Key Technologies and Field Applications of Intelligent Perception in Offshore Drilling and Completion

-

摘要:

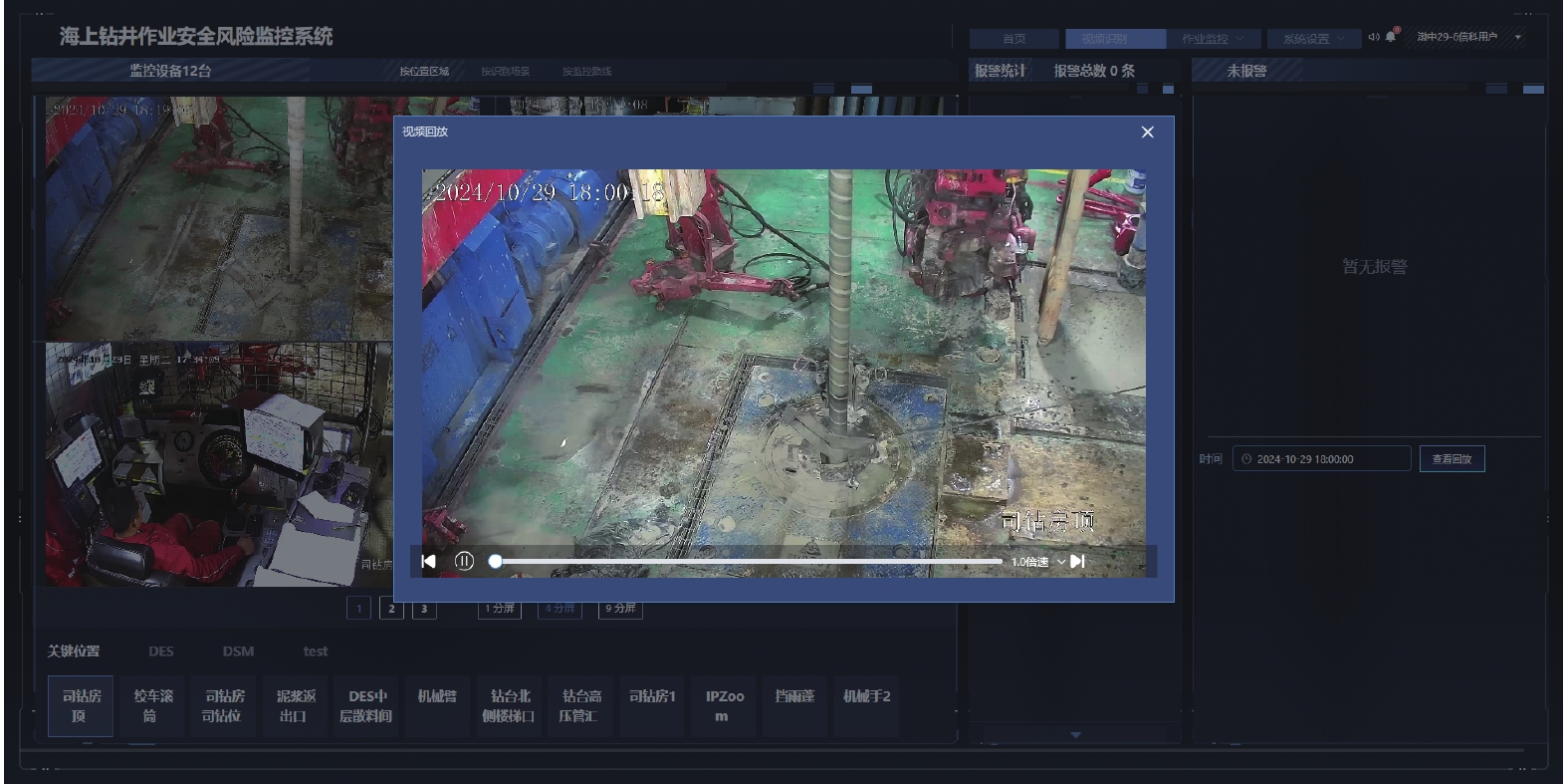

海洋油气开发远离陆地,通信和布网面临巨大挑战,智能感知技术是发展海洋智能钻完井必须解决的难题之一。海洋智能钻完井技术是海洋钻完井工程与人工智能、大数据、云计算等先进技术的有机融合,可实现海洋油气钻完井过程的精细表征、决策优化和闭环调控,大幅提升钻完井效率和油气采收率。分析了目前海上智能钻完井在基础建设、智能钻井、智能井筒等方面的技术难点,从地层、工具、流体和装备等4个方面研究了海洋钻完井智能感知领域的关键技术,建成了海洋钻井智能监控系统,实现了海洋钻完井全生命周期的全面感知。现场应用海洋智能钻井监控系统后,使用的平台自开钻起至首批开发井完成,全程未发生任何安全事故。海洋钻完井智能感知关键技术作为建设海上智能钻完井的基础,为推动海洋油气田的数字化转型和智能化发展提供了技术支撑。

Abstract:Offshore oil and gas development is conducted far away from the land, and the communication and network deployment face great challenges. Intelligent perception technology is one of the difficult problems that must be solved in the development of offshore intelligent drilling and completion. Offshore intelligent drilling and completion technology is the organic integration of offshore drilling and completion engineering and advanced technologies such as artificial intelligence, big data, and cloud computing, which can realize fine characterization, decision optimization, and closed-loop control of offshore oil and gas drilling and completion process and greatly improve drilling and completion efficiency and oil and gas recovery efficiency. To this end, the current technical difficulties of offshore intelligent drilling and completion in infrastructure construction, intelligent drilling, and intelligent wellbore were analyzed. The key technologies in the field of intelligent perception in offshore drilling and completion were studied from four aspects of formation, tools, fluids, and equipment, and an intelligent monitoring system for offshore drilling was constructed to realize a comprehensive perception of the whole life cycle of offshore drilling and completion. After the application of the intelligent monitoring system for offshore drilling, the platform had no safety accident from drilling to completion of the first batch of development wells. The key intelligent perception technologies for offshore drilling and completion, as the basis for the construction of offshore intelligent drilling and completion, provide technical support for promoting the digital transformation and intelligent development of offshore oil and gas fields.

-

-

表 1 海洋钻井常见设备与系统

Table 1 Common equipment and system of offshore drilling

组网对象 系统名称 目标集成软件 目标集成硬件 录井与MWD 录井系统 数据传输服务 服务器 MWD数据接收系统 上位机软件 PC 作业控制类系统 集成司钻控制系统 集成司钻操作系统 服务器 SCM(水下采油树控制系统) 上位机软件 服务器 控压钻井/固井系统 组态软件 PLC(具备网络模块) 固井撬系统 数据网关输出 PLC(配合数据网关) 防喷器控制系统 PLC具体IO点位 PLC(开放适配接口) 其他工控系统(火气/气象) PLC具体IO点位 PLC(开放适配接口) 作业辅助类系统 海上钻井智能监控系统 网站系统 服务器 钻完井作业日志填报系统 日志填报系统 PC 智能钻井新工具 智能钻井决策系统 软件 服务器 智能钻杆(井下数据传输) 数据接收上位机 服务器 -

[1] 李金蔓,周守为,孙金声,等. 数字技术赋能海上油田开发:渤海智能油田建设探索[J]. 石油钻采工艺,2022,44(3):376–382. LI Jinman, ZHOU Shouwei, SUN Jinsheng, et al. Digital technology energizes offshore oilfield development: an attempt to build the Bohai smart oilfield[J]. Drilling & Production Technology, 2022, 44(3): 376–382.

[2] 李中,张祯祥,杨进,等. 地层压力随钻监测方法在深水高温高压井中的研究与应用[J]. 地球科学,2019,44(8):2597–2602. LI Zhong, ZHANG Zhenxiang, YANG Jin, et al. Research and application of formation pressure monitoring while drilling in deepwater with high temperature and high pressure[J]. Earth Science, 2019, 44(8): 2597–2602.

[3] DENNEY D. Optimizing marginal subsea-well developments with intelligent completions[J]. Journal of Petroleum Technology, 2003, 55(8): 43–44. doi: 10.2118/0803-0043-JPT

[4] 马英文,杨进,李文龙,等. 渤中26-6油田发现井钻井设计与施工[J]. 石油钻探技术,2023,51(3):9–15. MA Yingwen, YANG Jin, LI Wenlong, et al. Drilling design and construction of a discovery well in Bozhong 26-6 Oilfield[J]. Petroleum Drilling Techniques, 2023, 51(3): 9–15.

[5] ABUGHABAN M, ALSHAARAWI A, MENG Cui, et al. Optimization of drilling performance based on an intelligent drilling advisory system[R]. IPTC 19269, 2019.

[6] 李根生,宋先知,祝兆鹏,等. 智能钻完井技术研究进展与前景展望[J]. 石油钻探技术,2023,51(4):35–47. LI Gensheng, SONG Xianzhi, ZHU Zhaopeng, et al. Research progress and the prospect of intelligent drilling and completion technologies[J]. Petroleum Drilling Techniques, 2023, 51(4): 35–47.

[7] 张世昆,陈作. 人工智能在压裂技术中的应用现状及前景展望[J]. 石油钻探技术,2023,51(1):69–77. ZHANG Shikun, CHEN Zuo. Status and prospect of artificial intelligence application in fracturing technology[J]. Petroleum Drilling Techniques, 2023, 51(1): 69–77.

[8] 李根生,宋先知,田守嶒. 智能钻井技术研究现状及发展趋势[J]. 石油钻探技术,2020,48(1):1–8. LI Gensheng, SONG Xianzhi, TIAN Shouceng. Intelligent drilling technology research status and development trends[J]. Petroleum Drilling Techniques, 2020, 48(1): 1–8.

[9] 林杨. 基于工业互联网云边协同技术在渤海某智能油田的实践[J]. 信息系统工程,2021(11):47–50. LIN Yang. Based on the practice of industrial internet cloud-edge collaboration technology in an intelligent oilfield in Bohai[J]. China CIO News, 2021(11): 47–50.

[10] 高仁. 钻井工程参数监测系统体系结构与数据采集传输模块的研究[D]. 重庆:重庆大学,2014. GAO Ren. Development of drilling parameters monitoring system architecture and data acquisition & transmission module[D]. Chongqing: Chongqing University, 2014.

[11] 张伟. 基于油田多源数据分析的油藏管理研究[D]. 西安:长安大学,2013. ZHANG Wei. Reservoir management research based on multisource data analysis of oilfield[D]. Xi’an: Chang’an University, 2013.

[12] 盛茂,李根生,田守嶒,等. 人工智能在油气压裂增产中的研究现状与展望[J]. 钻采工艺,2022,45(4):1–8. SHENG Mao, LI Gensheng, TIAN Shouceng, et al. Research status and prospect of artificial intelligence in reservoir fracturing stimulation[J]. Drilling & Production Technology, 2022, 45(4): 1–8.

[13] 田飞,底青云,郑文浩,等. 面向地质导向的地层智能评价解决方案[J]. 地球物理学报,2023,66(9):3975–3989. TIAN Fei, DI Qingyun, ZHENG Wenhao, et al. A formation intelligent evaluation solution for geosteering[J]. Chinese Journal of Geophysics, 2023, 66(9): 3975–3989.

[14] 马海. 基于多源信息整合的钻井地质特征参数估计与预测方法研究[D]. 青岛:中国石油大学(华东),2010. MA Hai. Estimation and prediction of drilling geologic characteristic parameters based on multi-source information fusion[D]. Qingdao: China University of Petroleum(East China), 2010.

[15] 范廷恩,胡光义,王晖,等. 井震结合储层研究[C]//中国地球物理学会第二十二届年会. 北京:中国地球物理学会,2006:116. FAN Ting’en, HU Guangyi, WANG Hui, et al. Well-seismic combined reservoir research[C]//The 22nd Annual Meeting of the Chinese Geophysical Society. Beijing: Chinese Geophysical Society, 2006: 116.

[16] 李中,谢仁军,袁俊亮. 深水高温高压气田窄压力窗口地层钻井安全概率区间[J]. 天然气工业,2020,40(12):88–94. LI Zhong, XIE Renjun, YUAN Junliang. Study on the drilling safety probability interval in narrow pressure window formation in deepwater HPHT gas fields[J]. Natural Gas Industry, 2020, 40(12): 88–94.

[17] 郭永峰. 能使井底参数上互联网的 “遥测钻杆” 技术[J]. 中国海上油气,2004,16(1):17. GUO Yongfeng. The “telemetry drill pipe” technology that can make the bottom hole parameters on the Internet[J]. China Offshore Oil and Gas, 2004, 16(1): 17.

[18] ADIL M, SANTHIRASEKARAN L, THAM N A, et al. Injection profiling for intelligently completed wells equipped with fiber optics[R]. SPE 211402, 2022.

[19] SEABROOK B, ROMERO E, MATTESON C. Fiber optic surveillance of subsea developments including intelligent well completions (IWCs)[C]//EAGE Workshop on Fiber Optic Sensing for Energy Applications in Asia Pacific. Houten: European Association of Geoscientists & Engineers, 2020: 1-5.

[20] 赵正彬,石光伟,张舜钦,等. 基于超融合架构的船舶云设计平台[J]. 船舶设计通讯,2022(2):92–96. ZHAO Zhengbin, SHI Guangwei, ZHANG Shunqin, et al. Ship cloud design platform based on hyper converged infrastructure[J]. Journal of Ship Design, 2022(2): 92–96.

[21] 李洪星. 网络时间同步与授时技术研究[D]. 北京:北京邮电大学,2021. LI Hongxing. Research on network time synchronization and time service technologies[D]. Beijing: Beijing University of Posts and Telecommunications, 2021.

[22] CARPENTER C. Intelligent drilling advisory system optimizes performance[J]. Journal of Petroleum Technology, 2020, 72(2): 65–67. doi: 10.2118/0220-0065-JPT

-

期刊类型引用(2)

1. 刘承婷,胡传峰,王智刚,董佩鑫,彭占刚,管恩东. 通道压裂支撑剂缝内分布规律研究. 河南科学. 2024(01): 8-15 .  百度学术

百度学术

2. 戴一凡,侯冰,廖志豪. 基于相场法的深层干热岩储层水力压裂模拟研究. 石油钻探技术. 2024(02): 229-235 .  本站查看

本站查看

其他类型引用(2)

下载:

下载: