目前,常规PDC钻头主要用于钻进软到中硬地层,而在硬地层中的钻进效果不太理想[1,2]。其中,犁切型PDC钻头,采用异于常规PDC的锥形PDC齿作为切削齿,已在国外实验室以及一些现场钻进硬地层试验中取得了很好的破岩效果,具备了钻进硬地层的能力[3,4,5,6,7]。但是,国内外关于锥形PDC齿破岩规律的研究尚属空白,需进一步探索和研究[8,9,10,11,12,13]。为此,笔者通过锥形PDC齿破岩试验对锥形PDC齿在不同切削角、齿形及钻压下的破岩规律进行了分析,以期优选出破岩效率高的齿形及切削角,为锥形PDC齿钻头的优化设计提供依据,满足深井钻进硬地层提速的迫切需求。

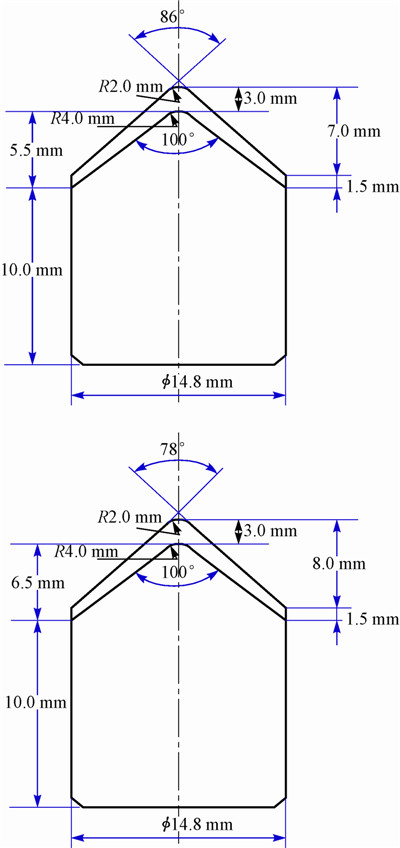

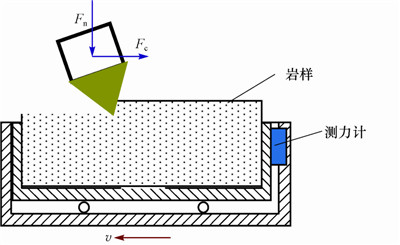

1 锥形PDC单齿破岩试验 1.1 试验装置试验装置由ZXTM-40钻铣床(经过特殊改装)、岩样夹持装置、锥形PDC齿小钻头(锥形PDC齿夹持装置)、冲击力传感器和数据采集系统等部分组成,如图 1所示。试验选用2种Φ14.8 mm锥形PDC齿,1齿的锥顶角为86°,2齿的锥顶角为78°,2种锥形齿的其他参数如图 2所示。

|

| 图 1 单齿破岩试验装置 Fig. 1 Experimental device of cutter rock-breaking |

|

| 图 2 2种锥形齿的设计参数 Fig. 2 Key parameters of two conical cutters |

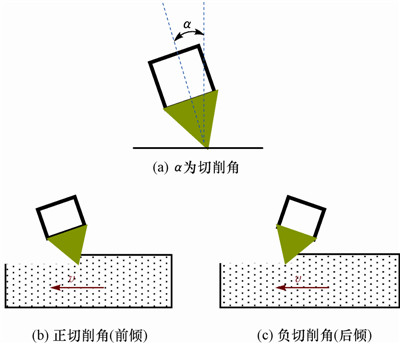

每次试验时,将表面平整的岩样固定在岩样夹持装置上,通过更换不同角度的小钻头实现切削角的变化,用加压装置给锥形PDC齿施加不同的钻压,然后摇动钻铣床滑枕,带动岩样做直线运动,使锥形PDC齿切削岩样形成沟槽;在切削过程中,利用切向力传感器实时测量锥形PDC齿所受的水平切削力,由数据采集系统记录并显示试验数据,其原理如图 3所示。为分析锥形PDC齿的切削角、锥顶角及钻压对破岩效率的影响规律,分别进行了不同切削角(0°,±5°,±10°,±15°,±20°,±25°,±30°,角度如图 4所示)、不同锥顶角(86°和78°)和不同钻压(1.0,1.5,2.0,2.5和3.0 kN)的破岩试验。岩样选用玄武岩,其可钻性级值为9.27。

|

| 图 3 单齿破岩试验原理示意 Fig. 3 Principle of cutter rock-breaking |

|

| 图 4 切削角度示意 Fig. 4 Diagram of cutting angle |

试验以岩样沟槽的深度(即切削深度)和水平切削力2个指标综合评价锥形PDC齿的破岩效果,分析各因素对锥形PDC齿破岩效率的影响规律。

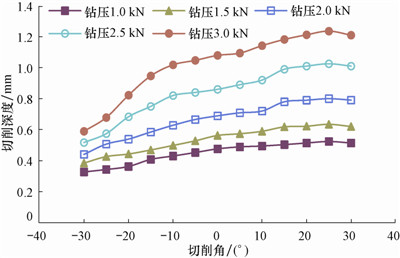

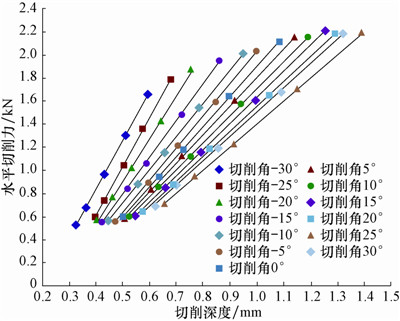

2.1 切削角以1齿为例,绘制不同钻压下切削深度与切削角的关系曲线(见图 5)及不同切削角下水平切削力与切削深度的关系曲线(见图 6)。由图 5可知,在相同钻压下,随着切削角从负到正的逐渐增大,切削深度先增大后减小,当切削角为25°时,切削深度达到最大;当钻压较大时,正切削角下的切削深度明显高于负切削角,但是当钻压较小时,正切削角下的切削深度虽然大于负切削角,但变化幅度较小。由图 6可知,锥形PDC齿受到的水平切削力随着切削深度增大而增大,且两者为线性关系;当切削深度相同时,切削角为25°时,所受水平切削力最小,表明切削角为25°时,锥形PDC齿在钻进玄武岩时所需的破岩比能最小、破岩效率最高。

|

| 图 5 不同钻压下切削深度与切削角的关系曲线 Fig. 5 Relation between cutting depth and cutting angle at different WOBs |

|

| 图 6 不同切削角下水平切削力与切削深度的关系曲线 Fig. 6 Relation between horizontal cutting force and cutting depth at different cutting angles |

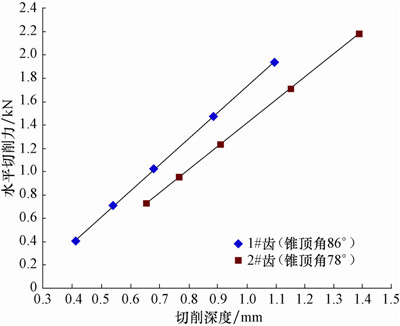

图 7为2齿不同切削角下水平切削力与切削深度的关系曲线。图 8为2种锥形PDC齿在切削角为25°时水平切削力和切屑深度的关系曲线。由图 8可知,当切削角为25°时,相同切削深度下,1锥形PDC齿(锥顶角86°)受到的水平切削力大于2锥形PDC齿(锥顶角78°)。由图 6和图 7可知,当切削角相同时,切削相同的深度,1齿所需的水平切削力均大于2齿。这表明,在相同切削条件下,2锥形PDC齿(锥顶角78°)的破岩效率高于1锥形PDC齿(锥顶角86°)。

|

| 图 7 不同切削角下水平切削力与切削深度的关系曲线 Fig. 7 Relation between cutting depth and horizontal cutting force at different cutting angles |

|

| 图 8 2种锥形PDC齿水平切削力与切削深度的关系曲线 Fig. 8 Relations between cutting depth and horizontal cutting force for two conical PDC cutters |

图 9为2种锥形PDC齿切削深度与钻压的关系曲线。由图 9可知:钻压较小时,锥形PDC齿的切削深度很小,而钻压较大时,切削深度迅速增大;随着钻压增大,切削深度上升的幅度逐渐增大,呈现指数增长趋势;不同锥顶角和切削角下的锥形PDC齿的切削深度随钻压的变化规律基本一致,均与钻压呈指数关系;在相同钻压下,当切削角为25°时,2种锥形PDC齿的切削深度最大;在相同钻压和切削角下,2齿的切削深度均大于1齿。

|

| 图 9 2种锥形PDC齿的切削深度与钻压的关系曲线 Fig. 9 Relation between cutting depth and WOB for two conical PDC cutters |

1) 锥形PDC齿适合其齿尖指向钻头轴线安装在钻头上,当钻进条件相同时,切削角为25°时的破岩效果最好。结合钻头布齿设计理论、锥形齿的抗冲击性能及不同地层的适应性,切削角推荐选用20°~25°。

2 ) 锥形PDC齿在小钻压下的破岩效果较差,随着钻压增大,破岩效果迅速得到提高。

3) 文中试验条件下,锥顶角小的锥形PDC齿的破岩效率优于锥顶角大的锥形PDC齿。

4 ) 文中试验只选用了2种锥顶角和1种岩样,建议后续试验中增加锥形PDC齿的齿型和岩样类型,以进一步探讨锥顶角对破岩效率的影响规律和锥形PDC齿在不同硬地层的破岩规律。

| [1] |

罗恒荣, 唐玉响, 徐玉超, 等.新型定向井PDC钻头的研制与应用[J].石油钻探技术, 2007, 35(5):86-89. Luo Hengrong, Tang Yuxiang, Xu Yuchao, et al.Research and application of a new PDC bit in directional well[J].Petroleum Drilling Techniques, 2007, 35(5):86-89. |

| [2] |

杨顺辉, 武汉杰, 牛成成, 等.特种孕镶块加强PDC钻头的研制与试验[J].石油钻探技术, 2014, 42(6):111-114. Yang Shunhui, Wu Hanjie, Niu Chengcheng, et al.Manufacture and application of PDC bit enhanced by special diamond-impregnated segment[J].Petroleum Drilling Techniques, 2014, 42(6):111-114. |

| [3] |

常领, 陈华忠.PDC钻头在胜利油田深井钻井中的应用[J].石油钻探技术, 2007, 35(4):92-93. Chang Ling, Chen Huazhong.Application of PDC bits to deep wells in Shengli Oilfield[J].Petroleum Drilling Techniques, 2007, 35(4):92-93. |

| [4] | Durrand C J, Skeem M R, Hall D R.Thick PDC, shaped cutters for geothermal drilling:a fixed cutter solution for a roller cone drilling environment: the 44th US Rock Mechanics Symposium and 5th US-Canada Rock Mechanics Symposium, Salt Lake City, June 27-30, 2010[C]. |

| [5] |

于鹏.适应硬地层的犁削型PDC钻头研究[D].青岛:中国石油大学(华东)石油工程学院, 2013. Yu Peng.Reseach on plow-crushing PDC bit adapted to hard formation[D].Qingdao:China University of Petroleum(Huadang), School of Petroleum Engineering, 2013. |

| [6] |

邹德永, 于鹏, 杨光.硬地层破岩工具最新进展[J].石油机械, 2013, 41(6):1-5. Zou Deyong, Yu Peng, Yang Guang.Latest development of rock-crushing tools adapted to hard formation[J].China Petroleum Machinery, 2013, 41(6):1-5. |

| [7] |

刘亚军, 王晓鹏, 王昆剑, 等.绥中36-1油田新型钻头的优化设计及应用[J].断块油气田, 2011, 18(5):669-671. Liu Yajun, Wang Xiaopeng, Wang Kunjian, et al.Optimization design and application of new drill bit in SZ36-1 Oilfield[J].Fault-Block oil & Gas Field, 2011, 18(5):669-671. |

| [8] | Michael Azar, Allen White, Steven Segal, et al.Pointing towards improved PDC bit performance:innovative stinger shaped polycrystalline diamond element achieves higher rop and total footage[R].SPE/IADC 163521, 2013. |

| [9] | Jonak J.Influence of friction on the chip size in cutting the brittle materials[J].Journal of Mining Science, 2001, 37(4):407-410. |

| [10] | Kou S Q, Lindqvist P A, Tang C A, et al.Numerical simulation of the cutting of inhomogeneous rocks[J].International Journal of Rock Mechanics and Mining Sciences, 1999, 36(5):711-717. |

| [11] | Sunal O.Parametric study of a single PDC cutter with a numerical model[D].Morgantown:West Virginia University, 2009. |

| [12] | Mendoza J A, Gamwo I K, Zhang W, et al.Discrete element modeling of rock cutting using crushable particles:the 44th US Rock Mechanics Symposium and 5th US-Canada Rock Mechanics Symposium, Salt Lake City, June 27-30, 2010[C]. |

| [13] | Pierry Joelle, Robert Charlier.Finite element modelling of shear band localisation and application to rock cutting by a PDC tool[R].SPE 28052, 1994. |