Drilling Fluid Technology for Complex Deep Cambrian Formationsin Tarim Basin

-

摘要:

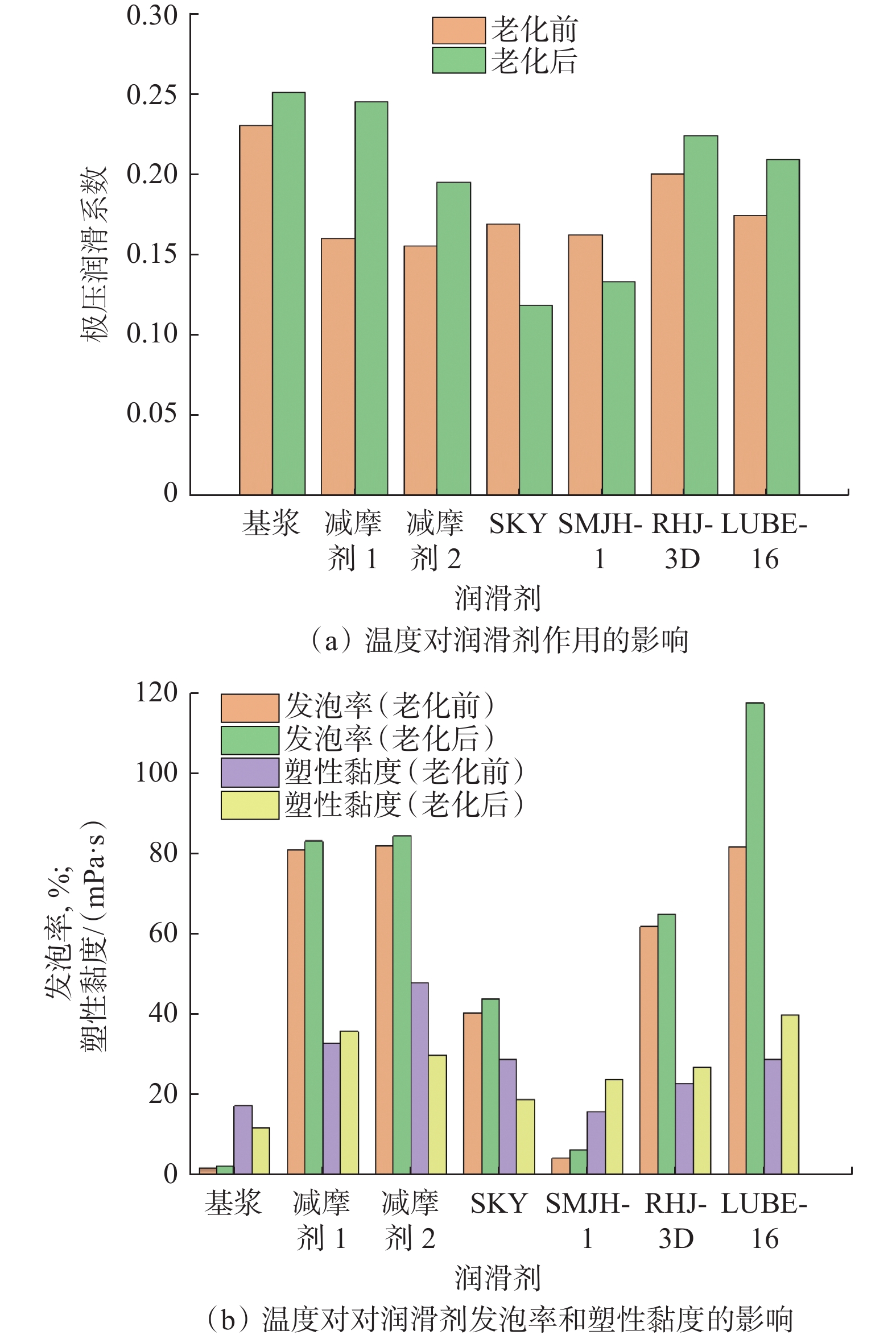

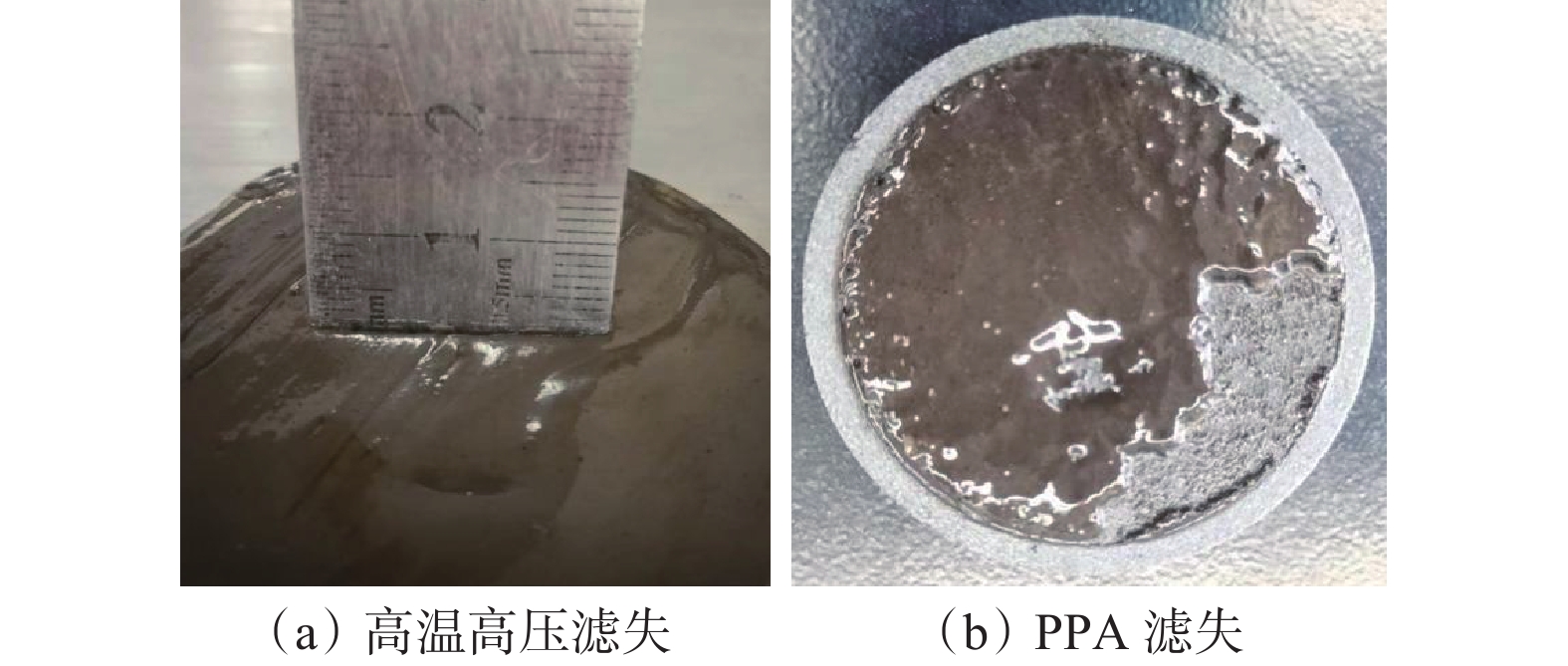

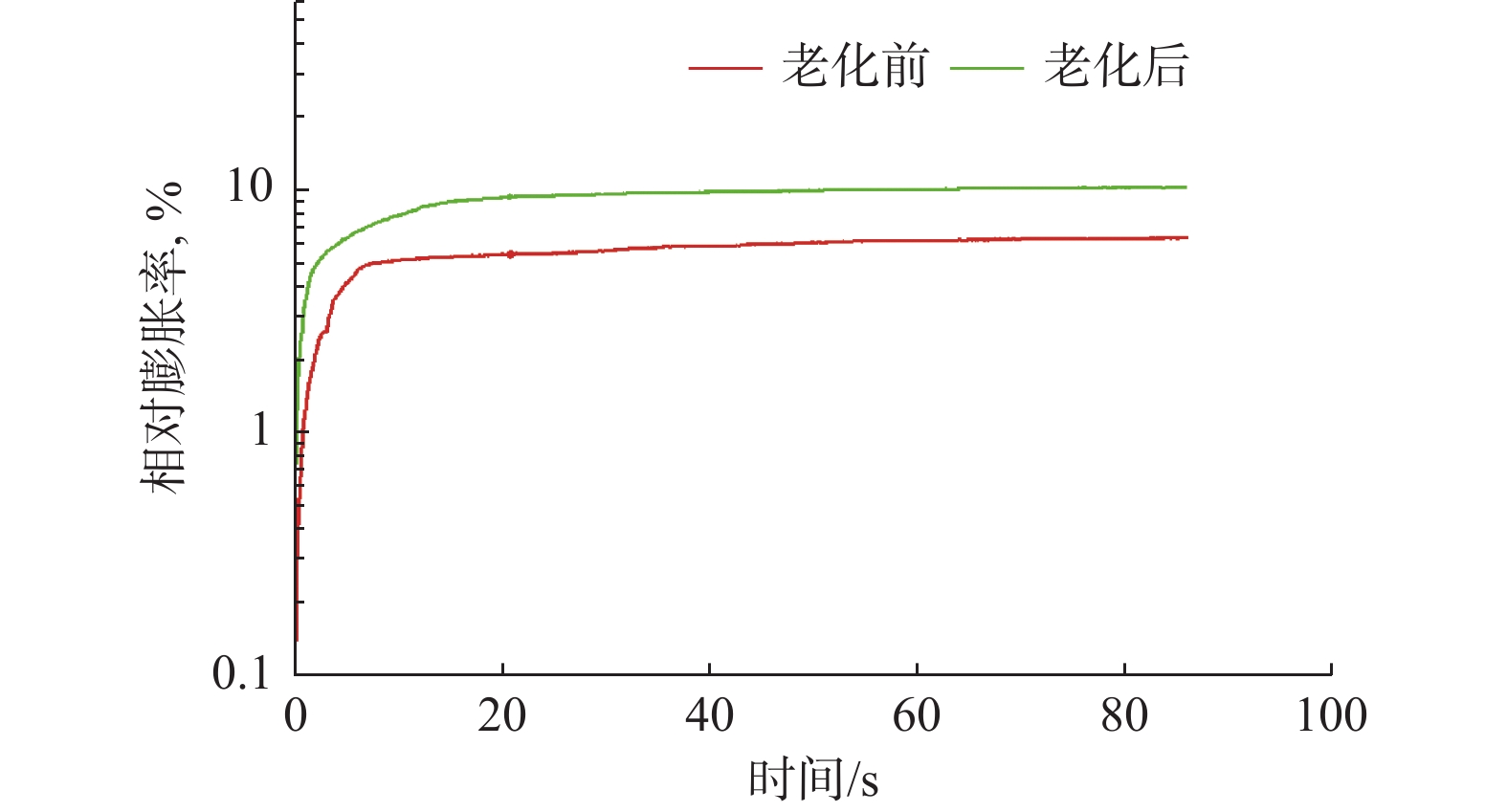

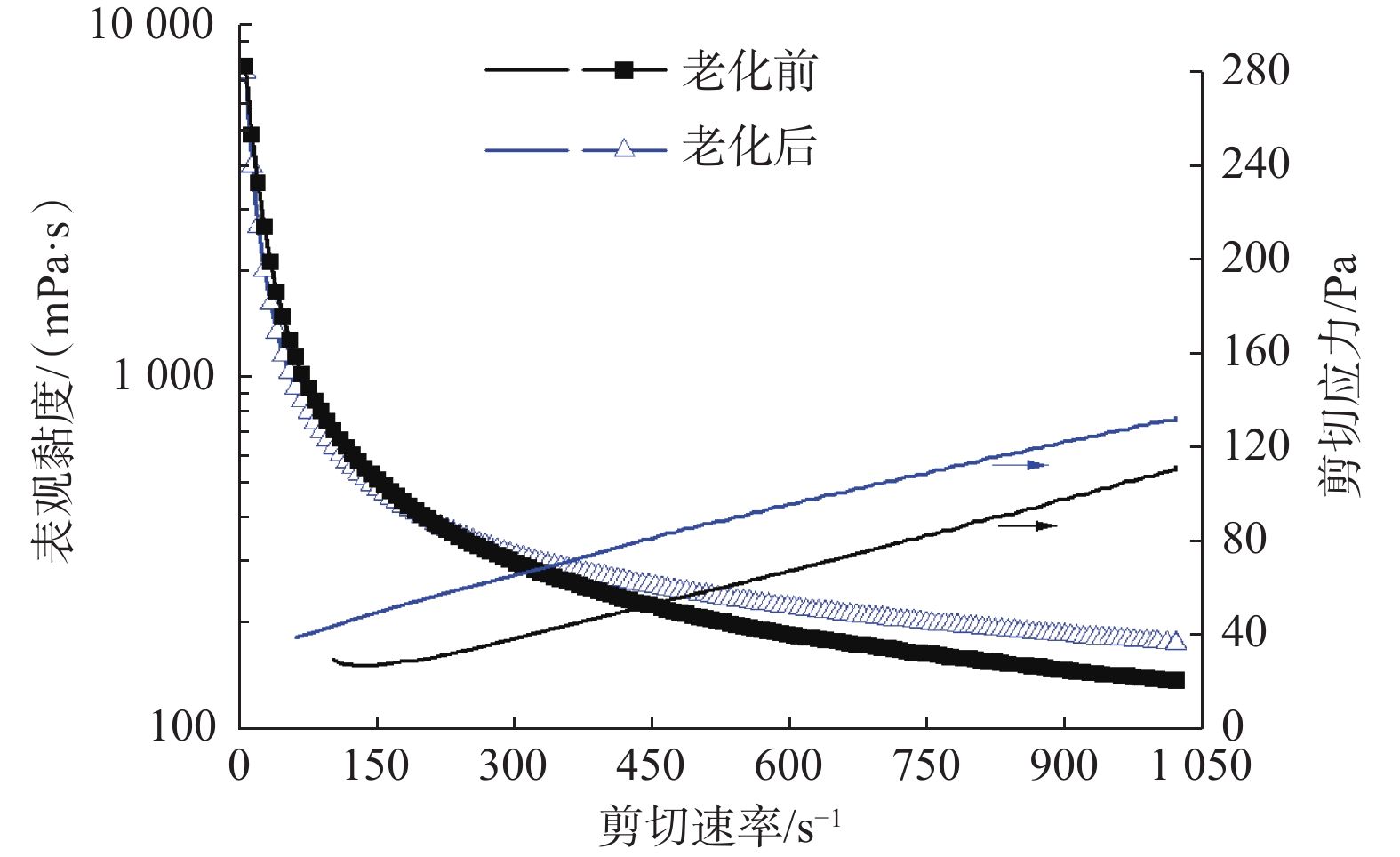

塔里木盆地寒武系复杂地层具有超深、超高温、超高压及岩性、流体和应力复杂等地质特征,钻井过程中白云岩破碎性地层垮塌、薄层膏岩溶解导致井壁失稳及钻井液污染、钻井液高温稳定性差等问题突出。基于理论分析,提出了“合理密度支撑、随钻多级封堵及封闭浆静态强化”破碎性地层防塌、“欠饱和、低滤失”含膏白云岩地层防卡、“聚合物、磺化材料协同抗温”调控钻井液高温性能的钻井液技术对策。采用抗高温封堵防塌剂、抗高温抗盐聚合物降滤失剂、多尺度宽尺度粒径随钻封堵防塌处理剂、磺化处理剂和抗高温高效润滑剂作为关键处理剂,通过室内试验优选了SMDP-2抗高温抗盐降滤失剂,确定了封堵防塌材料配方和SMJH-1润滑剂最优加量,构建了耐温200 ℃的抗高温强封堵欠饱和盐水钻井液。该钻井液在QSH1井等3口井进行了应用,表现出良好的抑制性、封堵防塌性和高温稳定性,实现了复杂地层快速钻进。其中,QSH1井下丘里塔格组及阿瓦塔格组井段日平均渗漏量较邻井降低45.6%,井眼扩大率为9.52%,电测、下套管均一次顺利到底,钻井周期缩短30.32%。研究结果表明,该钻井液技术可有效解决温度200 ℃以内的塔里木盆地寒武系复杂地层钻井液技术难点,为该类地层安全快速钻井提供了技术保障。

Abstract:The complex Cambrian formations in Tarim Basin exhibit complex geological characteristics such as large depth, ultra-high temperature, ultra-high pressure, complex lithology, fluids, and stress. Prominent issues during drilling include the collapse of fractured dolomite formations, instability of wellbore due to dissolution of thin gypsum layers, drilling fluid contamination, and poor stability of high-temperature drilling fluids. Based on theoretical analysis, strategy for preventing the collapse of fractured formations through “reasonable density support, multi-stage plugging while drilling, and static reinforcement with closed mud,” strategy for avoiding sticking in “unsaturated and low-filtration loss” gypsum-containing dolomite formations, and strategy for controlling high-temperature performance of drilling fluids through “polymer and sulphonation material synergy against temperature” were proposed. Key treatment agents such as high-temperature resistant plugging and collapse prevention agents, high-temperature resistant and salt-resistant polymer filtration reducers, multi-scale wide-size particle plugging and collapse prevention treatment agents, sulphonation treatment agents, and high-temperature resistant and efficient lubricants were used. Through laboratory experiments, SMDP-2 high-temperature resistant and salt-resistant filtration reducer was selected as the optimal agent, and the formulation of plugging and collapse prevention materials was determined. The optimal dosage of SMJH-1 lubricant was identified and high-temperature resistant, strong plugging, and unsaturated saltwater drilling fluid system capable of withstanding temperatures up to 200 °C was constructed. This drilling fluid has been applied in three wells including Well QSH1, demonstrating good inhibitory properties, plugging and collapse prevention properties, and high-temperature stability, achieving rapid drilling through complex formations. In Well QSH1, the average daily leakage rate of the Lower Qulitalik and Awatagulik formations decreased by 45.6% compared to adjacent wells, with a borehole enlargement rate of 9.52%, and downhole logging and casing were completed smoothly, reducing drilling time by 30.32%. The research indicates that this drilling fluid technology effectively addresses drilling challenges in complex Cambrian formations in Tarim Basin at temperatures below 200 °C, providing technical support for safe and rapid drilling in such formations.

-

Keywords:

- Cambrian /

- fractured formation /

- dolomite /

- wellbore collapse /

- unsaturated salt water drilling fluid /

- Tarim Basin

-

南海莺琼盆地的主要目的层为黄流组二段,构造面积大、砂体厚度大,地层温度高达200 ℃,地层压力系数大于2.3,水深90.00 m。目前,该盆地高温高压井完钻井深4 200.00~4 500.00 m,一般采用五开井身结构:一开,采用ϕ914.4 mm钻头钻进,下入ϕ762.0 mm套管;二开,采用ϕ660.4 mm钻头钻进,下入ϕ508.0 mm套管;三开,采用ϕ444.5 mm钻头钻进,下入ϕ339.7 mm套管;四开,采用ϕ311.1 mm钻头钻进,下入ϕ244.5 mm套管;五开,采用ϕ212.7 mm钻头钻进,裸眼完井。钻进黄流组二段地层时井漏频发,漏失量大,堵漏难度大,堵漏成功率低,严重影响了莺琼盆地的勘探开发进程[1-2]。国内外针对高温高压井的漏失机理尚未认识清楚,没有有效的堵漏手段,堵漏效果差。多年钻井实践及研究表明,莺琼盆地地层的安全密度窗口极窄,钻进过程中产生的激动压力极易超过地层漏失压力,且在高压下易产生诱导裂缝[3-7]。常用堵漏材料抗高温能力差,在高温条件下易碳化,且很难准确掌握高压诱导裂缝的尺寸,造成堵漏材料对诱导裂缝的适应性差,导致堵漏成功率低,复漏频发。为此,笔者在分析莺琼盆地地层漏失原因的基础上,优选抗高温堵漏材料,针对诱导性裂缝的特点,将抗高温刚性堵漏材料与弹性堵漏材料复配,形成了适用于高温高压井的堵漏浆。该堵漏浆在莺琼盆地10口高温高压井进行了应用,堵漏成功率得到显著提高,堵漏效果较好。

1. 井漏原因分析

1.1 安全密度窗口窄

莺琼盆地从上至下依次钻遇乐东组、莺歌海组和黄流组地层,其中乐东组及莺歌海组地层岩性以灰色厚层状泥岩、粉砂质泥岩为主,厚度超过2 000.00 m,为天然良好盖层。目的层黄流组地层岩性为浅灰色中砂岩、细砂岩、粉砂岩和灰色泥岩,且砂岩与泥岩呈不等厚互层。莺琼盆地底部发育大型泥–流体底辟构造,且成群成带分布,在快速沉积、大型泥–流体底辟作用及热流体活动共同作用下,底辟带形成了高温高压环境,造成地层压力抬升快、台阶多,莺歌海组地层压力系数自垂深2 000.00 m由1.0迅速升至2.0,黄流组局部地层压力系数超过2.3,同时地层温度高达200 ℃[8];同时,黄流组砂层薄弱,承压能力低,导致目的层安全密度窗口极窄。莺琼盆地部分高温高压井目的层井段的安全密度窗口统计结果见表1。

表 1 莺琼盆地高温高压井目的层井段安全密度窗口统计结果Table 1. Statistical result of safety density windows of HTHP wells in the Yingqiong Basin井名 井眼直径/mm 地层温度/℃ 漏失压力当量密度/(kg·L–1) 地层压力系数 安全密度窗口/(kg·L–1) LD161-A 212.7 185 2.30 2.27 0.03 LD101-B 212.7 188 2.28 2.27 0.01 LD102-A 212.7 188 2.37 2.26 0.11 LD101-C 212.7 194 2.39 2.26 0.13 LD103-A 212.7 188 2.40 2.28 0.12 由表1可以看出,目的层井段安全密度窗口在0.10 kg/L左右,部分井几乎无安全密度窗口。钻井过程中,起下钻速度、排量、转速等变化产生的激动压力极易超过上层套管鞋及薄弱层的漏失压力,造成井漏。

1.2 地层诱导裂缝发育

莺琼盆地目的层渗透率为0.1~5.0 mD,泥质含量较高,部分井段地层泥质含量高达59%。井壁成像测井结果显示,目的层井壁发育诱导裂缝,诱导裂缝宽且长。这是由于井下存在着各种应力,高温高压井眼内钻井液液柱压力大,将在井壁最大主应力方向上产生足以使井壁发生张性破裂的张应力,从而产生诱导裂缝,钻井液在压差作用下通过诱导裂缝进入地层,加上目的层井段地层泥质含量高,导致诱导裂缝进一步扩大、延伸,进而引发井漏[9-11]。

2. 堵漏浆构建及性能评价

2.1 堵漏思路

由于莺琼盆地高温高压井目的层井段安全密度窗口窄,同时井底温度高,要求所使用的堵漏材料与其他钻井液添加剂配伍性好,不能影响高密度钻井液的性能,以避免因钻井液性能变化引起激动压力过大,导致井漏进一步恶化;同时,要求堵漏材料抗温能力强,避免在高温环境下失效。

为有效封堵诱导裂缝,采用刚性堵漏材料及弹性堵漏材料相结合的方式:首先选用高强度刚性材料在诱导裂缝端部架桥,再选用具有高压缩性、能够自适应不同尺寸及不同形状裂缝形态的弹性堵漏材料,在压力作用下充填在诱导裂缝根部及端部空隙中,形成致密封堵层,以阻止诱导裂缝进一步延伸扩大,提高地层承压能力。

2.2 堵漏剂评价

目前大部分堵漏材料在温度超过180 ℃时容易碳化,造成其强度降低。经过大量试验筛选出了刚性堵漏材料高硬度果壳粉DXD和抗高温弹性堵漏材料弹性石墨TXD。果壳粉DXD和石墨TXD在200 ℃下老化前后的粒度分布如图1所示。从图1可以看出,经过200 ℃老化后,DXD和TXD的粒度分布与老化前相差不大。高温老化前,DXD和TXD的抗压强度分别为10和34 MPa;高温老化后,DXD和TXD的抗压强度分别为8和33 MPa。这说明DXD和TXD没有出现高温碳化现象,其抗温能力超过200 ℃。

2.3 堵漏浆配方的确定

井壁成像测井解释结果表明,莺琼盆地目的层诱导裂缝的宽度集中在120~200 μm,根据三分之一架桥理论,堵漏材料的粒径在40~66 μm时架桥堵漏效果最好,5.0%DXD和3.0%TXD复配后的平均粒径为50~60 μm,可取得较好的架桥堵漏效果。将5.0%DXD和3.0%TXD加入莺琼盆地某井使用的密度为2.30 kg/L的井浆(配方为0.8%膨润土+0.6%烧碱+3.0%有机树脂Resinex+0.3%高温降滤失剂Calovis+3.5%褐煤树脂XP–20K 2.0%磺化沥青Soltex+3.0%碳酸钙QWY)中,评价其在200 ℃下老化16 h后的流变性及滤失性能,结果见表2。从表2可以看出,加入堵漏材料后井浆的API滤失量和高温高压滤失量均有所降低,漏斗黏度和塑性黏度有所增大,但仍满足现场泵入要求。因此,堵漏浆的配方可确定为:0.8%膨润土+0.6%烧碱+3.0%有机树脂Resinex+0.3%高温降滤失剂Calovis+3.5%褐煤树脂XP–20K+2.0%磺化沥青Soltex+3.0%碳酸钙QWY+5.0%刚性堵漏材料DXD+3.0%弹性堵漏材料TXD。

表 2 堵漏浆基本性能评价结果Table 2. Results of basic performance evaluation of plugging slurry试验浆 试验条件 漏斗黏度/s 塑性黏度/(mPa·s) 动切力/Pa API滤失量/mL 高温高压滤失量/mL 井浆 40 22 9 4.2 6.8 井浆+5.0%DXD + 3.0%TXD 老化后 44 27 9 3.2 5.4 2.4 砂盘漏失试验

选取了2个渗透率相当的陶瓷砂盘(砂盘渗透率分别为4.6和5.3 mD,孔喉直径为80~200 μm,接近地层诱导裂缝大小),进行井浆和堵漏浆的砂盘漏失试验,试验温度设置为200 ℃,试验压差设置为6.89 MPa,结果见表3。由表3可知,堵漏浆的瞬时滤失量为18 mL,低于井浆瞬时滤失量(32 mL),2 h后堵漏浆的滤失量仅为25 mL,而井浆的滤失量为60 mL,说明堵漏浆的降滤失性能较强。

表 3 堵漏浆及井浆砂盘漏失试验结果Table 3. Results of plugging slurry and original mud sand disc leakage test试验浆 瞬时漏失量/mL 不同时间累计漏失量/mL 0.5 h 1.0 h 1.5 h 2.0 h 堵漏浆 18 24 25 25 25 井浆 32 41 49 54 60 用扫描电镜观测堵漏浆砂盘漏失试验所用的砂盘,结果如图2所示。由图2可知,漏失试验后砂盘的孔隙被堵漏材料封堵,形成了致密的封堵层。主要是刚性堵漏材料首先充填在砂盘孔隙中,可压缩的弹性石墨材料在高压作用下,进一步充填于剩余孔隙中,形成了致密的封堵层。

2.5 封堵性能评价

应用传统裂缝堵漏仪评价堵漏浆封堵性能时,采用了平行缝方式,无法真实模拟地层裂缝形态,因此,利用CDL-Ⅱ型高温高压动态堵漏仪,用1.0 mm梯形缝(进口缝宽3.0 mm、出口缝宽1.0 mm)模拟井壁裂缝来评价堵漏浆的封堵性能,试验温度为200 ℃。密度2.30 kg/L井浆及堵漏浆对梯形缝的堵漏效果如图3所示。由图3可知,井浆承压能力约为5 MPa,堵漏浆的承压能力稳定在18 MPa,与井浆相比,堵漏浆的承压堵漏能力更强。分析认为,刚性堵漏材料DXD在裂缝中先进行架桥,然后具有较高压缩率的弹性堵漏材料TXD在压差作用下继续充填于裂缝剩余孔隙中,形成致密封堵层,从而提高了承压能力[11-14]。

3. 现场应用

莺琼盆地高温高压井堵漏技术在10口井进行了现场应用,堵漏浆密度最高达2.40 kg/L,井底温度最高达212 ℃。总体应用效果良好,在堵漏的同时提高了地层承压能力,复漏发生次数大大减少,堵漏成功率由采用常规堵漏技术的不到30%提高到了80%以上。下面以LD101–E井为例介绍具体应用情况。

LD101–E井钻至井深4 105.00 m(已进入目的层)时,录井监测系统显示,泵压由10.34 MPa突然降至8.28 MPa,返出钻井液量由24%降至1%,判断发生了井漏。静止观察3 h,计量罐液量突然增加1 m3,判断发生了溢流,现场关井进行节流排气,开井后钻井液出口密度降至2.22 kg/L。该井段上层套管鞋处漏失当量密度为2.40 kg/L,发生井漏时钻井液密度为2.24 kg/L,随钻显示井底当量循环密度为2.33 kg/L,可见井深4 105.00 m处的安全密度窗口小于0.10 kg/L。循环排气结束后,通过控制排量维持井底当量循环密度在2.28~2.29 kg/L进行钻进,期间逐步将钻井液密度提高至2.23 kg/L。钻至井深4 138.00 m时,返出钻井液量增多,活动池液量增加3.5 m3,再次发生溢流,关井循环排气,控制排量维持井底当量循环密度在2.32~2.33 kg/L,将钻井液密度调整至2.29 kg/L,静止观察井筒稳定性。

由于安全密度窗口窄,决定起钻,下光钻杆静止挤入堵漏浆,提高地层承压能力。按照配方在井浆中加入抗高温堵漏材料DXD和TXD配制堵漏浆,并调整其性能满足要求后,向井底泵入15 m3堵漏浆,关防喷器,从环空挤堵堵漏浆。LD101–E井挤堵漏浆时的地面泵压曲线如图4所示。由图4可知,地面最高泵压4.48 MPa,并稳定10 min,折算钻井液当量密度为2.40 kg/L。

挤堵漏浆结束后,起出光钻杆,下钻控制井底当量循环密度不超过2.40 kg/L继续钻进,钻至完钻井深4 352.00 m,钻进期间未发生井漏及溢流。该井电测结果显示井底温度为198 ℃,井壁成像测井结果如图5所示。由图5可见,该井4 097.00~4 113.00 m井段发育纵向延伸的诱导裂缝,裂缝宽度为0.2 mm。LD101–E井堵漏成功,说明优化后的堵漏浆能封堵诱导裂缝,提高地层承压能力。

4. 结论与建议

1)莺琼盆地高温高压井发生井漏的原因是钻井液安全密度窗口窄和目的层诱导裂缝发育。

2)针对莺琼盆地高温高压井井漏的原因,采用耐高温刚性堵漏材料和耐高温弹性堵漏材料相结合的方法,构建了密度达2.40 kg/L、抗温能力200 ℃的堵漏浆,显著提高了堵漏成功率,减少了复漏的发生。

3)分析堵漏浆的堵漏原理得知,堵漏浆中的刚性堵漏材料在诱导缝中形成架桥,弹性堵漏材料充填于剩余孔隙中,封堵了诱导裂缝,较好地防止了诱导缝的进一步延伸扩大,提高了地层承压能力。

4)建议进一步开展用于深水高温高压井的堵漏浆研究,为南海深水高温高压油气资源的高效勘探开发提供技术支持。

-

表 1 含封堵防塌剂基浆200 ℃高温老化16 h后的性能

Table 1 Performance of base mud containing plugging and collapse prevention agents after 16 h high-temperature aging at 200 °C

防塌剂配方 试验条件 高温高压滤失量/mL PPA滤失量/mL 粒径中值/μm 基浆 200 ℃老化16 h 56.0 21.2 6.309 基浆+2.5%超细碳酸钙Ⅰ+1.0%超细碳酸钙Ⅲ+1.0%超细碳酸钙Ⅶ 200 ℃老化16 h 32.6 14.6 12.304 基浆+1.0%超细碳酸钙Ⅰ+1.5%超细碳酸钙Ⅲ+2.5%超细碳酸钙Ⅶ 200 ℃老化16 h 33.2 15.2 9.608 基浆+1.0%超细碳酸钙Ⅰ+2.5%超细碳酸钙Ⅲ+1.0%超细碳酸钙Ⅶ 200 ℃老化16 h 31.8 14.0 10.252 基浆+2.0%超细碳酸钙Ⅰ+1.0%超细碳酸钙Ⅲ+1.5%超细碳酸钙Ⅶ 200 ℃老化16 h 22.8 13.0 11.116 表 2 不同磺化材料加量下抗高温钻井液的性能

Table 2 Performance of high-temperature resistant drilling fluid with different sulfonated material dosages

序号 配方 试验条件 表观黏度/

(mPa·s)塑性黏度/

(mPa·s)动切力/

Pa高温高压滤失量/mL 表面张力/

(mN·m−1)0# 基本配方 老化前 32 23 9 200 ℃老化16 h 27 20 7 26.0 57.4 1# 0#+4%SMC+4%SMP-3 老化前 41 33 8 200 ℃老化16 h 27 21 6 17.2 41.0 2# 0#+3%SMC+3%SMP-3 老化前 38 30 8 200 ℃老化16 h 26 20 6 14.4 52.5 3# 0#+3%SMC+3%SMP-3+2%SPNH 老化前 39 31 8 200 ℃老化16 h 26 19 7 14.2 42.5 4# 0#+2%SMC+2%SMP-3+4%SPNH 老化前 32 25 7 200 ℃老化16 h 23 18 5 14.4 46.2 5# 0#+2%SMC+4%SMP-3+2%SPNH 老化前 36 28 8 200 ℃老化16 h 27 20 7 12.2 49.6 表 3 抗高温强封堵欠饱和盐水钻井液老化前后的性能

Table 3 Performance of high-temperature resistant, strong plugging, and unsaturated saltwater drilling fluid before and after aging

试验条件 漏斗黏度/s 动切力/

Pa静切力/Pa API滤失量/

mL高温高压滤失量/

mLPPA滤失量/

mL初切 终切 老化前 29 13 3.0 6.0 9.2 老化后 26 15 3.5 6.5 2.6 11.8 10.4 -

[1] 马永生,黎茂稳,蔡勋育,等. 中国海相深层油气富集机理与勘探开发:研究现状、关键技术瓶颈与基础科学问题[J]. 石油与天然气地质,2020,41(4):655–672. MA Yongsheng, LI Maowen, CAI Xunyu, et al. Mechanisms and exploitation of deep marine petroleum accumulations in China: advances, technological bottlenecks and basic scientific problems[J]. Oil & Gas Geology, 2020, 41(4): 655–672.

[2] 史今雄,赵向原,潘仁芳,等. 川中地区震旦系灯影组碳酸盐岩天然裂缝特征及其对气井产能影响[J]. 石油与天然气地质,2023,44(2):393–405. SHI Jinxiong, ZHAO Xiangyuan, PAN Renfang, et al. Characteristics of natural fractures in carbonate reservoirs and their impacts on well productivity in the Sinian Dengying Formation, central Sichuan Basin[J]. Oil & Gas Geology, 2023, 44(2): 393–405.

[3] 张煜,李海英,陈修平,等. 塔里木盆地顺北地区超深断控缝洞型油气藏地质–工程一体化实践与成效[J]. 石油与天然气地质,2022,43(6):1466–1480. ZHANG Yu, LI Haiying, CHEN Xiuping, et al. Practice and effect of geology-engineering integration in the development of ultra-deep fault-controlled fractured-vuggy oil/gas reservoirs, Shunbei Area, Tarim Basin[J]. Oil & Gas Geology, 2022, 43(6): 1466–1480.

[4] 马永生,蔡勋育,云露,等. 塔里木盆地顺北超深层碳酸盐岩油气田勘探开发实践与理论技术进展[J]. 石油勘探与开发,2022,49(1):1–17. doi: 10.1016/S1876-3804(22)60001-6 MA Yongsheng, CAI Xunyu, YUN Lu, et al. Practice and theoretical and technical progress in exploration and development of Shunbei ultra-deep carbonate oil and gas field, Tarim Basin, NW China[J]. Petroleum Exploration and Development, 2022, 49(1): 1–17. doi: 10.1016/S1876-3804(22)60001-6

[5] 何成江,姜应兵,文欢,等. 塔河油田缝洞型油藏“一井多控”高效开发关键技术[J]. 石油钻探技术,2022,50(4):37–44. doi: 10.11911/syztjs.2022077 HE Chengjiang, JIANG Yingbing, WEN Huan, et al . Key technologies for high-efficiency one-well multi-control development of fractured-vuggy reservoirs in Tahe Oilfield [J]. Petroleum Drilling Techniques , 2022, 50(4): 37–44. doi: 10.11911/syztjs.2022077

[6] 桂亚倩,朱光有,阮壮,等. 塔里木盆地塔北隆起寒武系地层水化学特征、成因及矿物溶解–沉淀模拟[J]. 石油与天然气地质,2022,43(1):196–206. GUI Yaqian, ZHU Guangyou, Ruan Zhuang, et al. Geochemical features and origin of the Cambrian formation water in Tabei Uplift, Tarim Basin and its mineral dissolution-precipitation simulation[J]. Oil & Gas Geology, 2022, 43(1): 196–206.

[7] 陈宗琦,刘湘华,白彬珍,等. 顺北油气田特深井钻井完井技术进展与发展思考[J]. 石油钻探技术,2022,50(4):1–10. CHEN Zongqi, LIU Xianghua, BAI Binzhen, et al. Technical progress and development consideration of drilling and completion engineering for ultra-deep wells in the Shunbei Oil & Gas Field[J]. Petroleum Drilling Techniques, 2022, 50(4): 1–10.

[8] 王建云,杨晓波,王鹏,等. 顺北碳酸盐岩裂缝性气藏安全钻井关键技术[J]. 石油钻探技术,2020,48(3):8–15. WANG Jianyun, YANG Xiaobo, WANG Peng, et al. Key technolo-gies for the safe drilling of fractured carbonate gas reservoirs in the Shunbei Oil and Gas Field[J]. Petroleum Drilling Techniques, 2020, 48(3): 8–15.

[9] 黄少英,张玮,罗彩明,等. 塔里木盆地中部满深1断裂带的多期断裂活动[J]. 地质科学,2021,56(4):1015–1033. HUANG Shaoying, ZHANG Wei, LUO Caiming, et al. The faults and faulting phases of the Manshen-1 Fault Belt, central Tarim Basin[J]. Chinese Journal of Geology, 2021, 56(4): 1015–1033.

[10] 方俊伟,张翼,李双贵,等. 顺北一区裂缝性碳酸盐岩储层抗高温可酸溶暂堵技术[J]. 石油钻探技术,2020,48(2):17–22. FANG Junwei, ZHANG Yi, LI Shuanggui, et al. Acid-soluble temporary plugging technology for ultra-deep fractured carbonate reservoirs in Block 1 of the Shunbei area[J]. Petroleum Drilling Techniques, 2020, 48(2): 17–22.

[11] 王文静,方少林,王飞扬,等. 膏盐岩类研究现状、分布特征及存在问题分析[J]. 地球科学前沿,2022,12(12):1631–1645. doi: 10.12677/AG.2022.1212159 WANG Wenjing, FANG Shaolin, WANG Feiyang, et al. Analysis of research status, distribution characteristics and existing problems of salt paste[J]. Advances in Geosciences, 2022, 12(12): 1631–1645. doi: 10.12677/AG.2022.1212159

[12] 吴鲜,李丹,韩俊,等. 塔里木盆地顺托果勒北部地区超深层现今地温场特征[J]. 石油学报,2022,43(1):29–40. WU Xian, LI Dan, HAN Jun, et al. Characteristics of present ultra-deep geothermal field in the northern Shuntuoguole low uplift, Tarim Basin[J]. Acta Petrolei Sinica, 2022, 43(1): 29–40.

[13] 王伟吉,李大奇,金军斌,等. 顺北油气田破碎性地层井壁稳定技术难题与对策[J]. 科学技术与工程,2022,22(13):5205–5212. WANG Weiji, LI Daqi, JIN Junbin, et al. Technical problems and measures of wellbore stability of broken formation in Shunbei Oil and Gas Field[J]. Science Technology and Engineering, 2022, 22(13): 5205–5212.

[14] 张亚云,李大奇,高书阳,等. 顺北油气田奥陶系破碎性地层井壁失稳影响因素分析[J]. 断块油气田,2022,29(2):256–260. ZHANG Yayun, LI Daqi, GAO Shuyang, et al. Analysis on influencing factors of wellbore instability of Ordovician fractured formation in Shunbei Oil and Gas Field[J]. Fault-Block Oil & Gas Field, 2022, 29(2): 256–260.

[15] 李雄,董晓强,金军斌,等. 超高温高密度钻井液体系的研究与应用[J]. 钻井液与完井液,2020,37(6):694–700. LI Xiong, DONG Xiaoqiang, JIN Junbin, et al. Study and application of an ultra-high temperature high density drilling fluid[J]. Drilling Fluid & Completion Fluid, 2020, 37(6): 694–700.

[16] 董晓强,方俊伟,李雄,等. 顺北4XH井抗高温高密度钻井液技术研究及应用[J]. 石油钻采工艺,2022,44(2):161–167. DONG Xiaoqiang, FANG Junwei, LI Xiong, et al. Research and application of a high-temperature high-density drilling fluid system in Well Shunbei-4XH[J]. Oil Drilling & Production Technology, 2022, 44(2): 161–167.

[17] 王强,袁和义,刘阳,等. 深井超深井裂缝性地层致密承压封堵实验研究[J]. 西南石油大学学报(自然科学版),2021,43(4):109–117. WANG Qiang, YUAN Heyi, LIU Yang, et al. An experimental investigation on pressure bearing and tight plugging of fractured formations in deep and ultra-deep wells[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2021, 43(4): 109–117.

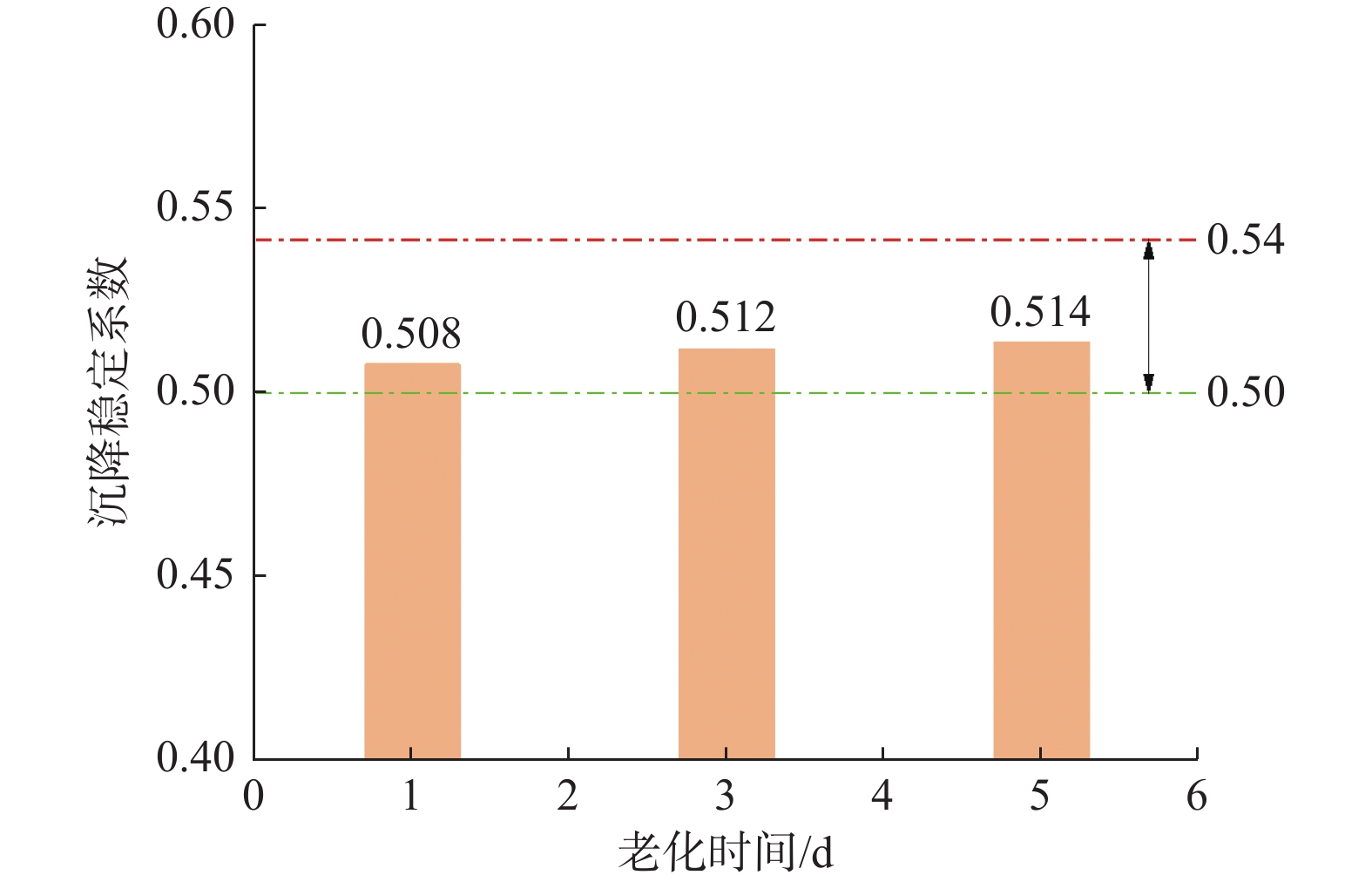

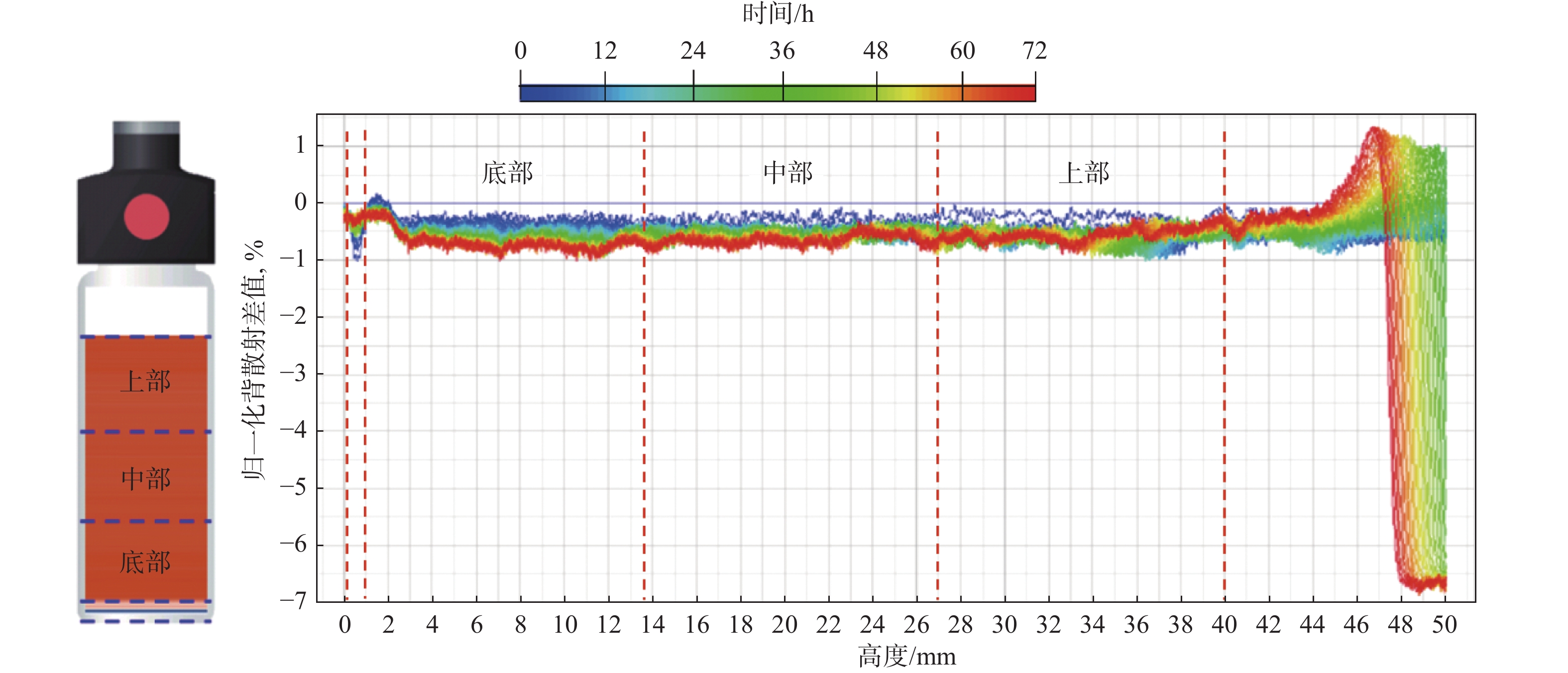

[18] 董晓强,李雄,方俊伟,等. 高密度钻井液高温静态沉降稳定性室内研究[J]. 钻井液与完井液,2020,37(5):626–630. DONG Xiaoqiang, LI Xiong, FANG Junwei, et al. Laboratory study on static sedimentation stability of high-density drilling fluids at high temperatures[J]. Drilling Fluid & Completion Fluid, 2020, 37(5): 626–630.

[19] 钱晓琳,宣扬,林永学,等. 钻井液环保润滑剂SMLUB-E的研制及应用[J]. 石油钻探技术,2020,48(1):34–39. QIAN Xiaolin, XUAN Yang, LIN Yongxue, et al. Development and application of an environmental-friendly drilling fluid lubricant SMLUB-E[J]. Petroleum Drilling Techniques, 2020, 48(1): 34–39.

[20] 金军斌,张杜杰,李大奇,等. 顺北油气田深部破碎性地层井壁失稳机理及对策研究[J]. 钻采工艺,2023,46(1):42–49. JIN Junbin, ZHANG Dujie, LI Daqi, et al. Study on the wellbore instability mechanisms and drilling fluid countermeasures of deep fractured formation in Shunbei Oil and Gas Field[J]. Drilling & Production Technology, 2023, 46(1): 42–49.

[21] 李科,赵怀珍,李秀灵,等. 抗高温高性能水基钻井液及其在顺北801X井的应用[J]. 钻井液与完井液,2022,39(3):279–284. LI Ke, ZHAO Huaizhen, LI Xiuling, et al. The development and application of high-temperature and high-performance water base drilling fluid on the Well Shunbei 801X[J]. Drilling Fluid & Completion Fluid, 2022, 39(3): 279–284.

[22] 林永学,王伟吉,金军斌. 顺北油气田鹰1井超深井段钻井液关键技术[J]. 石油钻探技术,2019,47(3):113–120. LIN Yongxue, WANG Weiji, JIN Junbin. Key drilling fluid technology in the ultra deep section of Well Ying-1 in the Shunbei Oil and Gas Field[J]. Petroleum Drilling Techniques, 2019, 47(3): 113–120.

-

期刊类型引用(2)

1. 王鹏. 海洋在役井筒完整性风险量化分级研究. 中国石油和化工标准与质量. 2022(02): 1-3+6 .  百度学术

百度学术

2. 何汉平. 油气井井筒完整性系统风险评估方法. 石油钻探技术. 2017(03): 72-76 .  本站查看

本站查看

其他类型引用(1)

下载:

下载: