Status and Tendency of Physical Simulation Technology for Hydraulic Fracturing of Shale Reservoirs

-

摘要:

传统压裂物理模拟难以仿真深部储层高温高压、复杂地应力和工况环境,在模拟分段细分射孔工艺和实时监测裂缝扩展路径等方面存在一定挑战。系统调研了真三轴压裂物理模拟试验的试样制备、压裂井型和射孔组合、装置原理、相似准则和裂缝监测方式等,探究变排量、交替注液作用模式,穿层压裂缝高延伸机制,缝群压裂竞争扩展和暂堵转向模式;研究厘清了变排量和交替注液在提升缝网改造规模上的差异性,归纳了层状页岩储层水力裂缝缝高穿层主控因素排序,揭示了密切割多段多簇施工模式下裂缝群竞争扩展下的非平面、非对称和非均衡等扩展特征,总结了暂堵后裂缝转向扩展形态,指出“井工厂”立体压裂物理模拟、智能化和数字化为未来研究趋势。采取调整压裂时机、改变射孔参数和优化压裂液性能等措施可以有效控制裂缝扩展路径,能大幅度开启多尺度弱面,增大页岩储层压裂造缝规模。研究结果对深层和超深层页岩储层优化压裂施工参数、提升压裂改造效果具有一定的借鉴作用。

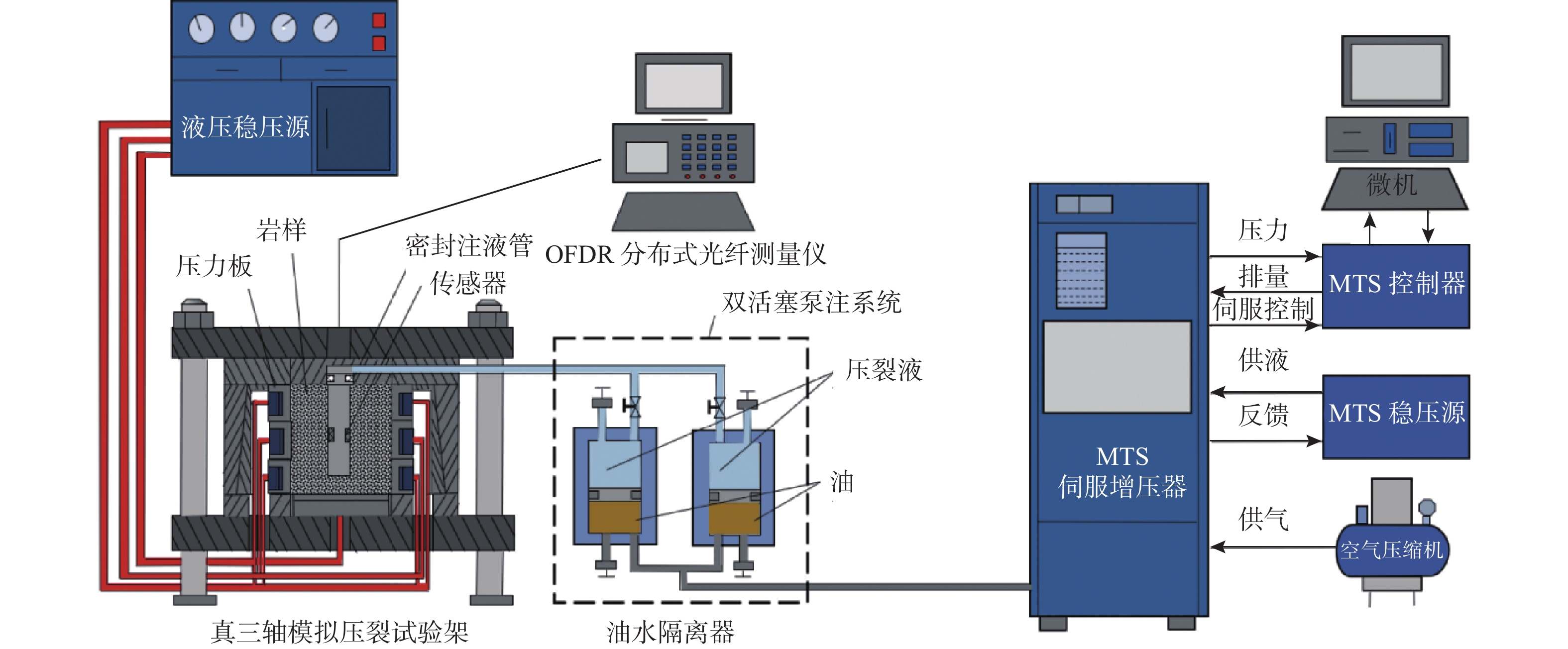

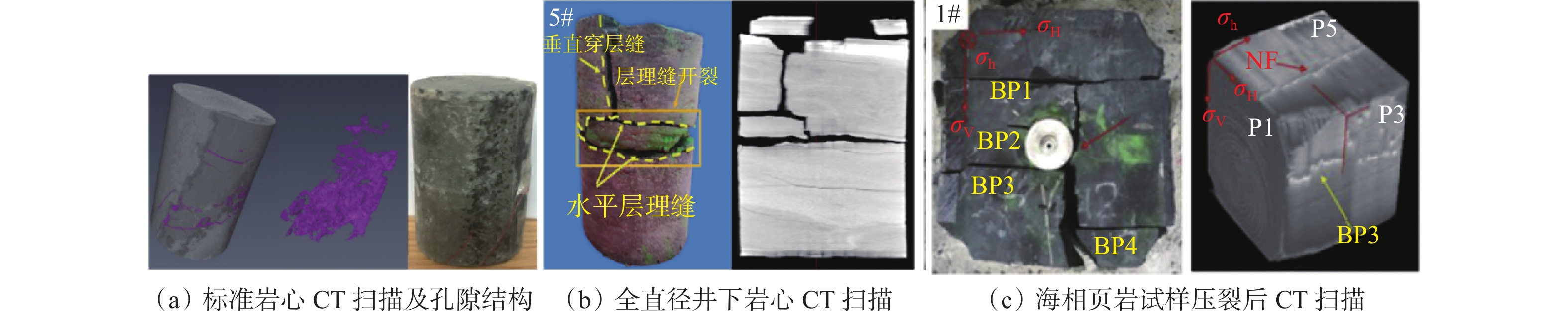

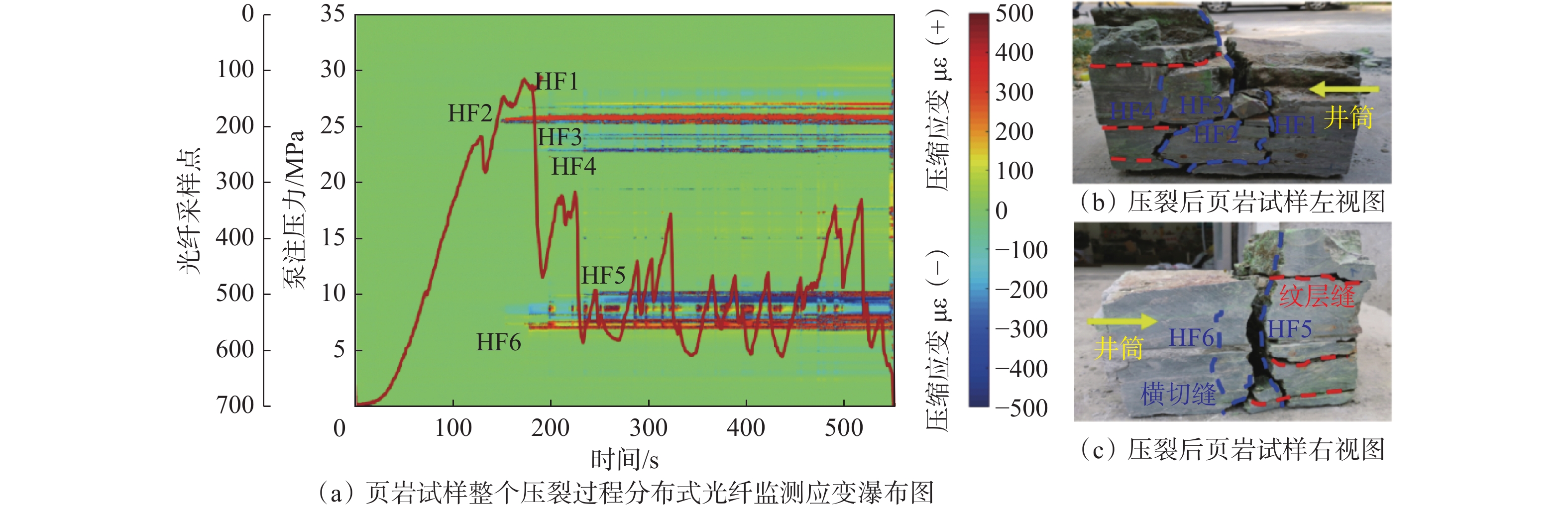

Abstract:Traditional hydraulic fracturing physical simulations face challenges such as simulating high temperature and high pressure, complex in-situ stress and working conditions, staged and subdivided perforation technologies, and real-time monitoring of fracture propagation. The sample preparation, well type and perforation combinations, device principles, similarity criteria, and fracture monitoring methods in true triaxial fracturing physical simulation experiment were systematically investigated. The variable displacement, alternating fluid injection modes, vertical fracture propagation mechanisms, competitive propagation among fracture groups, and fracture turning modes after temporary plugging were explored. The differences between variable displacement and alternating fluid injection in improving the scale of fracture network stimulation were clarified, and the ranking of the main controlling factors for hydraulic fractures and vertical fracture propagation in layered shale reservoirs was summarized. The non-planar, asymmetric, and unbalanced propagation characteristics of fracture groups in competitive propagation under dense cutting and multistage/multi-cluster fracturing were revealed, and the fracture propagation pattern after temporary plugging was summarized. Three-dimensional fracturing physical simulation, intelligence, and digitization of well plants were pointed out as future research trends. Adjusting the fracturing timing, modifying perforation parameters, and optimizing fracturing fluid properties could effectively control fracture propagation, significantly open multi-scale weak surfaces, and increase stimulation scale for shale reservoirs. This overview can serve as a reference for optimizing fracturing operation parameters and improving the effectiveness of fracturing stimulation for deep and ultra-deep shale reservoirs.

-

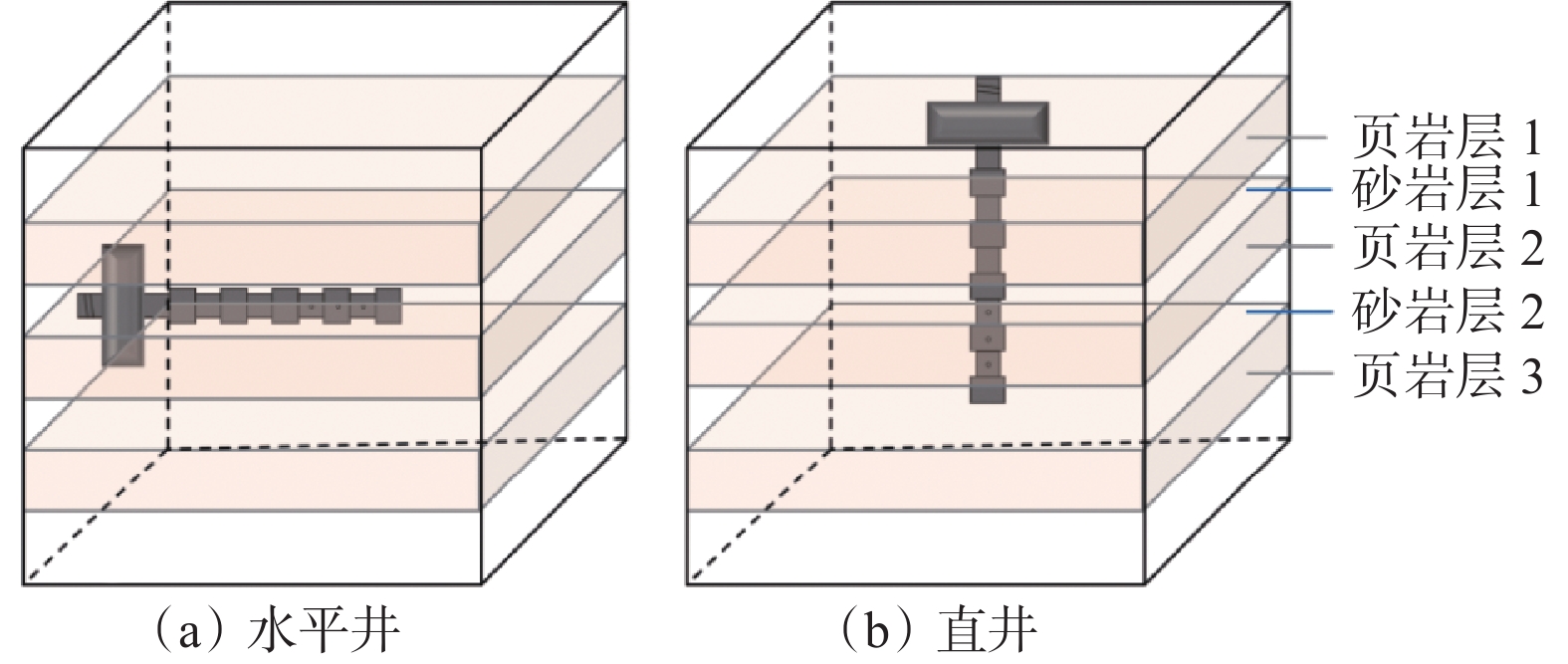

目前,随着国内页岩油气勘探开发进程的加快,陆相页岩油气逐渐成为新的油气产量增长点和研究热点[1-3],如渤海湾盆地济阳洼陷页岩油[4-10]、鄂尔多斯盆地庆城页岩油[11-12]、松辽盆地古龙凹陷页岩油[13-15]等。陆相沉积页岩油气资源丰富,仅四川盆地侏罗系湖相页岩气评价资源量就超过1×1012 m3,是中国石化“十四五”规模增储上产的重要产能接替区。上述页岩油气田的经济开发主要依赖水平井钻井及体积压裂技术。

与海相页岩油气储层相比,陆相页岩油气储层具有纵向多岩性夹层、黏土含量高、天然裂缝相对不发育和含油气丰度低等特点,导致采用常规水力压裂技术时存在缝高受限、裂缝复杂性程度低及压后预计最终可采储量(estimated ultimate recovery,EUR)低等瓶颈问题,极大地制约了陆相页岩油气的有效勘探与经济开发。

大量页岩油气储层岩心的观察结果发现,大多数页岩的水平层理缝分布密度大,每米分布多达8 000~10 000条层理缝,且油气显示级别较高,判断应是油气的主要储集空间。分析认为,水平井体积压裂的主要矛盾是在储层可压性评价与密切割主裂缝长度达到设计预期的前提下,如何尽可能地增加裂缝的平均缝高(包括造缝缝高及支撑缝高,基于缝长加权平均),才能最大限度地增大裂缝整体的泄流面积,进而在密切割的协同作用下,实现水平井穿层体积压裂的技术目标。为此,笔者研究提出了陆相页岩油气水平井穿层体积压裂技术,包括陆相页岩油气储层可压性评价、以EUR为目标的裂缝参数优化、以单簇裂缝模拟为基础的压裂施工参数优化、以提高远井缝高为基础的全程穿层压裂工艺优化、渗吸驱油一体化压裂液体系及性能评价和以渗吸机理为基础的压后闷井制度优化方法,以期提高陆相页岩油气的压裂水平及勘探开发效益。

1. 陆相页岩油气储层可压性评价

陆相湖盆离物源较近且受构造、气候等因素影响显著,陆相细粒沉积岩的成因机制不只是单一的“安静水体环境中缓慢悬浮沉积”,也可以是浊流、异重流、流体化沉积物流、风暴作用等搬运成因[16]。以四川盆地元坝地区、复兴地区的陆相页岩和涪陵海相页岩为例,对比了陆相沉积页岩与海相页岩的可压性参数,结果见表1。

表 1 陆相页岩与海相页岩可压性参数对比Table 1. Comparison of fracibility parameters between continental and marine shale类别 评价参数 陆相沉积 海相沉积 JY1井 YY3井 YY2井 TY1井 FY10井 PA1井 涪陵海相页岩 地质

可压

性参

数深度/m 3165~3209 3565~3567 3858~3800 2584~2651 2778~2770 2992~3011 2250~3500 页岩层厚/m 44.00 14.12 17.50 25.00 17.60 27.00 38.00 总有机碳

含量,%2.36 1.97 1.03 2.40 1.95 1.24 3.50~6.00 热成熟度,% 1.53 1.30~1.60 1.10~1.40 1.40~2.00 1.55 2.42~2.80 孔隙度,% 6.70 3.52 3.95 3.03~3.53 5.86 3.40~7.00 2.50~7.10 含气量/(m3· t−1) 0.76 1.51 1.22 1.31 0.97 3.20 4.70~5.70 压力系数 1.00 1.80 1.95 1.30 1.75 1.80~1.90 1.35~1.55 工程

可压

性参

数硅质含量,% 41.00 37.19 36.97 42.00 28.30 52.30 黏土含量,% 36.00 48.17 38.62 41.00 60.20 41.00 31.20 碳酸盐含量,% 14.00 6.49 15.73 6.70 9.80 11.00 弹性模量/GPa 21.70~24.70 34.50 23.30 33.50 12.10 38.00 泊松比 0.20~0.36 0.26 0.24 0.27 0.24 0.24~0.28 0.20~0.22 水平应力差/MPa 12.20~13.92 13.60 12.70 6.85 7.00 3.80~11.90 脆性指数,% 55.00 43.68 52.70 48.70 38.10 39.20 56.60 天然裂缝 层理缝发育 不发育 不发育 发育 不发育 层理缝发育 从表1可以看出,与海相页岩相比,陆相页岩的总有机碳含量、含气量、脆性矿物含量、弹性模量及天然裂缝发育程度等相对较低,黏土含量、泊松比、水平应力差等相对较高。总体而言,陆相页岩的可压性相对较低。

2. 穿层压裂参数和工艺优化

2.1 以EUR为目标的穿层压裂裂缝参数优化

为了实现页岩油效益开发,需要遵循“逆向设计,正向施工”的模式,以效益开发需要达到的EUR为目标,对裂缝参数进行优化。页岩油储层纵向非均质较强,存在薄互层或夹层,有较大应力遮挡,并且纹层较为发育,导致缝高扩展非常困难,极大地影响压裂改造体积。因此,要想取得较好的压裂效果,一般需要采用穿层压裂的工艺模式。预测了A井不同缝高下不同年份的累计产油量(预测了10年),结果如图1所示。

由于EUR不易获得,笔者以生产10年的累计产油量替代EUR进行分析。从图1可以看出,穿层缝高对EUR影响极大。就A井而言,当缝高由10 m增至20 m时,EUR可提高30%以上。在以EUR为目标优化穿层压裂裂缝参数后,需以此优化的裂缝参数组合为目标,优化压裂工艺参数。

2.2 以单簇裂缝模拟为基础的穿层压裂工艺参数优化

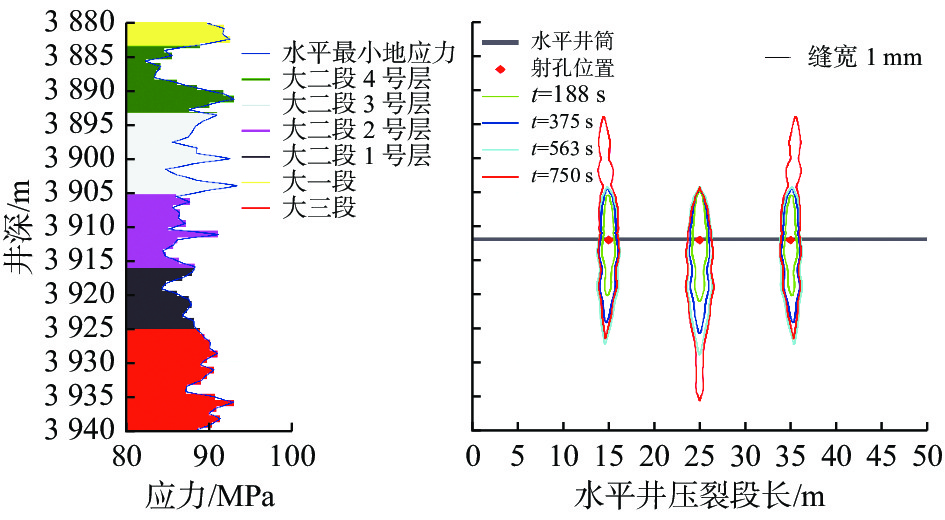

首先进行单簇裂缝模拟,然后基于设备能力确定最大允许射孔簇数,此为不加暂堵球最大允许射孔簇数。如为了降低压裂成本,设计射孔簇数大于上述优化射孔簇数,则需设计暂堵球参数。基于离散元数值模拟方法,进行了不同射孔簇下水力裂缝的扩展数值模拟。图2为射孔3簇条件下某陆相页岩地层裂缝的缝高剖面模拟结果(缝宽放大1 000倍),由图2可知,射孔3簇时,裂缝高度基本可以实现压裂裂缝优化目标。

由于陆相页岩油开采的复杂性,为了提高开采效益,通常采用少段多簇的压裂模式。为了多簇裂缝均衡开启延伸,通常需要投加暂堵球,以实现对已开启优势进液孔道的封堵,开启未打开射孔孔眼。其中,如何进行投球前的分级裂缝起裂延伸,防止投球前所有簇不同程度开启,是提高暂堵球压裂效果的重要前提。基于物理模拟与数值模拟研究,提出低排量较长时间注入、优化射孔方式、非均匀布酸等几种工艺方式来实现分级起裂。

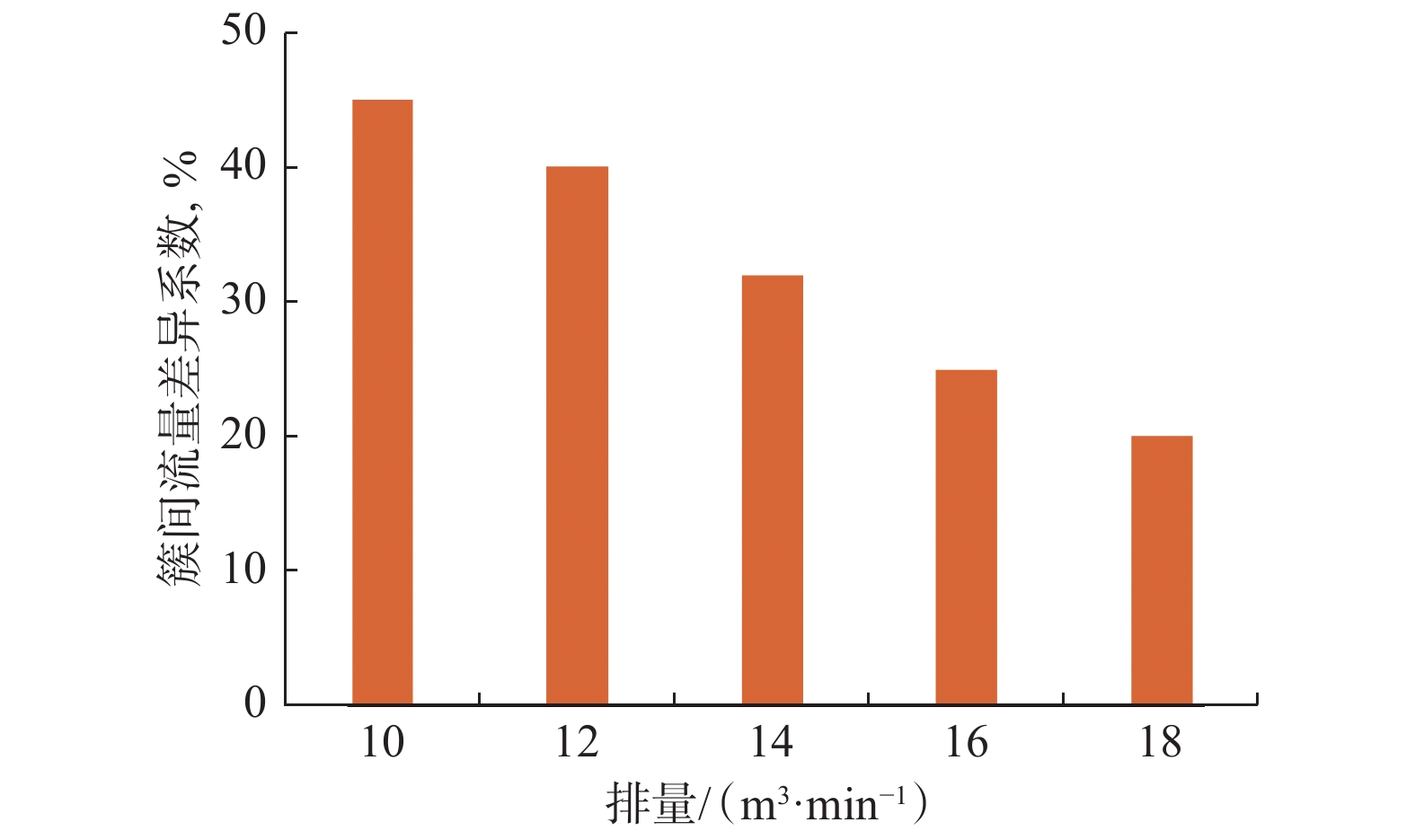

1)低排量较长时间注入。通过研究不同排量条件下多簇裂缝的簇间流量差异系数变化情况(见图3),发现排量由18 m3降至10 m3时,5簇裂缝的簇间流量差异系数可由20%增至45%。可见,排量越低,簇间流量差异系数越大,因此,可通过控制泵注初期排量,实现部分段簇的优先开启,待此部分裂缝充分扩展延伸后,通过投加暂堵球实现液流转向,开启未打开孔道,从而实现多簇裂缝均衡起裂延伸。

2)优化射孔方式。为了实现段内多簇裂缝的分批起裂,可以对水平段应力分布状况进行精细描述,选择在应力差异较大的位置射孔,从而使低应力位置先起裂,高应力位置后起裂。此外,还可以通过设置射孔方式,增大不同簇间储层的破裂压力差异,从而实现分批起裂。研究表明,在段内可以采用螺旋射孔与近平面射孔复合的射孔方式。螺旋射孔和近平面射孔条件下裂缝参数的对比情况见表2。

表 2 螺旋射孔和近平面射孔条件下裂缝参数的对比Table 2. Comparison of fracture parameters between spiral and plane perforation conditions射孔方式 螺旋射孔 平面射孔 总液量/m3 2 000 2 000 排量/(m3·min−1) 12 12 单段簇数 5 5 射孔密度 20孔/m 4孔/周 起裂压力/MPa 81.7 75.4 单缝缝高/m 48 51 单缝缝宽/mm 3.0 3.2 单缝缝长/m 220 260 单缝有效改造体积/m³ 8.00×104 94.8×104 由表2可知,近平面射孔的起裂压力较低,可以优先起裂,然后通过暂堵实现螺旋射孔簇的开启。

同时,采用变参数射孔方式也可以实现多簇裂缝的分级起裂。一般采用增大趾部簇孔密或孔径的方式实现:增大趾端的孔密或孔径,会降低压裂液的流动摩阻,从而实现趾端优先起裂。

3)非均匀布酸。非均匀布酸会使不同射孔簇的溶蚀程度不同,造成破裂压力降低程度各异,从而实现分批起裂扩展。现场通过替酸时快速提高顶替排量的方式实现非均匀布酸,使酸大部分向趾端方向运移分布,且优先进入趾端缝簇,进而较大幅度地降低破裂压力。

2.3 以提高远井缝高为基础的全程穿层压裂工艺优化

即使是单一岩性储层,水力裂缝的扩展形态也是近井筒处缝高最高,越往裂缝端部方向缝高越低,甚至接近0。这是因为,随着压裂液造缝和滤失的进行,越往端部,造缝的排量及净压力越低。而对陆相页岩油气纵向多岩性夹层的情况而言,即使是在近井筒处,可能也难以实现裂缝的纵向贯通,远井的缝高延伸程度就更低了。因此,只有大幅度提高裂缝的平均缝高,尤其是远井缝高,才能促使油气从纵向不同岩性夹层及不同的水平层理缝中水平地流向裂缝,然后再从裂缝中水平地流向井筒。换言之,对于纵向多岩性夹层和多个密集分布的水平层理缝而言,水平方向的渗透率远大于垂向渗透率,因此必须依靠水力裂缝实现纵向上的全覆盖,才能在短簇间距的协同作用下,最大限度地提高单井EUR[17]。

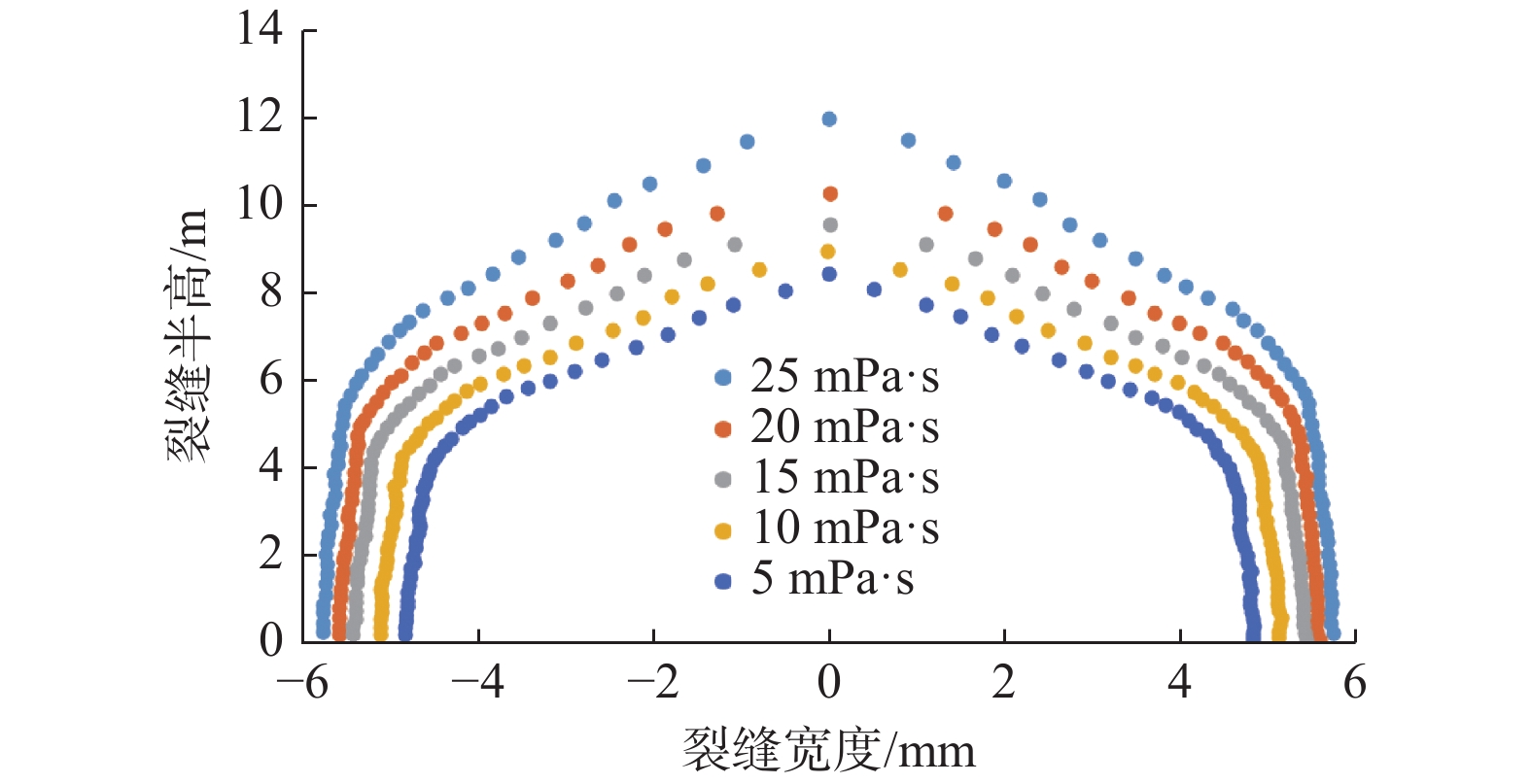

在提高纵向裂缝穿层方面,目前主要采用基于高黏度胶液前置的逆压裂模式结合快速提高排量的策略,以快速在井筒内积聚起足够高的压力。基于某口陆相页岩油井应力剖面,利用压裂软件,模拟了不同黏度压裂液条件下水力裂缝缝高的延伸情况,结果见图4。

此外,还采用高黏度胶液的中顶手段,但效果不佳。因其暂堵的起压效果确实不尽如人意。

虽然以往也提出过“3次暂堵球+4次暂堵剂”的多级暂堵模式,但基本上只能实现一次缝内暂堵,因不同级的暂堵剂是针对投球压开的新裂缝而言的,且暂堵的位置大部分可能仅局限于近井地带,因暂堵后压力升高的速度大部分相对较大,这是近井筒暂堵的压力特征响应。

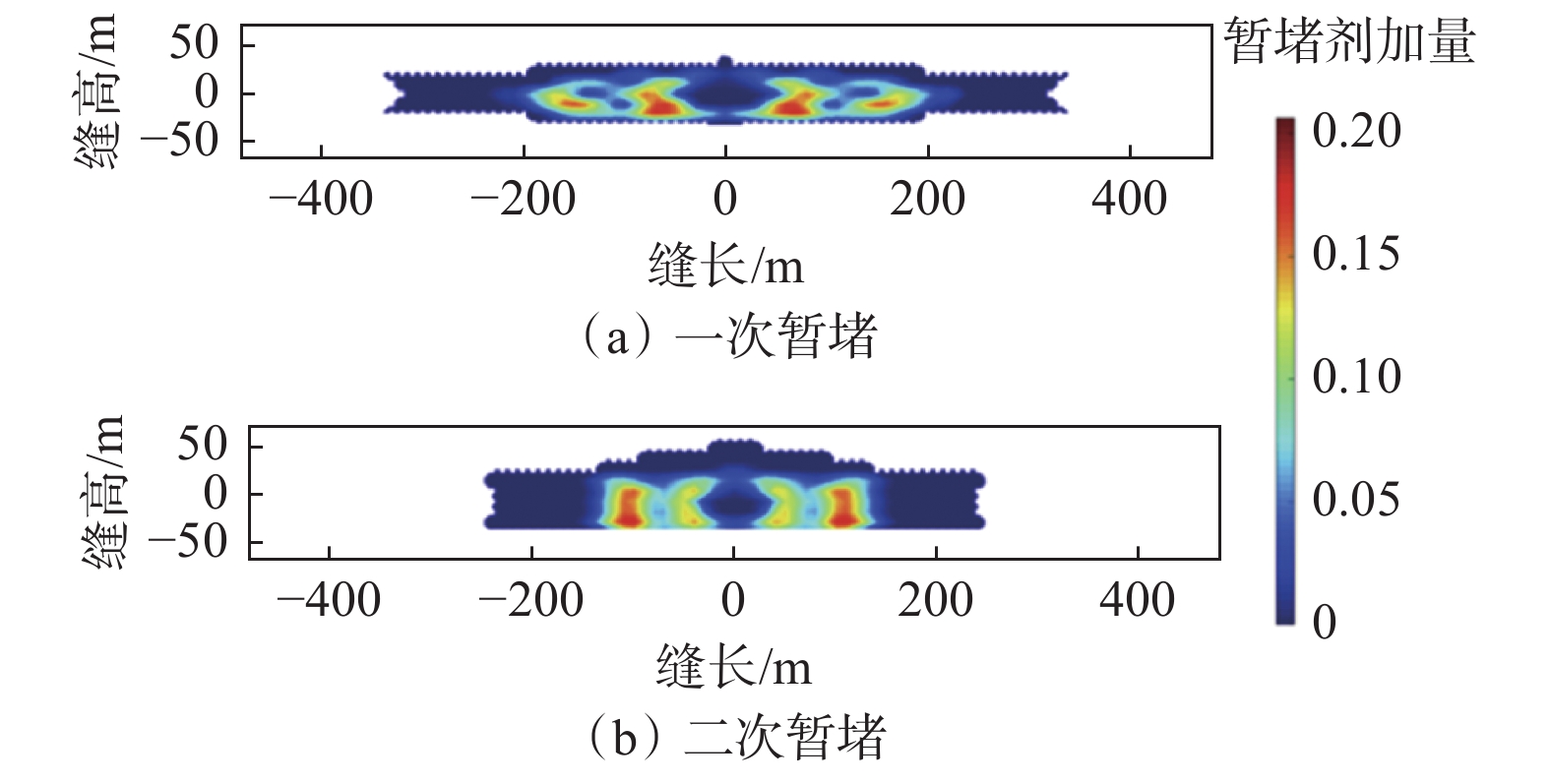

因此,本文提出一次或二次缝内暂堵的策略。如果是采用一次缝内暂堵,则应在裂缝中部进行定点暂堵设计;如果是二次暂堵,则应分别在裂缝的前1/3和后1/3进行定点暂堵。定点暂堵设计目前已基本成型,就是利用成熟的压裂优化设计软件,将暂堵剂当作支撑剂,模拟预期暂堵处暂堵剂的纵横向覆盖程度,如基本覆盖,且基于暂堵剂浓度计算的支撑缝宽与该处的造缝宽度基本相当,则说明暂堵剂实现了定点暂堵。需要指出的是,缝内二次暂堵设计时,一般第二次暂堵时暂堵剂的浓度及用量等应大于第一次暂堵时的对应参数,因为第二次暂堵时的裂缝几何尺寸都大于第一次暂堵处的对应值。

一旦实现了一次或二次缝内定点暂堵,则暂堵处必然优先憋压,因此,该处的缝高也在一定程度上得以继续扩展。基于自研软件,模拟了一次暂堵和二次暂堵条件下裂缝的缝高扩展情况,具体模拟结果如图5所示(以井筒中心为0点,水平方向为缝长方向,垂直方向为缝高方向)。

由图5可知,实施二次暂堵后,由于暂堵剂的集聚效应,会在缝长方向一定位置处憋压,使缝内净压力升高,造成暂堵处的缝高进一步扩展。对于多纹层的陆相页岩而言,纹层内游离烃相较为富集,缝高的扩展会极大提升压裂后改造效果。

3. 渗吸驱油一体化压裂液及性能评价

水平井穿层体积压裂包括2个过程:1)压裂施工期间的快改造过程,在施工的3~4 h内即实现水力造缝及支撑剂的有效充填,该过程相当于压裂后把常规中等规模的长期注水补能过程浓缩到上述极短的施工周期内,并将注水量一次性在该周期内注入完毕;2)压裂液水化渗吸的慢改造过程,虽然涉及临界渗吸的概念,但只是达到上述临界渗吸时间点后的渗吸速度变慢而已。实际上,只要压裂液没有返排完,上述水化渗吸机制就一直存在。而水化(一般大于黏土膨胀效应)可在垂直于裂缝壁面相当大的范围内,实现对岩石基质的长期慢改造。

因此,要求压裂液具有渗吸–驱油一体化功能是必然的选择。通过在压裂液中加入渗吸剂,进一步促进水化渗吸效果。同时,在压裂液中加入驱油剂,可在压后生产过程中进一步降低油气流动阻力。

通过优选具有特殊结构的阴离子表面活性剂,实现表面活性剂分子在溶液表面的紧密排布,降低表面张力。同时,由于分子疏水端的特殊结构,使分子界面润湿性强,能够显著降低润湿角。加入一定量的阳离子表面活性剂,通过与阴离子表面活性剂的静电吸引作用,增加表面分子吸附膜的紧密度,进一步协同降低表面张力。配方中加入两性表面活性剂,强化低界面张力和对油藏中重质成分的剥离性能。引入非离子表面活性剂,利用其良好的渗透性,进一步强化界面油剥离。中国石化石油工程技术研究院研发了压裂用渗吸剂SFDB,其为淡黄色水溶性液体。性能测试表明,SFDB加量大于0.1%的水溶液界面张力小于1 mN/m,表面张力小于28 mN/m,满足助排剂的指标要求;岩心渗吸试验结果表明,加入渗吸剂前后,渗吸率提高28.8%。

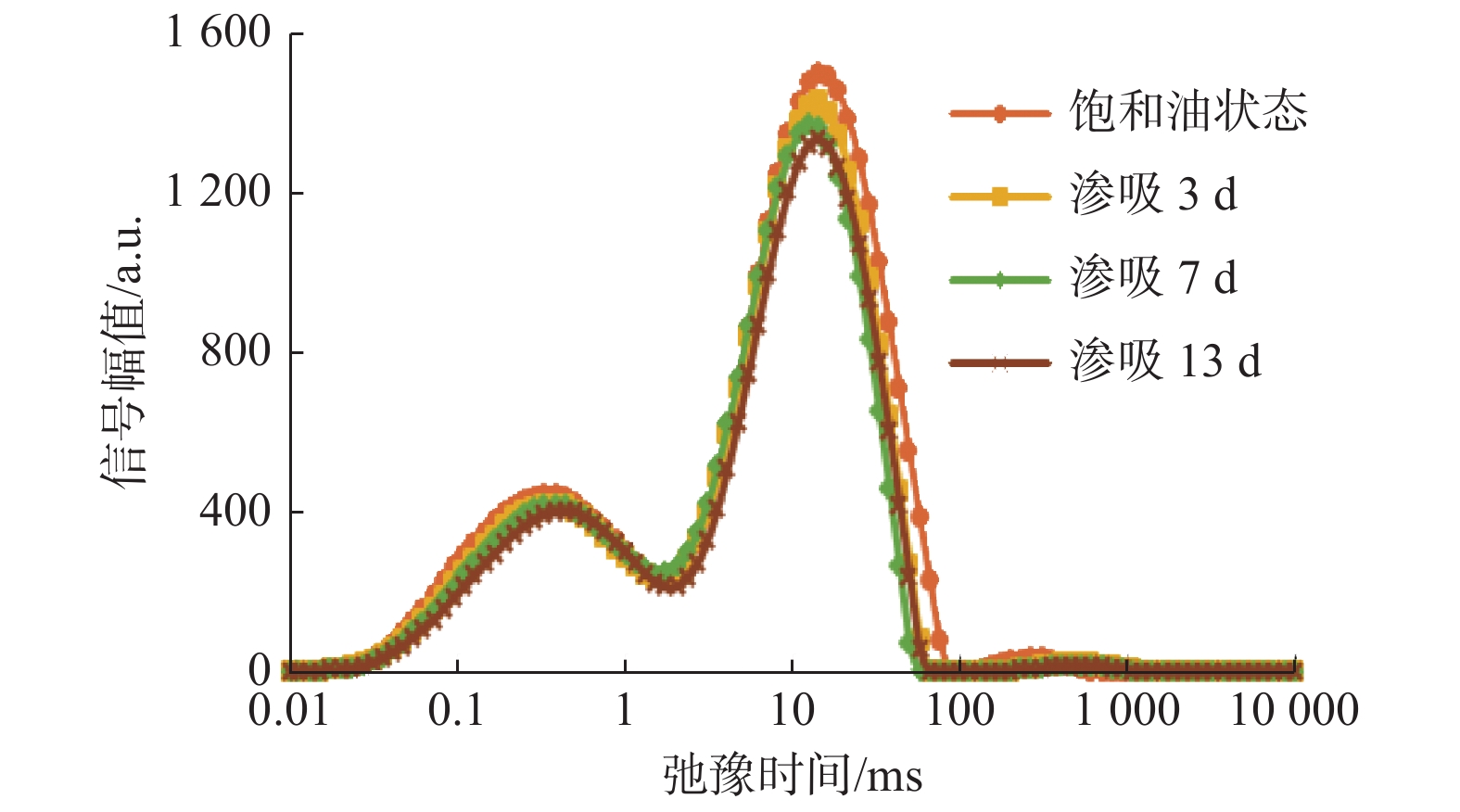

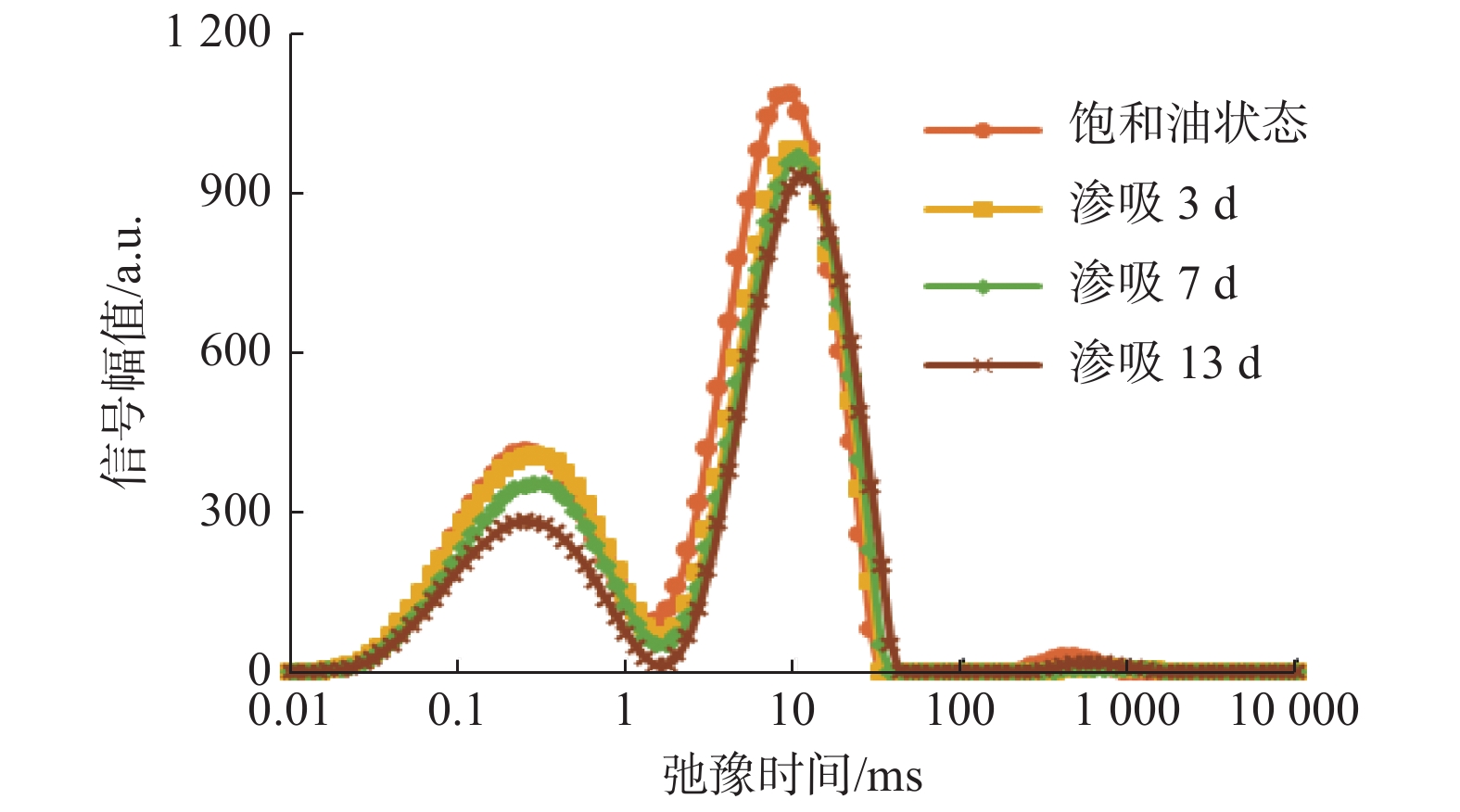

采用页岩岩心分别进行水自发渗吸(见图6)和0.1%SFDB溶液自发渗吸(见图7),并采用低场核磁共振技术跟踪观察。观察可知,加入渗吸剂后更容易将较小孔隙内的油渗吸出来。试验条件下,13 d时水的自发渗吸采收率为17.56%,0.1%SFDB溶液的自发渗吸采收率为20.73%,加入渗吸剂后采收率提高了3.17百分点。

4. 以渗吸为基础的压后闷井制度优化

页岩油气储层压裂之所以强调压后闷井,主要原因在于水化渗吸对岩石基质的扩孔增渗效应还没有完全释放到位。以往一般基于室内物理模拟和数值模拟等手段进行相应的研究。但水化渗吸对裂缝壁面岩石基质的影响范围及影响参数,还难以耦合进数值模型中去,因为从室内岩心尺度的水化渗吸效应如何放大到油藏尺度是个难题。

鉴于此,可基于现场闷井期间的压力下降速度进行综合评判。优化的目标是最大限度地发挥水化渗吸的效果。理论上,以连续3 d的井口压力下降速度趋于0为标准确定最佳闷井时间,但这可能需要很长的时间,现场条件也不允许,因此需要一个相对折中的方案。因为刚开始闷井时,水化渗吸还处于早期阶段,扩孔增渗效应相对较大,因此,每天的压力下降速度相对较大,如大于2 MPa/d。但随着闷井时间延长,水化渗吸效应逐渐减弱,井口压力的下降速度也逐渐减缓,有时甚至低于0.1 MPa/d。特别是,当压力下降速度低于某个临界值后,压力的下降速度也大幅度下降,有时压力下降0.1 MPa,可能需要10多天甚至一个月以上的时间。因此,可折中取0.1 MPa/d作为闷井时间的优化依据。

5. 现场试验

陆相页岩油气水平井穿层体积压裂技术在页岩油气水平井A井和B井进行了现场先导试验,施工概况见表3。

表 3 A井和B井穿层压裂概况Table 3. Overview of vertical penetration fracturing in Wells A and B井名 垂深/m 射孔方式 暂堵方式 穿层缝高/m 渗吸闷井时间/d 压裂改造效果 A井 2 932 变孔密射孔 二次暂堵 22~26 15 产油量13.0 m3/d B井 3 380 变孔密射孔 二次暂堵 17~20 25 产气量10.3×104 m3/d 其中,A井以EUR=3×104 m3为目标开展压裂参数优化,采用了“密切割段簇划分+复杂缝造缝+渗吸提产”的主体思路,共泵注压裂液88 000 m3,支撑剂8 600 m3,暂堵剂7.5 t,采用了渗吸驱油一体化压裂液体系,压后根据压力变化情况闷井15 d,压后反演裂缝缝高22~26 m,全部覆盖了产层(16~23 m),实现了穿层压裂。

B井以EUR为目标开展压裂参数优化,共实施23段压裂施工,泵注压裂液51 900 m3,支撑剂3 250 m3,暂堵剂2.4 t,压后根据压力变化情况闷井20 d,压后反演裂缝缝高17~20 m,全部覆盖主力产层(15~19 m),取得了较好的改造效果。

6. 结论与建议

1)研究提出了陆相页岩油气水平井穿层体积压裂技术,主要包括储层可压性评价、穿层裂缝参数优化、穿层压裂工艺参数优化、渗吸–驱油一体化压裂液及闷井时间优化等。

2)现场试验结果表明,陆相页岩油气水平井穿层体积压裂技术适应性好,针对性和可操作性也相对较好,可实现多纹层陆相页岩油气储层缝高的有效覆盖。

3)要实现真正的穿层体积压裂,必须强化地质–工程一体化及钻井与压裂一体化。建议从以下方面进一步深化研究:进一步细化纵向多夹层及水平层理缝的地应力剖面研究,有时因夹层薄受上下岩性的影响相对较大,在分层地应力模型研究上如何避免上下邻层的影响,难度极大,但必须攻克;加强缝内暂堵有效性的判识方法研究,如考虑水击效应对暂堵压力响应特征的影响及模型研究等;进一步加强岩心尺度水化渗吸的扩孔增渗效应与油气藏尺度数值模型的耦合研究,以便从模型优化上提出合理闷井时间。

-

-

[1] 胡素云,赵文智,侯连华,等. 中国陆相页岩油发展潜力与技术对策[J]. 石油勘探与开发,2020,47(4):819–828. doi: 10.11698/PED.2020.04.19 HU Suyun, ZHAO Wenzhi, HOU Lianhua, et al. Development potential and technical strategy of continental shale oil in China[J]. Petroleum Exploration and Development, 2020, 47(4): 819–828. doi: 10.11698/PED.2020.04.19

[2] 曾义金. 深层页岩气开发工程技术进展[J]. 石油科学通报,2019,4(3):233–241. doi: 10.3969/j.issn.2096-1693.2019.03.021 ZENG Yijin. Progress in engineering technologies for the development of deep shale gas[J]. Petroleum Science Bulletin, 2019, 4(3): 233–241. doi: 10.3969/j.issn.2096-1693.2019.03.021

[3] ZHANG Qixing, HOU Bing, LIN Botao, et al. Integration of discrete fracture reconstruction and dual porosity/dual permeability models for gas production analysis in a deformable fractured shale reservoir[J]. Journal of Natural Gas Science and Engineering, 2021, 93: 104028. doi: 10.1016/j.jngse.2021.104028

[4] 尹光志,李铭辉,许江,等. 多功能真三轴流固耦合试验系统的研制与应用[J]. 岩石力学与工程学报,2015,34(12):2436–2445. YIN Guangzhi, LI Minghui, XU Jiang, et al. A new multi-functional true triaxial fluid-solid coupling experiment system and its applications[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(12): 2436–2445.

[5] 黄荣樽. 水力压裂裂缝的起裂和扩展[J]. 石油勘探与开发,1981,8(5):62–74. HUANG Rongzun. Initiation and propagation of hydraulic fracturing fractures[J]. Petroleum Exploration and Development, 1981, 8(5): 62–74.

[6] 蒋海,肖阳,王栋,等. 页岩气体积改造人工缝网优化设计[J]. 特种油气藏,2022,29(5):154–160. doi: 10.3969/j.issn.1006-6535.2022.05.022 JIANG Hai, XIAO Yang, WANG Dong, et al. Optimal design of artificial fracture network for shale gas volume stimulation[J]. Special Oil & Gas Reservoirs, 2022, 29(5): 154–160. doi: 10.3969/j.issn.1006-6535.2022.05.022

[7] 谢紫霄,黄中伟,熊建华,等. 天然裂缝对干热岩水力压裂裂缝扩展的影响规律[J]. 天然气工业,2022,42(4):63–72. doi: 10.3787/j.issn.1000-0976.2022.04.006 XIE Zixiao, HUANG Zhongwei, XIONG Jianhua, et al. Influence of natural fractures on the propagation of hydraulic fractures in hot dry rock[J]. Natural Gas Industry, 2022, 42(4): 63–72. doi: 10.3787/j.issn.1000-0976.2022.04.006

[8] 侯冰,陈勉,刁策,等. 砂泥交互储层定向井压裂裂缝穿层扩展真三轴实验研究[J]. 科学技术与工程,2015,15(26):54–59. HOU Bing, CHEN Mian, DIAO Ce, et al. True triaxial experimental study of hydraulic fracture penetrating sand and mud interbedding in deviated wellbore science[J]. Science Technology and Engineering, 2015, 15(26): 54–59.

[9] 侯振坤,杨春和,王磊,等. 大尺寸真三轴页岩水平井水力压裂物理模拟试验与裂缝延伸规律分析[J]. 岩土力学,2016,37(2):407–414. HOU Zhenkun, YANG Chunhe, WANG Lei, et al. Hydraulic fracture propagation of shale horizontal well by large-scale true triaxial physical simulation test[J]. Rock and Soil Mechanics, 2016, 37(2): 407–414.

[10] 周健,陈勉,金衍,等. 裂缝性储层水力裂缝扩展机理试验研究[J]. 石油学报,2007,28(5):109–113. ZHOU Jian, CHEN Mian, JIN Yan, et al. Experimental study on propagation mechanism of hydraulic fracture in naturally fractured reservoir[J]. Acta Petrolei Sinica, 2007, 28(5): 109–113.

[11] 王燚钊,侯冰,王栋,等. 页岩油多储集层穿层压裂缝高扩展特征[J]. 石油勘探与开发,2021,48(2):402–410. doi: 10.11698/PED.2021.02.17 WANG Yizhao, HOU Bing, WANG Dong, et al. Features of fracture height propagation in cross-layer fracturing of shale oil reservoirs[J]. Petroleum Exploration and Development, 2021, 48(2): 402–410. doi: 10.11698/PED.2021.02.17

[12] 侯冰,武安安,常智,等. 页岩油储层多甜点压裂裂缝垂向扩展试验研究[J]. 岩土工程学报,2021,43(7):1322–1330. doi: 10.11779/CJGE202107018 HOU Bing, WU Anan, CHANG Zhi, et al. Experimental study on vertical propagation of fractures of multi-sweet of spots shale oil reservoir[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(7): 1322–1330. doi: 10.11779/CJGE202107018

[13] 侯冰,张儒鑫,刁策,等. 大斜度井水力压裂裂缝扩展模拟实验分析[J]. 中国海上油气,2016,28(5):85–91. HOU Bing, ZHANG Ruxin, DIAO Ce, et al. Experimental study on hydraulic fracture propagation in highly deviated wells[J]. China Offshore Oil and Gas, 2016, 28(5): 85–91.

[14] 李润森. 干热岩储层压裂缝网形成力学机理及传热特性研究[D]. 西安: 西安石油大学, 2022. LI Runsen. Study on mechanism of fracture network forming during hydraulic fracturing and heat-transfer characteristic in hot dry rock reservoir[D]. Xi’an: Xi’an Shiyou University, 2022.

[15] 柳贡慧,庞飞,陈治喜. 水力压裂模拟实验中的相似准则[J]. 石油大学学报(自然科学版),2000,24(5):45–48. LIU Gonghui, PANG Fei, CHEN Zhixi. Development of scaling laws for hydraulic fracture simulation tests[J]. Journal of the University of Petroleum, China, 2000, 24(5): 45–48.

[16] 侯冰,陈勉,李志猛,等. 页岩储集层水力裂缝网络扩展规模评价方法[J]. 石油勘探与开发,2014,41(6):763–768. doi: 10.11698/PED.2014.06.18 HOU Bing, CHEN Mian, LI Zhimeng, et al. Propagation area evaluation of hydraulic fracture networks in shale gas reservoirs[J]. Petroleum Exploration and Development, 2014, 41(6): 763–768. doi: 10.11698/PED.2014.06.18

[17] 侯冰,程万,陈勉,等. 裂缝性页岩储层水力裂缝非平面扩展实验[J]. 天然气工业,2014,34(12):81–86. HOU Bing, CHENG Wan, CHEN Mian, et al. Experiments on the non-planar extension of hydraulic fractures in fractured shale gas reservoirs[J]. Natural Gas Industry, 2014, 34(12): 81–86.

[18] 郭天魁,刘晓强,顾启林. 射孔井水力压裂模拟实验相似准则推导[J]. 中国海上油气,2015,27(3):108–112. GUO Tiankui, LIU Xiaoqiang, GU Qilin. Deduction of similarity laws of hydraulic fracturing simulation experiments for perforated wells[J]. China Offshore Oil and Gas, 2015, 27(3): 108–112.

[19] ZHOU Dawei, ZHANG Guangqing, ZHAO Pengyun, et al. Effects of post-instability induced by supercritical CO2 phase change on fracture dynamic propagation[J]. Journal of Petroleum Science and Engineering, 2018, 162: 358–366. doi: 10.1016/j.petrol.2017.12.066

[20] 付海峰,刘云志,梁天成,等. 四川省宜宾地区龙马溪组页岩水力裂缝形态实验研究[J]. 天然气地球科学,2016,27(12):2231–2236. doi: 10.11764/j.issn.1672-1926.2016.12.2231 FU Haifeng, LIU Yunzhi, LIANG Tiancheng, et al. Laboratory study on hydraulic fracture geometry of Longmaxi Formation shale in Yibin area of Sichuan Province[J]. Natural Gas Geoscience, 2016, 27(12): 2231–2236. doi: 10.11764/j.issn.1672-1926.2016.12.2231

[21] KEAR J, WHITE J, BUNGER A P, et al. Three dimensional forms of closely-spaced hydraulic fractures[R]. ISRM-ICHF-2013-024, 2013.

[22] 侯冰,戴一凡,范濛,等. 基于相场法的酸压裂缝连通孔洞数值模拟[J]. 石油学报,2022,43(6):849–859. HOU Bing, DAI Yifan, FAN Meng, et al. Numerical simulation of pores connection by acid fracturing based on phase field method[J]. Acta Petrolei Sinica, 2022, 43(6): 849–859.

[23] 邱园. 煤层裂缝扩展模拟与完井方式优选[D]. 北京: 中国石油大学(北京), 2011. QIU Yuan. Simulation of coal seam crack propagation and optimization of completion methods[D]. Beijing: China University of Petroleum(Beijing), 2011.

[24] 侯冰,陈勉,谭鹏,等. 页岩气藏缝网压裂物理模拟的声发射监测初探[J]. 中国石油大学学报(自然科学版),2015,39(1):66–71. HOU Bing, CHEN Mian, TAN Peng, et al. Monitoring of hydraulic fracture network by acoustic emission method in simulated tri-axial fracturing system of shale gas reservoirs[J]. Journal of China University of Petroleum (Edition of Natural Science), 2015, 39(1): 66–71.

[25] 贾利春,陈勉,孙良田,等. 结合CT技术的火山岩水力裂缝延伸实验[J]. 石油勘探与开发,2013,40(3):377–380. doi: 10.11698/PED.2013.03.18 JIA Lichun, CHEN Mian, SUN Liangtian, et al. Experimental study on propagation of hydraulic fracture in volcanic rocks using industrial CT technology[J]. Petroleum Exploration and Development, 2013, 40(3): 377–380. doi: 10.11698/PED.2013.03.18

[26] HOU Bing, ZHANG Qixing, LIU Xing, et al. Integration analysis of 3D fractures network reconstruction and frac hits response in shale wells[J]. Energy, 2022, 260: 124906. doi: 10.1016/j.energy.2022.124906

[27] 隋微波,温长云,孙文常,等. 水力压裂分布式光纤传感联合监测技术研究进展[J]. 天然气工业,2023,43(2):87–103. SUI Weibo, WEN Changyun, SUN Wenchang, et al. Joint application of distributed optical fiber sensing technologies for hydraulic fracturing monitoring[J]. Natural Gas Industry, 2023, 43(2): 87–103.

[28] 史璨,林伯韬. 页岩储层压裂裂缝扩展规律及影响因素研究探讨[J]. 石油科学通报,2021,6(1):92–113. doi: 10.3969/j.issn.2096-1693.2021.01.008 SHI Can, LIN Botao. Principles and influencing factors for shale formations[J]. Petroleum Science Bulletin, 2021, 6(1): 92–113. doi: 10.3969/j.issn.2096-1693.2021.01.008

[29] GU H, WENG X, LUND J, et al. Hydraulic fracture crossing natural fracture at nonorthogonal angles: a criterion and its validation[J]. SPE Production & Operations, 2012, 27(1): 20–26.

[30] 侯冰,木哈达斯•叶尔甫拉提,付卫能,等. 页岩暂堵转向压裂水力裂缝扩展物模试验研究[J]. 辽宁石油化工大学学报,2020,40(4):98–104. doi: 10.3969/j.issn.1672-6952.2020.04.014 HOU Bing, YEERFULATI Muhadasi, FU Weineng, et al. Experimental study on the hydraulic fracture propagation for shale temporary plugging and diverting fracturing[J]. Journal of Liaoning University of Petroleum & Chemical Technology, 2020, 40(4): 98–104. doi: 10.3969/j.issn.1672-6952.2020.04.014

[31] 张旭,蒋廷学,贾长贵,等. 页岩气储层水力压裂物理模拟试验研究[J]. 石油钻探技术,2013,41(2):70–74. doi: 10.3969/j.issn.1001-0890.2013.02.014 ZHANG Xu, JIANG Tingxue, JIA Changgui, et al. Physical simulation of hydraulic fracturing of shale gas reservoir[J]. Petroleum Drilling Techniques, 2013, 41(2): 70–74. doi: 10.3969/j.issn.1001-0890.2013.02.014

[32] 曾义金,周俊,王海涛,等. 深层页岩真三轴变排量水力压裂物理模拟研究[J]. 岩石力学与工程学报,2019,38(9):1758–1766. ZENG Yijin, ZHOU Jun, WANG Haitao, et al. Research on true triaxial hydraulic fracturing in deep shale with varying pumping rates[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(9): 1758–1766.

[33] HOU Bing, ZHANG Ruxin, ZENG Yijin, et al. Analysis of hydraulic fracture initiation and propagation in deep shale formation with high horizontal stress difference[J]. Journal of Petroleum Science and Engineering, 2018, 170: 231–243. doi: 10.1016/j.petrol.2018.06.060

[34] 考佳玮,金衍,付卫能,等. 注液方式对深层页岩裂缝形态影响实验研究[J]. 地下空间与工程学报,2019,15(1):32–38. KAO Jiawei, JIN Yan, FU Weineng, et al. Experiments research on the influence of injection method on hydraulic fracture morphology of deep shale[J]. Chinese Journal of Underground Space and Engineering, 2019, 15(1): 32–38.

[35] HOU Bing, CHANG Zhi, FU Weineng, et al. Fracture initiation and propagation in a deep shale gas reservoir subject to an alternating-fluid-injection hydraulic-fracturing treatment[J]. SPE Journal, 2019, 24(4): 1839–1855. doi: 10.2118/195571-PA

[36] TAN Peng, JIN Yan, YUAN Liang, et al. Understanding hydraulic fracture propagation behavior in tight sandstone–coal interbedded formations: An experimental investigation[J]. Petroleum Science, 2019, 16(1): 148–160. doi: 10.1007/s12182-018-0297-z

[37] 赵金洲,付永强,王振华,等. 页岩气水平井缝网压裂施工压力曲线的诊断识别方法[J]. 天然气工业,2022,42(2):11–19. doi: 10.3787/j.issn.1000-0976.2022.02.002 ZHAO Jinzhou, FU Yongqiang, WANG Zhenhua, et al. Study on diagnosis model of shale gas fracture network fracturing operation pressure curves[J]. Natural Gas Industry, 2022, 42(2): 11–19. doi: 10.3787/j.issn.1000-0976.2022.02.002

[38] 卞晓冰,蒋廷学,贾长贵,等. 基于施工曲线的页岩气井压后评估新方法[J]. 天然气工业,2016,36(2):60–65. BIAN Xiaobing, JIANG Tingxue, JIA Changgui, et al. A new post-fracturing evaluation method for shale gas wells based on fracturing curves[J]. Natural Gas Industry, 2016, 36(2): 60–65.

[39] ZHANG Qixing, HOU Bing, PANG Huiwen, et al. A comparison of shale gas fracturing based on deep and shallow shale reservoirs in the United States and China[J]. Computer Modeling in Engineering & Sciences, 2022, 133(3): 471–507.

[40] 程万,金衍,陈勉,等. 三维空间中水力裂缝穿透天然裂缝的判别准则[J]. 石油勘探与开发,2014,41(3):336–340. doi: 10.11698/PED.2014.03.09 CHENG Wan, JIN Yan, CHEN Mian, et al. A criterion for identifying hydraulic fractures crossing natural fractures in 3D space[J]. Petroleum Exploration and Development, 2014, 41(3): 336–340. doi: 10.11698/PED.2014.03.09

[41] RUNGAMORNRAT J, WHEELER M F, MEAR M E. A numerical technique for simulating nonplanar evolution of hydraulic fractures [R]. SPE 96968, 2005.

[42] 赵金洲,王强,胡永全,等. 多孔眼裂缝竞争起裂与扩展数值模拟[J]. 天然气地球科学,2020,31(10):1343–1354. ZHAO Jinzhou, WANG Qiang, HU Yongquan, et al. Numerical simulation of multi-hole fracture competition initiation and propagation[J]. Natural Gas Geoscience, 2020, 31(10): 1343–1354.

[43] 王士国,金衍,谭鹏,等. 煤系页岩储层多气共采水力裂缝扩展规律试验研究[J]. 岩土工程学报,2022,44(12):2290–2296. doi: 10.11779/CJGE202212016 WANG Shiguo, JIN Yan, TAN Peng, et al. Experimental investigation on hydraulic fracture propagation of coal shale reservoirs under multi-gas co-production[J]. Chinese Journal of Geotechnical Engineering, 2022, 44(12): 2290–2296. doi: 10.11779/CJGE202212016

[44] 李连崇, 梁正召, 李根, 等. 水力压裂裂缝穿层及扭转扩展的三维模拟分析[J]. 岩石力学与工程学报, 2010, 29(增刊1): 3208 − 3215. LI Lianchong, LIANG Zhengzhao, LI Gen, et al. Three-dimensional numerical analysis of traversing and twisted fractures in hydraulic fracturing[J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(supplement 1): 3208 − 3215.

[45] SETTGAST R R, FU Pengcheng, WALSH S D C, et al. A fully coupled method for massively parallel simulation of hydraulically driven fractures in 3-dimensions[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 2017, 41(5): 627–653. doi: 10.1002/nag.2557

[46] 曲占庆,田雨,李建雄,等. 水平井多段分簇压裂裂缝扩展形态数值模拟[J]. 中国石油大学学报(自然科学版),2017,41(1):102–109. QU Zhanqing, TIAN Yu, LI Jianxiong, et al. Numerical simulation study on fracture extension and morphology of multi-cluster staged fracturing for horizontal wells[J]. Journal of China University of Petroleum (Edition of Natural Science), 2017, 41(1): 102–109.

[47] 周大伟,张广清,刘志斌,等. 致密砂岩多段分簇压裂中孔隙压力场对多裂缝扩展的影响[J]. 石油学报,2017,38(7):830–839. doi: 10.7623/syxb201707010 ZHOU Dawei, ZHANG Guangqing, LIU Zhibin, et al. Influences of pore-pressure field on multi-fracture propagation during the multi-stage cluster fracturing of tight sandstone[J]. Acta Petrolei Sinica, 2017, 38(7): 830–839. doi: 10.7623/syxb201707010

[48] 程万,蒋国盛,周治东,等. 水平井中多条裂缝同步扩展时裂缝竞争机制[J]. 岩土力学,2018,39(12):4448–4456. doi: 10.16285/j.rsm.2017.2090 CHENG Wan, JIANG Guosheng, ZHOU Zhidong, et al. Fracture competition of simultaneous propagation of multiple hydraulic fractures in a horizontal well[J]. Rock and Soil Mechanics, 2018, 39(12): 4448–4456. doi: 10.16285/j.rsm.2017.2090

[49] 时贤,程远方,常鑫,等. 页岩气水平井段内多簇裂缝同步扩展模型建立与应用[J]. 石油钻采工艺,2018,40(2):247–252. doi: 10.13639/j.odpt.2018.02.018 SHI Xian, CHENG Yuanfang, CHANG Xin, et al. Establishment and application of the model for the synchronous propagation of multi-cluster fractures in the horizontal section of shale-gas horizontal well[J]. Oil Drilling & Production Technology, 2018, 40(2): 247–252. doi: 10.13639/j.odpt.2018.02.018

[50] LU Qianli, LIU Zhuang, GUO Jianchun, et al. Numerical investigation of fracture interference effects on multi-fractures propagation in fractured shale[J]. Engineering Fracture Mechanics, 2023, 286: 109322. doi: 10.1016/j.engfracmech.2023.109322

[51] LI Minghui, LV Wenjing, LIU Jinjun, et al. Effect of perforation friction on 3D in-stage multiple fracture propagation: A numerical study[J]. Engineering Fracture Mechanics, 2022, 267: 108415. doi: 10.1016/j.engfracmech.2022.108415

[52] 王小华,罗浩然,张丰收. 水平井射孔压裂完井下控制近井筒裂缝复杂度的参数优化[J]. 岩石力学与工程学报,2022,41(6):1223–1234. WANG Xiaohua, LUO Haoran, ZHANG Fengshou. Parameter optimization for controlling the complexity of near-wellbore fractures for perforated fracturing of horizontal wells[J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(6): 1223–1234.

[53] 侯冰,常智,武安安,等. 吉木萨尔凹陷页岩油密切割压裂多簇裂缝竞争扩展模拟[J]. 石油学报,2022,43(1):75–90. HOU Bing, CHANG Zhi, WU Anan, et al. Simulation of competitive propagation of multi-fractures on shale oil reservoir multi-clustered fracturing in Jimsar Sag[J]. Acta Petrolei Sinica, 2022, 43(1): 75–90.

[54] 王磊,盛志民,赵忠祥,等. 吉木萨尔页岩油水平井大段多簇压裂技术[J]. 石油钻探技术,2021,49(4):106–111. doi: 10.11911/syztjs.2021091 WANG Lei, SHENG Zhimin, ZHAO Zhongxiang, et al. Large-section and multi-cluster fracturing technology for horizontal wells in the Jimsar shale oil reservoir[J]. Petroleum Drilling Techniques, 2021, 49(4): 106–111. doi: 10.11911/syztjs.2021091

[55] 唐煊赫,朱海燕,车明光,等. 裂缝性页岩暂堵压裂复杂裂缝扩展模型与暂堵时机[J]. 石油勘探与开发,2023,50(1):139–151. doi: 10.11698/PED.20221011 TANG Xuanhe, ZHU Haiyan, CHE Mingguang, et al. Complex fracture propagation model and plugging timing optimization for temporary plugging fracturing in naturally fractured shale[J]. Petroleum Exploration and Development, 2023, 50(1): 139–151. doi: 10.11698/PED.20221011

[56] 郭建春,赵峰,詹立,等. 四川盆地页岩气储层暂堵转向压裂技术进展及发展建议[J]. 石油钻探技术,2023,51(4):170–183. doi: 10.11911/syztjs.2023039 GUO Jianchun, ZHAO Feng, ZHAN Li, et al. Recent advances in temporary plugging and diversion fracturing technology for shale gas reservoirs in the Sichuan Basin[J]. Petroleum Drilling Techniques, 2023, 51(4): 170–183. doi: 10.11911/syztjs.2023039

[57] 李彦超,张庆,沈建国,等. 页岩气藏长段多簇暂堵体积改造技术[J]. 天然气工业,2022,42(2):143–150. doi: 10.3787/j.issn.1000-0976.2022.02.015 LI Yanchao, ZHANG Qing, SHEN Jianguo, et al. Volumetric stimulation technology of long-section multi-cluster temporary plugging in shale gas reservoirs[J]. Natural Gas Industry, 2022, 42(2): 143–150. doi: 10.3787/j.issn.1000-0976.2022.02.015

[58] 伊西锋. 非常规油气水平井管内多级分段压裂新技术[J]. 石油机械,2014,42(4):62–66. doi: 10.3969/j.issn.1001-4578.2014.04.015 YI Xifeng. New technology of multistage staged fracturing for unconventional oil-gas horizontal well[J]. China Petroleum Machinery, 2014, 42(4): 62–66. doi: 10.3969/j.issn.1001-4578.2014.04.015

[59] 金智荣,孙悦铭,包敏新,等. 基于真三轴压裂物理模拟系统的暂堵压裂裂缝扩展规律试验研究[J]. 非常规油气,2021,8(6):98–105. doi: 10.19901/j.fcgyq.2021.06.14 JIN Zhirong, SUN Yueming, BAO Minxin, et al. Experimental study on crack propagation law of temporary plugging fracturing based on true triaxial fracturing physical simulation system[J]. Unconventional Oil & Gas, 2021, 8(6): 98–105. doi: 10.19901/j.fcgyq.2021.06.14

[60] 曹学军,王明贵,康杰,等. 四川盆地威荣区块深层页岩气水平井压裂改造工艺[J]. 天然气工业,2019,39(7):81–87. doi: 10.3787/j.issn.1000-0976.2019.07.010 CAO Xuejun, WANG Minggui, KANG Jie, et al. Fracturing technologies of deep shale gas horizontal wells in the Weirong Block, southern Sichuan Basin[J]. Natural Gas Industry, 2019, 39(7): 81–87. doi: 10.3787/j.issn.1000-0976.2019.07.010

[61] 陈钊,王天一,姜馨淳,等. 页岩气水平井段内多簇压裂暂堵技术的数值模拟研究及先导实验[J]. 天然气工业,2021,41(增刊1):158–163. CHEN Zhao, WANG Tianyi, JIANG Xinchun, et al. Numerical simulation study and pilot test of multi-cluster fracturing and temporary plugging technology in the horizontal hole section of shale-gas horizontal wells[J]. Natural Gas Industry, 2021, 41(supplement1): 158–163.

[62] 杨恒林,吕嘉昕,谭鹏,等. 基于三维扫描技术的页岩暂堵压裂物理模拟实验[J]. 断块油气田,2022,29(1):118–123. YANG Henglin, LYU Jiaxin, TAN Peng, et al. Physical simulation experiment on shale temporary plugging and fracturing based on 3D scanning technology[J]. Fault-Block Oil & Gas Field, 2022, 29(1): 118–123.

[63] 蒋廷学,王海涛. 中国石化页岩油水平井分段压裂技术现状与发展建议[J]. 石油钻探技术,2021,49(4):14–21. JIANG Tingxue, WANG Haitao. The current status and development suggestions for Sinopec’s staged fracturing technologies of horizontal shale oil wells[J]. Petroleum Drilling Techniques, 2021, 49(4): 14–21.

[64] HUANG Liuke, DONTSOV E, FU Haifeng, et al. Hydraulic fracture height growth in layered rocks: perspective from DEM simulation of different propagation regimes[J]. International Journal of Solids and Structures, 2022, 238: 111395. doi: 10.1016/j.ijsolstr.2021.111395

[65] ZHANG Fengshou, HUANG Liuke, YANG Lin, et al. Numerical investigation on the effect of depletion-induced stress reorientation on infill well hydraulic fracture propagation[J]. Petroleum Science, 2022, 19(1): 296–308. doi: 10.1016/j.petsci.2021.09.014

[66] WANG Xiaohua, ZHANG Fengshou, YIN Zirui, et al. Numerical investigation of refracturing with/without temporarily plugging diverters in tight reservoirs[J]. Petroleum Science, 2022, 19(5): 2210–2226. doi: 10.1016/j.petsci.2022.05.006

[67] 张其星,侯冰,武安安,等. 昭通龙马溪组页岩坍塌风险分层研究与应用[J]. 钻井液与完井液,2023,40(3):279–288. ZHANG Qixing, HOU Bing, WU Anan, et al. Study and application on risk stratification of wellbore collapse for the Longmaxi Formation shale in Zhaotong City[J]. Drilling Fluid & Completion Fluid, 2023, 40(3): 279–288.

[68] 金衍,薄克浩,张亚洲,等. 深层硬脆性泥页岩井壁稳定力学化学耦合研究进展与思考[J]. 石油钻探技术,2023,51(4):159–169. JIN Yan, BO Kehao, ZHANG Yazhou, et al. Advancements and considerations of chemo-mechanical coupling for wellbore stability in deep hard brittle shale[J]. Petroleum Drilling Techniques, 2023, 51(4): 159–169.

[69] XIONG Q, BRUDZINSKI M R, GOSSETT D, et al. Seismic magnitude clustering is prevalent in field and laboratory catalogs[J]. Nature Communications, 2023, 14(1): 2056. doi: 10.1038/s41467-023-37782-5

-

期刊类型引用(2)

1. 杨玉贵,邢希金,孙文化. 强分散性地层大位移井钻井液关键技术研究. 石油化工应用. 2022(05): 15-20 .  百度学术

百度学术

2. 孟也,李相方,何敏侠,蒋明洁. 气泡卡断过程中的喉道液领形态与聚并模型. 断块油气田. 2019(05): 632-637 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: