥质含量指数;{\delta }_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}} 为泥质识别函数;{\{\boldsymbol{V}}_{\mathrm{s}}\},{\{\boldsymbol{V}}_{\mathrm{m}}\} 分别为砂岩测点集合和泥岩测点集合;{l}_{n} 为测量值各灰度在总灰度划分区域所占比例;{L}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}},{L}_{\mathrm{s}\mathrm{a}\mathrm{n}\mathrm{d}} 分别为泥岩、砂岩测量值各灰度在总灰度划分区域所占比例;M,S 为窗长内测点的行数和列数;{V}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}} 为泥质含量。根据加权系数计算结果,计算每个等级灰度区域的泥质含量,然后计算水平电阻率和垂直电阻率:

\frac{1}{{R}_{\mathrm{h}}}=\frac{{V}_{\mathrm{s}\mathrm{a}\mathrm{n}\mathrm{d}}}{{R}_{\mathrm{s}\mathrm{a}\mathrm{n}\mathrm{d}}}+\frac{{V}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}}}{{R}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}}} (10) {R}_{\mathrm{v}}={R}_{\mathrm{s}\mathrm{a}\mathrm{n}\mathrm{d}} {V}_{\mathrm{s}\mathrm{a}\mathrm{n}\mathrm{d}}+{R}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}} {V}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}} (11) {V}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}}=f\left[\frac{GR-{GR}_{\mathrm{m}\mathrm{i}\mathrm{n}}}{{GR}_{\mathrm{m}\mathrm{a}\mathrm{x}}-{GR}_{\mathrm{m}\mathrm{i}\mathrm{n}}} {\left(\frac{{L}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}}}{{L}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}}+{L}_{\mathrm{s}\mathrm{a}\mathrm{n}\mathrm{d}}}\right)}^{2}\right] (12) 不考虑孔隙度时,等效体积关系满足:

{V}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}} + {V}_{\mathrm{s}\mathrm{a}\mathrm{n}\mathrm{d}} =1 (13) 考虑孔隙度时,砂泥岩体积关系满足:

{V}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}} + {V}_{\mathrm{s}\mathrm{a}\mathrm{n}\mathrm{d}} =1- \phi (14) 式中:

{R}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}},{R}_{\mathrm{s}\mathrm{a}\mathrm{n}\mathrm{d}} 分别为泥岩、砂岩电阻率,Ω∙m;{R}_{\mathrm{h}},{R}_{\mathrm{v}} 分别为等效水平、垂直电阻率,Ω∙m;{V}_{\mathrm{s}\mathrm{h}\mathrm{a}\mathrm{l}\mathrm{e}}, {V}_{\mathrm{s}\mathrm{a}\mathrm{n}\mathrm{d}} 分别为泥岩、砂岩等效体积;\phi 为地层孔隙度。计算得到

{R}_{\mathrm{h}} 和{R}_{\mathrm{v}} 后,即可计算出地层的各向异性系数。3. 应用效果分析

微电阻率成像各向异性表征处理流程为:1)基于微电阻率成像测井进行对比与分层,分层时根据自然伽马曲线或电阻率曲线,将测井值处于同一测量值附近的连续井段划分为一层,以曲线半幅点位置作为分层界面;2)在层内根据成像数据划分图像灰度等级,并在选定窗长内统计同等级灰度测量区域体积,计算其总体积比例,并建立体积模型;3)计算窗长内测量点灰度等级概率密度,将概率密度与灰度值的积分作为窗长内均质性的权系数,与体积模型结合形成各向异性评价的体积模型;4)根据体积模型中不同灰度区域代表的电阻率,利用体积比例和权系数计算出水平电阻率和垂直电阻率;5)计算地层各向异性系数。

目前该方法在东海累计应用超过30井次。采用微电阻率成像计算的地层各向异性信息对随钻电磁波电阻率进行校正处理,为含水饱和度定量计算提供了技术支持。图3为A井微电阻率成像各向异性表征成果图,其中,第1道为井深,第2道为微电阻率静态图像,第3道为微电阻率动态图像,第4道为各向异性表征方法获取的各向异性系数(

\lambda )。从图3可以看出,非均质性强区域、裂缝区域、薄互层区域的各向异性系数大,其他均质区域的各向异性系数小,微电阻率成像提取的各向异性系数能清晰地表征地层的非均质性。

为进一步检验微电阻率成像提取各向异性系数的准确性和适用性,选择与大斜度井随钻电阻率提取得到的各向异性系数进行对比和统一处理。各向异性统一评价流程为:在大斜度井中分别进行随钻电阻率、微电阻率成像各向异性系数提取和统计,对比同深度井段各向异性系数变化,建立微电阻率成像各向异性系数与随钻电阻率各向异性系数的相关关系。

B井分别利用随钻电阻率、微电阻率成像提取的各向异性系数如图4所示。图4中,第6道、第7道随钻电磁波电阻率测井曲线差异明显,呈现相位差电阻率大于幅度比电阻率、长源距测量值大于短源距测量值的各向异性响应特征,指示地层存在明显的各向异性。微电阻率成像显示,存在薄互层特征。图4中第2道成像各向异性曲线为微电阻率成像提取的各向异性系数,第5道随钻计算各向异性曲线为随钻电阻率提取的各向异性系数。

以随钻电阻率提取的各向异性系数为横轴,以微电阻率成像计算的各向异性系数为纵轴,建立回归方程:

y=0.885x+0.615 (15) 基于上述回归方程进行各向异性一致性评价,结果如图5所示。

由图5可知,随钻电阻率各向异性系数与微电阻率成像各向异性系数具有很好的一致性,微电阻率成像提取的各向异性系数分辨率更高。

从一致性评价结果可知:不同测量工具间受井斜角、仪器探测特性及测量环境等因素的影响,各向异性分辨率存在一定差异;随钻电阻率、微电阻率成像均为电性采集数据,其各向异性系数具有相关性,通过各向异性一致性评价,两者有效互补,能有效提高地层各向异性系数评价的准确性和适用性。

4. 结 论

1)各向异性地层随钻电磁波电阻率正演模拟显示,当井眼与地层的夹角小于30°时,不同探测模式测量的视电阻率重合且大于地层的水平电阻率,各向异性对视电阻率的放大效应依然存在,但是基于电阻率曲线差异信息来计算地层各向异性系数的方法不再适用。

2)基于微电阻率成像测井的高分辨率和不同方位电阻率的差异性特征,采用数理统计方法,通过划分图像灰度等级并建立等效体积模型,根据体积模型中不同灰度区域代表的电阻率,结合泥质含量和加权系数计算地层等效的水平电阻率、垂直电阻率和各向异性系数,解决了井斜角较小井中无法利用曲线差异反演获得各向异性系数的难题。

3)微电阻率成像计算的各向异性系数与随钻电阻率计算的各向异性系数对比结果表明,二者一致性好,且微电阻率成像计算的各向异性系数分辨率更高,能够更好地反映裂缝、孔洞、非均质井段的各向异性特征。

-

表 1 录井与钻井智慧平台架构的对比

Table 1 Comparison of intelligent platform architecture between drilling and logging

层次 智能录井[64] 智能钻完井[1] 钻井[28] 用户层 移动端、Pad端、PC端的实时监控、技术支持、协同研究、远程决策 钻井工程师、完井工程师、地质工程师、管理人员、管理员 网络层 局域网、广域网 应用层 数据管理平台(分类存储与查询等)、数据挖掘平台(统计分析方法)、成果输出平台(岩性自动识别、物性评价、油气层解释、工程智能预警等) 机械钻速智能预测与参数优化、井眼轨迹智能优化与闭环调控、钻井风险智能预警与动态调控、固井质量智能评价与优化控制、压裂方案智能设计和优化调控、完井方案智能设计与生产优化及钻完井多过程动态耦合与多目标协同优化 钻头选型、井壁稳定、钻速预测、卡钻预警、钻井参数优化等 装备层 智能钻头、井下测量短节、智能导向工具、智能钻杆、智能滑套、智能钻机 算法层/数据操作层 机理数据融化、数据增强、小样本学习、迁移学习、强化学习、卷积神经网络、小波分析、在线学习、图算法、遗传算法 数据清洗、资源调度、计算工程 数据层 各类录井仪器、传感器采集的数据、图像、音频/视频等信息 物探数据、综合录井数据、测井数据、岩心数据、地质资料数据、随钻数据、文档资料、其他数据 井信息、录井、测井、地质、地震实时级历时数据 表 2 录井信息处理与解释评价技术体系

Table 2 Technical system of logging information processing, interpretation, and evaluation

录井信息处理 解释 评价及应用 深度校正与数据源深度匹配

影响因素校正或消除

散失量恢复或原位重构

解谱解耦与信息挖掘

曲线、图谱、影像特征提取

多元、多维、多尺度数据融合

平滑、抽稀、插值等处理

标准化、归一化处理岩性、岩相识别

古生物鉴定及沉积环境识别

成分及结构、构造识别

地质层位及地质小层识别

流体类型及赋存状态识别

物源、油(气)源识别

油(气)成因识别

含水性及水型识别

有效储层识别

油气水层解释

VOCs类型识别

钻井工况与安全风险识别

高压层及其成因识别

溢流预警

井漏及其原因识别物性及孔隙结构评价

烃源岩特性评价

脆性、岩石力学、可压性评价

润湿性、水淹层评价

含油气丰度及油气性质评价

含水性或含水率评价

甜点评价或产能预测

单井评价或选区评价

地层压力随钻评价

可钻性、井壁稳定性评价

井筒封闭性或盖层评价

热储及锂、钾、铀丰度评价

钻井地质设计

水平井综合地质导向

压裂选层 -

[1] 李根生,宋先知,祝兆鹏,等. 智能钻完井技术研究进展与前景展望[J]. 石油钻探技术,2023,51(4):35–47. doi: 10.11911/syztjs.2023040 LI Gensheng, SONG Xianzhi, ZHU Zhaopeng, et al. Research progress and the prospect of intelligent drilling and completion technologies[J]. Petroleum Drilling Techniques, 2023, 51(4): 35–47. doi: 10.11911/syztjs.2023040

[2] 王敏生,光新军. 智能钻井技术现状与发展方向[J]. 石油学报,2020,41(4):505–512. doi: 10.7623/syxb202004013 WANG Minsheng, GUANG Xinjun. Status and development trends of intelligent drilling technology[J]. Acta Petrolei Sinica, 2020, 41(4): 505–512. doi: 10.7623/syxb202004013

[3] 李宗田,肖勇,李宁,等. 低油价下的页岩油气开发工程技术新进展[J]. 断块油气田,2021,28(5):577–585. LI Zongtian, XIAO Yong, LI Ning, et al. New progress in shale oil and gas development engineering technology under low oil prices[J]. Fault-Block Oil & Gas Field, 2021,28(5): 577–585.

[4] MCCARTHY J, MINSKY M L, ROCHESTER N, et al. A proposal for the Dartmouth summer research project on artificial intelligence: August 31, 1955[J]. AI Magazine, 2006, 27(4): 12–14.

[5] GAINITDINOV B, MESHALKIN Y, ORLOV D, et al. Predicting mineralogical composition in unconventional formations using machine learning and well logging data[R]. IPTC 23487, 2024.

[6] YANG Tao, ARIEF I H, NIEMANN M, et al. A machine learning approach to predict gas oil ratio based on advanced mud gas data[R]. SPE 195459, 2019.

[7] 陈凯枫,杨学文,宋先知,等. 基于工程录井数据的井漏智能诊断方法[J]. 石油机械,2022,50(11):16–22. CHEN Kaifeng, YANG Xuewen, SONG Xianzhi, et al. An intelligent diagnosis method for lost circulation based on engineering logging data[J]. China Petroleum Machinery, 2022, 50(11): 16–22.

[8] 刘枫. 顺北地区地层四压力智能预测软件研发与应用[D]. 北京:中国石油大学(北京),2023. LIU Feng. Research and application of intelligent prediction software for formation four pressure in Shunbei Area[D]. Beijing: China University of Petroleum(Beijing), 2023.

[9] 匡立春,刘合,任义丽,等. 人工智能在石油勘探开发领域的应用现状与发展趋势[J]. 石油勘探与开发,2021,48(1):1–11. doi: 10.11698/PED.2021.01.01 KUANG Lichun, LIU He, REN Yili, et al. Application and development trend of artificial intelligence in petroleum exploration and development[J]. Petroleum Exploration and Development, 2021, 48(1): 1–11. doi: 10.11698/PED.2021.01.01

[10] 王志战. 一体化、智能化时代的录井技术发展方向探讨[J]. 录井工程,2020,31(1):1–6. doi: 10.3969/j.issn.1672-9803.2020.01.001 WANG Zhizhan. Discussion on the development direction of mud logging technology in the era of integration and intellectualization[J]. Mud Logging Engineering, 2020, 31(1): 1–6. doi: 10.3969/j.issn.1672-9803.2020.01.001

[11] 王志战. 中国石化录井技术新进展与发展方向思考[J]. 石油钻探技术,2023,51(4):124–133. doi: 10.11911/syztjs.2023027 WANG Zhizhan. Thoughts for new progress and development directions of Sinopec's surface logging technology[J]. Petroleum Drilling Techniques, 2023, 51(4): 124–133. doi: 10.11911/syztjs.2023027

[12] 闫铁,许瑞,刘维凯,等. 中国智能化钻井技术研究发展[J]. 东北石油大学学报,2020,44(4):15–21. doi: 10.3969/j.issn.2095-4107.2020.04.003 YAN Tie, XU Rui, LIU Weikai, et al. Research and development of intelligent drilling technology in China[J]. Journal of Northeast Petroleum University, 2020, 44(4): 15–21. doi: 10.3969/j.issn.2095-4107.2020.04.003

[13] 张鑫鑫,梁博文,张晓龙,等. 智能钻井装备与技术研究进展[J]. 煤田地质与勘探,2023,51(9):20–30. doi: 10.12363/issn.1001-1986.23.06.0324 ZHANG Xinxin, LIANG Bowen, ZHANG Xiaolong, et al. Research progress of intelligent drilling equipment and technology[J]. Coal Geology & Exploration, 2023, 51(9): 20–30. doi: 10.12363/issn.1001-1986.23.06.0324

[14] HU Qin, LIU Qingyou. Intelligent drilling: a prospective technology of tomorrow[R]. SPE 103781, 2006.

[15] RASSENFOSS S. Drilling automation: a robot takes over the drilling floor[J]. Journal of Petroleum Technology, 2021, 73(12): 18–22. doi: 10.2118/1221-0018-JPT

[16] LAWRENCE L, REDMOND B, RUSSELL R B, et al. Intelligent wired drill-pipe system provides significant improvements in drilling performance on offshore Australia development[R]. OTC 20067, 2009.

[17] JELLISON M J, PRIDECO G, HALL D R. Intelligent drill pipe creates the drilling network[R]. SPE 80454, 2003.

[18] TURNER D R, HEAD P F, YURATICH M A, et al. The all electric BHA: recent developments toward an intelligent coiled-tubing drilling system[R]. SPE 54469, 1999.

[19] VALVERDE E. Intelligent near-bit reamer affords same-trip drilling, hole enlargement and rathole reduction for optimal deepwater well construction[R]. OTC 28402, 2018.

[20] TILLEY J, NAIR V N, HAMOUDI L. Case study: intelligent RSS improving drilling performance on three mile laterals in the Appalachian Basin[R]. SPE 201723, 2020.

[21] AL ARFI S, ALSOWAIDI F, RUIZ F, et al. New intelligent push-the-bit rotary steerable system helped reducing well time and maximized directional drilling performance, Abu Dhabi, UAE[R]. SPE 207537, 2021.

[22] CORSER G P, HARMSE J E, CORSER B A, et al. Field test results for a real-time intelligent drilling monitor[R]. SPE 59227, 2000.

[23] ZHU J, ZENG L. Intelligent pressure control system on drilling process[R]. OTC 30828, 2020.

[24] SHEN Xinyu, LIU Sen, SU Qiang, et al. Intelligent switch control algorithm of the push-the-bit rotary steerable drilling system[R]. ARMA 20233-0558, 2023.

[25] ROWSELL P J, WALLER M D. Intelligent control of drilling systems[R]. SPE 21927, 1991.

[26] WAN Youwei, LIU Xiangjun, XIONG Jian, et al. Intelligent prediction of drilling rate of penetration based on method-data dual validity analysis[J]. SPE Journal, 2024, 29(5): 2257–2274. doi: 10.2118/217977-PA

[27] ABUGHABAN M, ALSHAARAWI A, MENG Cui, et al. Optimization of drilling performance based on an intelligent drilling advisory system[R]. IPTC 19269, 2019.

[28] XIE Tao, HOU Xinxin, HUO Hongbo, et al. Improving drilling efficiency using intelligent decision system for drilling in Bohai Oilfield based on big data[R]. SPE 215427, 2023.

[29] RASHIDI B, HARELAND G, TAHMEEN M, et al. Real-time bit wear optimization using the intelligent drilling advisory system[R]. SPE 136006, 2010.

[30] WANG Jianhua, GUAN Zhen, LIU Muchen, et al. Drilling stuck probability intelligent prediction based on LSTM considering local interpretability[R]. ARMA 2023-0326, 2023.

[31] 殷启帅,杨进,曹博涵,等. 基于长短期记忆神经网络的深水钻井工况实时智能判别模型[J]. 石油钻采工艺,2022,44(1):97–104. YIN Qishuai, YANG Jin, CAO Bohan, et al. Real-time intelligent rig activities classification model of deep-water drilling using long short-term memory (LSTM) network[J]. Oil Drilling & Production Technology, 2022, 44(1): 97–104.

[32] 李雪松,张骁,管震,等. 基于图像识别技术的钻井井漏溢流智能报警系统开发[J]. 世界石油工业,2021,28(1):48–54. LI Xuesong, ZHANG Xiao, GUAN Zhen, et al. Development of the drilling mud loss and overflow intelligent alarm system based on the image recognition technology[J]. World Petroleum Industry, 2021, 28(1): 48–54.

[33] WANG Han, CHEN Dong, YE Zhihui, et al. Intelligent planning of drilling trajectory based on computer vision[R]. SPE 197362, 2019.

[34] 张晓东,朱正喜. 智能钻井技术研究[J]. 石油钻采工艺,2010,32(1):1–4. doi: 10.3969/j.issn.1000-7393.2010.01.002 ZHANG Xiaodong, ZHU Zhengxi. Study of intelligent drilling technology[J]. Oil Drilling & Production Technology, 2010, 32(1): 1–4. doi: 10.3969/j.issn.1000-7393.2010.01.002

[35] de WARDT J. Guest editorial: trends in remote operations and drilling systems automation point to an expanding footprint what comes next and when?[J]. Journal of Petroleum Technology, 2022, 74(11): 10–13. doi: 10.2118/1122-0010-JPT

[36] 刘合. 油气勘探开发数字化转型人工智能应用大势所趋[J]. 石油科技论坛,2023,42(3):1–9. LIU He. Digital transformation of oil and gas exploration and development; unstoppable AI application[J]. Petroleum Science and Technology Forum, 2023, 42(3): 1–9.

[37] 宋先知,姚学喆,李根生,等. 基于LSTM-BP神经网络的地层孔隙压力计算方法[J]. 石油科学通报,2022,7(1):12–23. doi: 10.3969/j.issn.2096-1693.2022.01.002 SONG Xianzhi, YAO Xuezhe, LI Gensheng, et al. A novel method to calculate formation pressure based on the LSTM-BP neural network[J]. Petroleum Science Bulletin, 2022, 7(1): 12–23. doi: 10.3969/j.issn.2096-1693.2022.01.002

[38] ROWE H, MAINALI P, NIETO M, et al. Geochemical perspectives on cuttings-based chemostratigraphy and mineral modeling in the Delaware Basin, Texas and New Mexico[R]. URTEC 2019-1068, 2019.

[39] HUSSAIN M, AMAO A, AL-RAMADAN K, et al. A novel method to develop chemostratigraphy using X-ray fluorescence spectral raw data[R]. URTEC 2021-5478, 2021.

[40] MICHAEL N A, SCHEIBE C, CRAIGIE N W. Automations in chemostratigraphy: toward robust chemical data analysis and interpretation[R]. SPE 204892, 2021.

[41] 唐诚,王崇敬,梁波,等. 基于机器学习算法的页岩气评价参数计算模型研究[J]. 录井工程,2021,32(4):18–22. doi: 10.3969/j.issn.1672-9803.2021.04.003 TANG Cheng, WANG Chongjing, LIANG Bo, et al. Study on shale gas evaluation parameter calculation model based on machine learning algorithm[J]. Mud Logging Engineering, 2021, 32(4): 18–22. doi: 10.3969/j.issn.1672-9803.2021.04.003

[42] 刘雨龙. 基于深度学习的岩屑智能分析方法研究[D]. 北京:中国石油大学(北京),2023. LIU Yulong. Research on intelligent analysis method of cuttings based on deep learning[D]. Beijing: China University of Petro-leum(Beijing), 2023.

[43] 夏文鹤,谢万洋,唐印东,等. 砂样岩屑图像特征的岩性智能高效识别[J]. 石油地球物理勘探,2023,58(3):495–506. XIA Wenhe, XIE Wanyang, TANG Yindong, et al. Intelligent and efficient lithology identification based on image features of returned cuttings[J]. Oil Geophysical Prospecting, 2023, 58(3): 495–506.

[44] 张德君,魏伟,刘明艳,等. 基于综合录井数据的地层岩性智能识别方法[J]. 西部探矿工程,2023,35(4):54–59. doi: 10.3969/j.issn.1004-5716.2023.04.016 ZHANG Dejun, WEI Wei, LIU Mingyan, et al. Intelligent identification method of formation lithology based on comprehensive logging data[J]. West-China Exploration Engineering, 2023, 35(4): 54–59. doi: 10.3969/j.issn.1004-5716.2023.04.016

[45] JACOBS T. Mud-gas breakthrough Equinor develops real-time reservoir-fluid identification[J]. Journal of Petroleum Technolog, 2021, 73(2): 37–39. doi: 10.2118/0221-0037-JPT

[46] HAFIDZ ARIEF I, YANG Tao. Real time reservoir fluid log from advanced mud gas data[R]. SPE 201323, 2020.

[47] YANG Tao, YERKINKYZY G, ULEBERG K, et al. Predicting reservoir fluid properties from advanced mud gas data[J]. SPE Reservoir Evaluation & Engineering, 2021, 24(2): 358–366.

[48] UNGAR F, MCGILL A, NYGAARD M T, et al. Fluid identification from mud gas in the overburden: a case study for the Snorre Field[R]. SPE 214440, 2023.

[49] YANG Tao, ULEBERG K, CELY A, et al. Unlock large potentials of standard mud gas for real-time fluid typing[R]. SPWLA 2022-0007, 2022.

[50] KOPAL M, YERKINKYZY G, NYGÅRD M T, et al. Real-time fluid identification from integrating advanced mud gas and petrophysical logs[R]. SPWLA 2022-0009, 2022.

[51] BUCKLE P S G, ABDULLAH A F H, ZAINI N, et al. Utilization of digitalized numerical model derived from advanced mud gas data for low cost fluid phase identification, derisking drilling and effective completion plan in depleted reservoir[R]. SPWLA 2022-0092, 2022.

[52] WRIGHT A C. Estimation of gas/oil ratios and detection of unusual formation fluids from mud logging gas data[R]. SPWLA 1996-CC, 1996.

[53] MALIK M, HANSON S A, CLINCH S. Maximizing value from mudlogs: integrated approach to determine net pay[R]. SPWLA 5028, 2020.

[54] 严伟丽,高楚桥,赵彬,等. 基于气测录井资料的气油比定量计算方法[J]. 科学技术与工程,2020,20(23):9287–9292. YAN Weili, GAO Chuqiao, ZHAO Bin, et al. Quantitative calculation method of gas-oil ratio in gas logging data[J]. Science Technology and Engineering, 2020, 20(23): 9287–9292.

[55] JIANG Han, DAIGLE H, TIAN Xiao, et al. A comparison of clustering algorithms applied to fluid characterization using NMRT1-T2 maps of shale[J]. Computers & Geosciences, 2019, 126: 52–61.

[56] 夏文鹤,唐印东,李皋,等. 基于岩屑录井图像的井壁稳定性智能预测方法[J]. 天然气工业,2023,43(12):71–83. XIA Wenhe, TANG Yindong, LI Gao, et al. An intelligent prediction method for wellbore stability based on drilling cuttings logging images[J]. Natural Gas Industry, 2023, 43(12): 71–83.

[57] ZHANG Shaohui, HUANG Weihe, BI Guoqiang, et al. Intelligent risk identification and warning model for typical drilling operation scenes and its application[R]. SPE 214599, 2023.

[58] 胡志强,杨进,王磊,等. 钻井工况智能识别与时效分析技术[J]. 石油钻采工艺,2022,44(2):241–246. HU Zhiqiang, YANG Jin, WANG Lei, et al. Intelligent identification and time-efficiency analysis of drilling operation conditions[J]. Oil Drilling & Production Technology, 2022, 44(2): 241–246.

[59] 张矿生,宫臣兴,陆红军,等. 基于集成学习的井漏智能预警模型及智能推理方法[J]. 石油钻采工艺,2023,45(1):47–54. ZHANG Kuangsheng, GONG Chenxing, LU Hongjun, et al. Intelligent early warning model and intelligent reasoning method based on integrated learning for loss circulation[J]. Oil Drilling & Production Technology, 2023, 45(1): 47–54.

[60] 张敏. 渤海中深层钻井地层三压力智能预测方法研究[D]. 北京:中国石油大学(北京),2023. ZHANG Min. Research on the intelligent prediction method of triple pressure in the middle and deep drilling strata in Bohai Sea[D]. Beijing: China University of Petroleum(Beijing), 2023.

[61] 阎荣辉,黄子舰,杨永强,等. “互联网+” 时代的智慧录井系统应用探索[J]. 录井工程,2020,31(2):1–5. doi: 10.3969/j.issn.1672-9803.2020.02.001 YAN Ronghui, HUANG Zijian, YANG Yongqiang, et al. Application and exploration of smart logging system in the Internet Plus era[J]. Mud Logging Engineering, 2020, 31(2): 1–5. doi: 10.3969/j.issn.1672-9803.2020.02.001

[62] 方铁园,马宏伟,郭龙飞,等. 智慧录井平台建设及其在长庆油田的创新应用[J]. 录井工程,2023,34(3):97–101. doi: 10.3969/j.issn.1672-9803.2023.03.015 FANG Tieyuan, MA Hongwei, GUO Longfei, et al. Construction of smart mud logging platform and its innovative application in Changqing Oilfield[J]. Mud Logging Engineering, 2023, 34(3): 97–101. doi: 10.3969/j.issn.1672-9803.2023.03.015

[63] 张锦宏,周爱照,成海,等. 中国石化石油工程技术新进展与展望[J]. 石油钻探技术,2023,51(4):149–158. ZHANG Jinhong, ZHOU Aizhao, CHENG Hai, et al. New progress and prospects for Sinopec’s petroleum engineering technologies[J]. Petroleum Drilling Techniques, 2023, 51(4): 149–158.

[64] 梁海波,宋洋,于志刚,等. 钻井液流变性实时测量方法及系统研究[J]. 石油机械,2022,50(1):10–18. LIANG Haibo, SONG Yang, YU Zhigang, et al. Real-time measurement method and systematic study on drilling fluid rheology[J]. China Petroleum Machinery, 2022, 50(1): 10–18.

[65] 孟济良,吴龙斌,张学亭. 岩屑录井的新技术:DL-1型地质录井自动捞砂机介绍[J]. 石油勘探与开发,1984,11(5):75–79. MENG Jiliang, WU Longbin, ZHANG Xueting. A new technology of cuttings logging: DL-1 type automatic cuttings acquisition machine[J]. Petroleum Exploration and Development, 1984, 11(5): 75–79.

[66] ALSHEHRI A, KATTERBAUER K, YOUSEF A. Real-time autoregressive deep learning framework for in-line automatic surface logging[R]. SPE 214079, 2023.

[67] LI Sanguo, XIAO Lizhi, LI Xin, et al. A novel NMR instrument for real time drilling fluid analysis[J]. Microporous and Mesoporous Materials, 2018, 269: 138–141. doi: 10.1016/j.micromeso.2017.08.038

[68] 张志财,刘保双,王忠杰,等. 钻井液性能在线监测系统的研制与现场应用[J]. 钻井液与完井液,2020,37(5):597–601. ZHANG Zhicai, LIU Baoshuang, WANG Zhongjie, et al. Development and field application of an online drilling fluid property monitoring system[J]. Drilling Fluid & Completion Fluid, 2020, 37(5): 597–601.

[69] 王鹏,刘伟,张果. 钻井液性能自动监测装置的现状及改进建议[J]. 钻采工艺,2022,45(3):42–47. doi: 10.3969/J.ISSN.1006-768X.2022.03.08 WANG Peng, LIU Wei, ZHANG Guo. Status quo and improvement suggestions of automatic monitoring equipment for drilling fluid performance[J]. Drilling & Production Technology, 2022, 45(3): 42–47. doi: 10.3969/J.ISSN.1006-768X.2022.03.08

[70] 张好林,杨传书,李昌盛,等. 钻井数字孪生系统设计与研发实践[J]. 石油钻探技术,2023,51(3):58–65. ZHANG Haolin, YANG Chuanshu, LI Changsheng, et al. Design and research practice of a drilling digital twin system[J]. Petroleum Drilling Techniques, 2023, 51(3): 58–65.

[71] BALACHANDRAN P A, PADMANABHAN K V K. Integrated operations system: implementation of a truly integrated digital oil field and development of digital twin[R]. OTC 32841, 2023.

[72] WANG Peixian, WANG Xiaolin, MA Jun, et al. Digital and intelligent technology in underground gas storage operation based on digital twin technologies[R]. ISOPE I-23-008, 2023.

[73] BUSOLLO C, ABDO E, KATTAR M, et al. Evolution of a digital twin for underground gas storage wells: thermal effects of tubing gas flow on annulus pressure in transient conditions[R]. SPE 220006, 2024.

[74] WANG Peixian, MA Jun, LI Zunzhao, et al. Integrated simulation technology of underground gas storage based on digital twin technologies[R]. ISOPE I-24-043, 2024.

[75] 刘合,任义丽,李欣,等. 油气行业人工智能大模型应用研究现状及展望[J]. 石油勘探与开发,2024,51(4):910–923. LIU He, REN Yili, LI Xin, et al. Research status and application of artificial intelligence large models in the oil and gas industry[J]. Petroleum Exploration and Development, 2024, 51(4): 910–923.

[76] YI M, CEGLINSKI K, ASHOK P, et al. Applications of large language models in well construction planning and real-time operation[R]. SPE 217700, 2024.

[77] PACIS F J, ALYAEV S, PELFRENE G, et al. Enhancing information retrieval in the drilling domain: zero-shot learning with large language models for question-answering[R]. SPE 217671, 2024.

[78] AMEUR-ZAIMECHE O, KECHICHED R, HEDDAM S, et al. Real-time porosity prediction using gas-while-drilling data and machine learning with reservoir associated gas: case study for Hassi Messaoud Field, Algeria[J]. Marine and Petroleum Geology, 2022, 140: 105631. doi: 10.1016/j.marpetgeo.2022.105631

[79] OULADMANSOUR A, AMEUR-ZAIMECHE O, KECHICHED R, et al. Integrating drilling parameters and machine learning tools to improve real-time porosity prediction of multi-zone reservoirs. Case study: Rhourd Chegga Oilfield, Algeria[J]. Geoenergy Science and Engineering, 2023, 223: 211511.

-

期刊类型引用(2)

1. 杨文景,史宏江,潘兴明,路一平,王志国. 耐磨集成测井电极优化设计. 石油矿场机械. 2024(03): 48-53 .  百度学术

百度学术

2. 曾祥安,朱丹丹,周昊,徐朝晖. 基于特征融合的微电阻率成像测井空白带无监督填充方法. 电子测量技术. 2024(08): 171-180 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: